Antistatic protection structure and reliability improving method of semiconductor panel

A technology for protecting structures and semiconductors, applied in the fields of semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., can solve problems such as high reliability risks of semiconductor panels, reduce the risk of short circuits, and improve reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

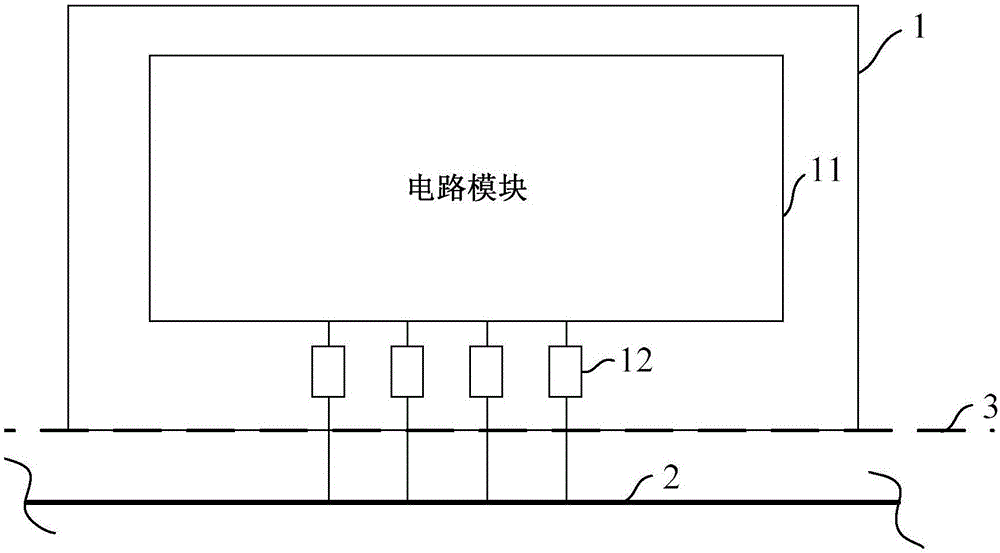

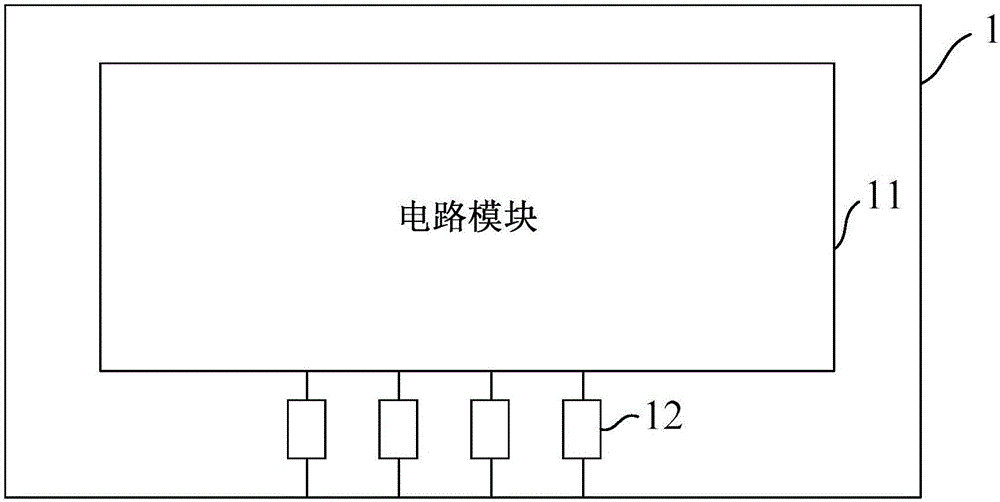

[0048] Such as Figure 4 As shown, the present invention provides an antistatic protection structure of a semiconductor panel, the antistatic protection structure of the semiconductor panel at least includes:

[0049] The anti-static protection ring 2 arranged on the periphery of the circuit area, the circuit area includes a circuit module 11 and a plurality of pads 12 connected to the circuit module 11, each pad 12 is connected to the anti-static protection ring through a short wire 14 respectively. The ring 2 is short-circuit connected; wherein, the part where the antistatic protection ring 2 is connected to each short wire 14 is located outside the cutting line 3 of the semiconductor panel 1, and the upper layer of the short wire 14 is covered with a passivation insulating layer 16, and the semiconductor The passivation insulating layer 16 above the short wires 14 in the panel 1 is provided with a cutout window 13 for exposing the film layer where each short wire is located...

Embodiment 2

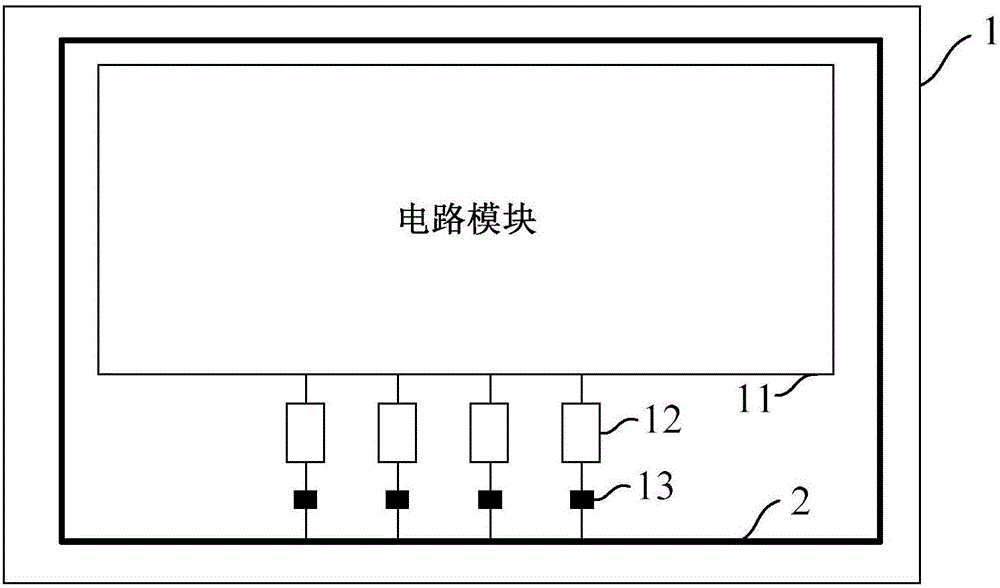

[0059] Such as Figure 5 As shown, the antistatic protection structure of a semiconductor panel is provided in this embodiment, and the difference from Embodiment 1 is that the semiconductor panel 1 is a thin film transistor area array drive panel of a flat panel display; the cut window 13 It is a groove spanning all the short wires 14 ; meanwhile, the part of the antistatic protection ring 2 not connected to each short wire 14 is located outside the semiconductor panel 1 .

[0060] Specifically, when the semiconductor panel 1 is a thin film transistor area array drive panel of a flat panel display, correspondingly, the conductive film layer on the passivation insulating layer 16 has the function of blocking electron radiation, ultraviolet rays and The material of the ITO layer (Indium Tin Oxides, Indium Tin Metal Oxide) with infrared rays can be set according to specific requirements, and will not be repeated here.

[0061] Specifically, such as Figure 5 As shown, the cutt...

Embodiment 3

[0065] Such as Figure 4 ~ Figure 9 As shown, the present invention also provides a method for improving the reliability of a semiconductor panel, and the method for improving the reliability of a semiconductor panel at least includes:

[0066] During the manufacturing process of the semiconductor panel, the anti-static protection structure of the semiconductor panel is prepared, and each point and each film layer of the circuit module is kept at the same potential to avoid electrostatic damage caused by local charge accumulation during the panel manufacturing process.

[0067] Specifically, thin films of different substances are deposited layer by layer on the substrate 15 to form the circuit module 11 and the pads 12 connected thereto in the circuit area. In this embodiment, the substrate 15 is glass. At the same time, if Figure 6 As shown, the short wiring 14 is formed on the substrate 15 between the circuit area and the antistatic protection ring 2, and a passivation ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com