Patents

Literature

46results about How to "Improve wetting effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

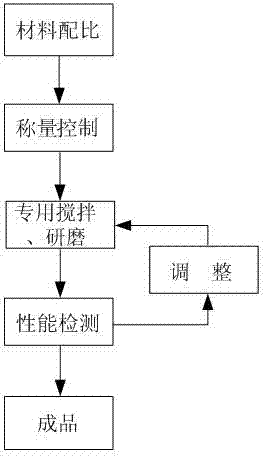

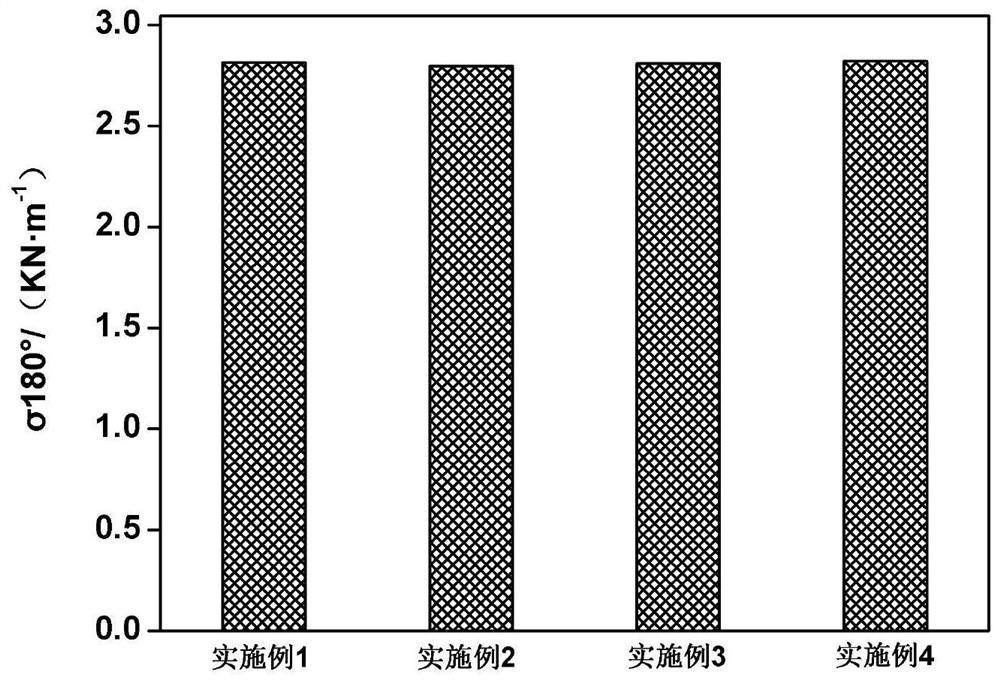

Preparation method for silane-modified moisture-curable polyurethane hot melt adhesive

ActiveCN104449535AEnhanced van der Waals forceImprove wetting effectNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterWhitening Agents

The invention discloses a preparation method for a silane-modified moisture-curable polyurethane hot melt adhesive. The method comprises the following steps: (1) heating and mixing polyester polyol, polyether polyol, tackifying resin, an antioxidant and a fluorescent whitening agent at a certain temperature, performing reduced pressure degassing for 2 hours, and cooling to 90 DEG C; (2) adding isocyanate and a catalyst into a reaction system under the nitrogen protection, and reacting at 85-95 DEG C for 45 minutes; (3) adding a chain extender and a silane coupler under the nitrogen protection, and reacting at 85-95 DEG C for 1 hour to obtain a prepolymer; (4) transferring a reaction mixture into an aluminum foil bag under the nitrogen protection, sealing, and curing at 85 DEG C for 6 hours to obtain the silane-modified moisture-curable polyurethane hot melt adhesive with excellent performance.

Owner:SHANGHAI TIANYANG HOT MELT ADHESIVE CO LTD +2

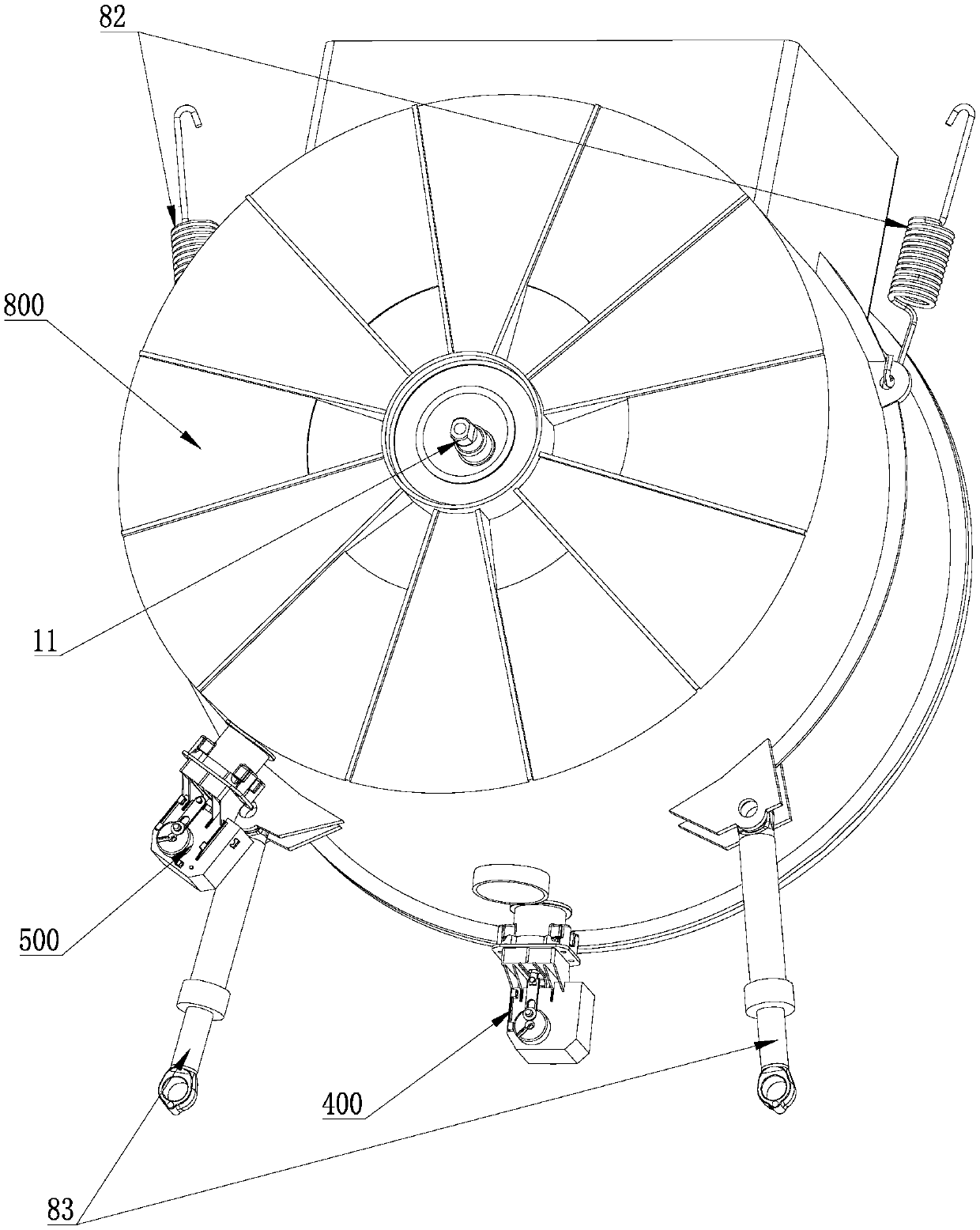

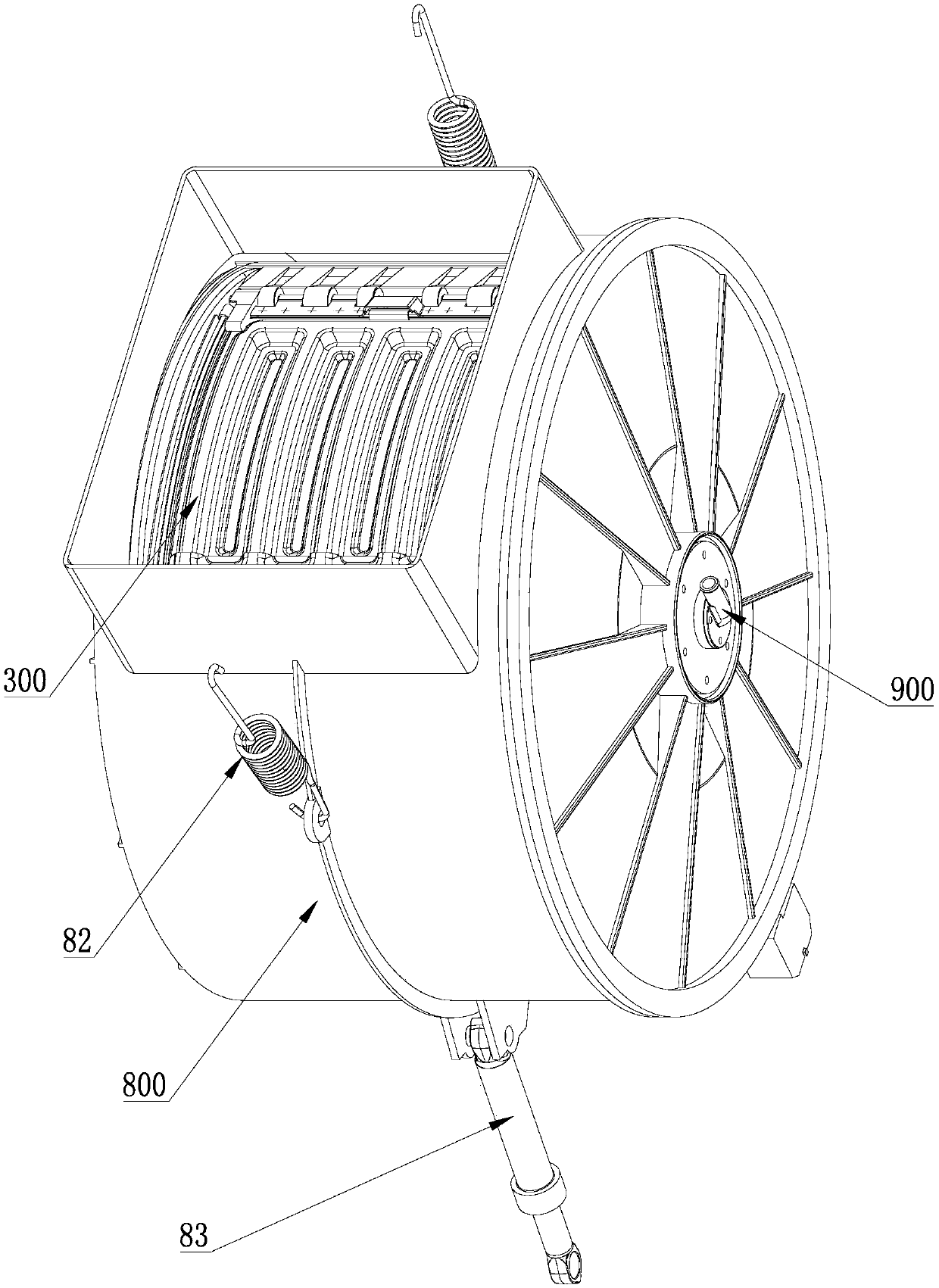

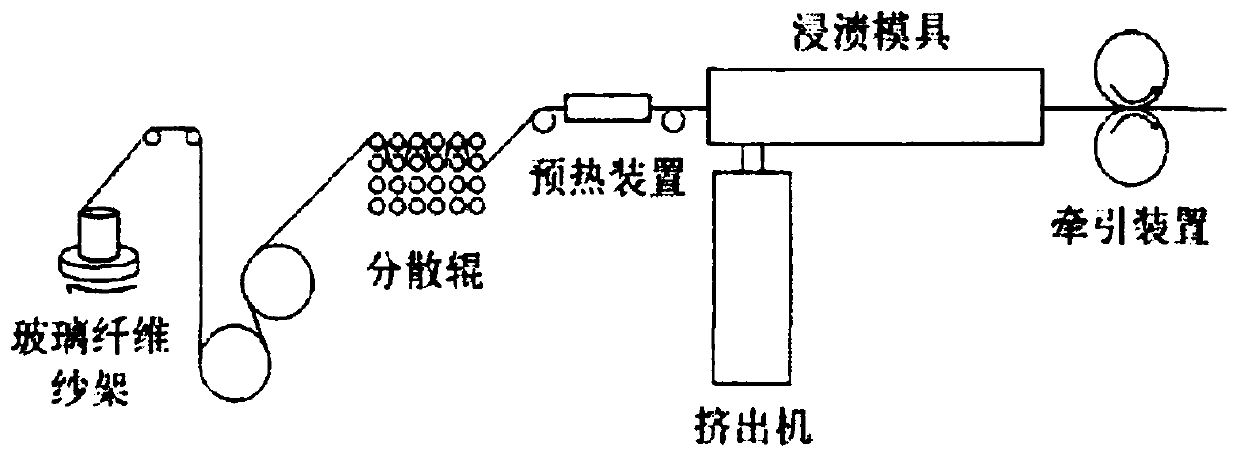

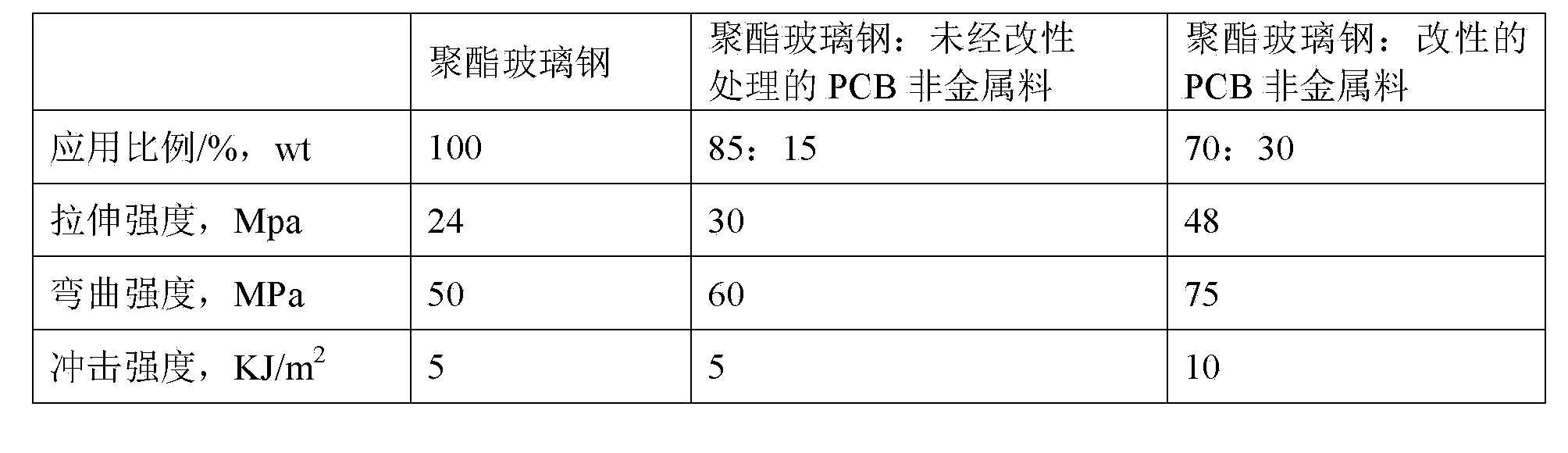

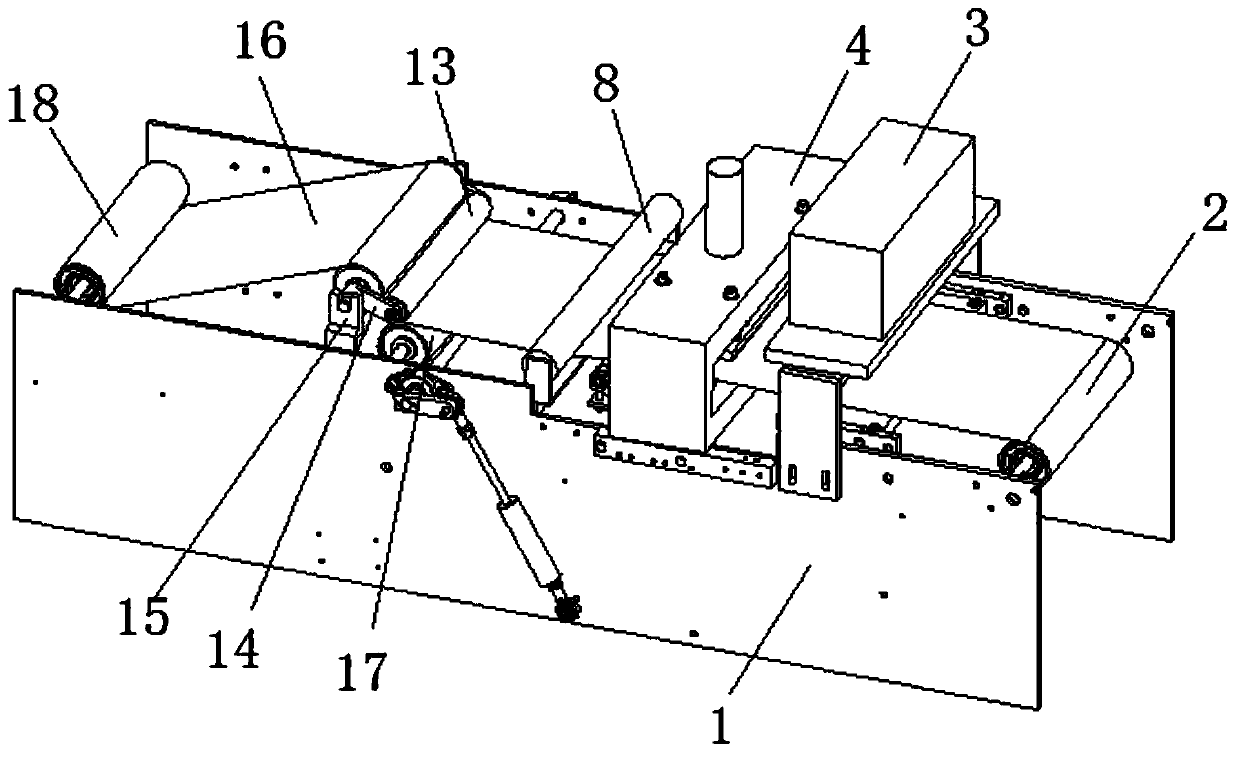

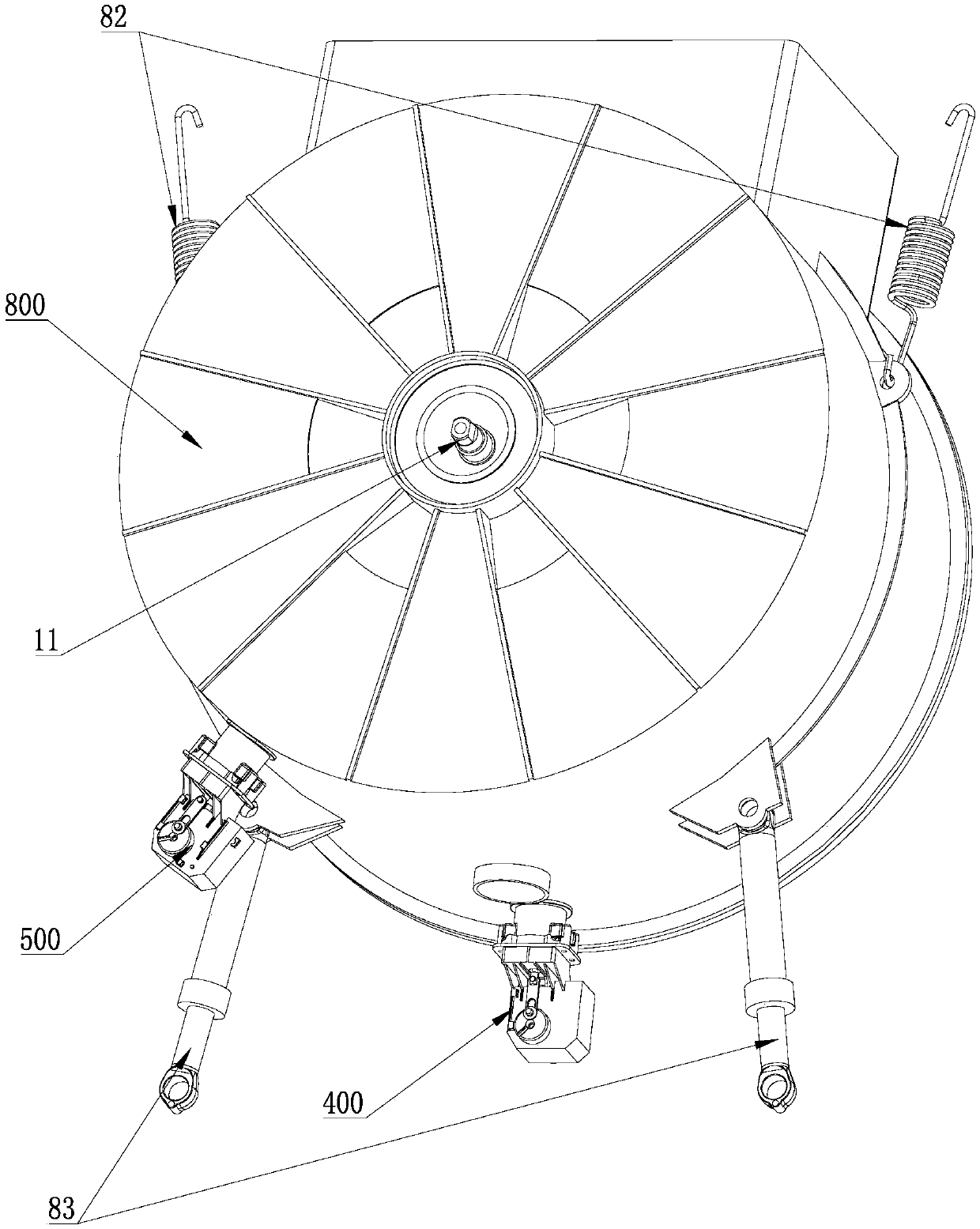

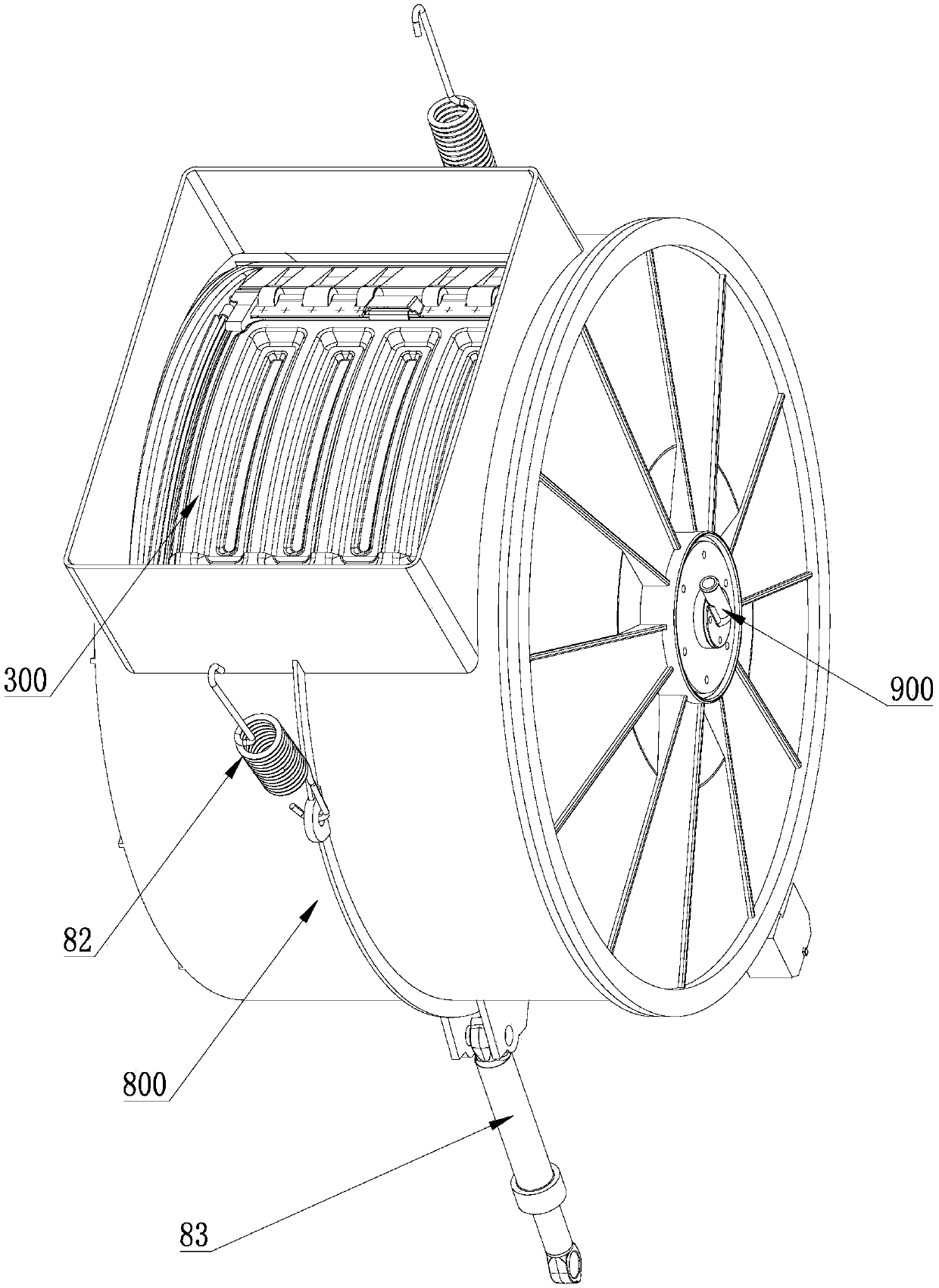

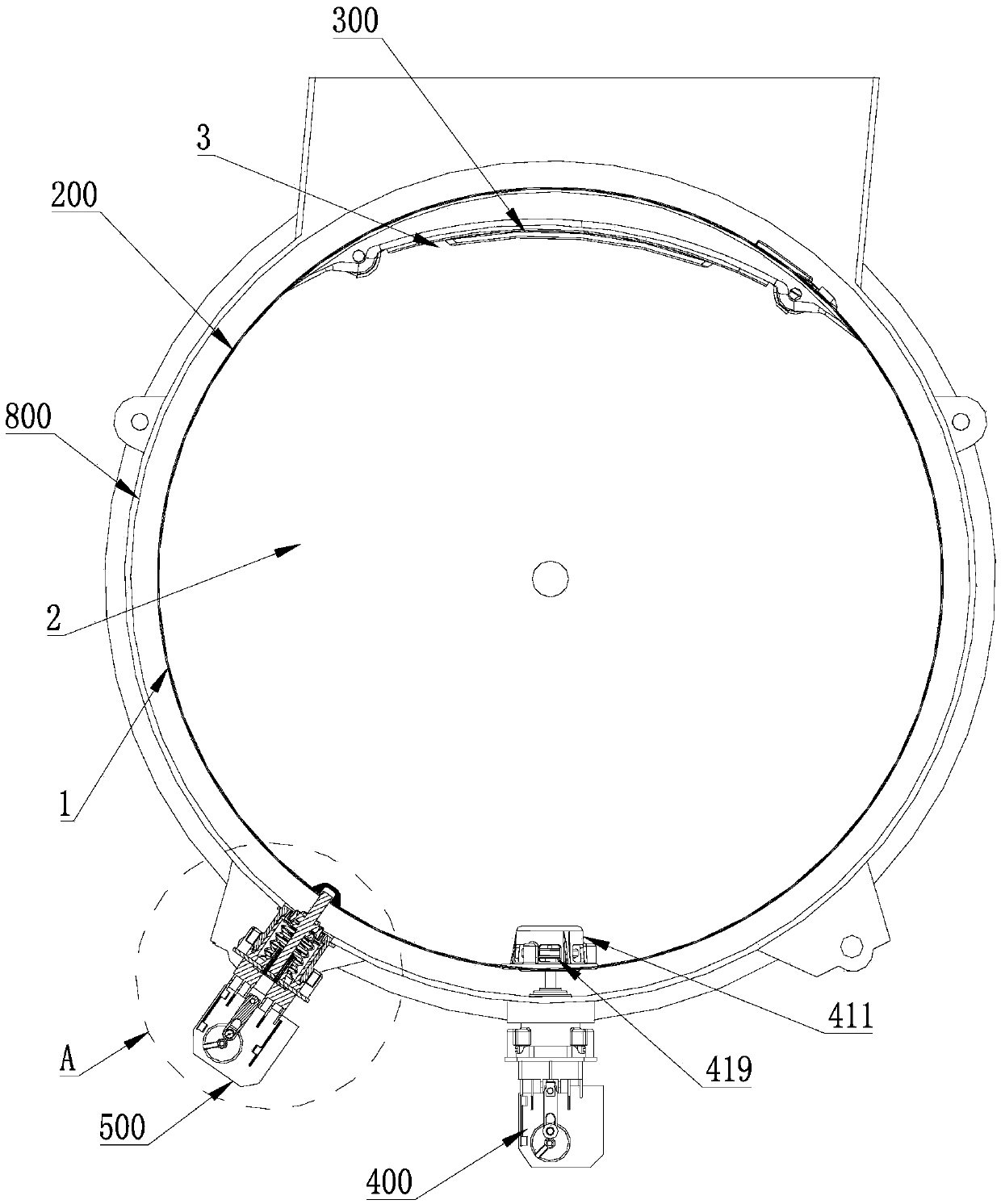

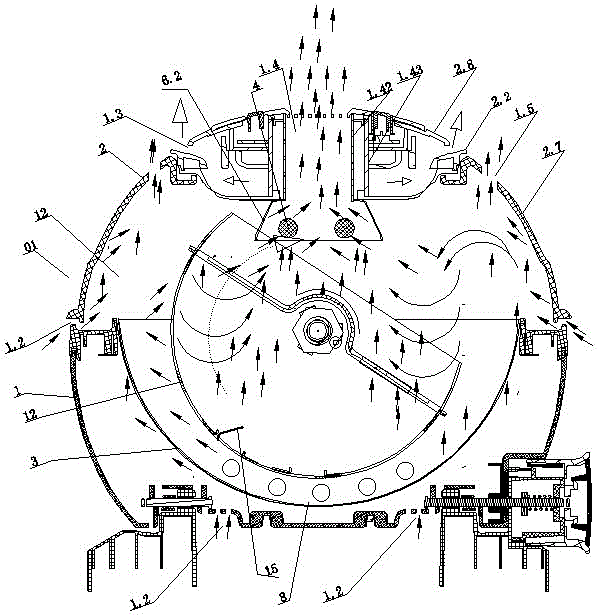

Manufacturing method and production line for thermoset carbon fiber plate for wind vane

ActiveCN105904746AImprove wetting effectSolve the operating environment pollutionDomestic articlesCoatingsMicrometerEngineering

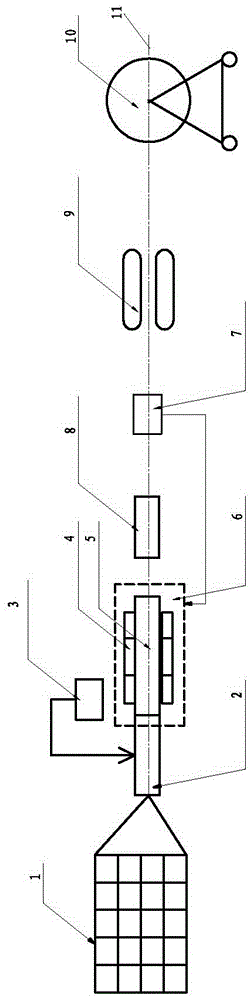

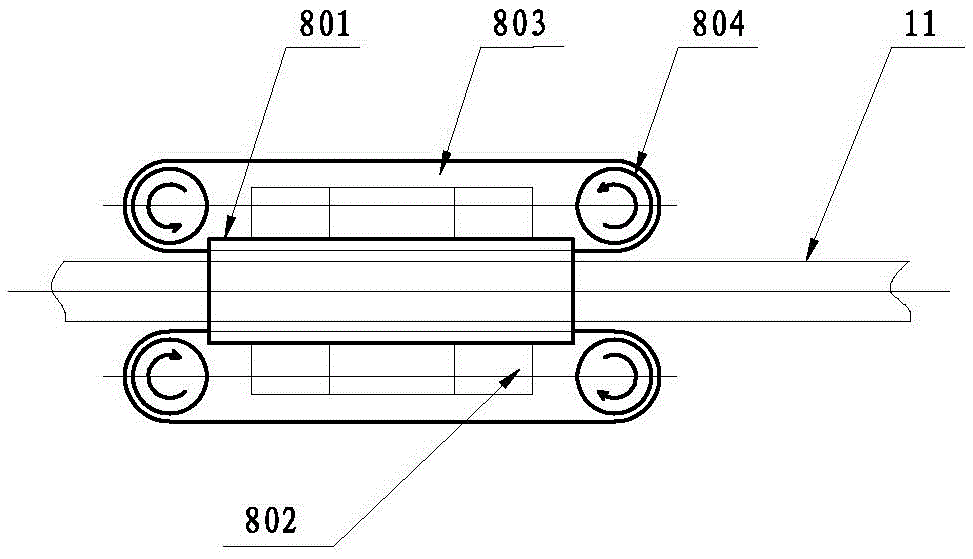

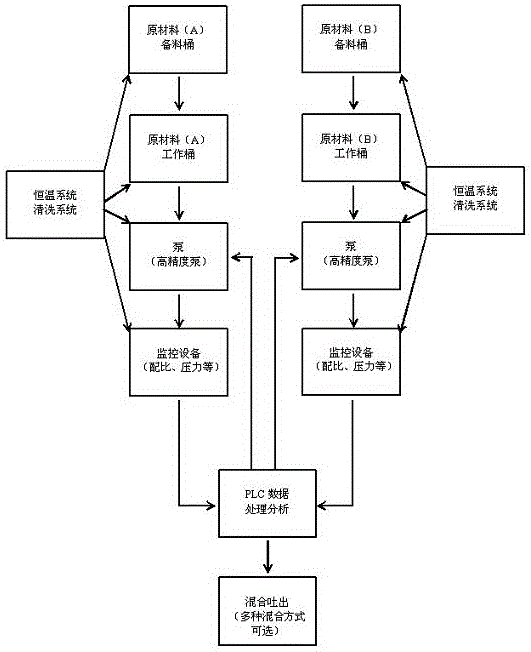

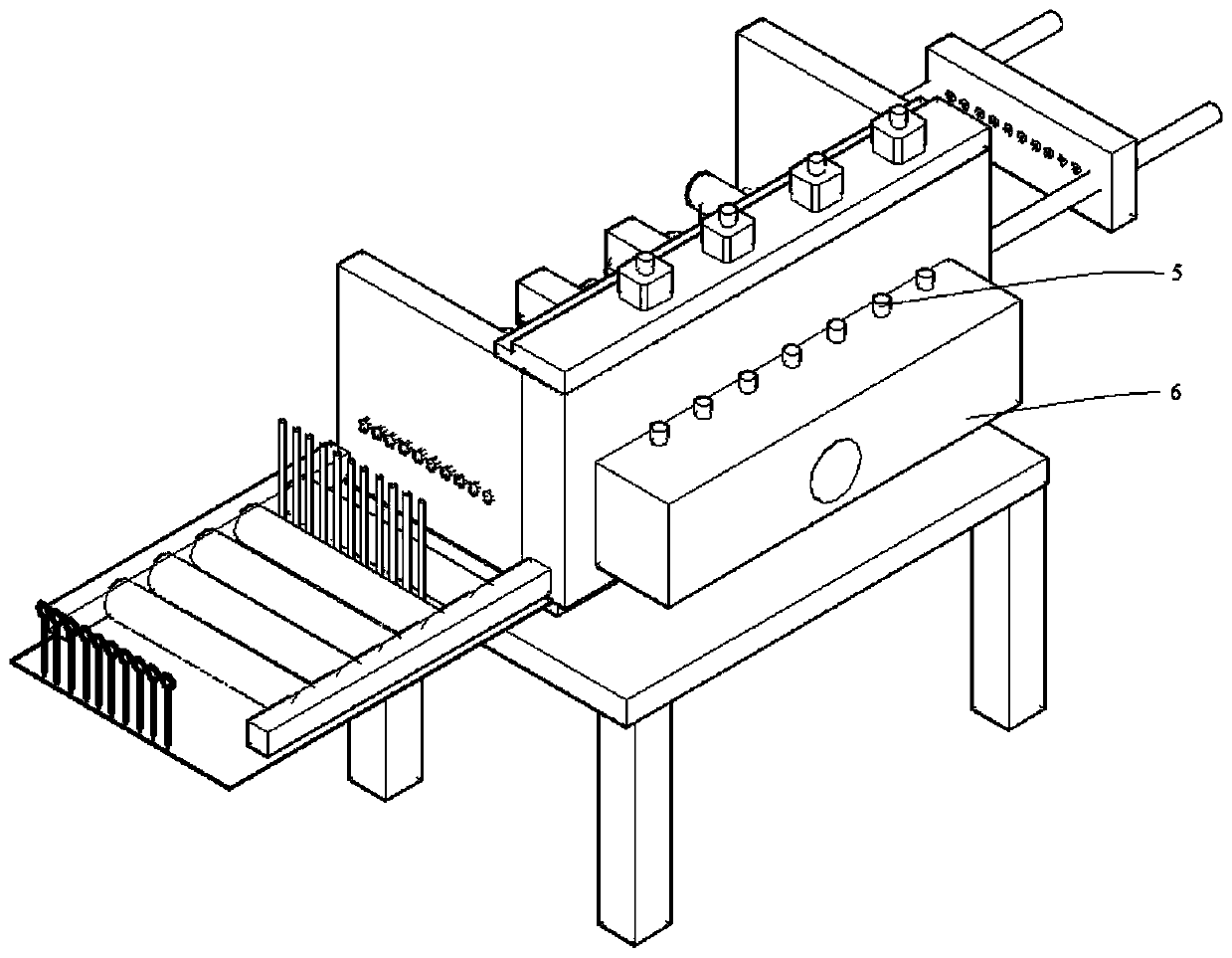

The invention provides a manufacturing method and production line for a thermoset carbon fiber plate for a wind vane. The manufacturing method is characterized by comprising the following steps that firstly, carbon fibers are guided into a sealed impregnation box (2) to be impregnated from a tension creel (1), and the sealed impregnation box is provided with a full-automatic proportioning and feeding device (3) which can conduct glue injection automatically according to the detected pressure and glue positions in the sealed impregnation box; secondly, the impregnated carbon fibers are pushed into a curing mold (5) to be heated, cured and shaped, so that a carbon fiber plate is obtained, and a centering correction mechanism is additionally installed at the outlet end of the curing mold (5), so that the cured carbon fiber plate is pulled out of the curing mold (5) with the set straightness; and thirdly, the cured carbon fiber plate is guided into a surface treatment device (6) to be subjected to surface polishing, and the surface roughness of the polished carbon fiber plate is kept between 0.3-1.0 micrometer; and fourthly, the carbon fiber plate subjected to surface polishing is pulled by a pulling mechanism (7) to be conveyed into a rolling mechanism to be rolled. The manufacturing method is simple, the production efficiency is high, and the quality is good.

Owner:南京诺尔泰复合材料设备制造有限公司

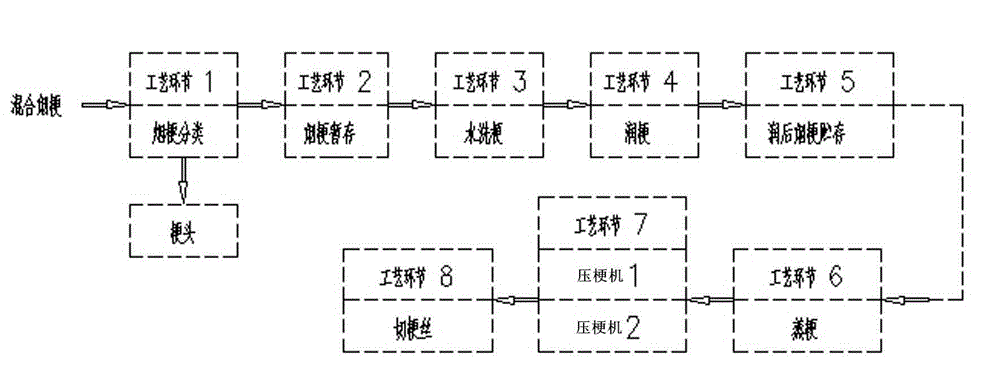

Tobacco stem classifying and processing method

InactiveCN102715645AImprove wetting effectUniform moisture contentTobacco treatmentFilamentationEngineering

The invention relates to a tobacco stem classifying and processing method. The tobacco stem classifying and processing method comprises the following steps of classifying tobacco stems by one or more methods of spectrum pickup classification, multi-stage vibrating screening classification and winnowing classification and removing heads from the tobacco stems; conveying the classified tobacco stems into temporary storage stations respectively, washing and moistening each kind of tobacco stems according to the production requirement, and conveying the tobacco stems into a storage cabinet or box type small-sized three-dimensional elevated library respectively to store; steaming and pressing the tobacco stems sequentially so as to press the tobacco stems into flat shapes; and finally conveying the flattened tobacco stems into the subsequent stem-cutting procedure. According to the invention, the filamentation ratio of the cut stems is increased, the uniformity of the cut stems is improved and the quality of the cut stems is improved.

Owner:YUNNAN KUNMING SHIPBUILDING DESIGN & RESEARCH INSTITUTE

Alcohol-free condensation fountain solution containing colloid silica prepared by magnetic activated water and preparation method thereof

The invention relates to a fountain solution for offset printing, and particularly to an alcohol-free condensation fountain solution containing colloid silica prepared by magnetic activated water and a preparation method thereof. The fountain solution is prepared by the following raw materials, by weight, 6 to 8 parts of glycerin, 0.5 to 0.8 part of dispersant MF, 2 to 3 parts of polyvinylpyrrolidone, 30 to 40 parts of magnetic activated water, a proper amount of acidic buffer, 2 to 3 parts of sodium alginate, 1 to 3 parts of sodium chloride, 2 to 3 parts of colloid silica, 3 to 4 parts of dipotassium hydrogen phosphate, and 1 to 2 parts of fatty alcohol polyoxyethylene ether. The magnetic micromolecule water is used as a solution of the fountain solution, the fountain solution can quickly spread to form a film, the dispersed colloid silica can further speed up adsorption and spread of a hydrophilic film on a printing surface, the wetting effect is improved, and the printing surface can be protected. The fountain solution does not contain volatile alcohols or other harmful substances, is more environmental friendly and safe. The fountain solution can make water and ink balance quickly, no ink accumulates, the printing quality and the printing speed can raised, the condensation fountain solution also is easy to store, hardly go bad, and the condensation fountain solution can be diluted into needed concentration when used.

Owner:HEFEI MEIJIA PRINTING

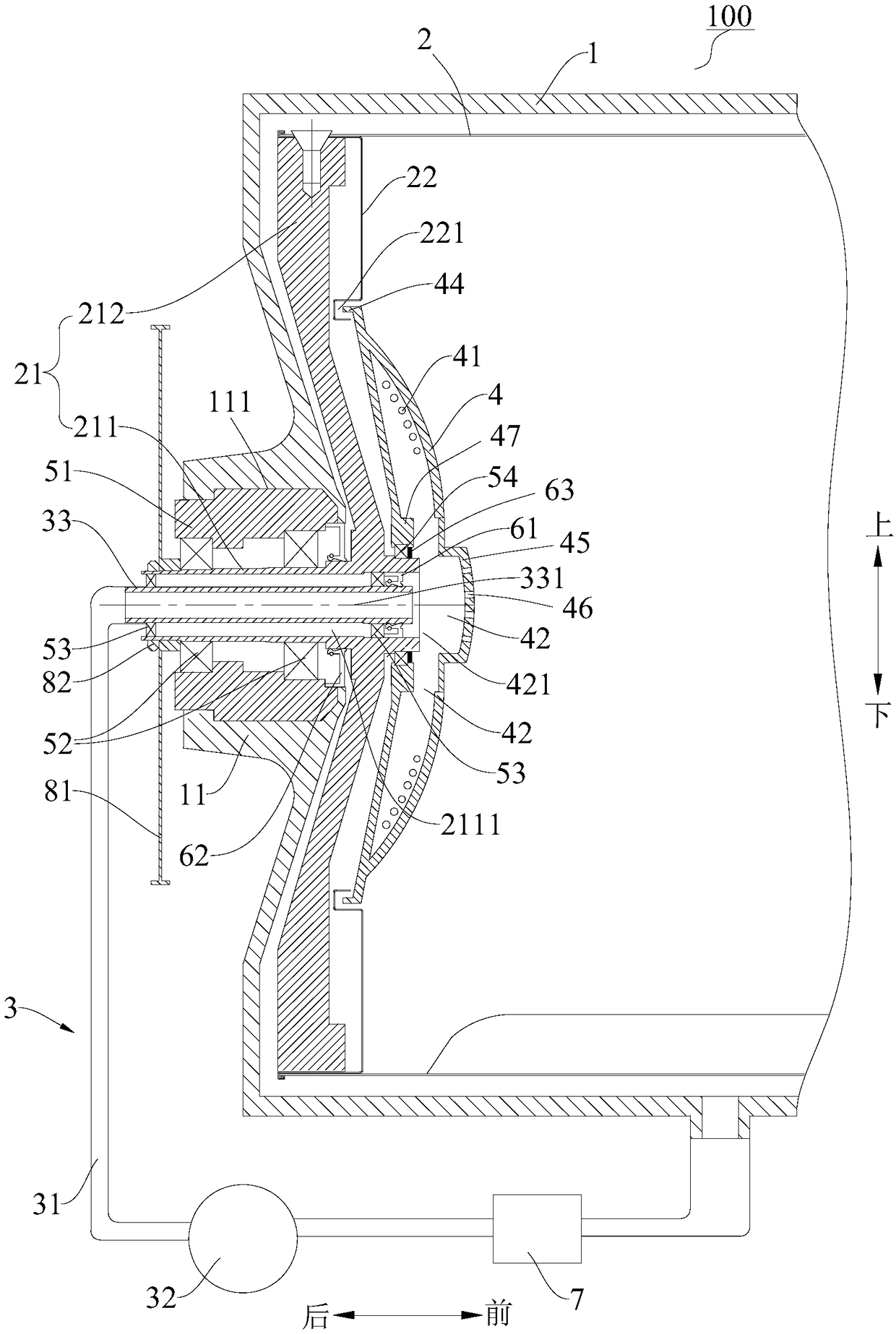

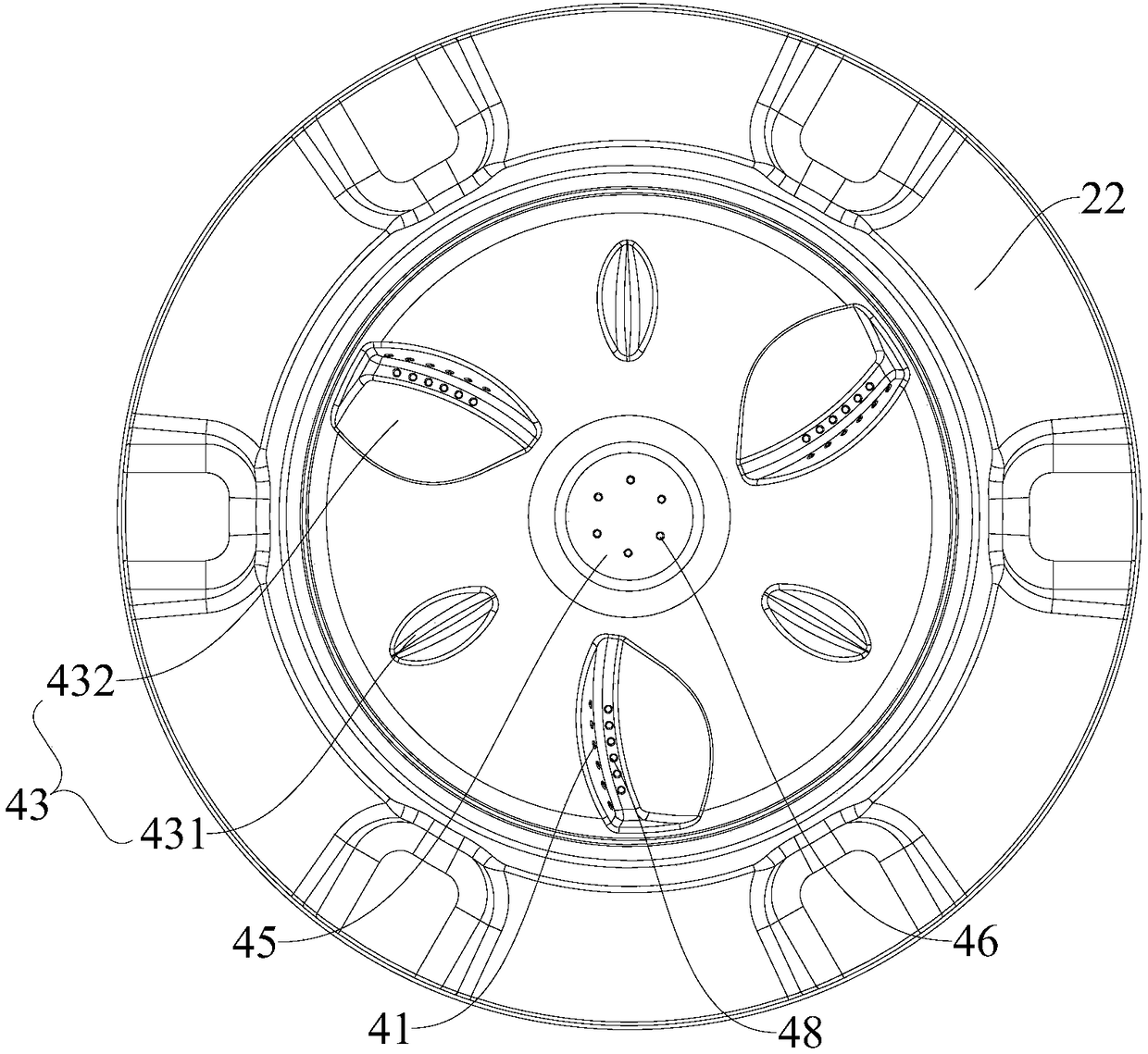

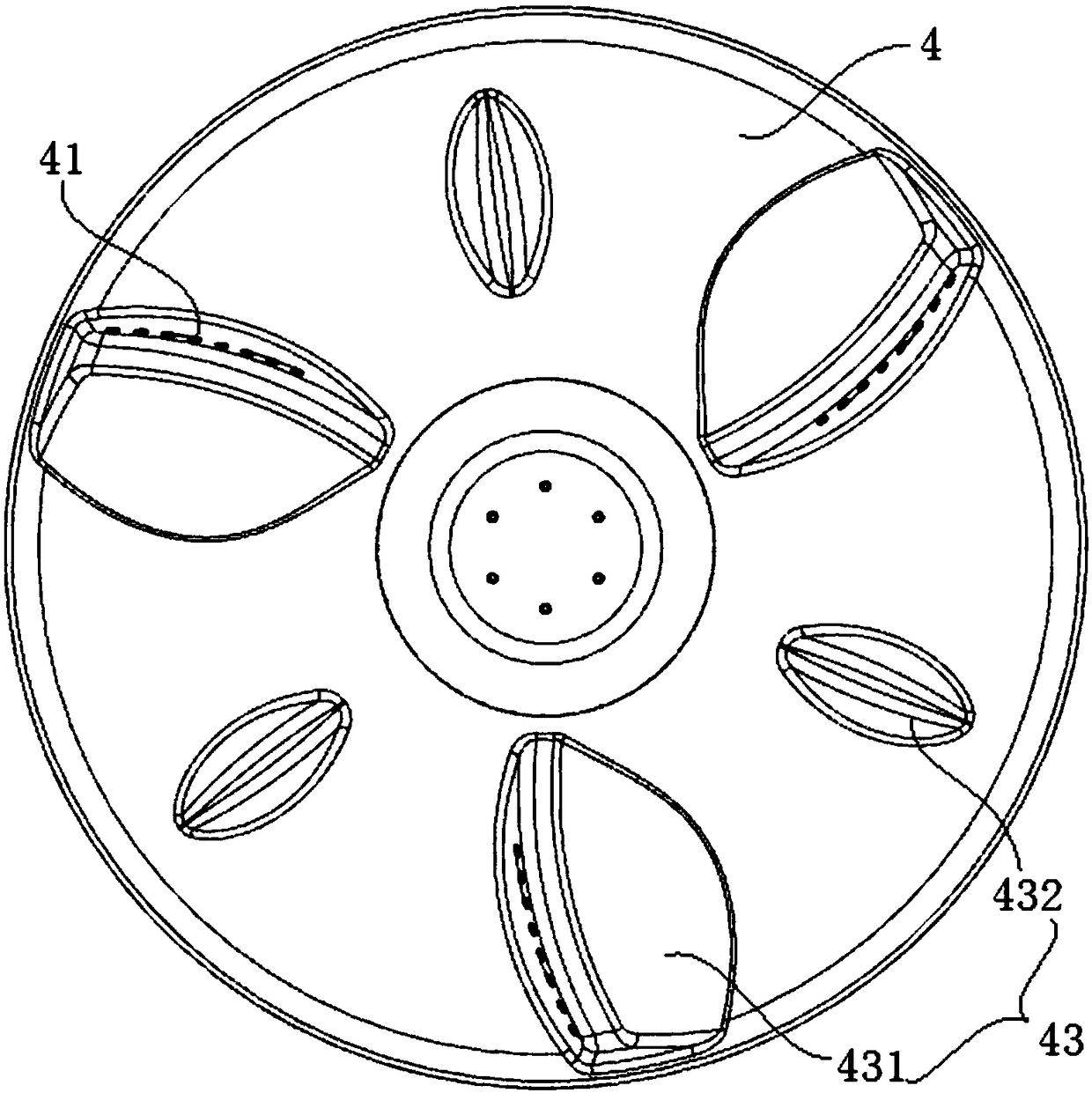

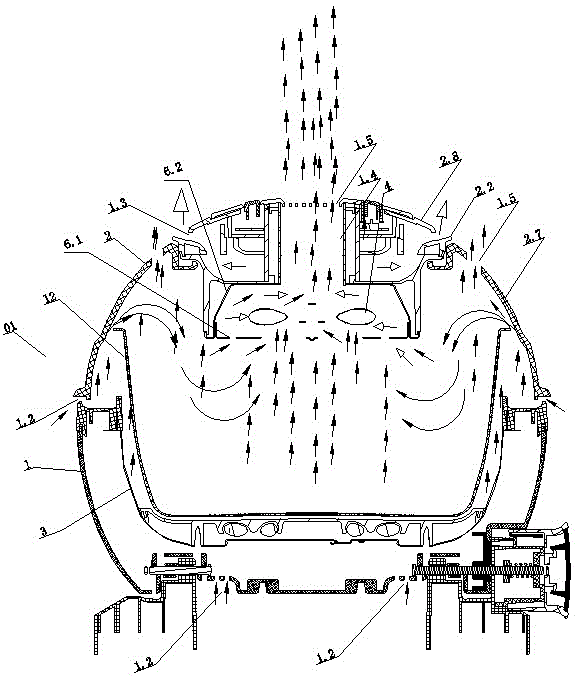

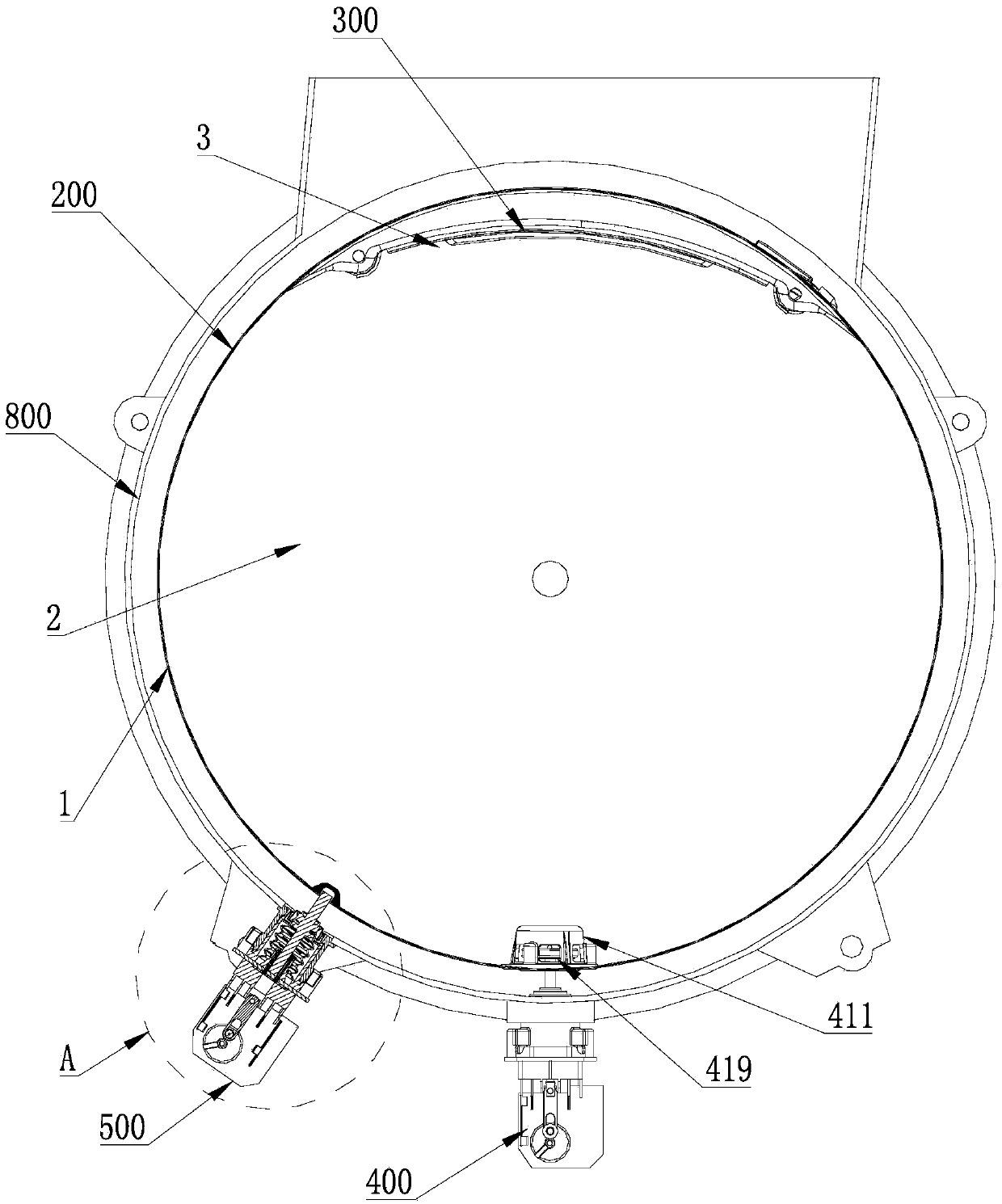

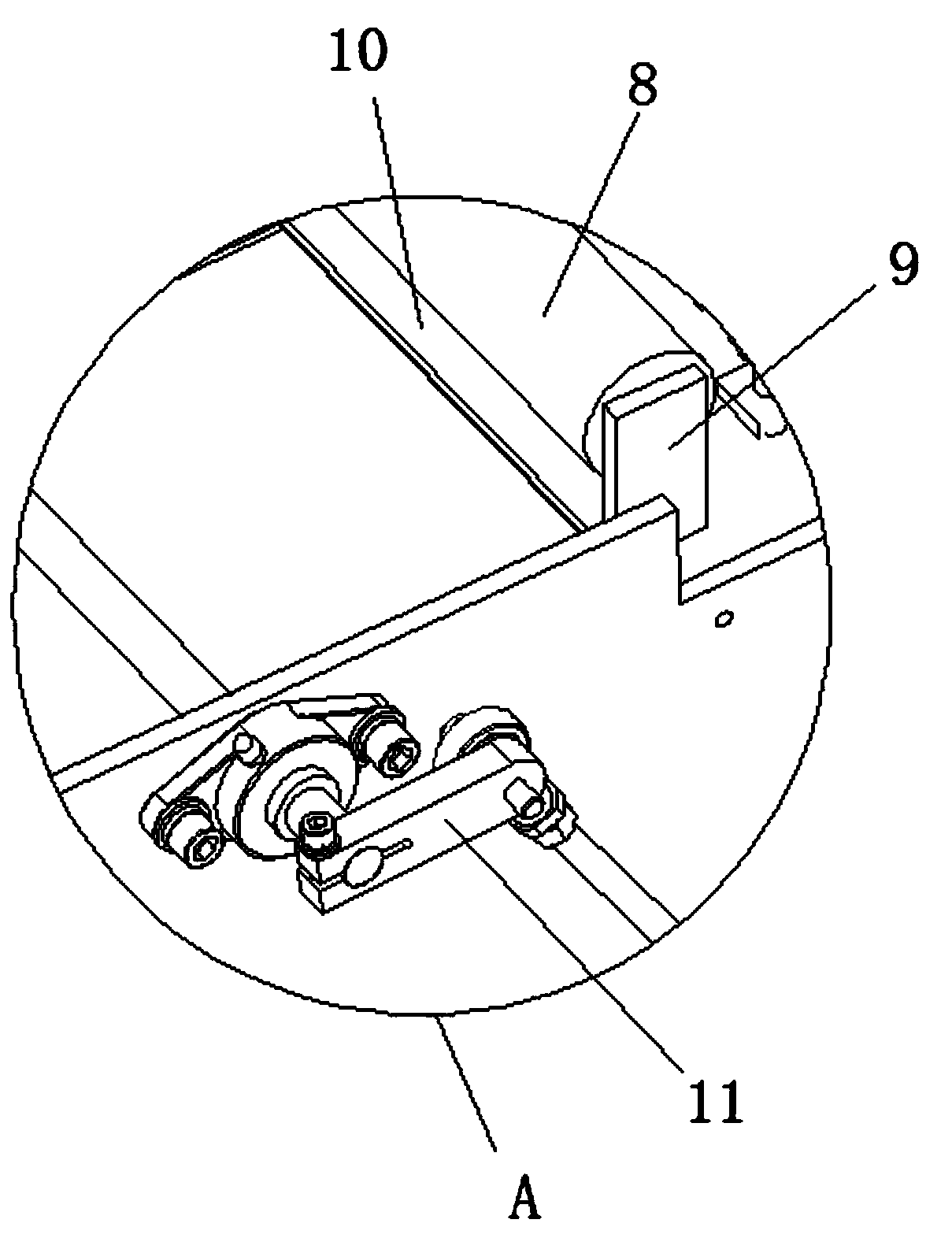

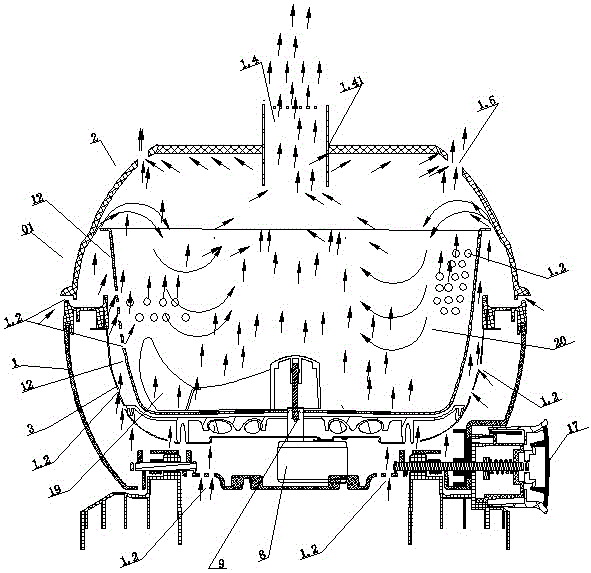

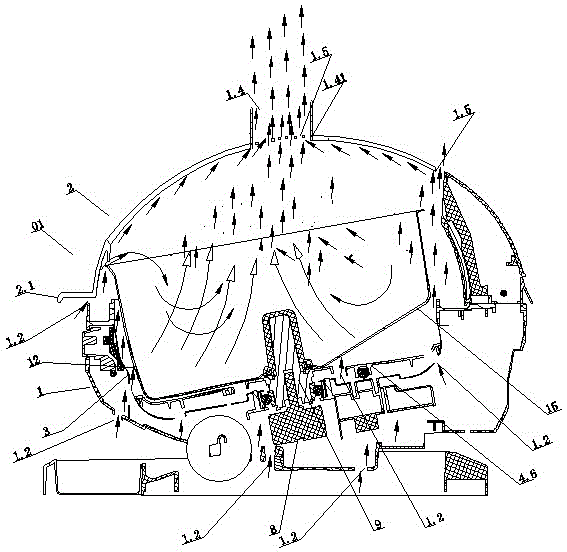

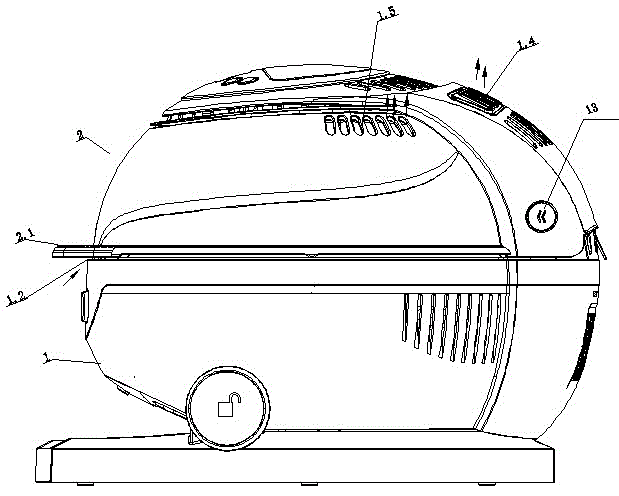

Roller washing machine

ActiveCN108950993ASimple structureSimplify the control problemOther washing machinesWashing machine with receptaclesElectric machineryEngineering

The invention discloses a roller washing machine. The washing machine comprises an outer bucket, an inner cylinder rotatablyarranged in the outer bucket, a water supplying device, and a stirrer arranged in the inner cylinder and connected with the water supplying device, and the stirrer is driven by water supplied by the water supplying device to rotate. According to the roller washing machine, the stirrer is arranged in the inner cylinder, the water supplying device is adopted for supplyingwater to the stirrer, the water supplied by the water supplying device can drive the stirrer to rotate,elements of a belt wheel, a motor and the like which are used for individually driving the stirrer to rotate in the prior art are not needed, the structure is simplified, the control is more convenient, and the cost is further reduced.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

Modified epoxy resin composite for strengthening concrete pole

InactiveCN101870799AImprove wetting effectInitiates microcracks wellTowersSurface modificationEpoxy resin composite

The invention discloses a modified epoxy resin composite for strengthening a concrete pole, which comprises carbon cloth and epoxy resin. The modified epoxy resin composite for strengthening the concrete pole is characterized in that: the carbon cloth is impregnated with the modified epoxy resin; the modified epoxy resin refers to 100 parts of the epoxy resin comprising 0.8 to 2 parts of surface-finished carbon nanotubes and 3 to 8 parts of nano silica; and carbon nanotubes are oxidized by the mixed acid of HNO3 and H2SO4 to carboxylate the surfaces of the carbon nanotubes to form the surface-finished carbon nanotubes. 30 to 60 parts of curing agent is added into the modified epoxy resin during construction and material mixing. The composite has the characteristics of high weather resistance, tensile property, high strength, impact resistance, corrosion resistance and the like and is a good material for strengthening the pole.

Owner:HUAIBEI KEAO ENG CONSTR

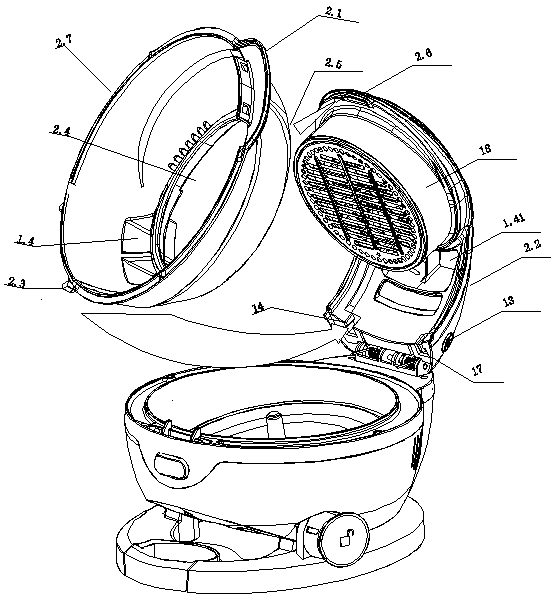

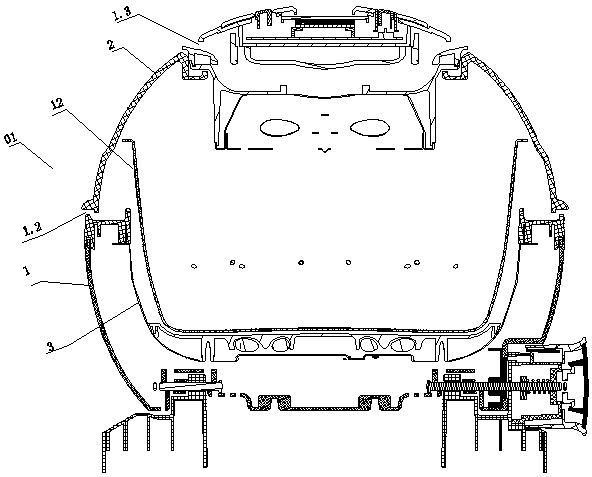

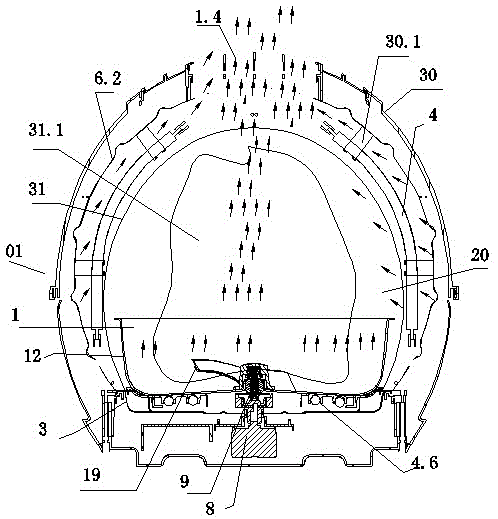

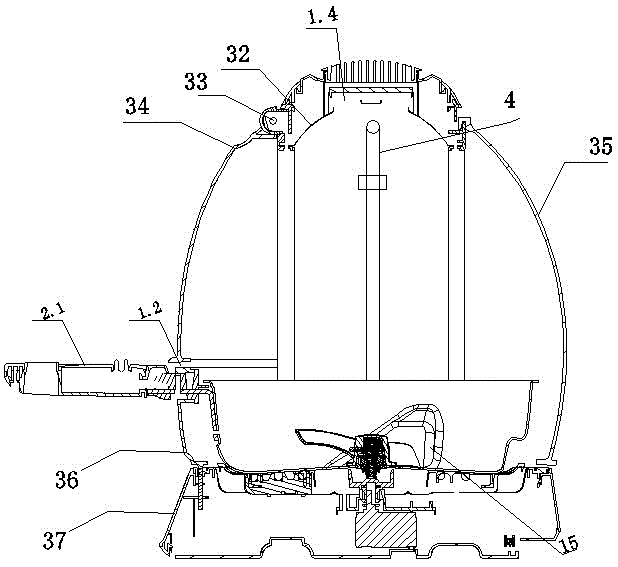

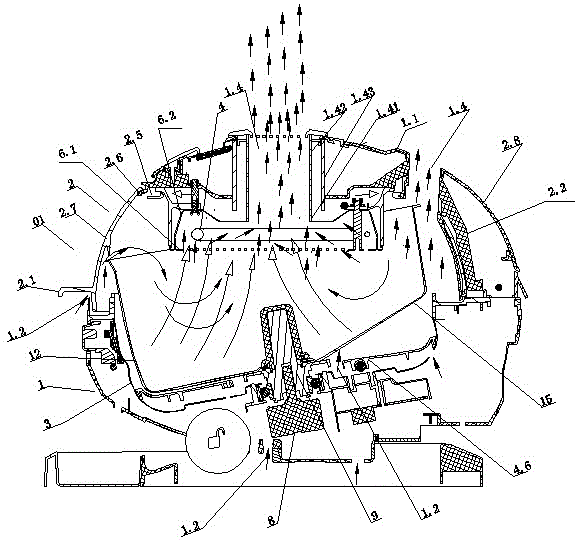

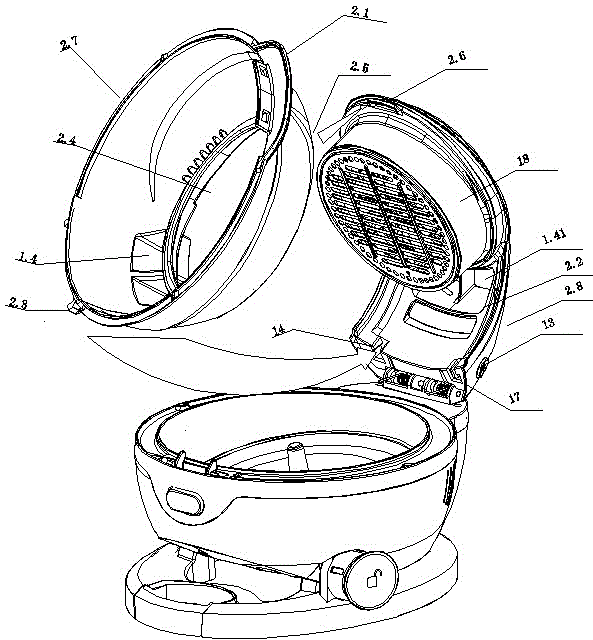

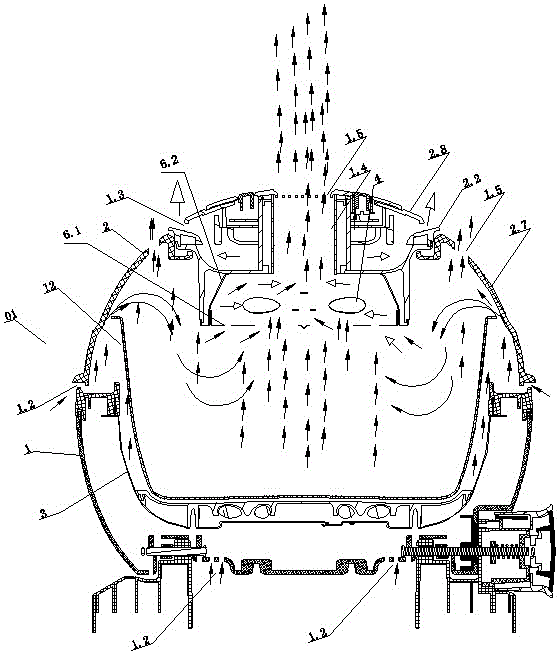

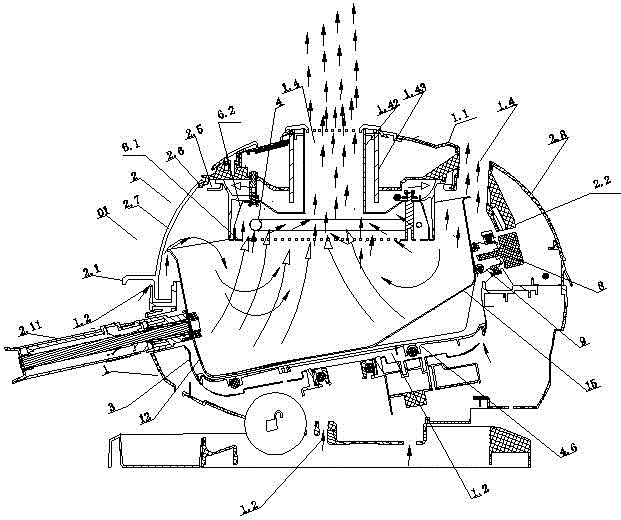

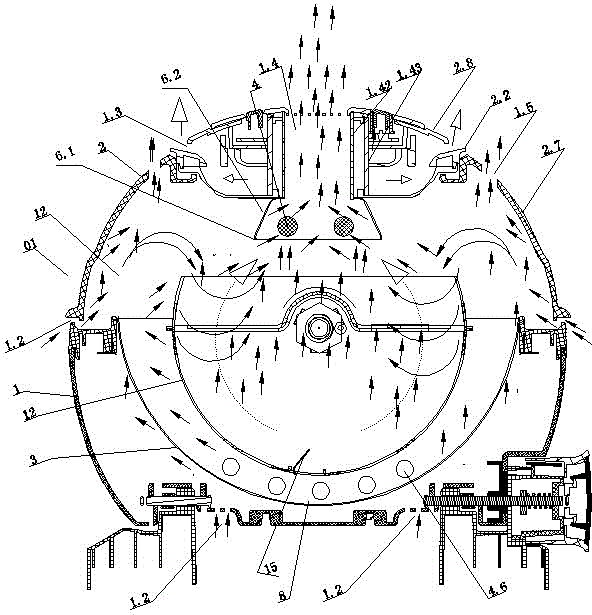

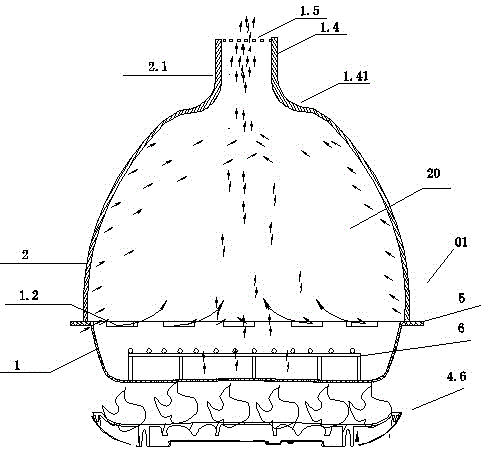

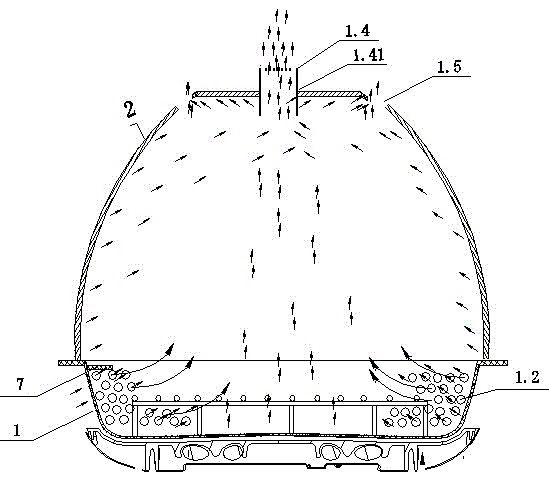

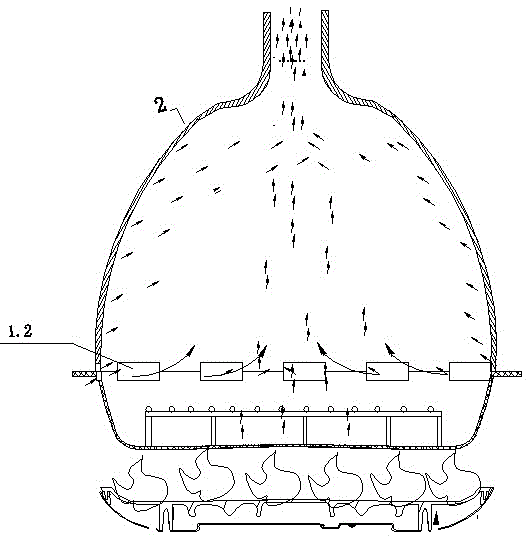

Oven with detachable upper cover and use method thereof

The invention provides an oven with a detachable upper cover. A main body of the oven comprises an upper body and a lower body, wherein the upper body is provided with the upper cover, a heating channel and a main body support of the upper body, the heating channel leads to the inside of a food container of the lower body, and the heating channel is arranged on the main body support of the upper body. The oven is characterized in th<input type='image' src='' / >at the lower end of the main body support of the upper body is rotatably connected with the lower body, a locking device is arranged between the main body support of the upper body and the upper cover, one end of the upper cover is hung at one end of the main body support of the upper body, and the other end of the upper cover is pushed to rotate and is tightly attached to the other end of the main body support of the upper cover, so that the upper cover is buckled and locked and does not disengage. The oven has the advantages of being simple and reasonable in structure, flexible in operation, easy to assemble and disassemble, easy to clean and wide in application range.

Owner:周林斌

Oven

The invention provides an oven with a detachable upper cover. A main body of the oven comprises an upper body and a lower body, wherein the upper body is provided with the upper cover, a heating channel and a main body support of the upper body, the heating channel leads to the inside of a food container of the lower body, and the heating channel is arranged on the main body support of the upper body. The oven is characterized in th<input type='image' src='' / >at the lower end of the main body support of the upper body is rotatably connected with the lower body, a locking device is arranged between the main body support of the upper body and the upper cover, one end of the upper cover is hung at one end of the main body support of the upper body, and the other end of the upper cover is pushed to rotate and is tightly attached to the other end of the main body support of the upper cover, so that the upper cover is buckled and locked and does not disengage. The oven has the advantages of being simple and reasonable in structure, flexible in operation, easy to assemble and disassemble, easy to clean and wide in application range.

Owner:周林斌

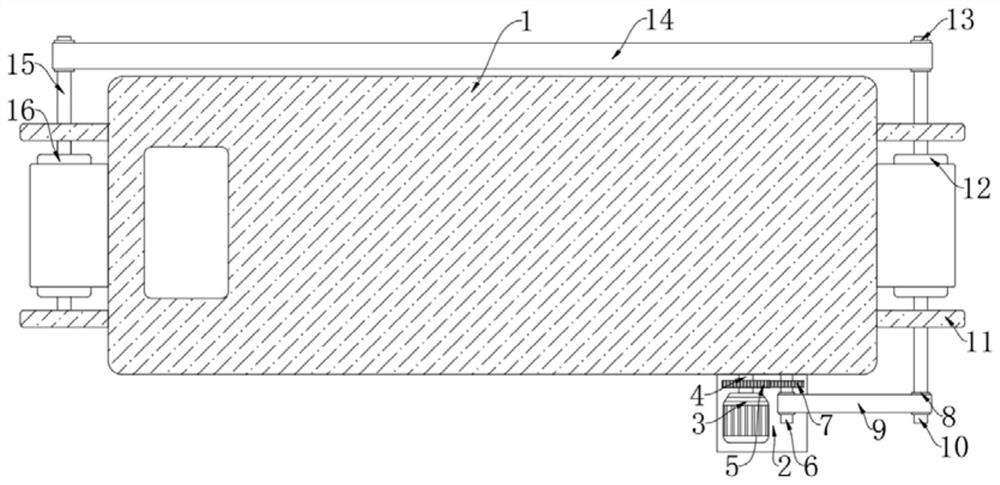

Water spraying transport case

InactiveCN108750380AImprove shock absorptionKeep moistLiving organism packagingContainers preventing decayCar drivingEngineering

The invention belongs to the field of transportation, in particular to a water spraying transport case which comprises a fixed tank. A movable tank is arranged in the fixed tank; the front end and therear end of the movable tank are fixedly connected with inner side walls of the fixed tank through a first air bag and a second air bag; repellent permanent magnet blocks are fixedly connected onto front and rear inner side walls of the first air bag and the second air bag; an intercommunicating cavity is arranged in peripheral side walls and a bottom side wall of the movable tank; water is stored in the cavity; a sealed pipe is arranged in the cavity and communicates with the first air bag through a first flexible pipe; the upper end of the sealed pipe penetrates through the cavity and is insealed connection with the cavity; the lower end of the sealed pipe communicates with the inner part of the cavity; a first piston block and a second piston block are in sealed connection into the sealed pipe in a sliding way; and the lower end of the first piston block and the upper end of the second piston block are fixedly connected through a connecting rod. According to the water spraying transport case provided by the invention, by utilizing the inertia during the automobile driving process, the water is sprayed for living organisms in the movable tank, so that the survival rate of the living organisms during transportation is effectively improved.

Owner:陈元珠

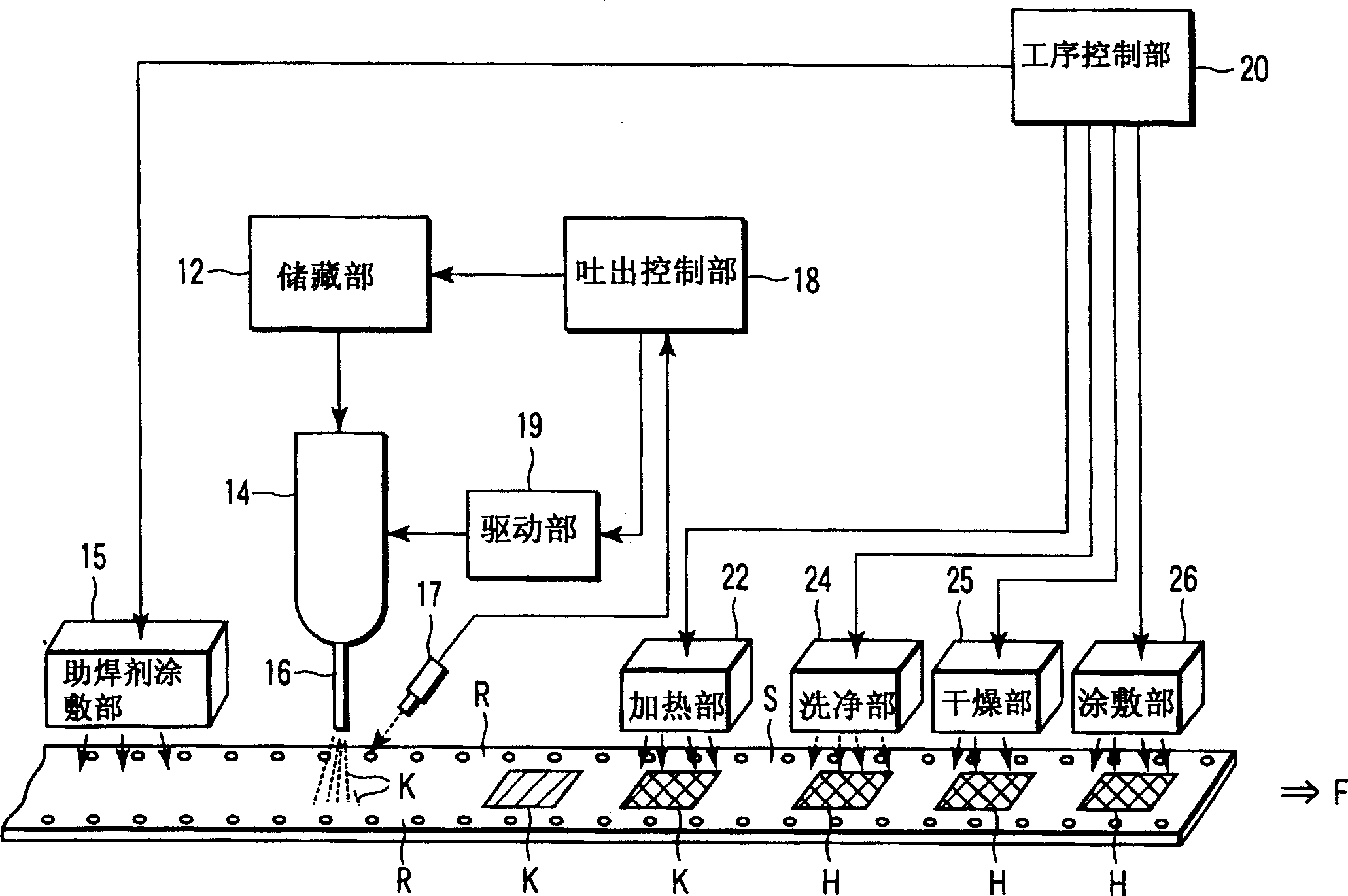

Composite material tool electrode for electrolytic deposition and electric spark and preparation method thereof

ActiveCN103878455AHigh specific heat capacityHigh hardnessElectrical-based machining electrodesMachined surfaceHardness

The invention discloses a composite material tool electrode for electrolytic deposition and electric spark and a preparation method of the composite material tool electrode, and belongs to the technical field of electrical discharge machining of electric spark. The composite material tool electrode for electrolytic deposition and electric spark is characterized by comprising, by weight, 16-18% of SiC particles, 14-16% of TiB2 particles, and the balance copper as a base body, and the SiC particles and the TiB2 particles are embedded in the base body. Due to the fact that the SiC particles and the TiB2 particles are added to the copper base body, compared with the method that only the SiC particles are added in the initial research stage, on the premise of not changing the total adding amount, the specific heat capacity of the tool electrode is improved by 10%, the coefficient of thermal expansion is lowered by 3%, the hardness is improved by 5%, and therefore the loss of the electrode under same electrical discharge machining parameters is lowered by 7%, and the roughness of a machined surface is lowered by 2%.

Owner:SHANDONG UNIV OF TECH

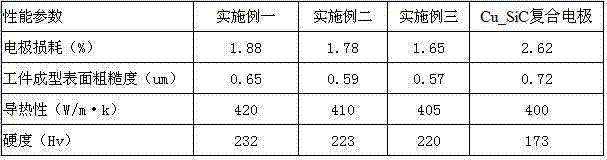

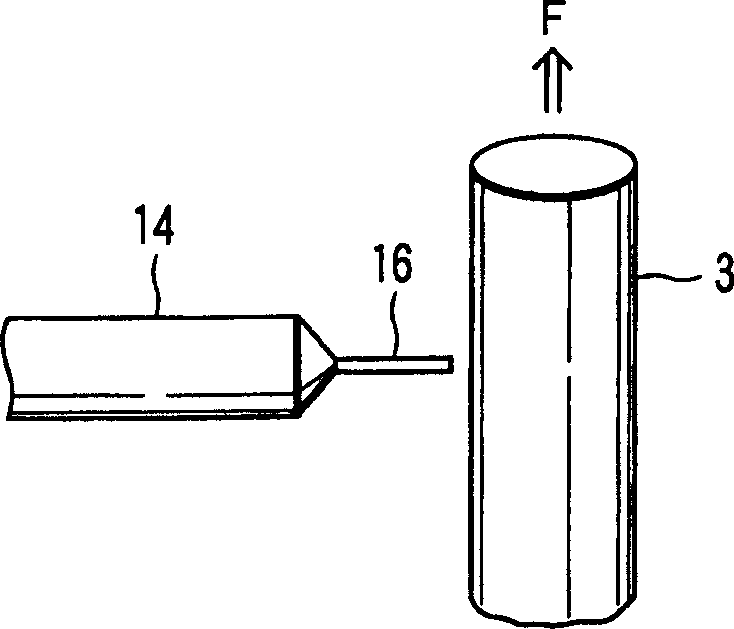

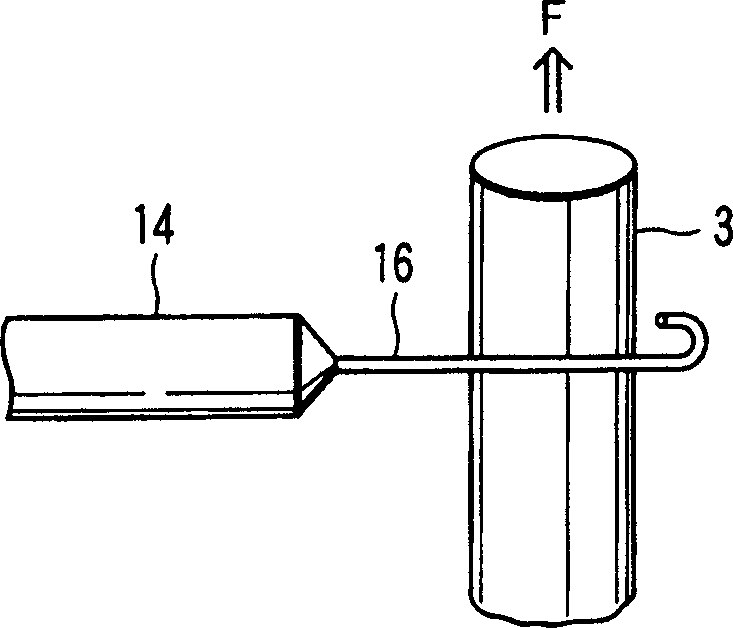

Soldering tin forming device, method and continuous plating device

InactiveCN1669715AHigh mechanical strengthWell formedSemiconductor/solid-state device detailsSolid-state devicesDischarge rateSolder paste

PROBLEM TO BE SOLVED: To form a solder region by solder paste, and to improve the reliability in joining, and the mechanical strength and quality of the solder itself.SOLUTION: The solder region formation device where a solder region H is formed on a member S is provided with: a storage part 12 of storing solder paste K; a dispenser 14 provided with a nozzle 16 discharging the solder paste K stored in the storage part 12 toward the member S; a discharge control part 18 of controlling the discharge amount and discharge rate of the solder paste K discharged from the nozzle 16; and a heating part 22 forming the solder region H on the member S by heating and melting the solder paste K discharged from the nozzle 16 in the dispenser 14 controlled by the discharge control part 18 and applied to the prescribed position.

Owner:MURATA KK

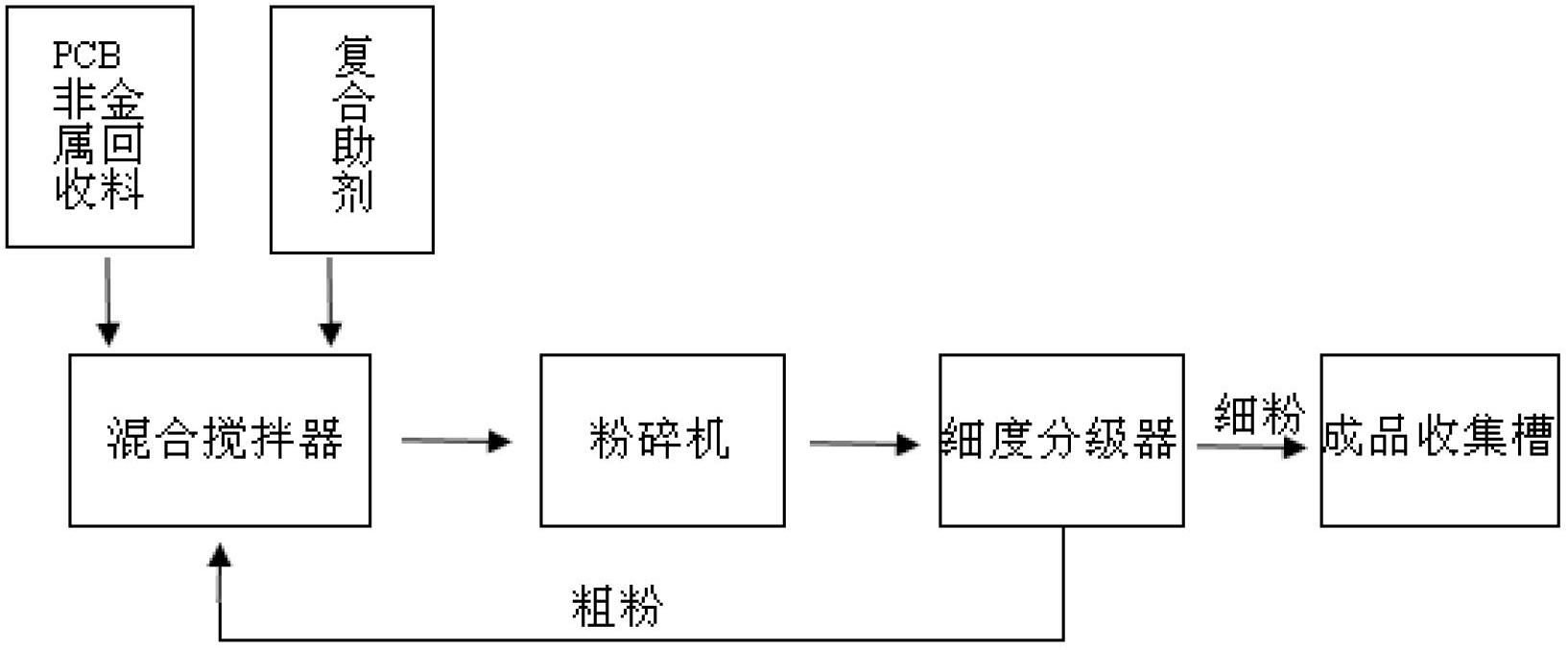

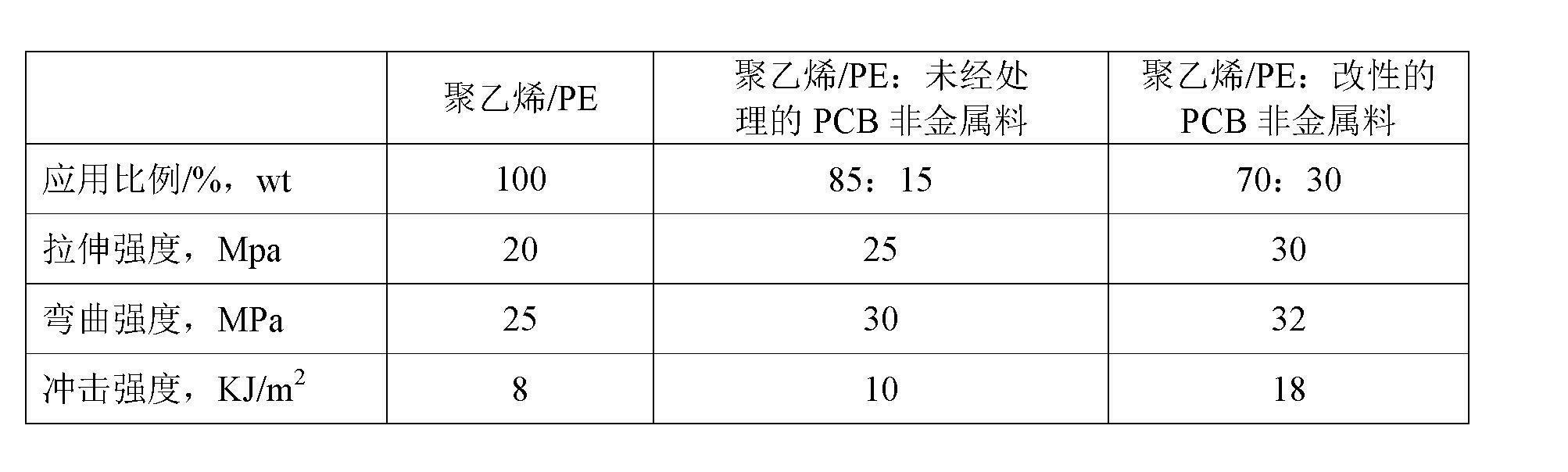

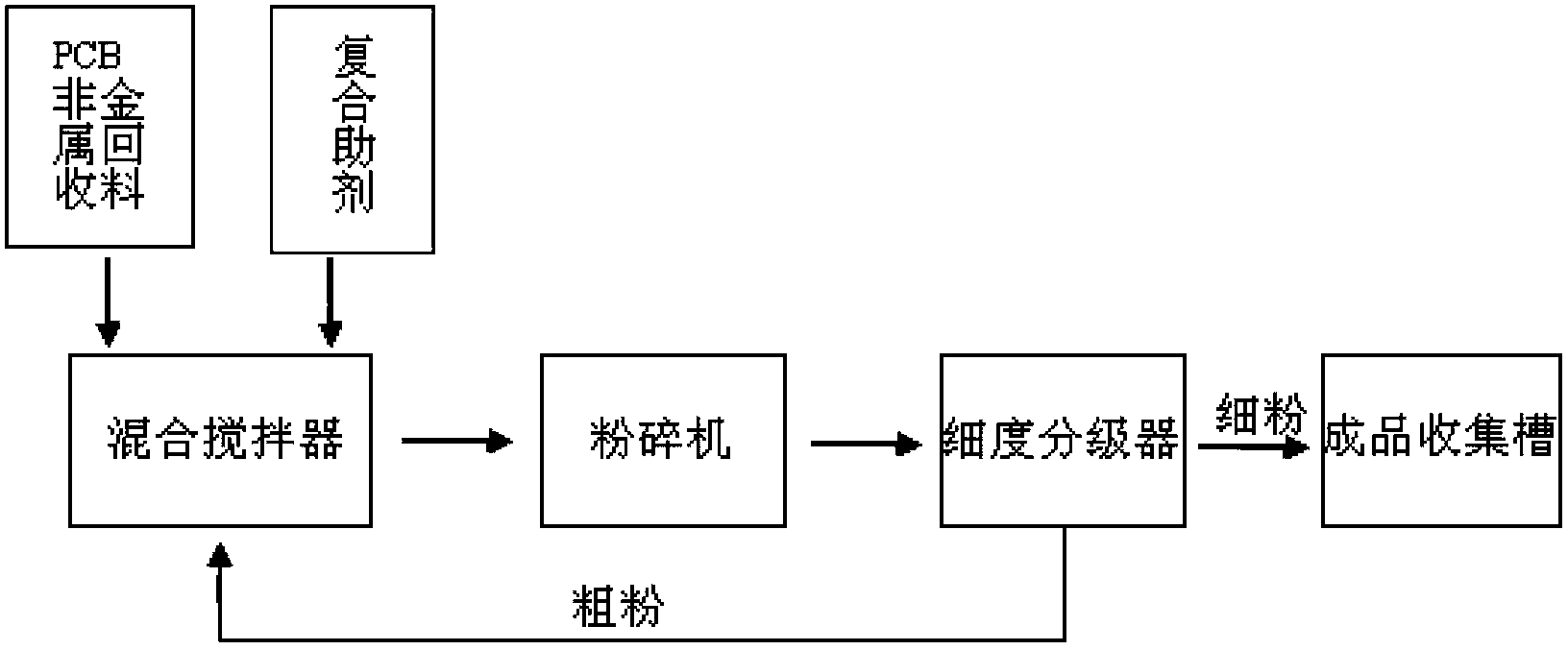

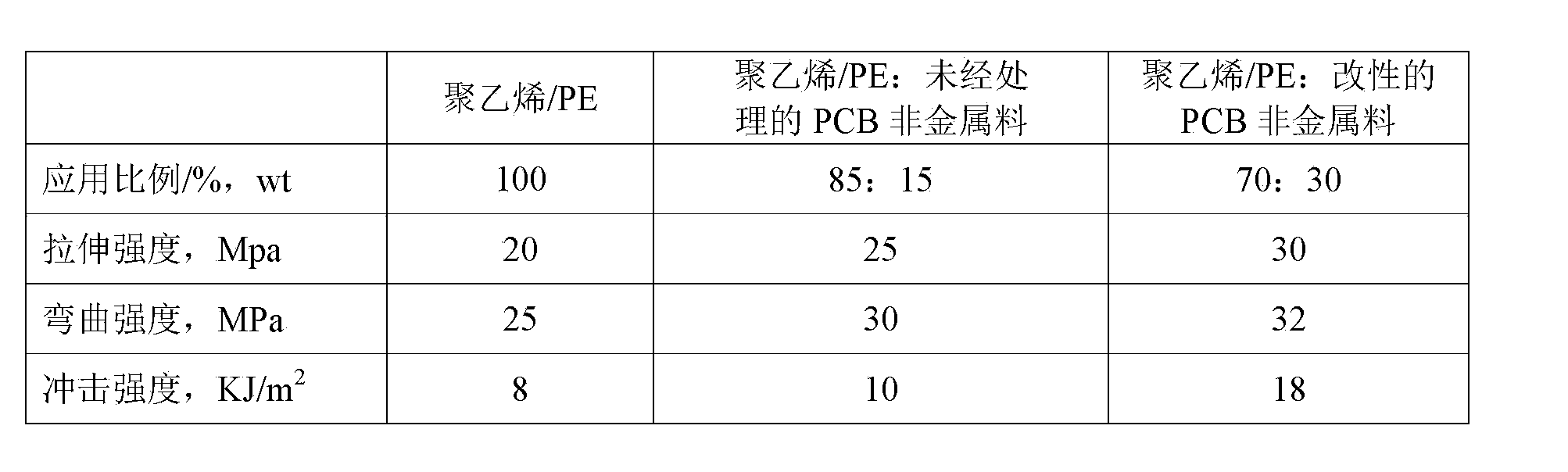

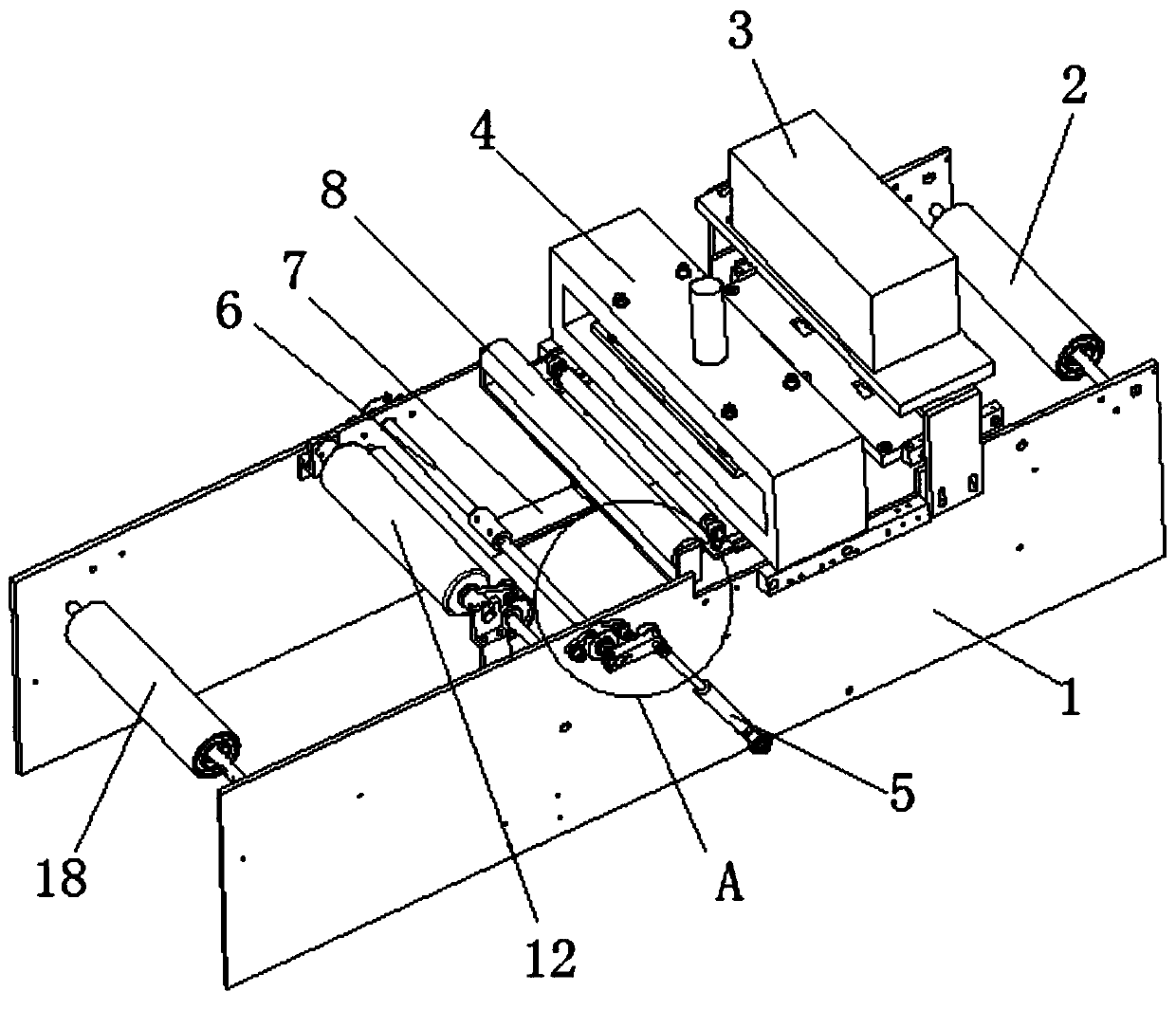

Modified nonmetallic reclaimed material of printed circuit board and preparation method thereof

ActiveCN102675717AFacilitate and intensify chemistryGood physical and mechanical propertiesChemical recyclingPigment treatment with macromolecular organic compoundsEngineeringPrinted circuit board

The invention discloses modified nonmetallic reclaimed material of a printed circuit board (PCB). The modified nonmetallic reclaimed material is prepared by a method comprising the following steps: after adding a compound assistant into nonmetallic reclaimed material of the printed circuit board and uniformly mixing, carrying out superfine crushing to obtain the modified nonmetallic reclaimed material of the printed circuit board, wherein the compound assistant comprises a crushing assistant, an active dispersing agent and a compatibilization modifier, the amount of the crushing assistant is 0.01%-10% of the weight of the nonmetallic reclaimed material of the printed circuit board, the amount of the active dispersing agent is 0.01%-10% of the weight of the nonmetallic reclaimed material of the printed circuit board, and the amount of the compatibilization modifier is 0.01%-10% of the weight of the nonmetallic reclaimed material of the printed circuit board. A finished fine power product of the modified nonmetallic reclaimed material of PCB has the advantages of effectively improved dispersion uniformity, interface compatibility and interface binding force, a mixing proportion can be increased, an application range is enlarged and application value is improved.

Owner:江苏嘉铂新材料有限公司

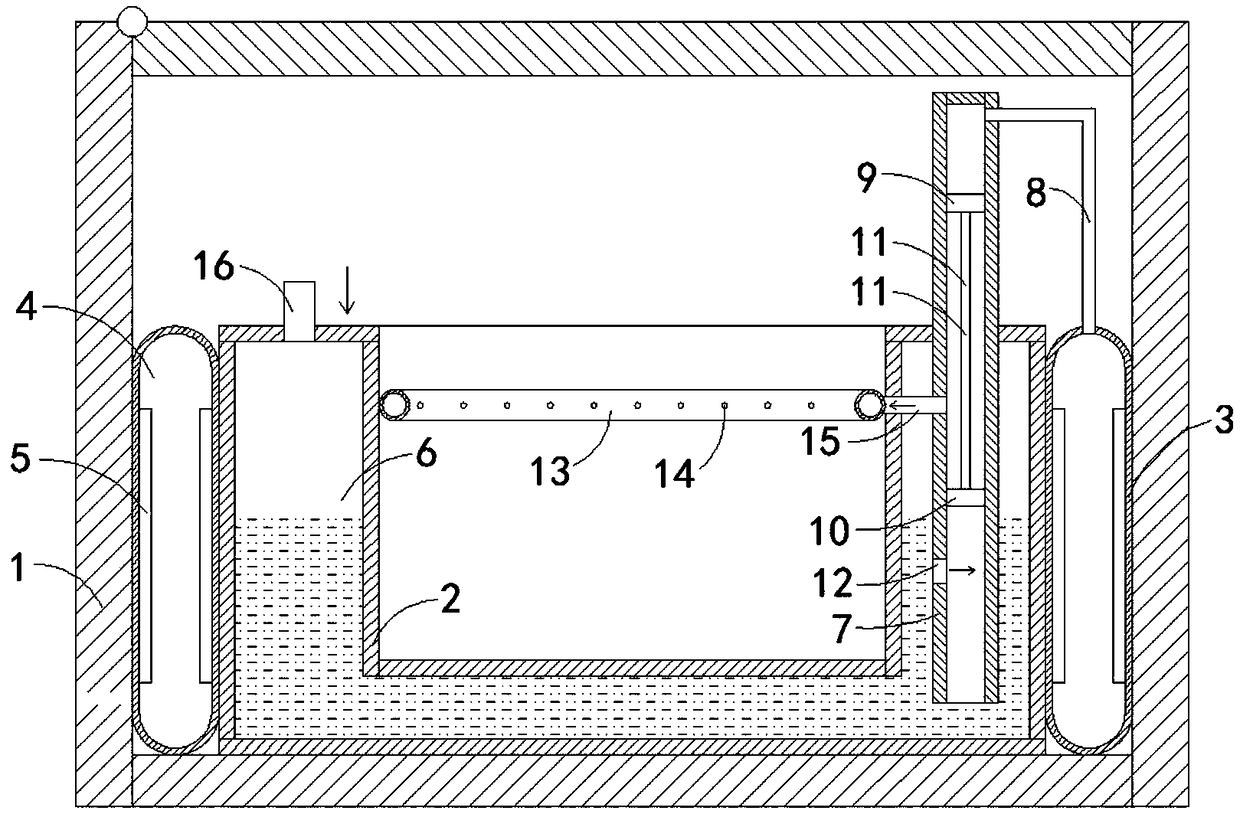

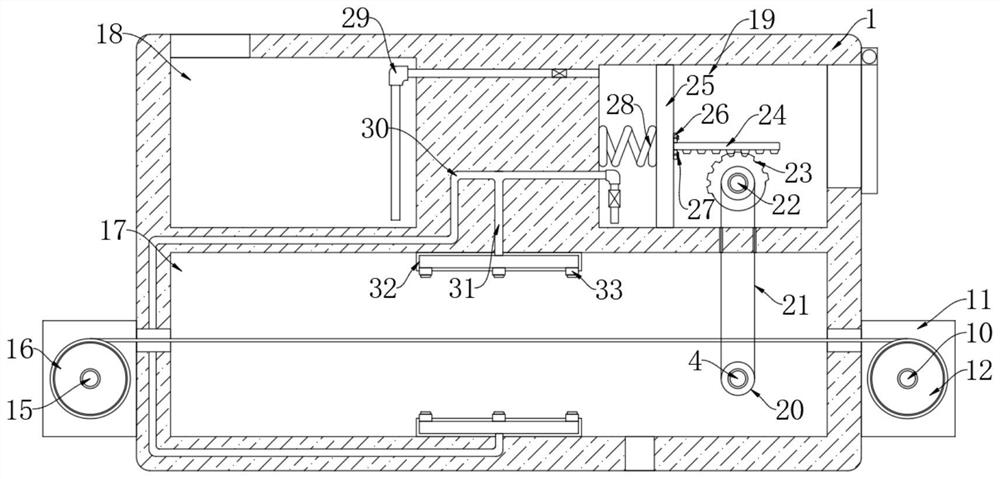

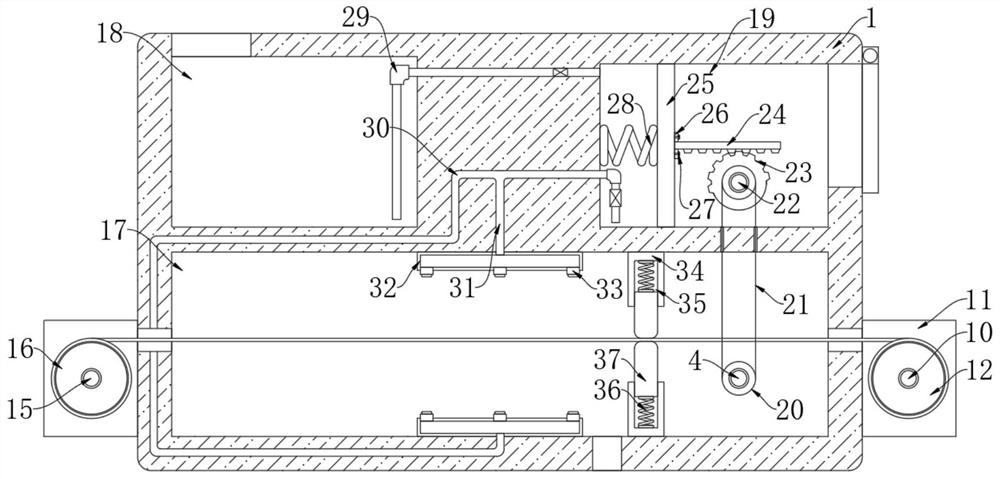

Humidifying device capable of controlling water quantity for non-woven fabric processing

PendingCN112301579AImprove wetting effectQuality improvementTextile treatment machine arrangementsLiquid/gas/vapor removal by squeezingProcess engineeringNonwoven fabric

The invention discloses a humidifying device capable of controlling water quantity for non-woven fabric processing. The humidifying device comprises a box body, wherein a spraying cavity is formed inthe box body, a water storage cavity and a rotating cavity are sequentially formed in the box body from left to right, the water storage cavity and the rotating cavity are both located above the spraying cavity, a water inlet in communication with the outside is formed in the inner top of the water storage cavity, an opening in communication with the outside is formed in the inner wall of the right side of the rotating cavity, and a sliding door is installed on the opening. According to the humidifying device, s motor drives a winding drum and a spraying device to operate at the same time, sothat a certain amount of water is sprayed to each section of non-woven fabric, the amount of water for humidifying can be controlled by replacing the specification of a rack, various types of non-woven fabric can be in the optimal water amount, the quality of the non-woven fabric is improved, double-sided spraying is conducted on the non-woven fabric, and the non-woven fabric is humidified more uniformly through the propping of propping blocks.

Owner:郑明增

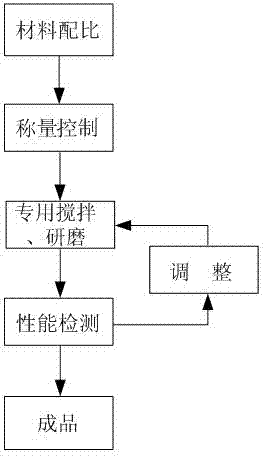

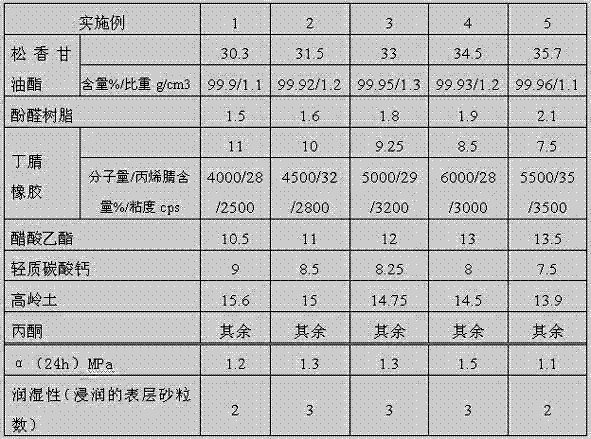

Quick-drying adhesive for casting sand mold

InactiveCN102391826AWith quick dryingShort curing timeNon-macromolecular adhesive additivesFoundry mouldsAdhesiveAcrylonitrile

The invention discloses a quick-drying adhesive for a casting sand mold, which is characterized in that the quick-drying adhesive comprises the following components by weight percent: 30.3%-35.7% of rosin glycerides, 1.5-2.1% of phenolic resin, 7.5-11% of butadiene-acrylonitrile rubber, 10.5%-13.5% of ethyl acetate, 13.9-15.6% of kaolin, 7.5-9% of light calcium carbonate and the balance of acetone. Through a large number of tests and summarization, a bonding system with short curing time and high final strength under normal temperature is developed, the auxiliary curing process step is not required, the displacement can be prevented within 15 minutes after bonding the sand mold during the use, and the bonding strength at 24 hours can be improved to above 1MPa. The quick-drying adhesive is coated on the breakage and the section of the sand mold, thereby being capable of effectively providing the bonding strength which is not lower than that of the sand mold when the sand mold is intact within a short period of time, reducing the number of damages of the sand mold during the casting production process, avoiding the repeated labor and the waste of energy and material, and improving the production efficiency.

Owner:鑫工艺(上海)材料科技有限公司

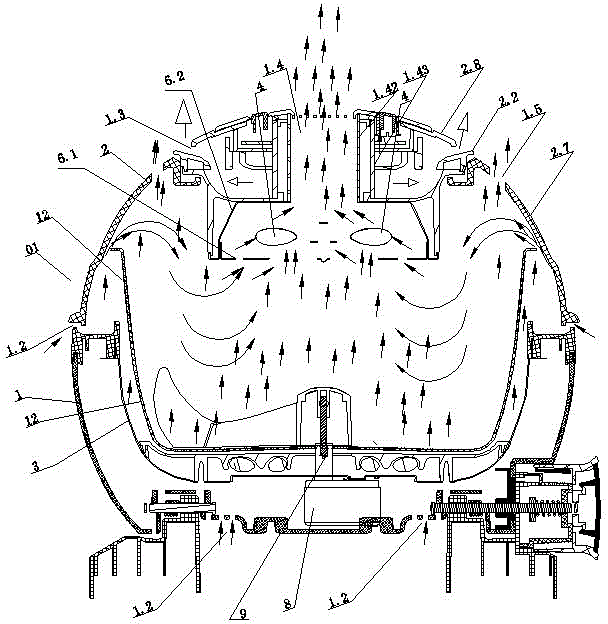

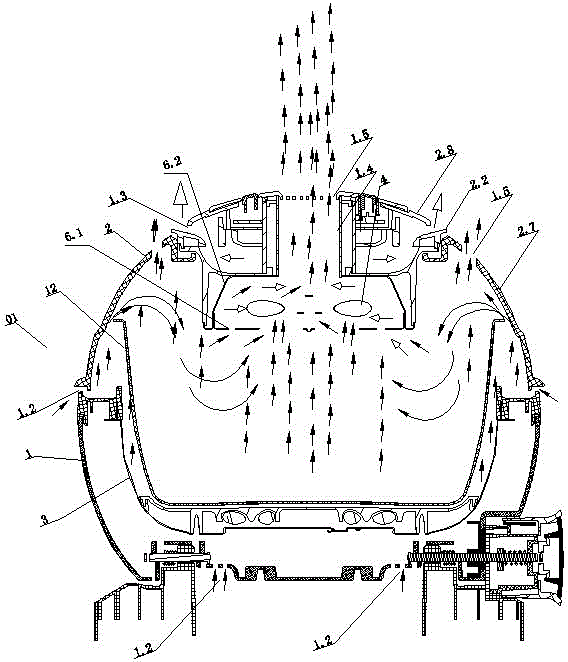

Drum washing machine

PendingCN111041762AImprove cleanlinessSimple structureOther washing machinesWashing machine with receptaclesEngineeringMechanical engineering

The invention discloses a drum washing machine. The drum washing machine comprises an imperforate drum which is arranged in a shell and does not have dewatering holes, a clothes input opening is formed in the side wall of the imperforate drum, and the drum is provided with a door body which can be turned over to open and close the clothes input opening; and two ends of the imperforate drum are sealed, the centers of the sealed ends are connected with the shell through rotating shafts in a relatively rotating way, the rotating shaft of at least one end is composed of a hollow sleeve, and the hollow part forms a flow channel and communicates with a water inlet pipe of the washing machine. A water inlet structure is arranged at the central rotating shaft of the drum, so that the use functionof the top-opening type washing machine for feeding water into the imperforate drum is realized, and water is enabled to flow into the imperforate drum smoothly.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

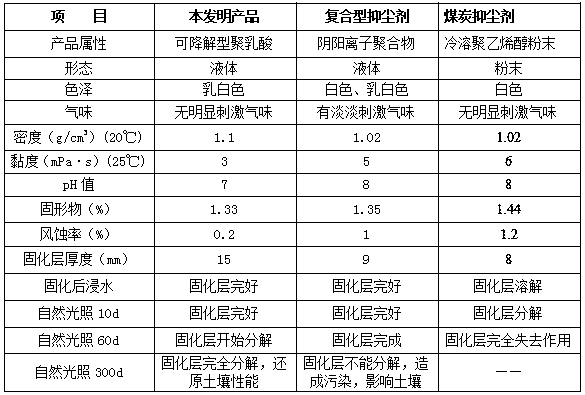

Degradable environment-friendly efficient dust suppressant and preparation method and use method thereof

PendingCN110951462AAvoid secondary pollutionGood compatibilityOther chemical processesPolylactic acidPolluted environment

The invention discloses a degradable environment-friendly efficient dust suppressant and a preparation method and use method thereof. The efficient dust suppressant is prepared from the following rawmaterials in percentage by weight: 6 to 10 percent of a water-based degradable emulsion; 1 to 3 percent of modified starch, 0.3 to 0.8 percent of modified cellulose, 0.2 to 0.6 percent of a dispersingagent, 0.1 to 0.5 percent of a wetting agent and 86 to 92 percent of water. The dust suppressant provided by the invention adopts starch, polylactic acid and other water-based degradable materials asmain raw materials, the starch and the polylactic acid can be automatically degraded after reaching the service life, residues polluting the environment cannot be generated, secondary pollution is avoided, and the dust suppressant is an environment-friendly material.

Owner:喜跃发国际环保新材料股份有限公司

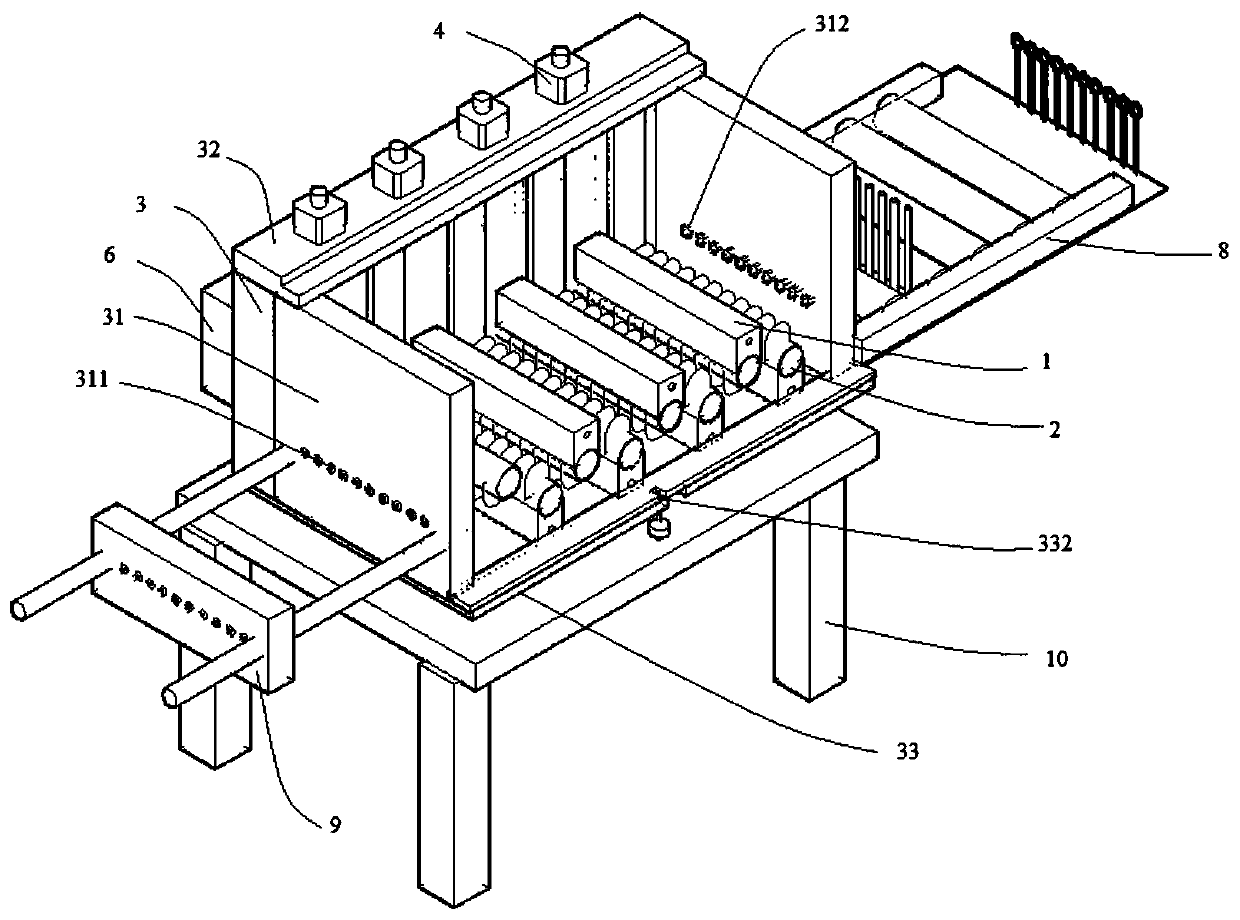

Long fiber reinforced thermoplastic composite material wetting mold and wetting process

InactiveCN110142892AImprove infiltration efficiency and effectImprove wetting effectLong-fiber-reinforced thermoplasticWetting

The invention discloses a long fiber reinforced thermoplastic composite material wetting mold and a wetting process. The mold comprises an upper pressing roller, a fixing assembly of the upper pressing roller, a lower pressing roller, a fixing assembly of the lower pressing roller, a mold shell, a lifting mechanism, a heating mechanism, a molten pool transition section and a connecting flange; themold shell comprises a mold sidewall, a mold upper cover plate and a mold lower cover plate; the upper pressing roller and the lower pressing roller are parallel and spaced apart from each other; andthe upper pressing roller and the lower pressing roller are both provided with through holes allowing resin to flow out. The upper pressing roller capable of lifting is combined with the fixed lowerpressing roller, resin overflow holes for the resin are formed in the contact faces of the upper and lower pressing rollers and fibers, continuous and even adding is carried out through the resin overflow holes in the pressing rollers, and the fiber wetting efficiency and effect can be improved. Through the design of the mold lower cover plate, under the condition that a mold upper cover does notneed to be opened, the resin left inside the mold can be quickly and cleanly removed, and the production efficiency of the fiber reinforced thermoplastic composite material is effectively improved.

Owner:山东鼎元致业新材料有限公司

Preparation method of skin-imitated woven summer sleeping mat synthetic leather

InactiveCN107460744ARich sourcesExtended service lifeSolvent-treatmentOrganic non-surface-active detergent compositionsFiberCarbon fibers

The invention discloses a preparation method of skin-imitated woven summer sleeping mat synthetic leather. The preparation method comprises the following steps: S1, soaking a synthetic leather base fabric into an immersion trough, beating while immersing, taking out the synthetic leather base fabric, squeezing out the water and ironing for later use; S2, dissolving polyurethane resin and polyether resin into a DMF (Dimethyl Formamide) solution, and then adding zinc stearate, calcium stearate, an antistatic agent, carbodiimide and 4,4'-diamido-3,3'-dichlorodiphenylmethane for mixing, then redispersing carbon fibers, aggregate, wood powder and a thickening agent, adding the DMF solution, and adjusting the viscosity of slurry, thus obtaining the slurry; and S3, coating the surface of the base fabric with the slurry until the slurry is completely solidified, taking out, washing with methyl tertiary butyl ether, ethanol and water, then drying, shaping, cooling and carrying out flower roll embossing, thus obtaining the skin-imitated woven summer sleeping mat synthetic leather. The preparation method provided by the invention has the advantages of simple operation, abundant resources of raw materials and low production cost; and in addition, the prepared product has the advantages of smooth surface, high hydrolysis resistance, high wear resistance and long service life.

Owner:TIANSHOU FUJIAN SUPERFIBER TECH

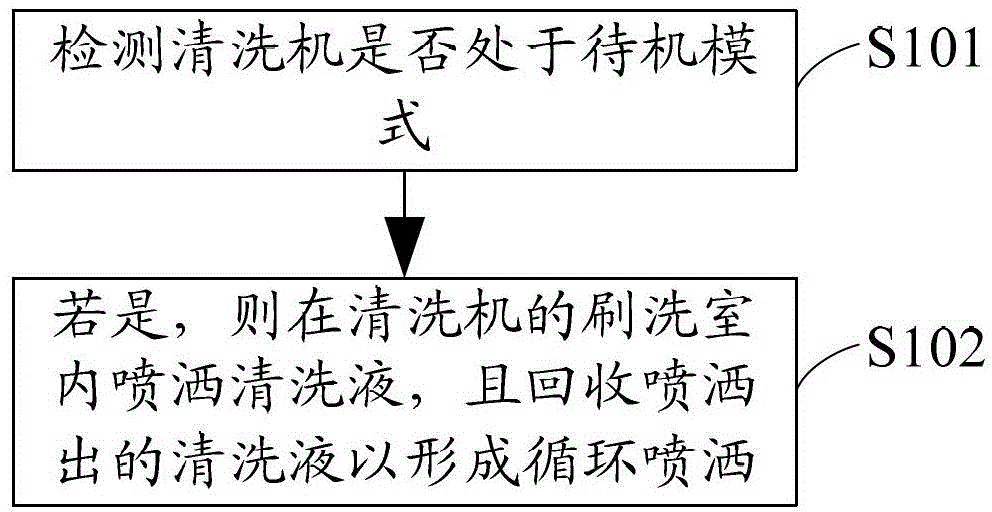

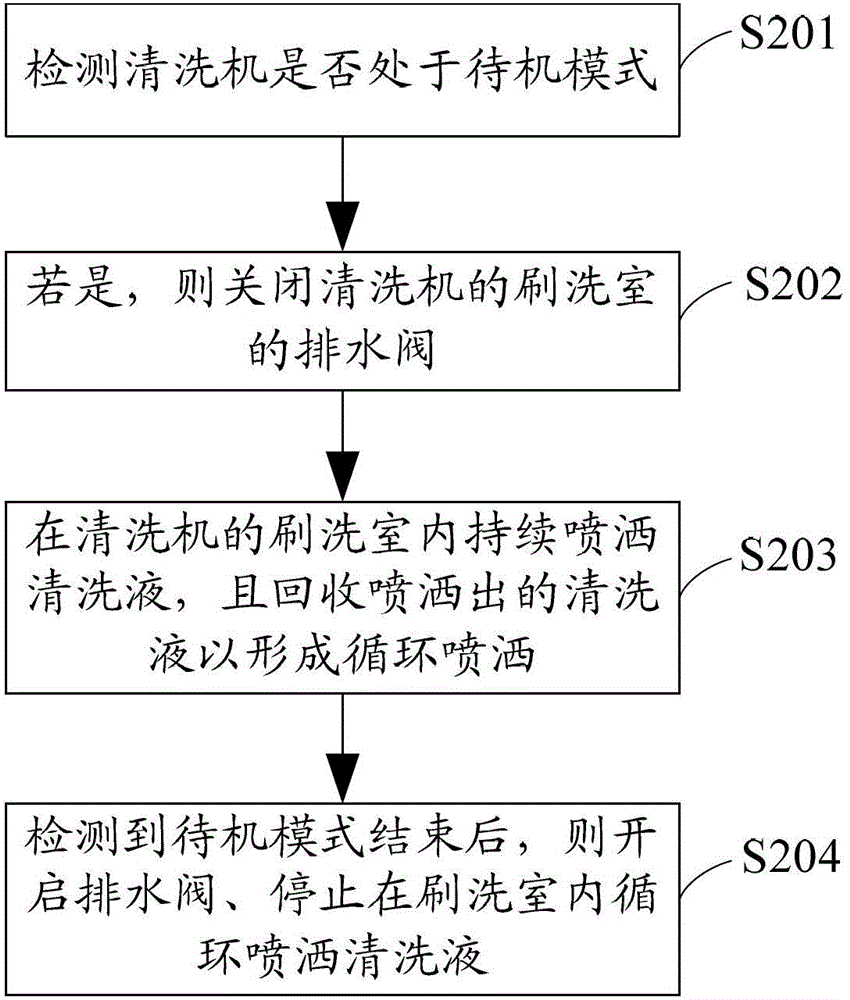

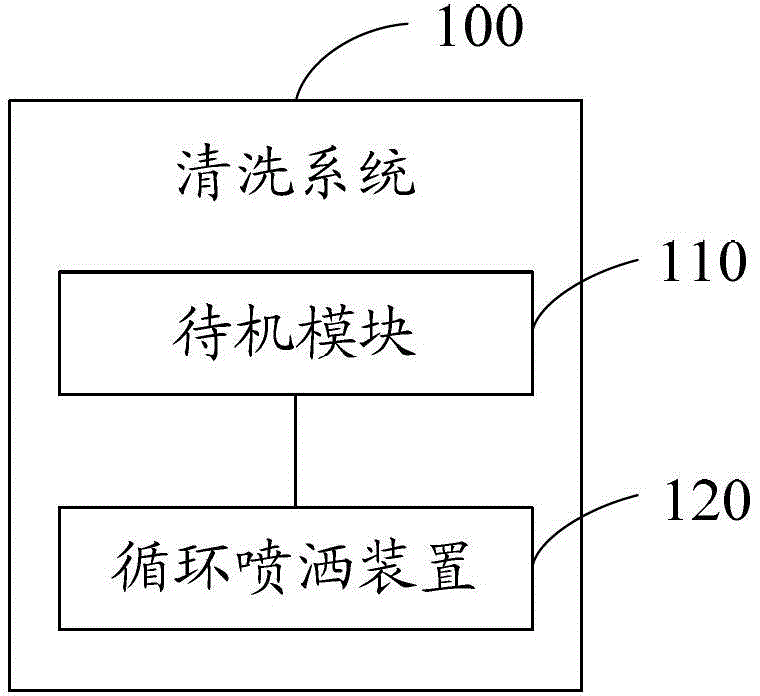

Cleaning method and cleaning system

InactiveCN102974583AImprove wetting effectImprove stabilityHollow article cleaningSemiconductor/solid-state device manufacturingWettingEngineering

The invention discloses a cleaning method and a cleaning system of a cleaning machine. The cleaning method comprises the following steps of: detecting whether the cleaning machine is in a standby mode; and if so, spraying a cleaning liquid into a scrubbing chamber of the cleaning machine, and recovering the sprayed cleaning liquid to realize circular spraying. The scrubbing chamber is controlled independently, and the cleaning liquid is sprayed into the scrubbing chamber separately, so that the spraying frequency of the cleaning liquid sprayed into the scrubbing chamber can be increased, even the cleaning liquid can be sprayed continuously, the wetting effect of a hair brush is enhanced, and the stability of a cleaning procedure is further enhanced; meanwhile, the startup frequency of a gas supply pipeline can be lowered when the cleaning machine is in the standby mode, so that gas consumption is lowered; and moreover, the sprayed cleaning liquid is recovered during spraying of the cleaning liquid into the scrubbing chamber to realize circular spraying, so that the cleaning liquid is used circularly in the scrubbing chamber, waste of the cleaning liquid is prevented, and the cost is lowered.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Oven of heater

InactiveCN104586276AReduce water vaporEvenly heatedRoasting apparatusRoasters/grillsEngineeringLower body

The invention provides an oven with a detachable upper cover. A main body of the oven comprises an upper body and a lower body, wherein the upper body is provided with the upper cover, a heating channel and a main body support of the upper body, the heating channel leads to the inside of a food container of the lower body, and the heating channel is arranged on the main body support of the upper body. The oven is characterized in th<input type='image' src='' / >at the lower end of the main body support of the upper body is rotatably connected with the lower body, a locking device is arranged between the main body support of the upper body and the upper cover, one end of the upper cover is hung at one end of the main body support of the upper body, and the other end of the upper cover is pushed to rotate and is tightly attached to the other end of the main body support of the upper cover, so that the upper cover is buckled and locked and does not disengage. The oven has the advantages of being simple and reasonable in structure, flexible in operation, easy to assemble and disassemble, easy to clean and wide in application range.

Owner:周林斌

Modified nonmetallic reclaimed material of printed circuit board and preparation method thereof

ActiveCN102675717BFacilitate and intensify chemistryGood physical and mechanical propertiesChemical recyclingPigment treatment with macromolecular organic compoundsEngineeringPrinted circuit board

Owner:江苏嘉铂新材料有限公司

Leveling process for textile product

The invention discloses a leveling process for a textile product. The leveling process comprises the specific steps: wetting a textile material sheet, tensioning the textile material sheet; ironing and leveling the textile material sheet; and extruding and rolling the textile material sheet. A leveling device comprises two vertical plates, an unreeling roll is mounted between the two vertical plates, a spraying assembly is arranged on one side of the unreeling roll, a leveling assembly is arranged on one side of the spraying assembly, a tightening roll is arranged on one side of the leveling assembly, a supporting roll is arranged on one side of the tightening roll, a rotary roll is arranged above the supporting roll, and a reeling roll is arranged on one side of the guiding roll. The textile material sheet is sprayed through a nozzle, so that the textile material sheet is prevented from being damaged by excessive heating of an ironing plate, and the leveling effect is improved. The contact degree of the ironing plate and the textile material sheet is controlled conveniently, the tightening roll presses down and tensions the textile material sheet, the wetting effect of the textilematerial sheet and the ironing and leveling effect are improved, the textile material sheet is extruded and leveled, and the leveling effect is good.

Owner:安徽弋尚纺织科技有限公司

Baking oven with upper cover capable of exhausting gas

The invention provides an oven with a detachable upper cover. A main body of the oven comprises an upper body and a lower body, wherein the upper body is provided with the upper cover, a heating channel and a main body support of the upper body, the heating channel leads to the inside of a food container of the lower body, and the heating channel is arranged on the main body support of the upper body. The oven is characterized in th<input type='image' src='' / >at the lower end of the main body support of the upper body is rotatably connected with the lower body, a locking device is arranged between the main body support of the upper body and the upper cover, one end of the upper cover is hung at one end of the main body support of the upper body, and the other end of the upper cover is pushed to rotate and is tightly attached to the other end of the main body support of the upper cover, so that the upper cover is buckled and locked and does not disengage. The oven has the advantages of being simple and reasonable in structure, flexible in operation, easy to assemble and disassemble, easy to clean and wide in application range.

Owner:周林斌

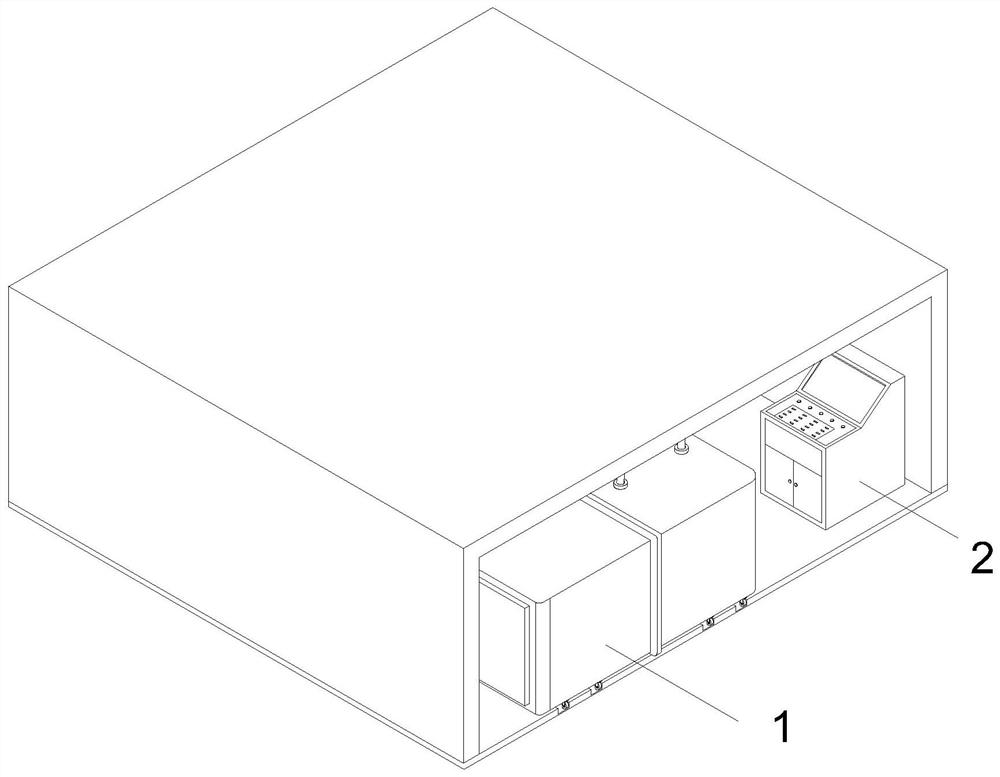

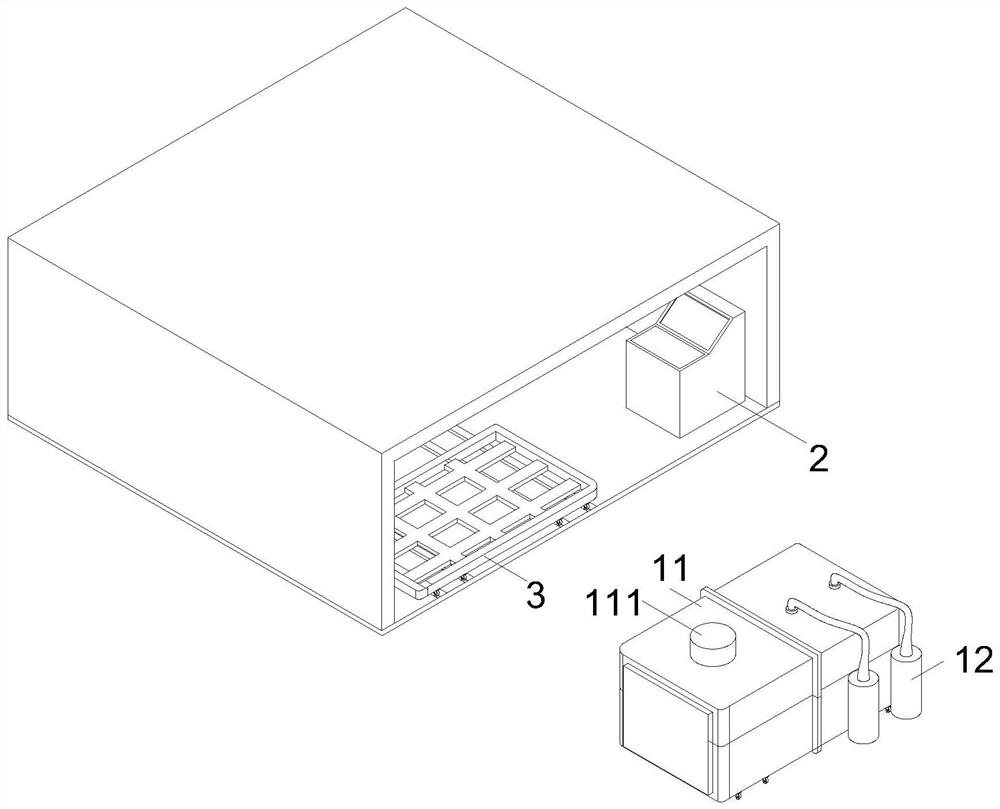

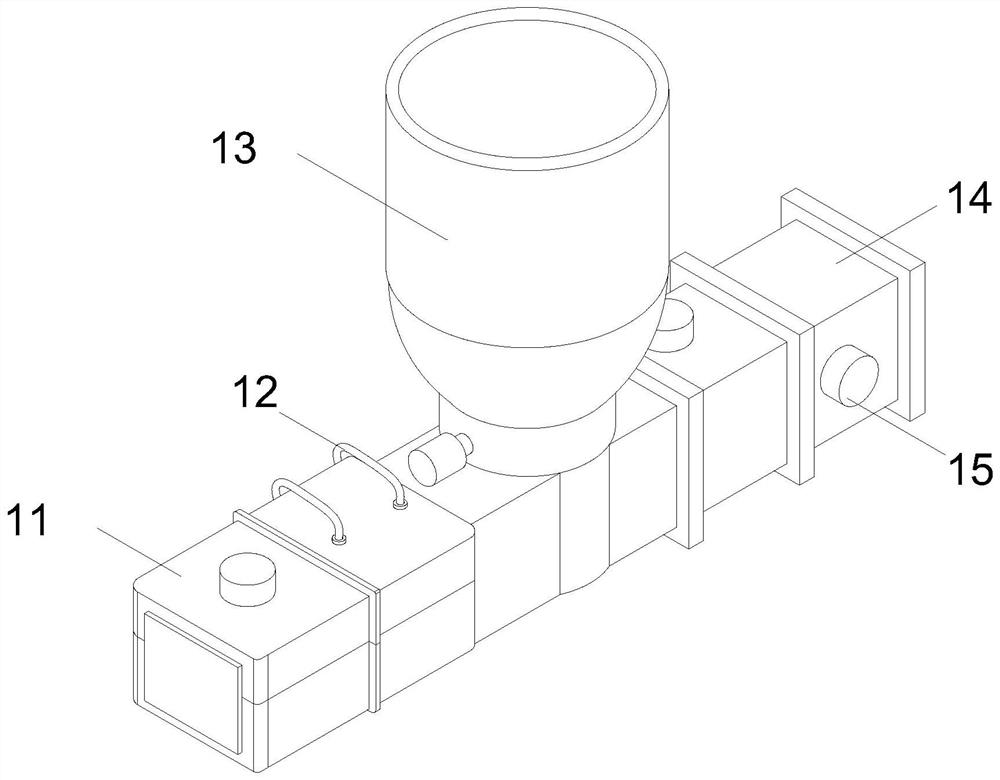

Modular garbage compression transfer station

PendingCN114229282AImprove structural stabilityHigh recycling valueRefuse receptaclesRefuse cleaningProcess engineeringRefuse Disposals

The modular garbage compression transfer station comprises a garbage treatment structure, a bottom frame and a control table, and the control table is electrically connected with the bottom frame and the garbage treatment structure; the garbage treatment processes are sequentially set according to the flow sequence; according to the technical scheme, in the initial process, the rough treatment process, the extrusion process, the detection process and the transfer process, through the arranged treatment structure, entering garbage is firstly smashed, then liquid medicine is sprayed for treatment, the contact area is increased, the soaking effect is improved, peculiar smells in the garbage are effectively removed, different sizes can be selected according to the actual use situation during pressing, and the practicability is high. And finally, the interior of the garbage is detected, the pressing unification is detected firstly, then harmful ingredients in gas of the garbage are detected, unqualified products are smashed, sprayed and pressed till the requirements are met, then pushing and stacking are conducted, the compression and transfer process is completed, and the practical value of garbage compression and transfer is improved.

Owner:北京东方同华科技股份有限公司

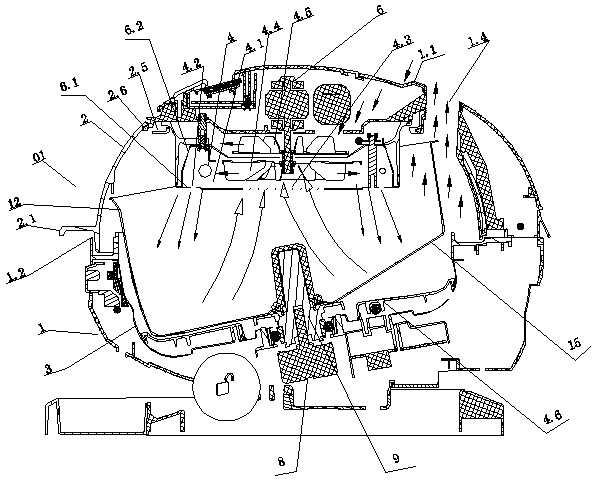

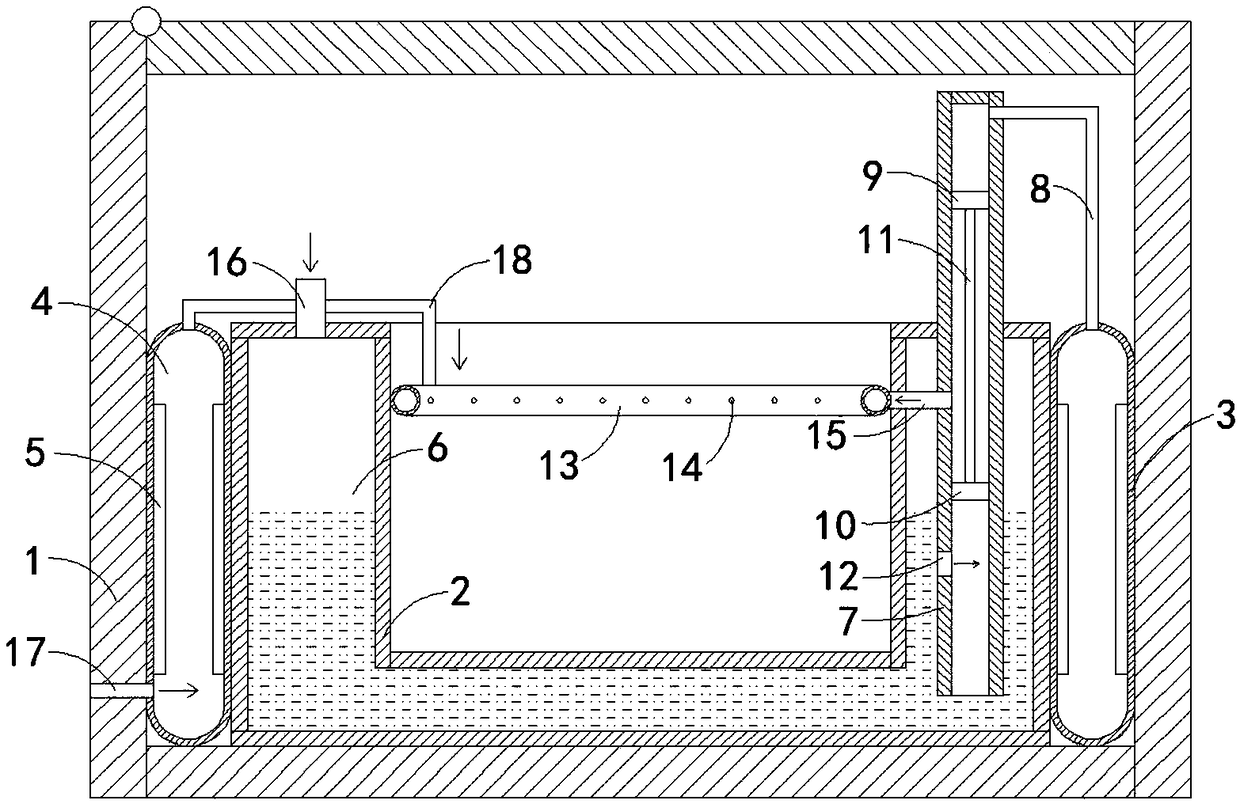

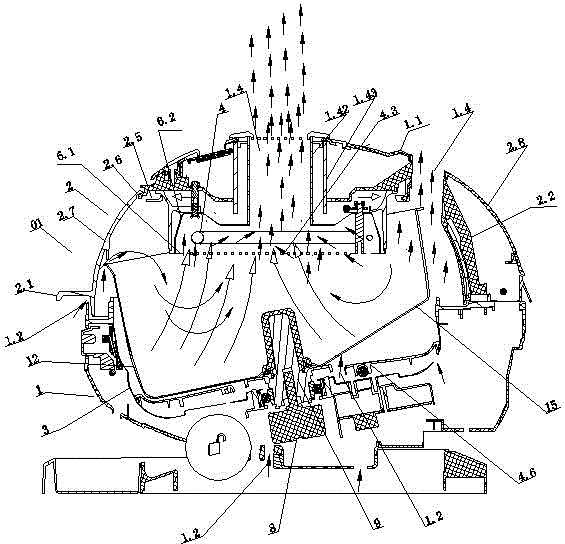

Water inlet end cover applied to holeless drum and drum washing machine

ActiveCN111041759AAvoid retaining dirtImprove cleanlinessOther washing machinesWashing machine with receptaclesLaundry washing machineWater flow

The invention discloses a water inlet end cover applied to a holeless drum. The water inlet end cover is mounted in a bowl-shaped upside-down mode on the inner wall of the drum; a water inlet cavity is surrounded by the water inlet end cover and the drum wall together; and the water inlet end cover is provided with at least one hollow-out part so as to communicate the water inlet cavity with the inside of the drum. The invention further discloses a drum washing machine, wherein a drum comprises a cylindrical side wall; both ends of the cylindrical side wall are respectively sealed so as to form a cylindrical sealed container; and the water inlet end cover is arranged at the center of a sealed end of the drum, so that the water inlet cavity is surrounded by the water inlet end cover and theinner wall of the drum together. By arranging the water inlet end cover at the center of the sealed end of the holeless drum, inlet water flow is blocked by the water inlet end cover to generate divergent spurting so as to increase a covering area of the inlet water flow and promote an immersion wetting effect on clothes. Meanwhile, the water inlet cavity surrounded by the water inlet end cover and the inner wall of the drum together is formed inside the drum so as to take a buffer effect on the inlet water flow and promote water inlet smoothness.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +2

Oven exhaust method

The invention provides an oven with a detachable upper cover. A main body of the oven comprises an upper body and a lower body, wherein the upper body is provided with the upper cover, a heating channel and a main body support of the upper body, the heating channel leads to the inside of a food container of the lower body, and the heating channel is arranged on the main body support of the upper body. The oven is characterized in th<input type='image' src='' / >at the lower end of the main body support of the upper body is rotatably connected with the lower body, a locking device is arranged between the main body support of the upper body and the upper cover, one end of the upper cover is hung at one end of the main body support of the upper body, and the other end of the upper cover is pushed to rotate and is tightly attached to the other end of the main body support of the upper cover, so that the upper cover is buckled and locked and does not disengage. The oven has the advantages of being simple and reasonable in structure, flexible in operation, easy to assemble and disassemble, easy to clean and wide in application range.

Owner:FOSHAN CASILE ELECTRIC CO LTD

Preparation method of modified polyvinylidene fluoride in lithium ion battery

ActiveCN113224305AImprove bonding effectImprove wetting effectCell electrodesSecondary cellsPolyvinylidene fluorideDimethyl formamide

The invention discloses a preparation method of modified polyvinylidene fluoride in a lithium ion battery. The method comprises the following steps: S1, adding graphene oxide into N, N-dimethylformamide, carrying out ultrasonic dispersion, then adding itaconic acid and azodiisobutyronitrile, heating to 60-70 DEG C in a nitrogen atmosphere, carrying out magnetic stirring reaction for 6-10 hours, cooling, filtering, and drying; and S2, adding the modified graphene oxide obtained in the step S1 into N, N-dimethylacetamide, then carrying out ultrasonic treatment for 5-8 hours, then adding tin dichloride, raising the temperature to 60-70 DEG C, stirring for 2-3 hours, then adding polyvinylidene fluoride and polyvinylpyrrolidone, continuously carrying out magnetic stirring for 10-16 hours at the temperature, cooling, carrying out vacuum drying, then putting into a ball mill, and grinding for 2-3 hours to obtain the adhesive.

Owner:山东天瀚新能源科技有限公司

Oven with upper cover evacuating

The invention provides an oven with a detachable upper cover. A main body of the oven comprises an upper body and a lower body, wherein the upper body is provided with the upper cover, a heating channel and a main body support of the upper body, the heating channel leads to the inside of a food container of the lower body, and the heating channel is arranged on the main body support of the upper body. The oven is characterized in th<input type='image' src='' / >at the lower end of the main body support of the upper body is rotatably connected with the lower body, a locking device is arranged between the main body support of the upper body and the upper cover, one end of the upper cover is hung at one end of the main body support of the upper body, and the other end of the upper cover is pushed to rotate and is tightly attached to the other end of the main body support of the upper cover, so that the upper cover is buckled and locked and does not disengage. The oven has the advantages of being simple and reasonable in structure, flexible in operation, easy to assemble and disassemble, easy to clean and wide in application range.

Owner:周林斌

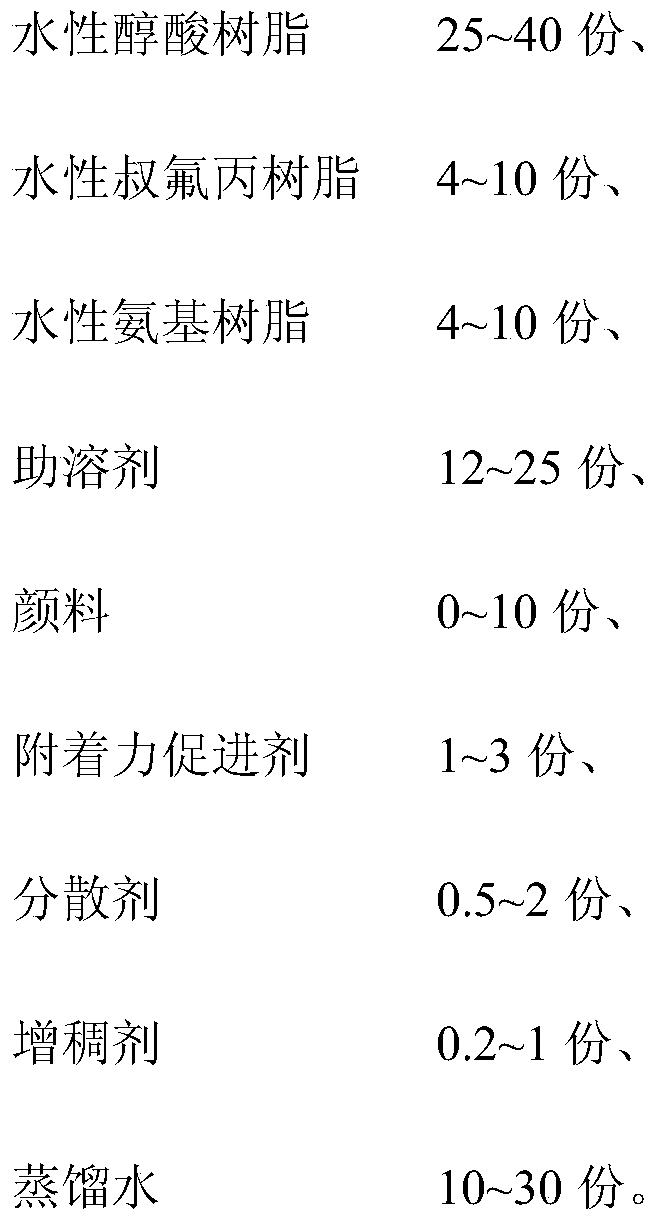

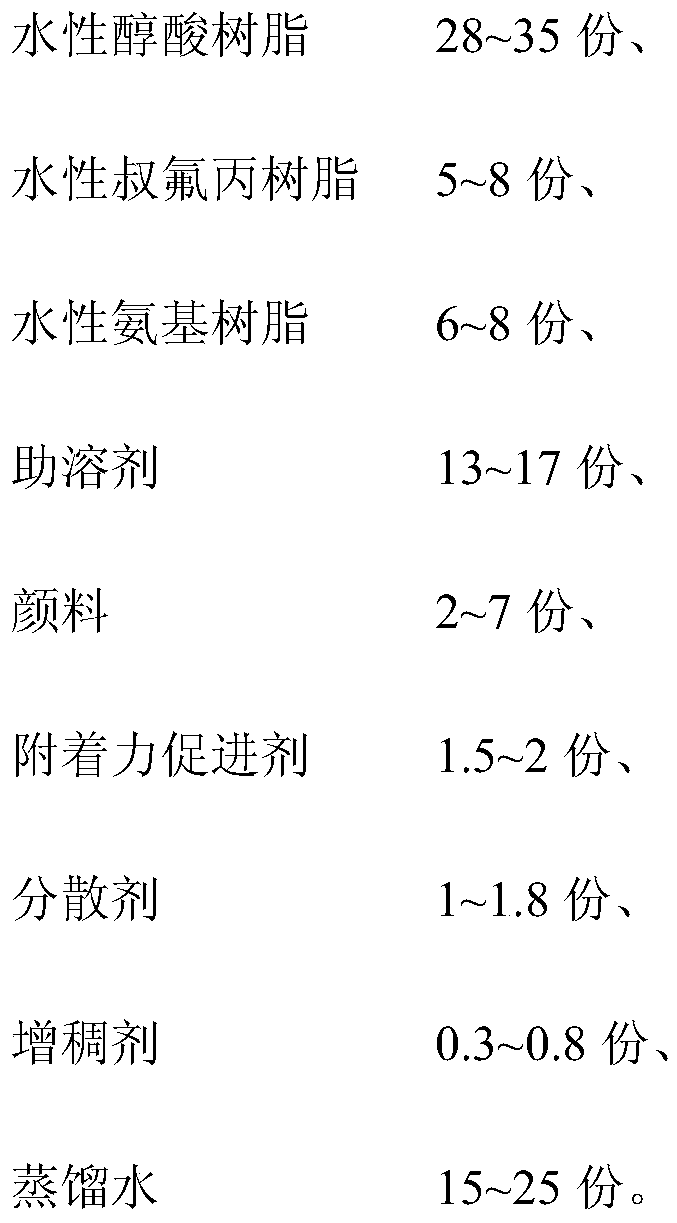

Water-based steel drum paint and preparation method thereof

InactiveCN111518461AReduce surface tensionImprove wetting effectPolyester coatingsSolventWeather resistance

The invention relates to the technical field of water-based paint, in particular to water-based steel drum paint and a preparation method thereof. The steel drum paint comprises the following raw materials in parts by weight: 25-40 parts of water-based alkyd resin, 4-10 parts of water-based tert-fluoroacrylic emulsion, 4-10 parts of water-based amino resin, 12-25 parts of cosolvent, 0-10 parts ofpigment, 1-3 parts of adhesion promoter, 0.5-2 parts of dispersing agent, 0.2-1 part of thickening agent and 10-30 parts of distilled water. The preparation method comprises the following steps: weighing raw materials, preparing a mixed solution A, preparing a mixed solution B and mixing the solutions. The water-based steel drum paint disclosed by the invention can be sprayed on the surface of anunclean steel drum with a small amount of impurities such as greasy dirt and the like, a good spraying effect is achieved, the glossiness, the strength and the adhesive force are high, the water-basedsteel drum paint has excellent water resistance and weather resistance, and a paint film does not have the defects of shrinkage cavities, orange peel, sagging and the like after being sprayed; the water-based steel drum paint provided by the invention is simple in preparation process, can be produced in batches, and saves time and resources.

Owner:山东七维新材料有限公司

Baking oven

The invention provides an oven with a detachable upper cover. A main body of the oven comprises an upper body and a lower body, wherein the upper body is provided with the upper cover, a heating channel and a main body support of the upper body, the heating channel leads to the inside of a food container of the lower body, and the heating channel is arranged on the main body support of the upper body. The oven is characterized in th<input type='image' src='' / >at the lower end of the main body support of the upper body is rotatably connected with the lower body, a locking device is arranged between the main body support of the upper body and the upper cover, one end of the upper cover is hung at one end of the main body support of the upper body, and the other end of the upper cover is pushed to rotate and is tightly attached to the other end of the main body support of the upper cover, so that the upper cover is buckled and locked and does not disengage. The oven has the advantages of being simple and reasonable in structure, flexible in operation, easy to assemble and disassemble, easy to clean and wide in application range.

Owner:周林斌

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com