Patents

Literature

31results about How to "Speed up the washing process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for mordant printing on fabric dyed by natural vegetable dye

The invention discloses a mordant printing method on the natural plant dye dyeing cloth, which is characterized by the following: preparing printing slurry through mordant, thickener, penetrant and permeability-reducing agent; proceeding cleaning and printing disposal for slurry on the natural plant dye dyeing cloth; steaming at 120-160 deg.c for 1-5 min or baking at 130-160 deg.c at 1-5 min to fix color; proceeding watering disposal at 40-60 deg.c to dry in the 80-100 deg.c condition. The invention can improves quality of natural plant dyeing plant and added quality of cloth, which is a printing cloth with health function.

Owner:DALIAN POLYTECHNIC UNIVERSITY

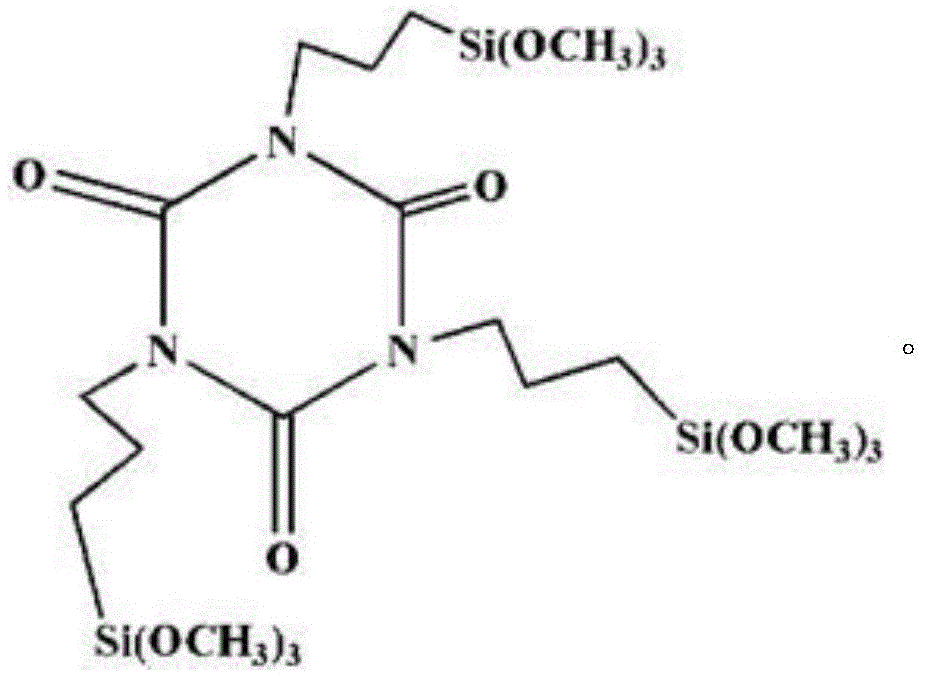

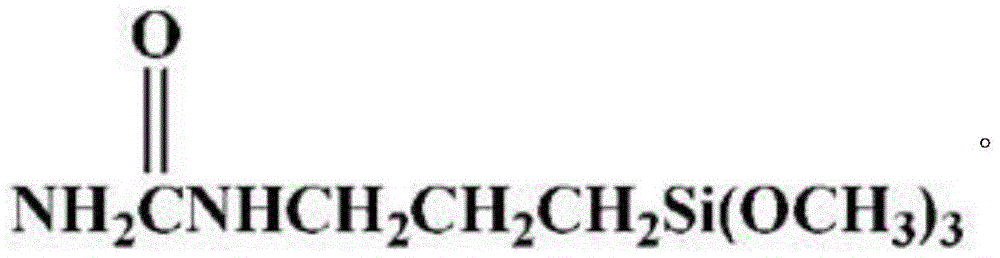

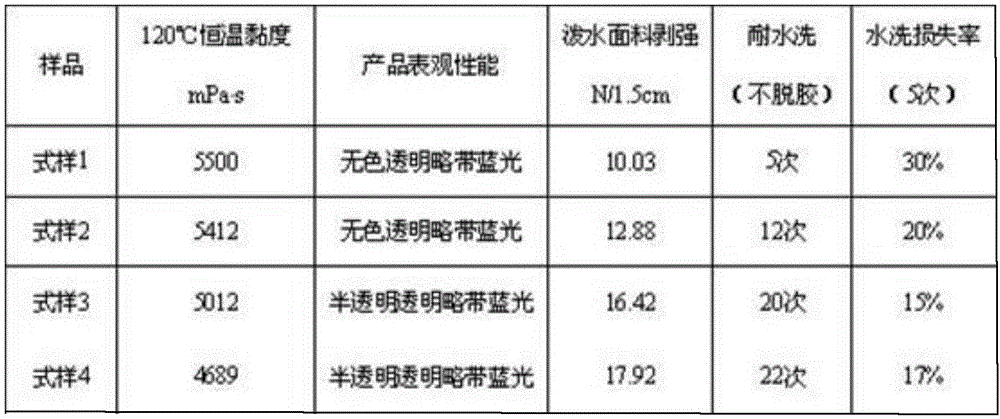

Preparation method for silane-modified moisture-curable polyurethane hot melt adhesive

ActiveCN104449535AEnhanced van der Waals forceImprove wetting effectNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterWhitening Agents

The invention discloses a preparation method for a silane-modified moisture-curable polyurethane hot melt adhesive. The method comprises the following steps: (1) heating and mixing polyester polyol, polyether polyol, tackifying resin, an antioxidant and a fluorescent whitening agent at a certain temperature, performing reduced pressure degassing for 2 hours, and cooling to 90 DEG C; (2) adding isocyanate and a catalyst into a reaction system under the nitrogen protection, and reacting at 85-95 DEG C for 45 minutes; (3) adding a chain extender and a silane coupler under the nitrogen protection, and reacting at 85-95 DEG C for 1 hour to obtain a prepolymer; (4) transferring a reaction mixture into an aluminum foil bag under the nitrogen protection, sealing, and curing at 85 DEG C for 6 hours to obtain the silane-modified moisture-curable polyurethane hot melt adhesive with excellent performance.

Owner:SHANGHAI TIANYANG HOT MELT ADHESIVE CO LTD +2

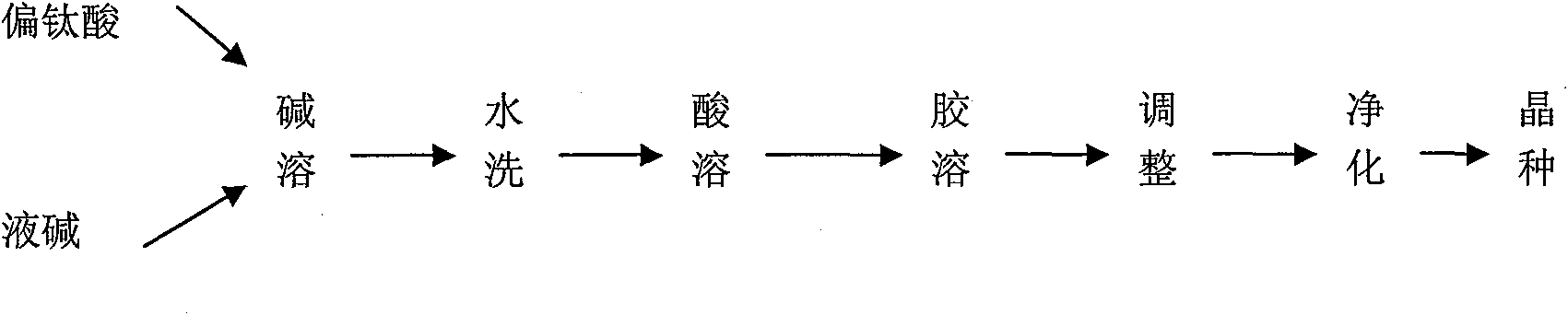

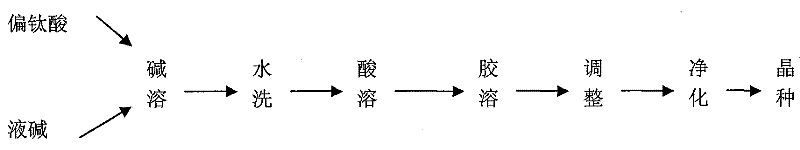

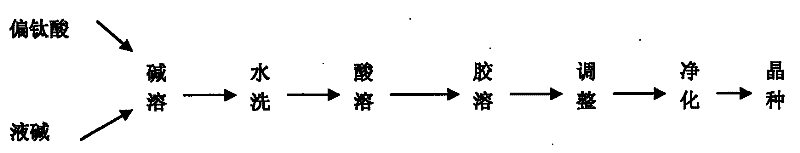

Preparation of white titanium pigment double action crystal seed from metatitanic acid

ActiveCN101565201AFast phase changeSimplify operating proceduresPigmenting treatmentTitanium dioxideX-raySodium sulfate

The invention relates to a preparation of white titanium pigment double action crystal seed from metatitanic acid, which is characterized in the process of (1) alkali dissolving, boiling the metatitanic acid purified by water washing with thermokalite; (2) water washing, removing residue sodium hydroxide and generated sodium sulfate thereby; (3) neutralizing and acid dissolving, neutralizing by hydrochloric acid and acid solution; (4) peptizing to generate a seed suspension, evaporating the suspension at a temperature from 105 to 300 DEG C., grinding, measuring the rutile microcrystalline with weight percentage over 90-98% by a X-ray diffractometer. The preparation uses metatitanic acid produced during sulphuric acid production process as raw material, adopts sol-gel process, with the produced rutile microcrystalline is safe and non-toxic, simple and easy to get raw material, low in cost, thus capable of evidently improving quality of product, enhancing stability of product quality and market competitiveness.

Owner:江西添光钛业有限公司

Natural plant dyestuff dyeing and finishing processing method for loose cellulose fiber

ActiveCN103938468AShort processImprove color yield and color fastnessDyeing processHemp fiberRegenerated cellulose

The invention relates to a natural plant dyestuff dyeing and finishing processing method for a loose cellulose fiber. Loose cotton and hemp fibers are processed by the following steps: oxygen bleaching, hot washing, directly dyeing in a same bath, soaping, fixing and softening, dewatering, baking and packaging into a product, wherein the cotton and hemp fibers after oxygen bleaching are added to a natural additive and natural plant dyestuff to be directly dyed in the same bath and then are directly soaped and fixed; regenerated loose cellulose fibers are processed by the following steps: directly dyeing in the same bath, soaping, fixing and softening, dewatering, baking and packaging into the product, wherein the regenerated loose cellulose fiber from which spinning oil is not removed is added to the natural additive and the natural plant dyestuff to be directly dyed in the same bath, and then are directly soaped and fixed. The natural plant dyestuff dyeing and finishing processing method has the advantages that the method does not need uncoiling and washing procedures for pretreatment, the natural additive and the natural dyestuff are adopted to dye in the same bath, direct dyeing can be carried out by simple washing after oxygen bleaching, and the colorized light and the dyeing rate are not affected.

Owner:苏州麻朵纺织科技有限公司

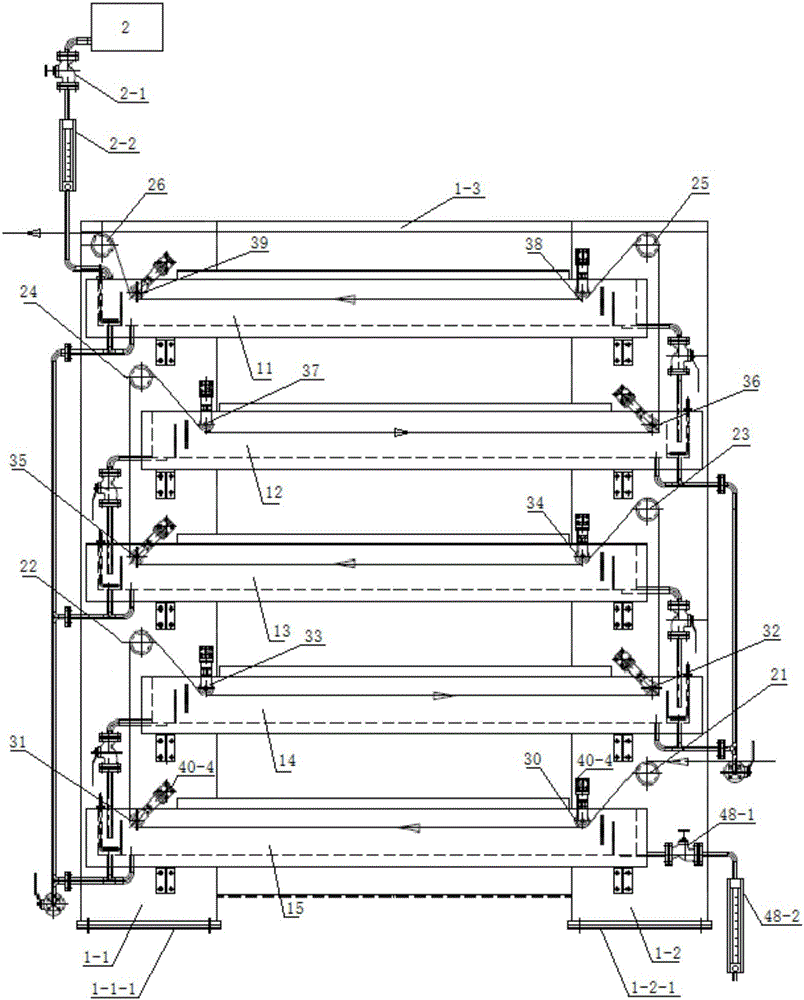

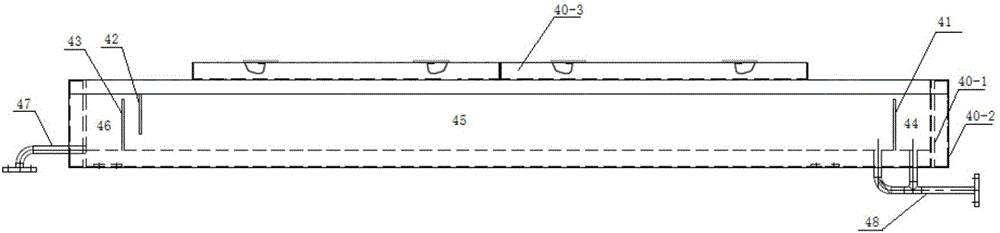

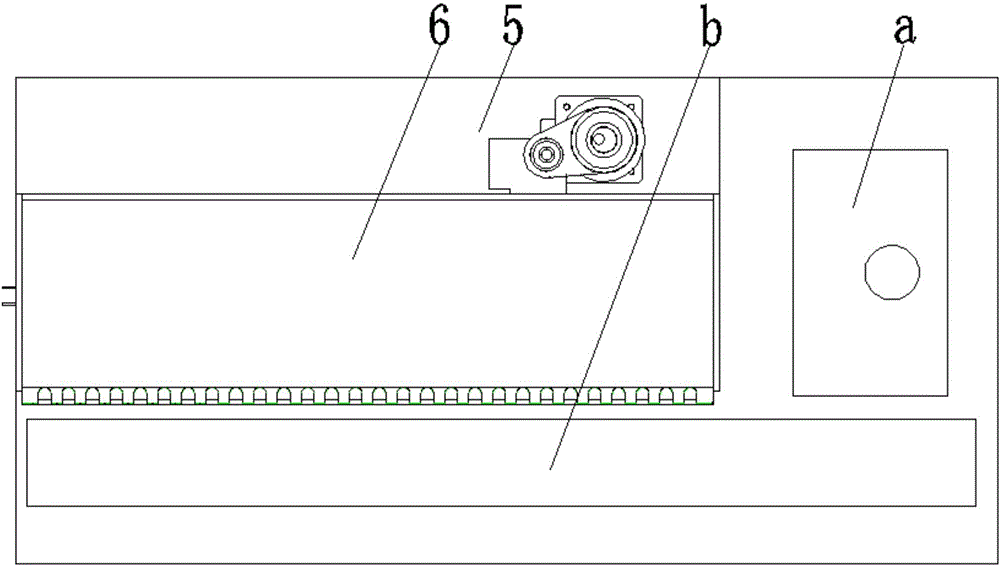

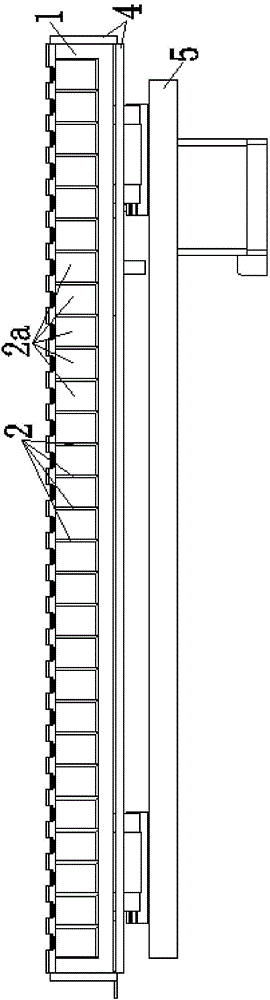

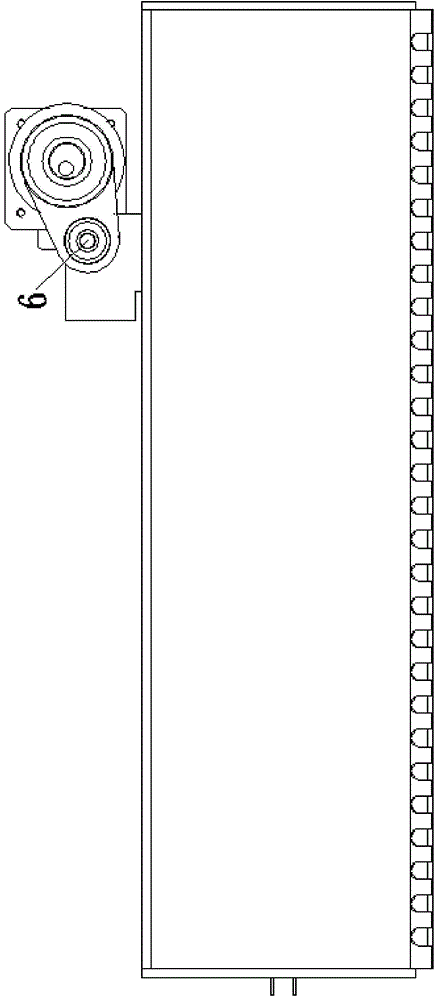

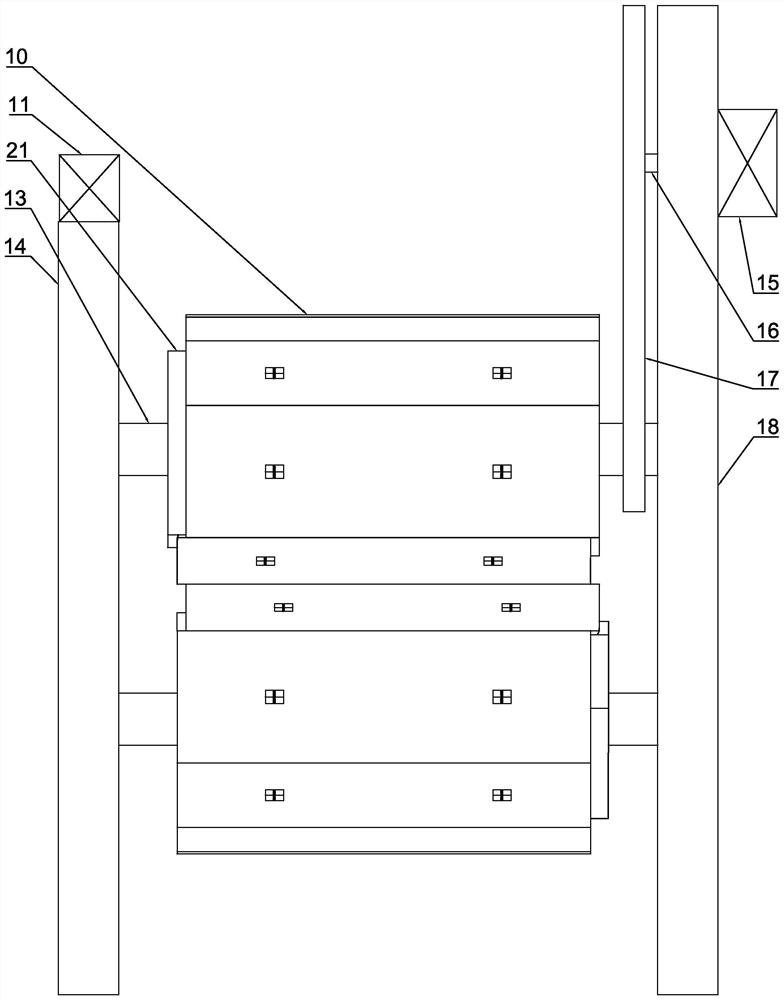

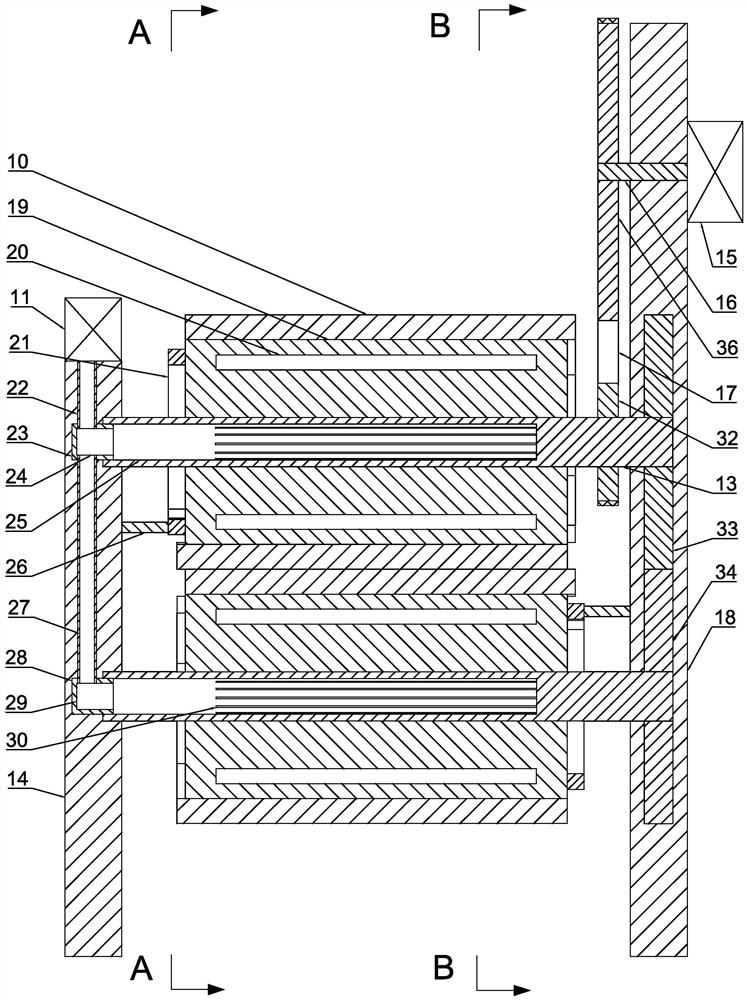

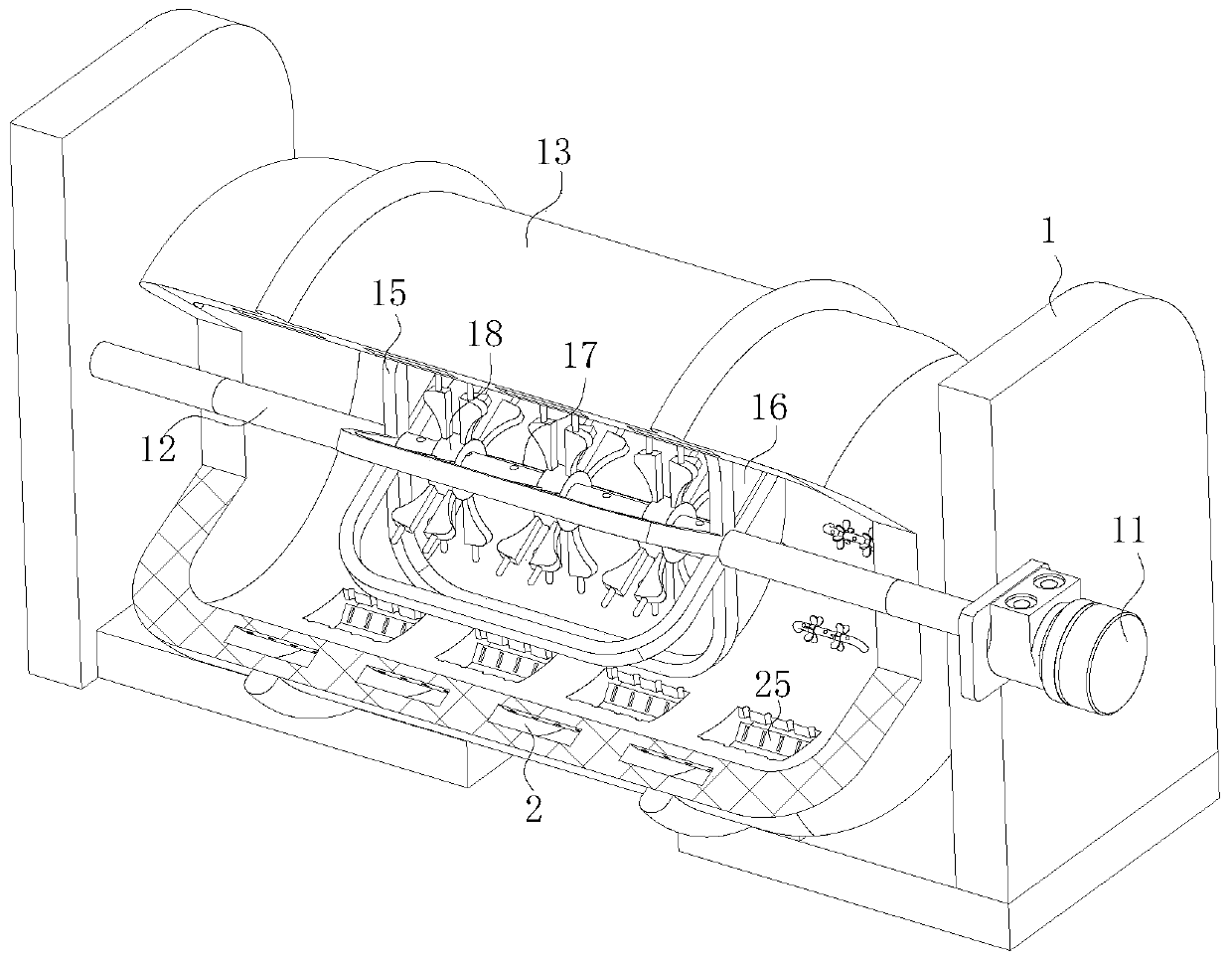

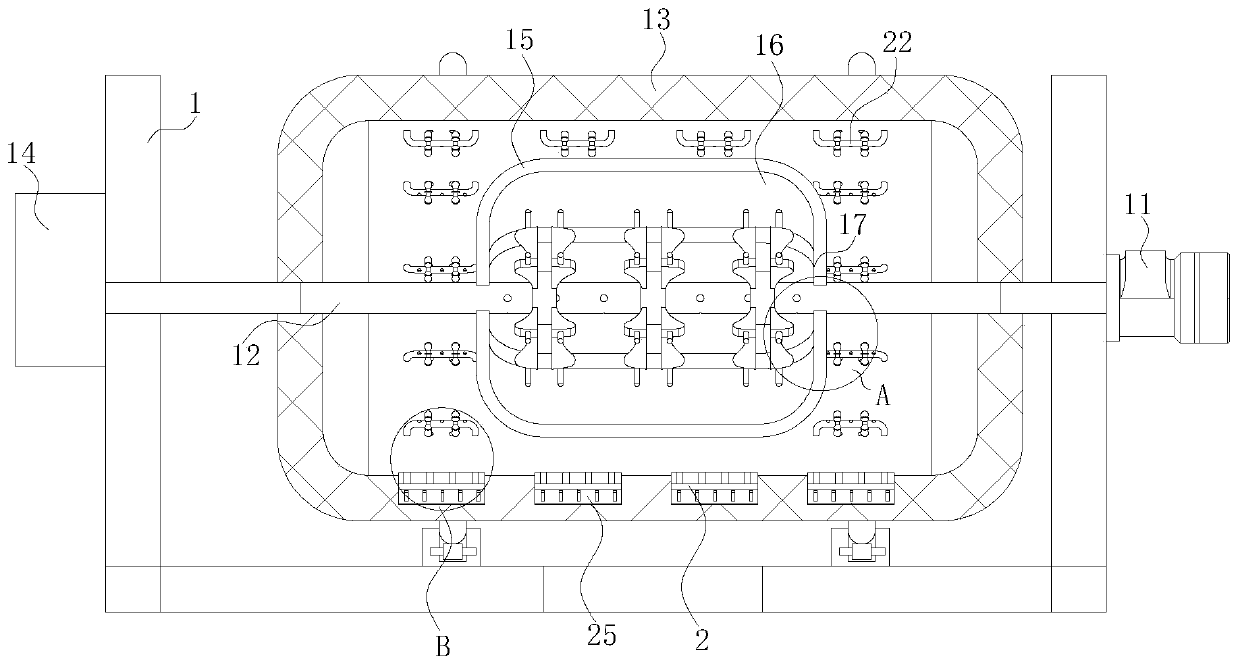

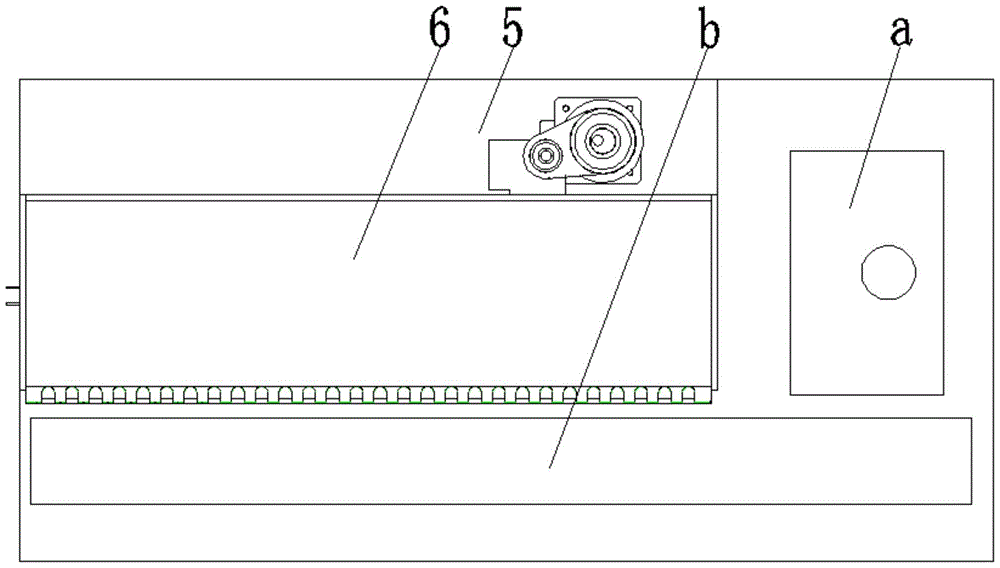

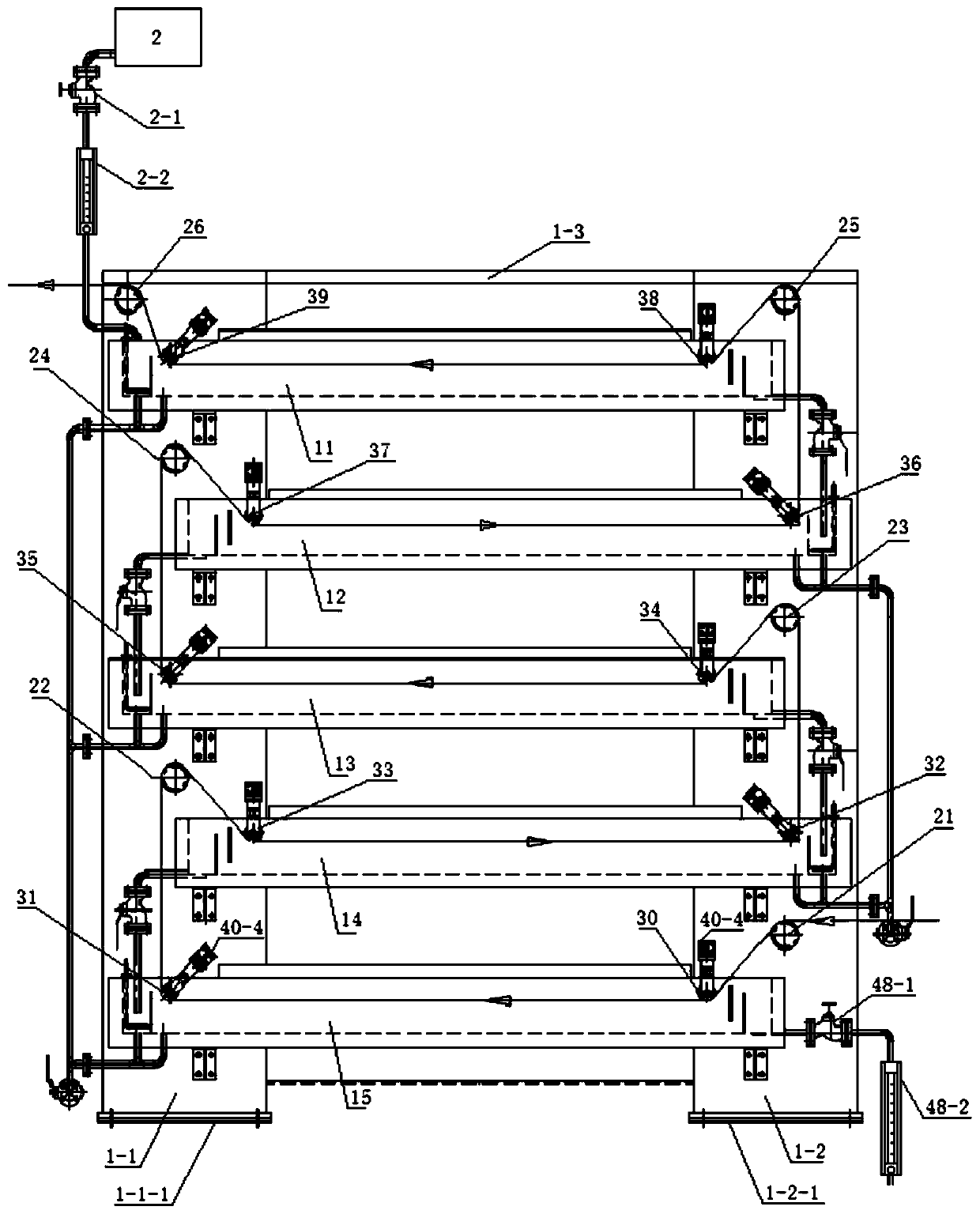

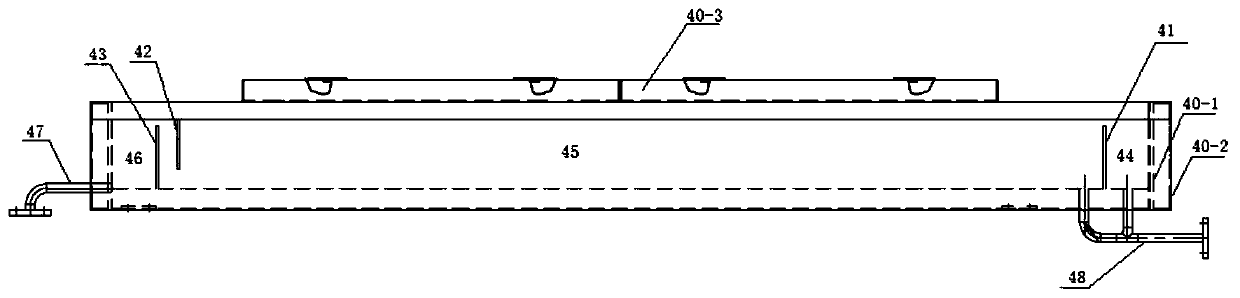

Carbon-fiber washing machine for carbon fiber precursor washing

ActiveCN106521848AAccurate transmissionSmooth transmissionSucessive textile treatmentsTextile treatment containersWater useFiber

The invention relates to a carbon-fiber washing machine for carbon fiber precursor washing. A multilevel washing trough is installed at the front portion of a machine frame 1, a driving roller and a guiding roller are installed on the machine frame 1, and two transmission systems are installed at the back portion of the machine frame 1. The carbon-fiber washing machine is superposed by five-level water troughs in a dislocation mode, the washing time is prolonged, and the occupied area of the device is saved to a maximum degree. As liquid level plates, flow stopping plates and overflowing plates are designed in the washing troughs, the washing process is intensified; as the two ends of the washing troughs are distributed in a dislocation mode, the number of driving roller is reduced, the contact area of fibers and rollers is reduced, and the broken filament generating probability caused by friction is reduced; deionized water used by the carbon-fiber washing machine flows to the next washing trough from the last washing trough and is recycled, and the cost is reduced while the washing effect is improved. The carbon-fiber washing machine has the advantages of being simple in structure and convenient to daily maintain and operate.

Owner:THE NORTHWEST RES INST OF CHEM IND

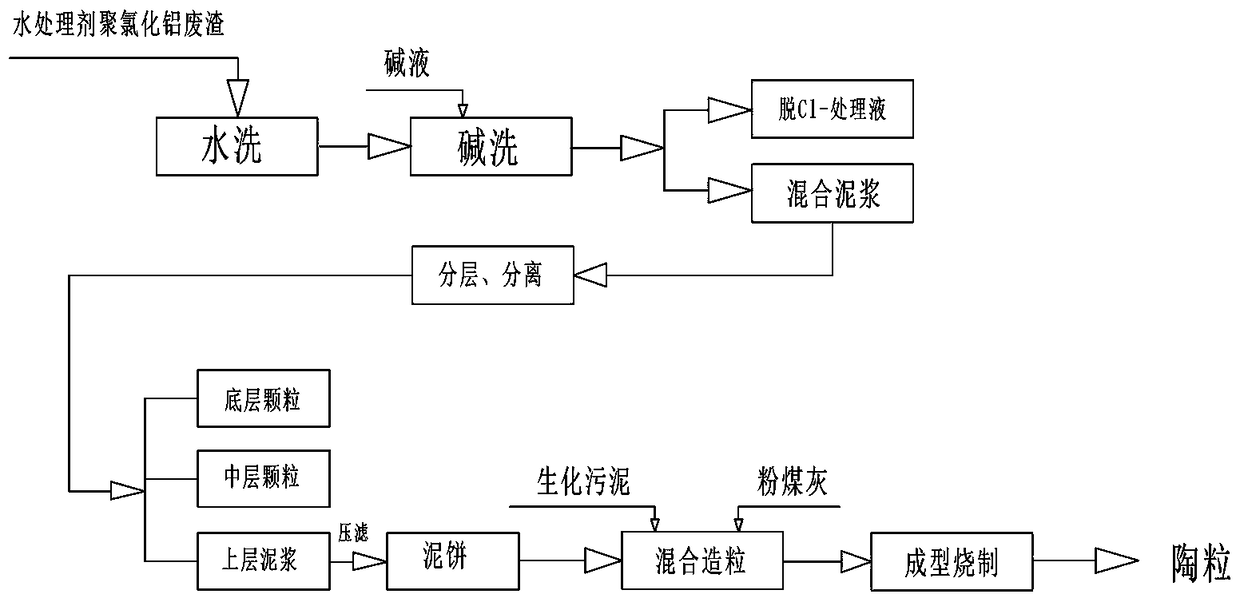

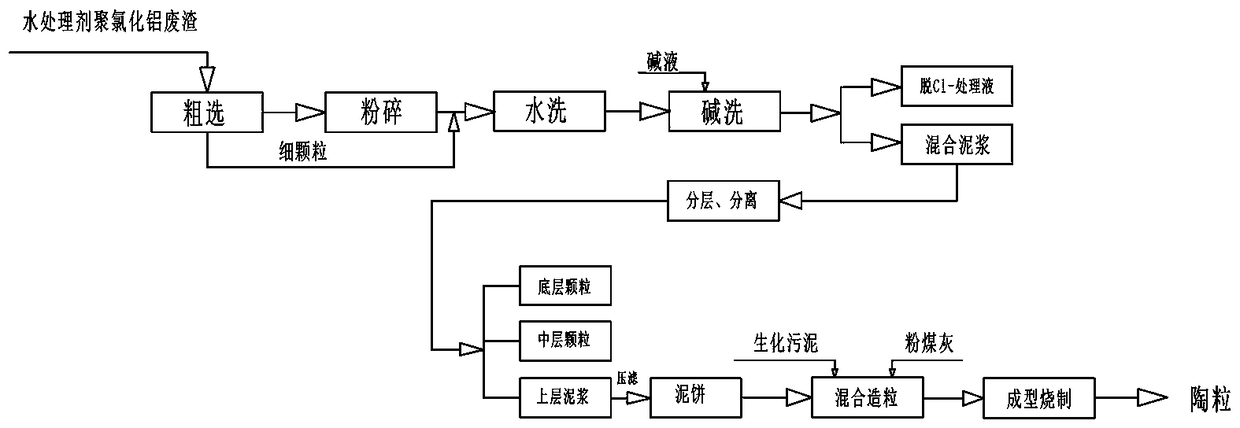

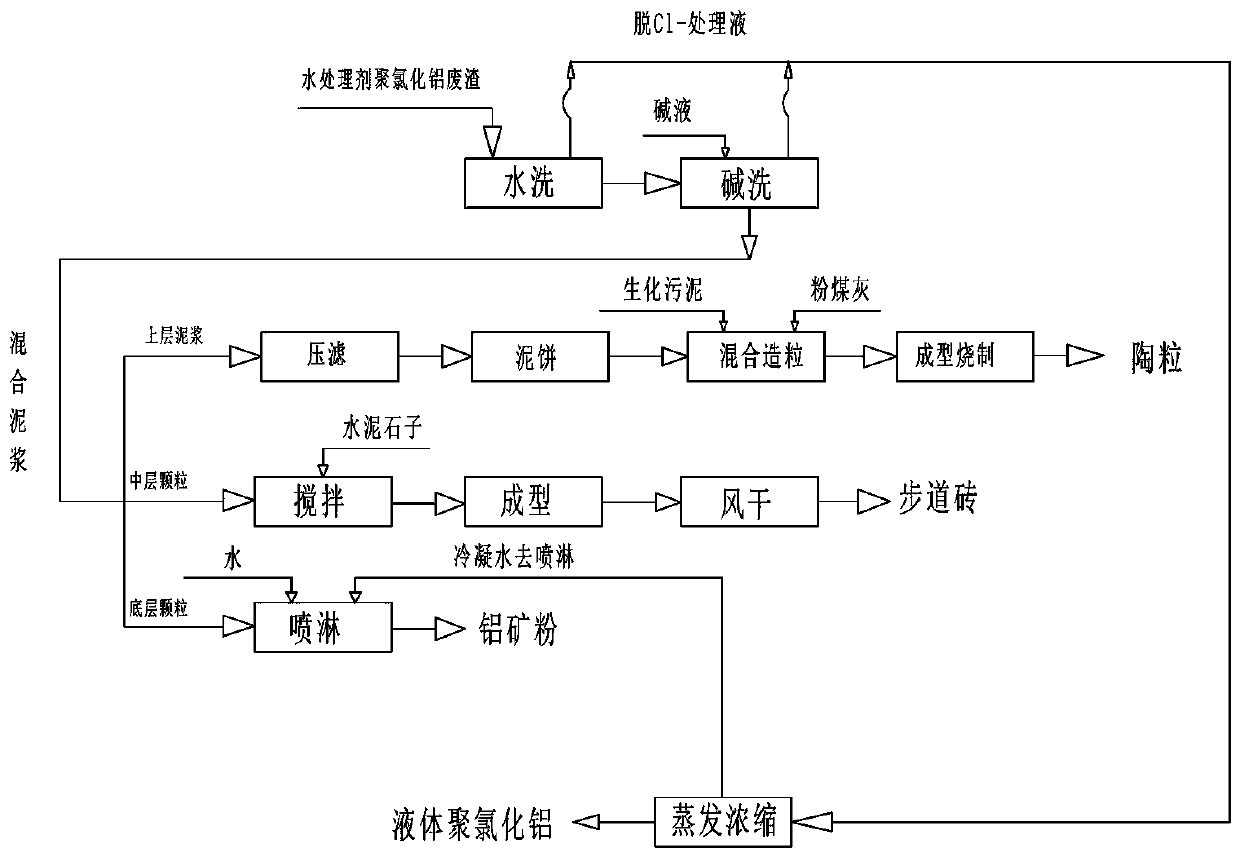

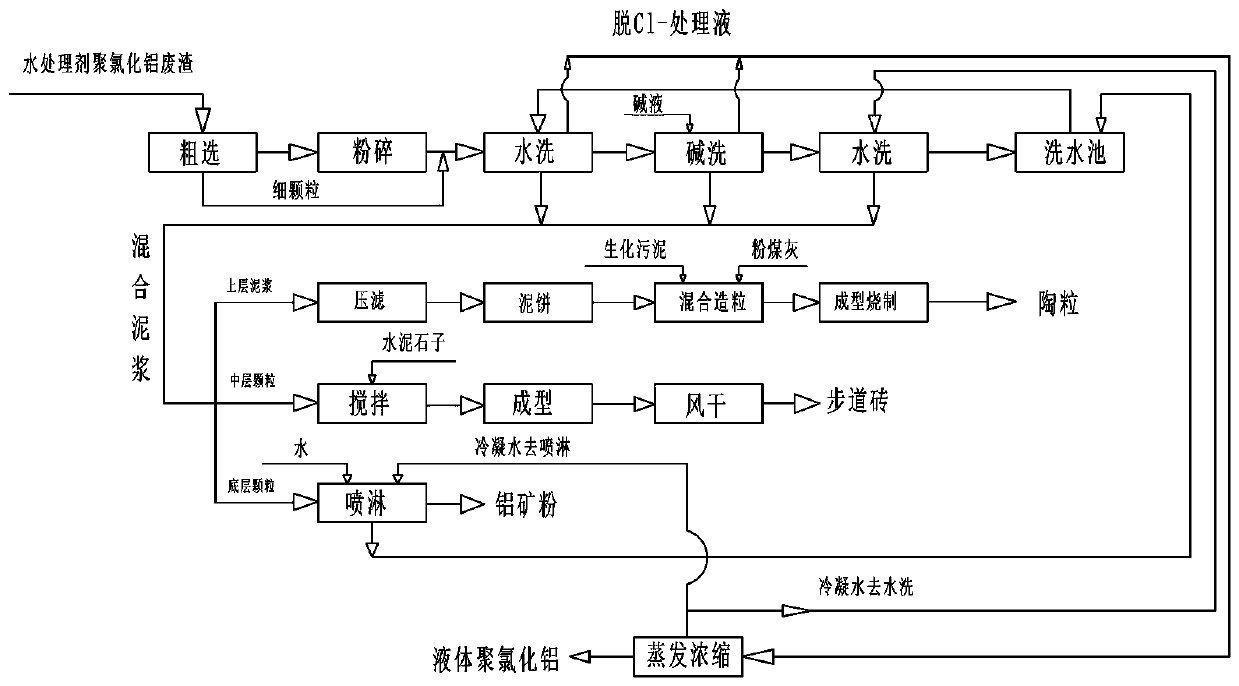

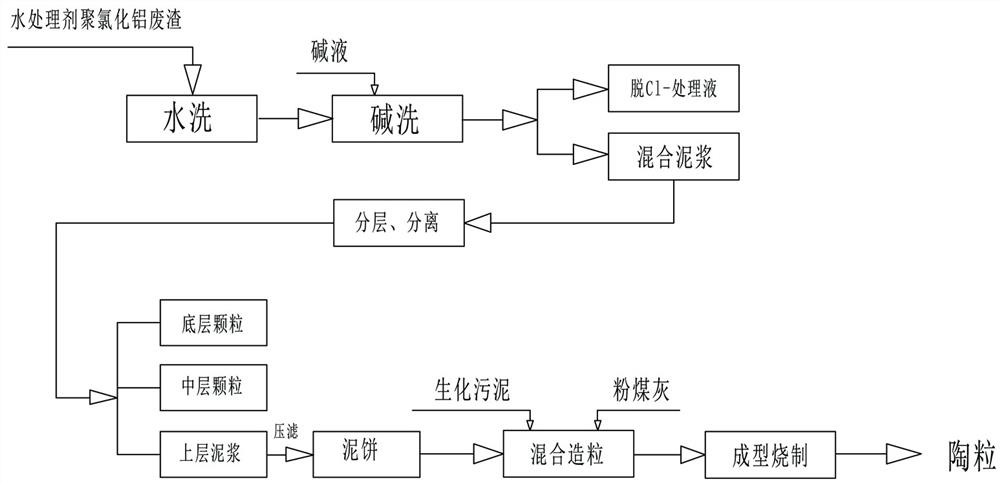

Method for preparing ceramsite by utilizing water treatment agent polyaluminium chloride residue

ActiveCN109437960AUniform internal organizationLarge specific surface areaCeramic materials productionCeramicwareAluminium chloridePrill

The invention provides a method for preparing ceramsite by utilizing water treatment agent polyaluminium chloride residue. The method comprises the following steps: performing dechlorinating treatmenton the water treatment agent polyaluminium chloride to obtain dechlorinated treating fluid and mixed slurry, and treating the mixed slurry in the manner of static settlement and screening to obtain bottom-layer grains, middle-layer grains and upper-layer slurry; filter-pressing clear liquor from the upper-layer slurry to obtain a filter cake; granulating by mixing the filter cake, biochemical sludge and coal ash at a mass ratio of (80-100):(0-20):(0-20) to obtain a to-be-burned granule; burning the to-be-burned granule under the temperature of 1000 DEG C-1300 DEG C; and cooling to room temperature to obtain the ceramsite. The internal tissue of the ceramsite prepared by the method is uniform; the water treatment agent polyaluminium chloride residue resource is fully utilized while the problem of environmental pollution caused by random stacking of biochemical sludge is solved; and the heat of combustible components in the biochemical sludge is also utilized. The method has simple andconvenient steps and is easy for industrial popularization.

Owner:河南省福可思环保科技有限公司

Composite fabric manufacturing process capable of preventing antibacterial effective substances from being lost

InactiveCN107571555AGuaranteed level dyeingGuaranteed uptake rateSynthetic resin layered productsDyeing processCardingFilamentation

The invention discloses a composite fabric manufacturing process capable of preventing antibacterial effective substances from being lost. The composite fabric manufacturing process comprises the following steps: selecting bamboo raw materials which are processed by bamboos of the current year, classifying and respectively cutting off the bamboo raw materials, putting bamboo slices into boiled water for scouring for primary softening, taking out the scoured bamboo slices after the process is completed, cleaning the bamboo slices with water, putting the bamboo slices into a soaking solution, processing the bamboo slices with machinery, separating coarse fibers through a filamentation machine, flushing the fibers with water for degumming, putting the bamboo fibers into a cooking boiler for secondary softening, cleaning the bamboo fibers subjected to the zymolysis, and carrying out bleaching, oiling, softening, opening and carding, thus obtaining raw bamboo fibers for spinning. The composite fabric manufacturing process keeps the strength of a fabric, guarantees the dye uptake of the fabric, reduces the shrinkage rate of the fabric improves the handfeel of the fabric, enhances the temperature resistance and the adsorption strength of the bamboo fibers, and achieves no-losing effect; the characteristic of high-temperature resistance of the bamboo fibers is improved, so that influence of the temperature on the fabric is low.

Owner:ZHEJIANG EMF COSPLAY CULTURE IND

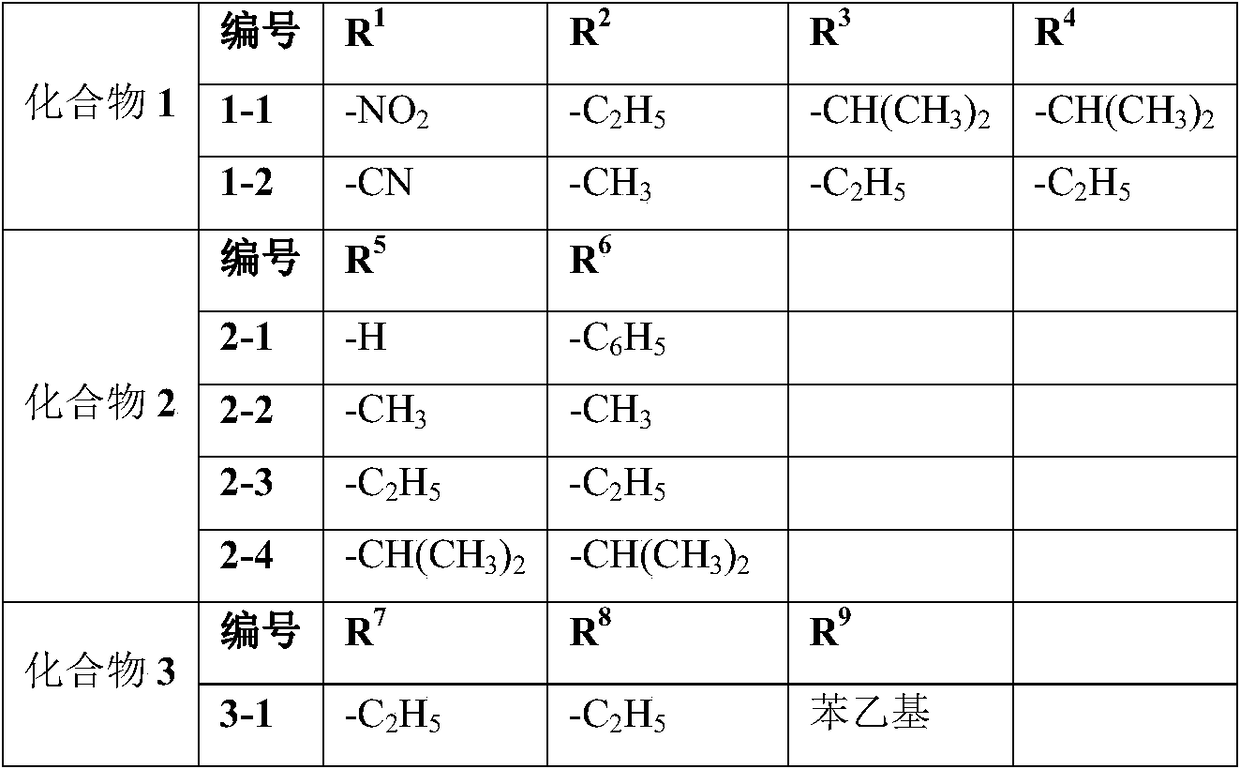

Chemiluminescence immunity analyzer incubator

ActiveCN104655865APlay a sealing rolePlay a limiting roleMaterial analysisBiochemical engineeringReagent

The invention discloses a chemiluminescence immunity analyzer incubator which comprises a box body, wherein an opening is formed in the side face of the box body; a plurality of parallel partition boards are arranged on the upper surface of a base plate of the box body; the partition boards are perpendicular with the base plate of the box body; a reaction cup base mounting groove is formed between every two adjacent partition boards; and one end of the reaction cup base mounting groove is communicated with the opening in the side face of the box body. The incubator disclosed by the invention has significant effects that strip-shaped reaction cup strips are placed stably, and blood and reaction reagents in reaction cups can react rapidly and sufficiently by maintaining temperature inside the incubator to be constant and by shaking the box body, so that detection and analysis results are accurate and reliable; and the incubator can wash and inject a substrate timely, so as to improve the accuracy of the detection result and increase detection and analysis efficiency.

Owner:CHONGQING KEYSMILE BIOLOGICAL TECH CO LTD

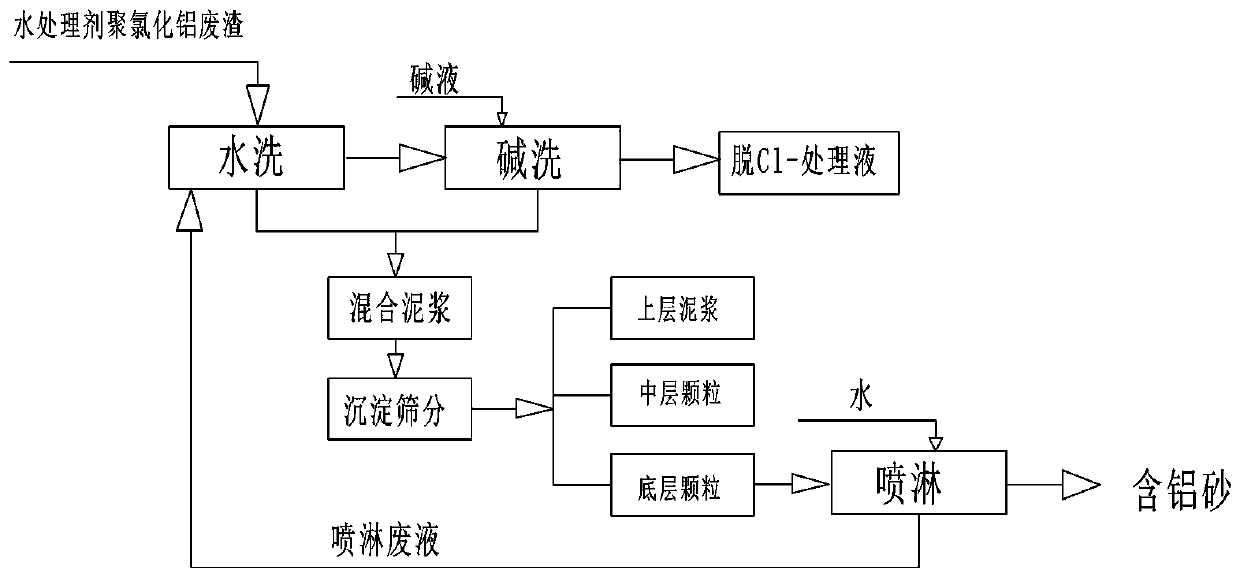

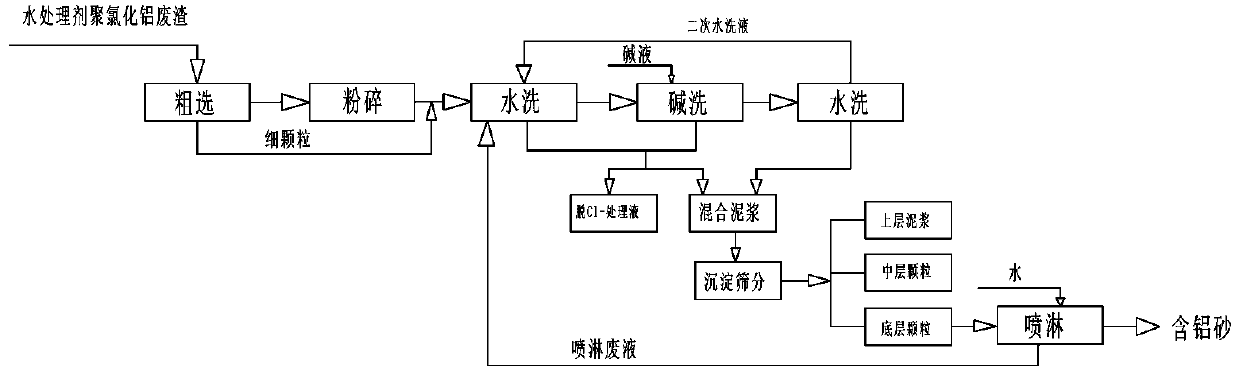

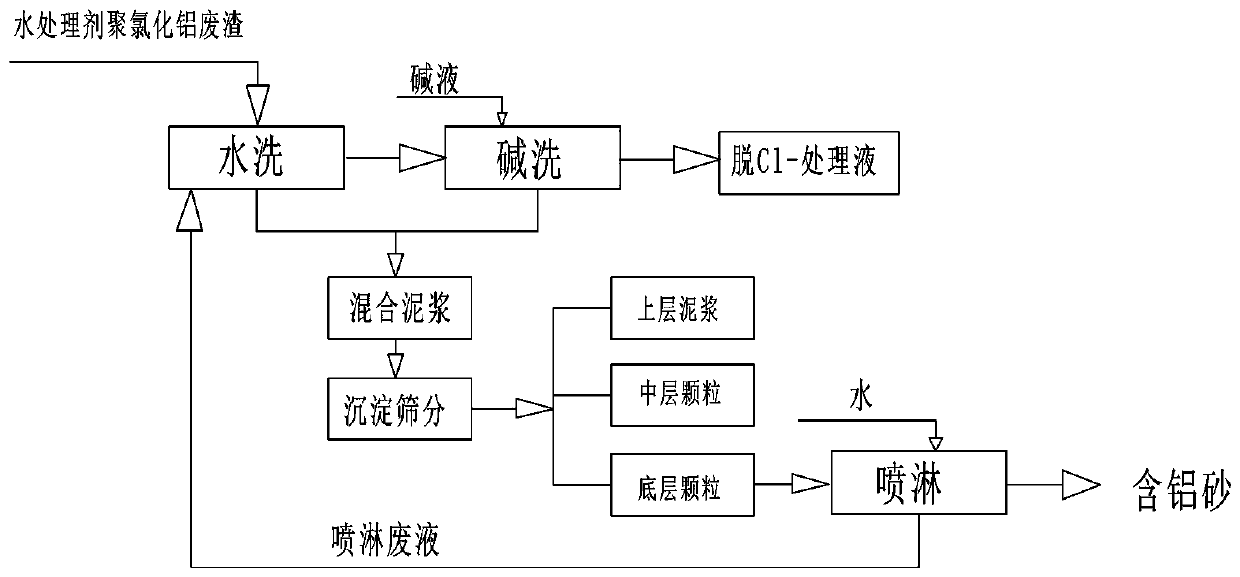

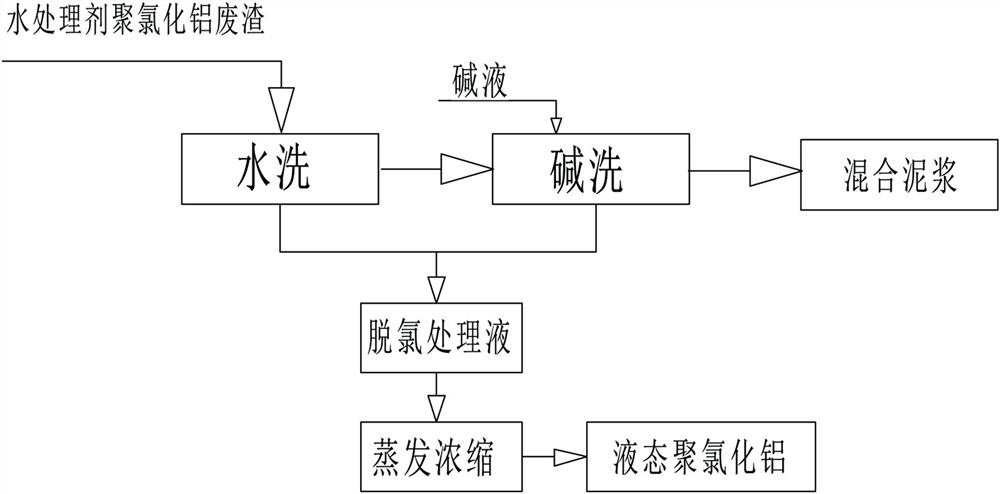

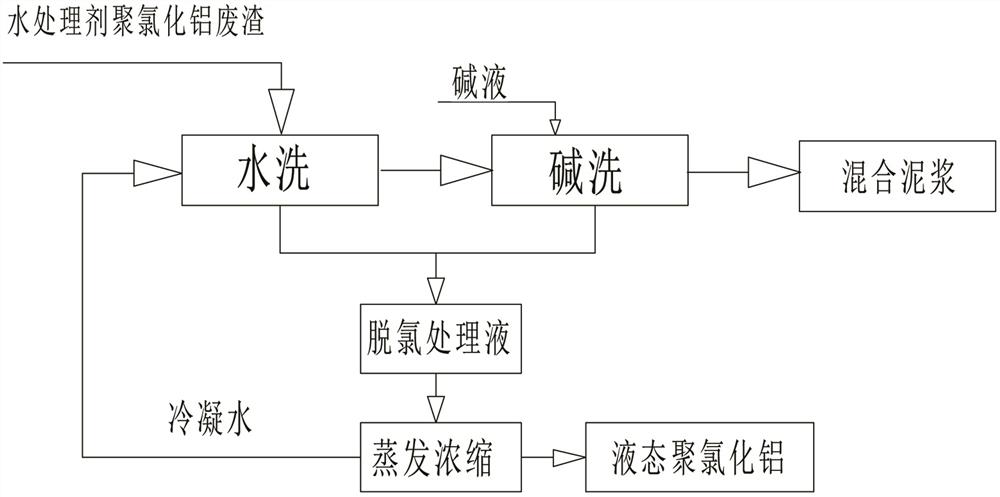

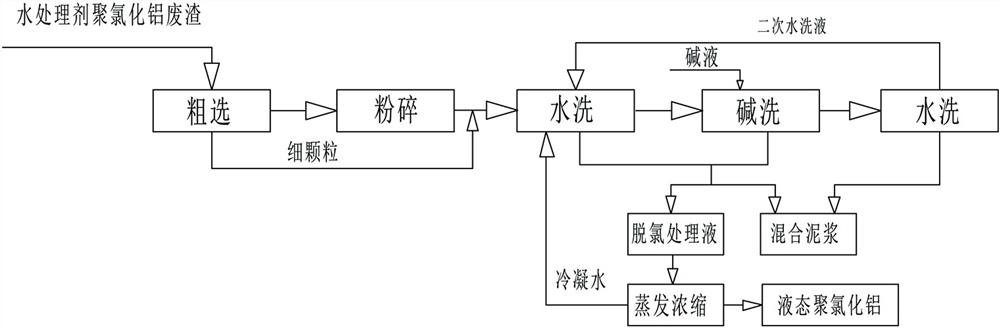

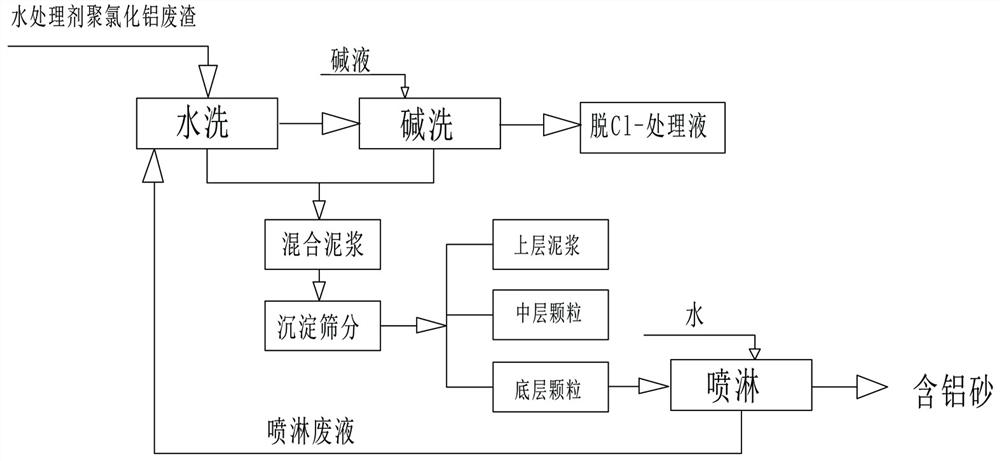

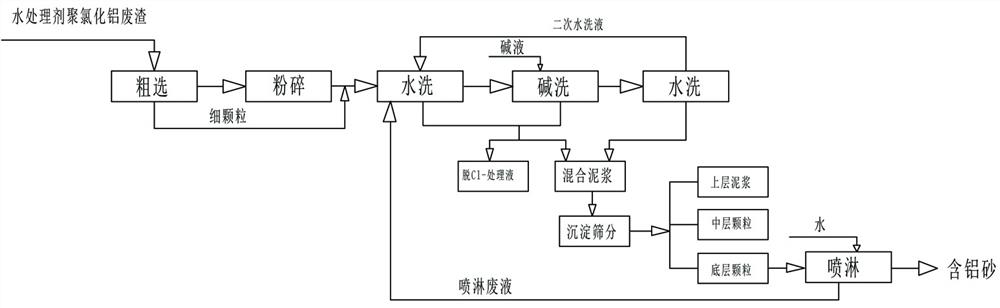

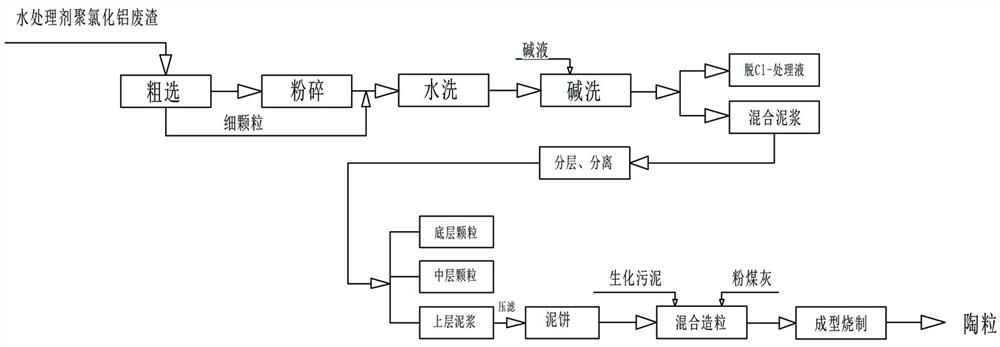

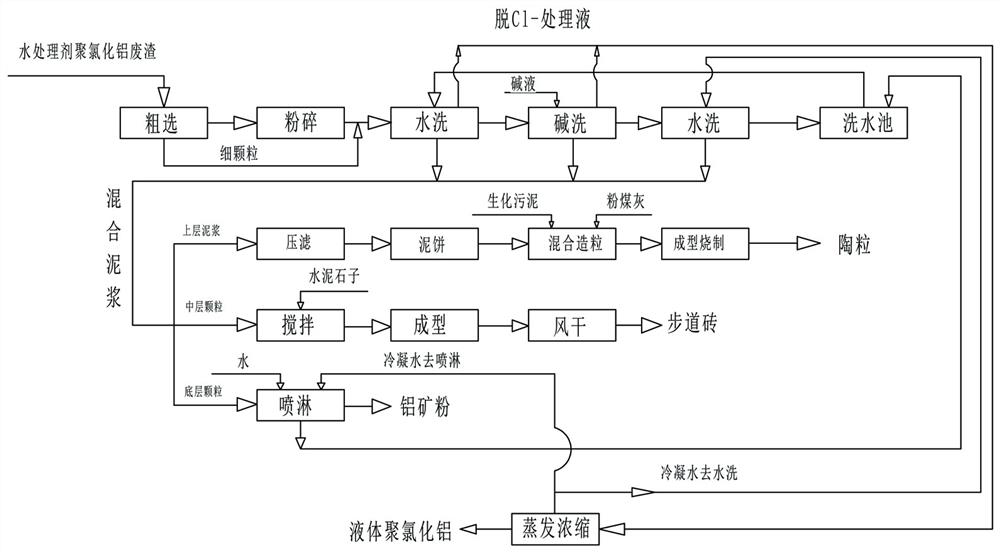

Method for recovering aluminum resources from water treatment agent polyaluminum chloride waste

ActiveCN109701991AAvoid it happening againReduce pollutionSolid waste disposalAluminium chloridePolyaluminium chloride

The invention provides a method for recovering aluminum resources from the water treatment agent polyaluminum chloride waste. The method includes the steps that water washing treatment is conducted onthe water treatment agent polyaluminum chloride waste, alkali washing treatment is conducted on the water treatment agent polyaluminum chloride waste with lye, treatment liquid with Cl<-> removed andmixed mud are obtained, static settlement and screening treatment are conducted on the mixed mud, upper layer mud, middle later particles and bottom layer particles are obtained, and sand containingaluminum and spraying waste liquid are obtained by spraying the bottom layer particles. The method realizes the recovery of the aluminum resources from the water treatment agent polyaluminum chloridewaste, reduces the waste of resources, and meanwhile, is easy to industrialize and popularize.

Owner:河南省福可思环保科技有限公司

Textile hemp fiber washing method

PendingCN113512836AImprove washing efficiencyImprove scrubbing effectTextile treatment machine arrangementsTextile treatment by spraying/projectingSpinningHemp fiber

The invention belongs to the field of spinning, and particularly relates to a textile hemp fiber washing method. The textile hemp fiber washing method is carried out in cooperation with a hemp fiber washing device, the hemp fiber washing device comprises a water pumping machine shell, a power machine shell is arranged opposite to the water pumping machine shell, two main rotating shafts are arranged between the power machine shell and the water pumping machine shell, and a water pumping mechanism is arranged between each main rotating shaft and the water pumping machine shell; a motor is arranged on the power machine shell, the output end of the motor is fixedly provided with a driving rotating shaft, the driving rotating shaft is in belt transmission connection with the main rotating shafts, the two main rotating shafts are in gear meshing transmission, each main rotating shaft is fixedly provided with a roller, and each roller is provided with a sliding rubbing mechanism; and the outer circumferential surface of each roller is uniformly provided with six outer sliding arc plates capable of sliding back and forth at 60 degrees, each outer sliding arc plate is provided with a one-way drainage mechanism, a water channel and a water storage mechanism are arranged in each roller, and control and pressing mechanisms are arranged on the water pumping machine shell and the power machine shell.

Owner:胡文生

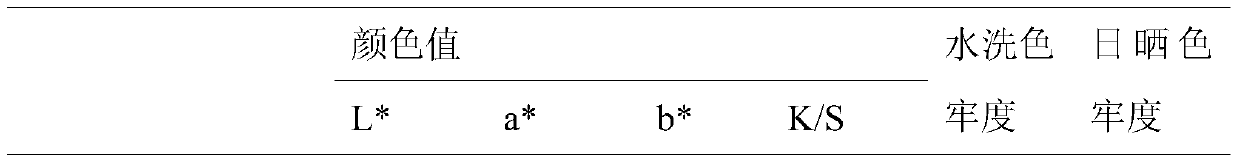

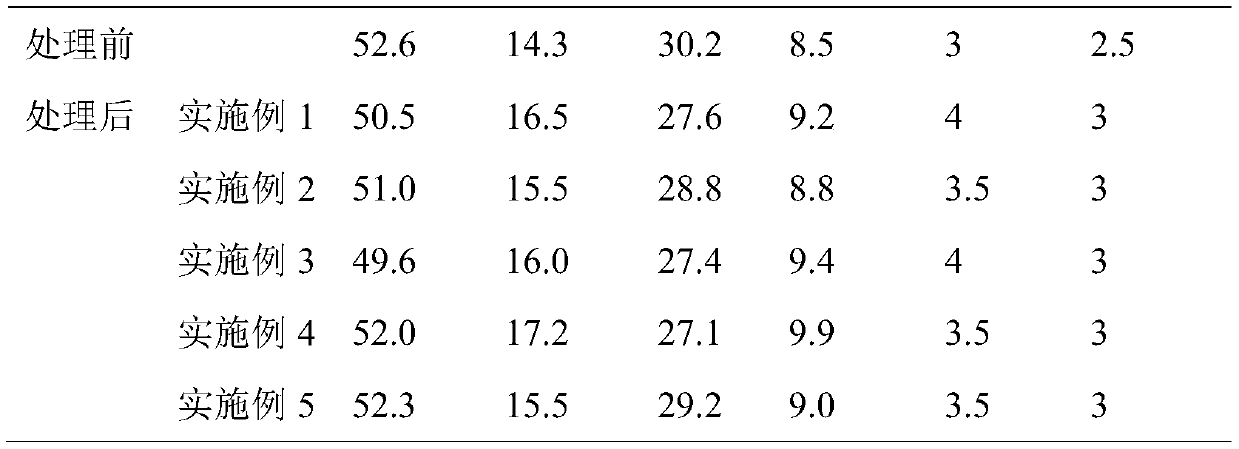

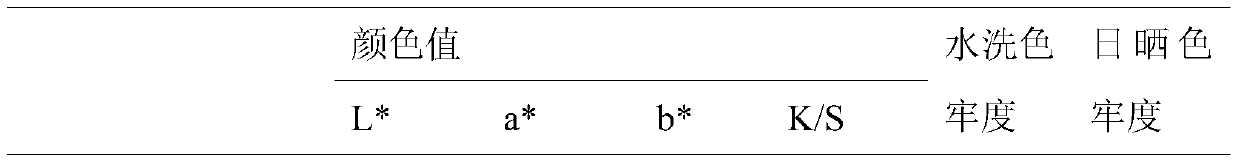

Processing method for improving natural colored cotton color depth and colour and luster stability

The invention discloses a processing method for improving the natural colored cotton color depth and colour and luster stability. The method comprises the steps that natural colored cotton obtained after color fixing is washed and dried; the natural colored cotton is dried, then the natural colored cotton obtained after drying is subjected to liquid ammonia treatment, and the natural colored cotton after liquid ammonia treatment is obtained; gelatin, penetrant and water are mixed to form a protein solution, then the protein solution is adjusted to reach the pH being 2.0-7.0, and a treatment solution is obtained; the natural colored cotton obtained after liquid ammonia treatment is put in the treatment solution for padding at 15-70 DEG C, so that the liquid-carrying rate of natural coloredcotton obtained after padding is 30-150%, and then cold reactor placement is conducted; the natural colored cotton after fixing treatment is obtained. By means of the method, the color of the naturalcolored cotton can become brighter, and the color is obviously deepened and become more uniform; the color fastness to washing and sunshine can be effectively improved.

Owner:ZHEJIANG SCI-TECH UNIV

Digital printing white ink coloring brightener and preparation method thereof

InactiveCN110453515AImprove the coloring rate and display rateReduce chromatic aberration and stainsDyeing processDigital printingPolypropylene

The invention provides a digital printing white ink coloring brightener. The digital printing white ink coloring brightener is prepared from, by mass percentage, 5.0%-8.0% of pyridine and derivativesthereof, 1.0%-5.0% of polyacrylic acid and derivatives thereof, 0.1%-10.0% of polypropylene polymer and derivatives thereof, 1.0%-15.0% of benzyl compounds, 2.0%-8.0% of an emulsifier, 8.0%-10.0% of fatty amines and derivatives thereof, 0.1%-10.0% of polysilicon oxides, 1.0%-5.0% of fatty alcohols, and the balance water. By adopting the digital printing white ink coloring brightener, after printing of white and light inks, patterns are prominent, layers are distinct, the coloring rate and the display rate are increased, the color difference and stain after printing are reduced, the light fastness, washing and soaping fastness, rubbing fastness, perspiration fastness, ironing fastness, sublimation fastness and the like are improved, and the pass rate of finished products is increased.

Owner:GUANGZHOU PANYU XIE YUN LAI CHEM NECESSITIES FACTORY

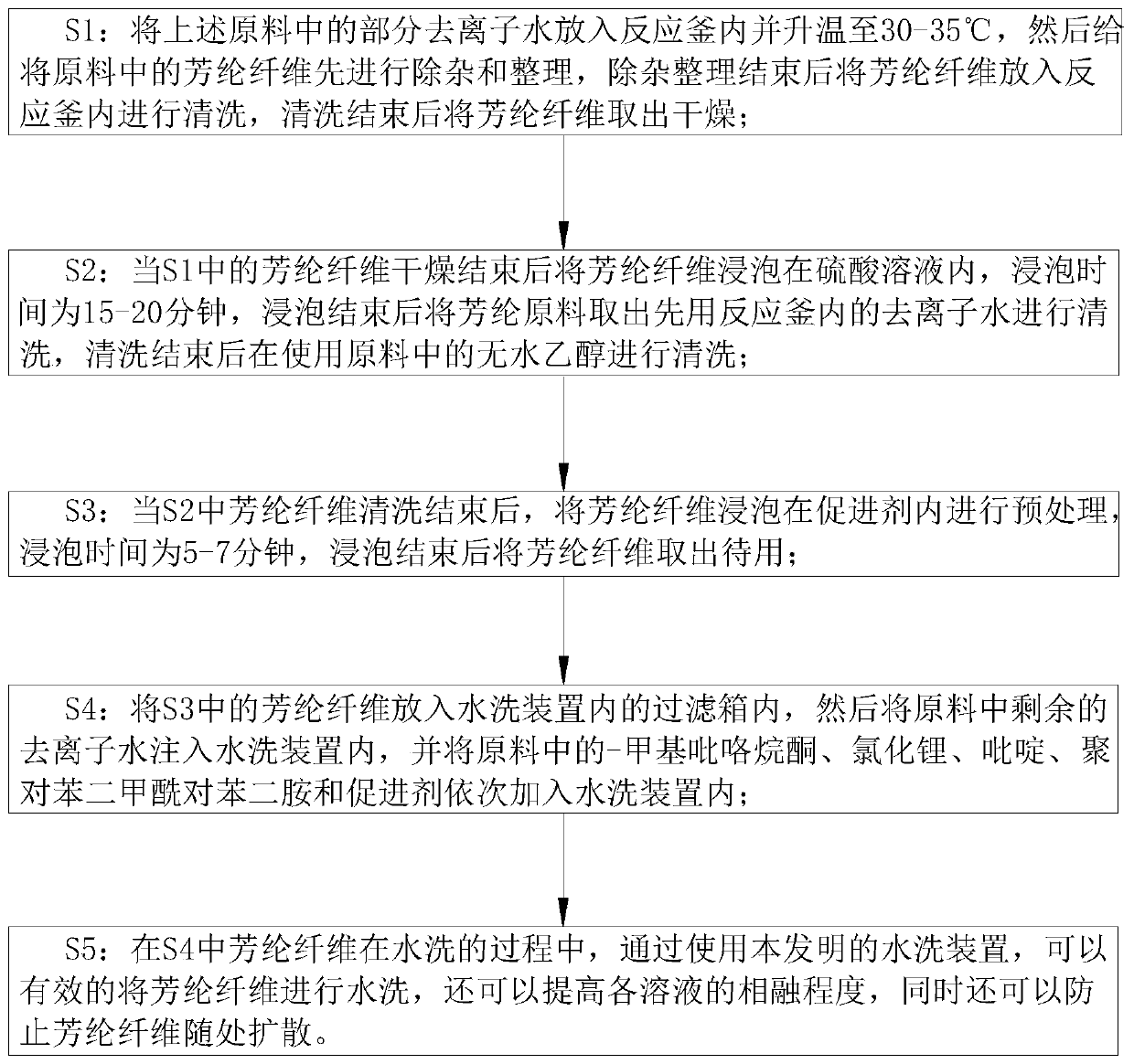

Modified aramid fiber and processing technology thereof

InactiveCN111535015AIncreased strength and corrosion resistanceHigh impact strengthLiquid/gas/vapor treatment machines driving mechanismsFibre typesEngineeringLiquid storage

The invention belongs to the technical field of modified aramid fiber, and particularly relates to modified aramid fiber and a processing technology thereof. A washing device comprises a supporting frame; a motor is fixedly connected to the end face of the right side of the supporting frame; a washing box is rotationally connected to the interior of the inner wall of the supporting frame through arotating pipe; the rotating pipe is fixedly connected with a driving shaft of the motor; a liquid storage box is fixedly connected to the end face of the left side of the supporting frame; the liquidstorage box is rotationally connected with the washing box through a guide pipe; and supports which are uniformly arranged are fixedly connected to the outer surface of the rotating pipe and locatedin a cavity of the washing box. The modified aramid fiber and the processing technology thereof are mainly used for solving the problems that in the modification process of aramid fiber on the marketat present, often, active groups are introduced into the aramid fiber for modification by adopting various chemical stock solutions, but the modification mode is long in technological process, the modification technology is relatively complex, meanwhile, some existing aramid fiber washing devices need long time, the aramid fiber is not washed thoroughly, and fiber filaments are easy to diffuse everywhere in the process of washing the fiber filaments by some washing devices.

Owner:淮南德友化工科技有限公司

Processing method for improving color depth and color stability of natural colored cotton

The invention discloses a processing method for improving the natural colored cotton color depth and colour and luster stability. The method comprises the steps that natural colored cotton obtained after color fixing is washed and dried; the natural colored cotton is dried, then the natural colored cotton obtained after drying is subjected to liquid ammonia treatment, and the natural colored cotton after liquid ammonia treatment is obtained; gelatin, penetrant and water are mixed to form a protein solution, then the protein solution is adjusted to reach the pH being 2.0-7.0, and a treatment solution is obtained; the natural colored cotton obtained after liquid ammonia treatment is put in the treatment solution for padding at 15-70 DEG C, so that the liquid-carrying rate of natural coloredcotton obtained after padding is 30-150%, and then cold reactor placement is conducted; the natural colored cotton after fixing treatment is obtained. By means of the method, the color of the naturalcolored cotton can become brighter, and the color is obviously deepened and become more uniform; the color fastness to washing and sunshine can be effectively improved.

Owner:ZHEJIANG SCI-TECH UNIV

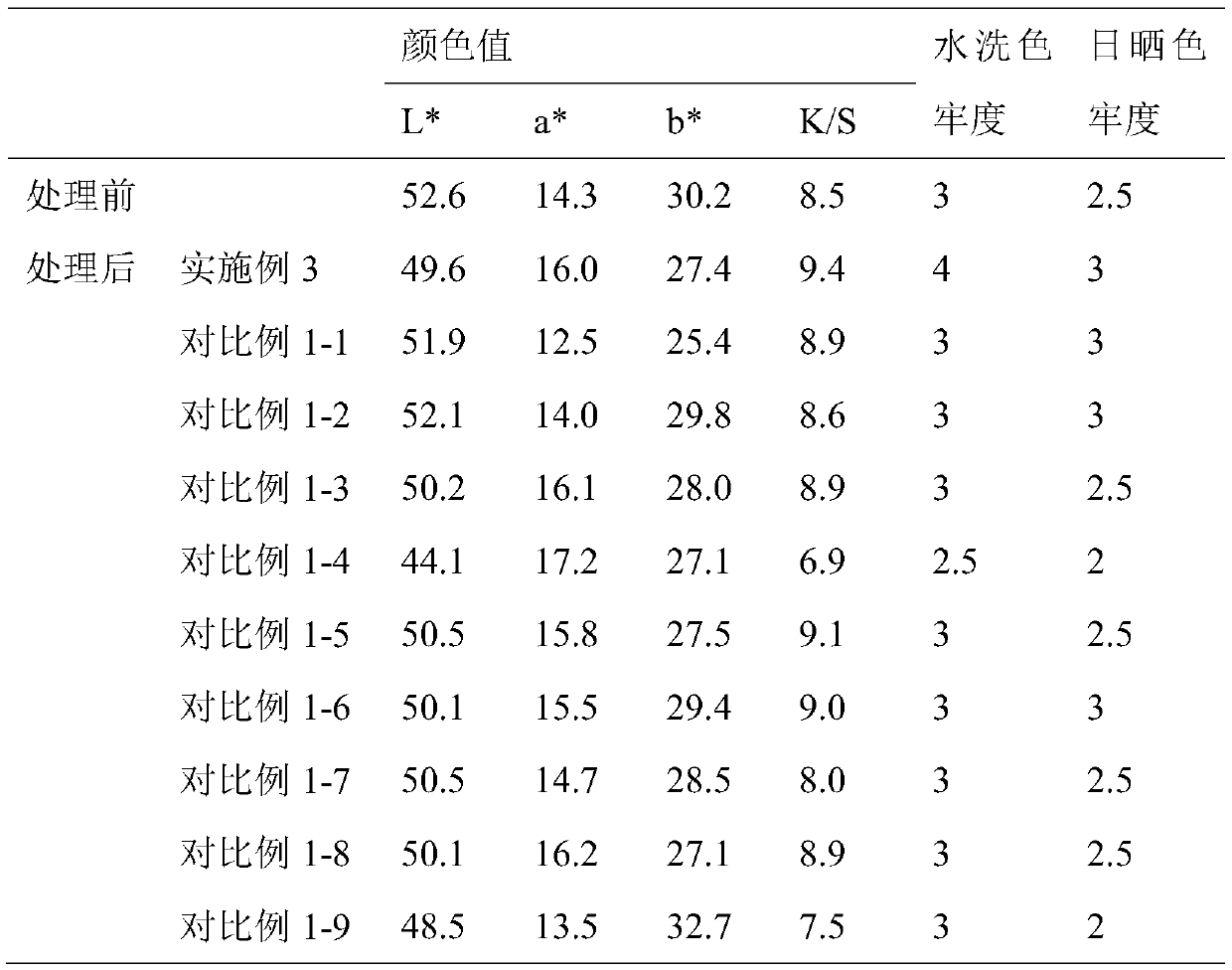

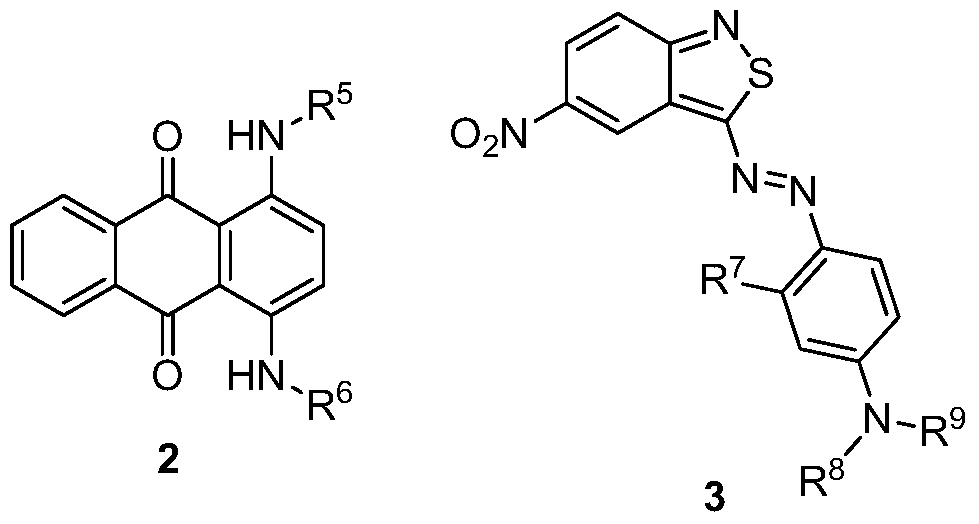

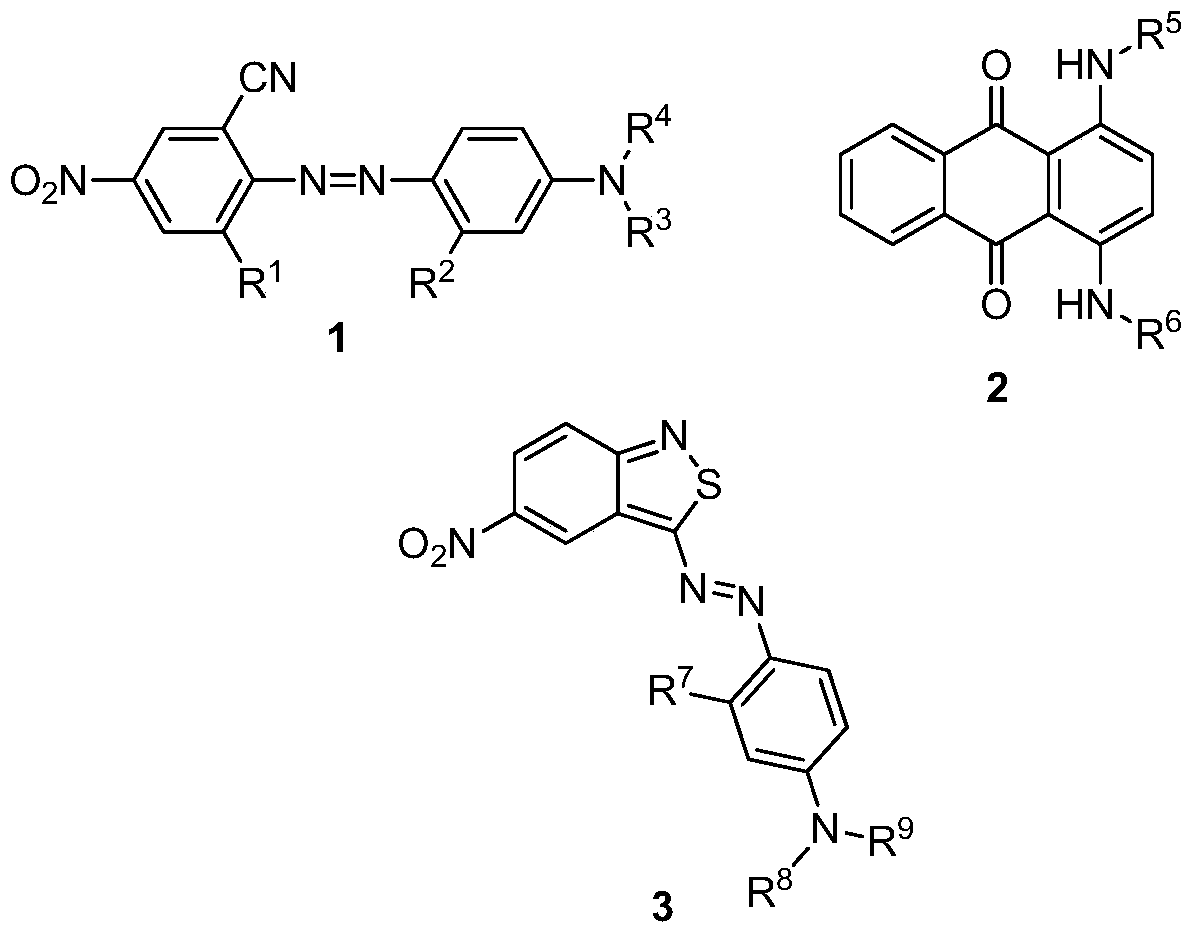

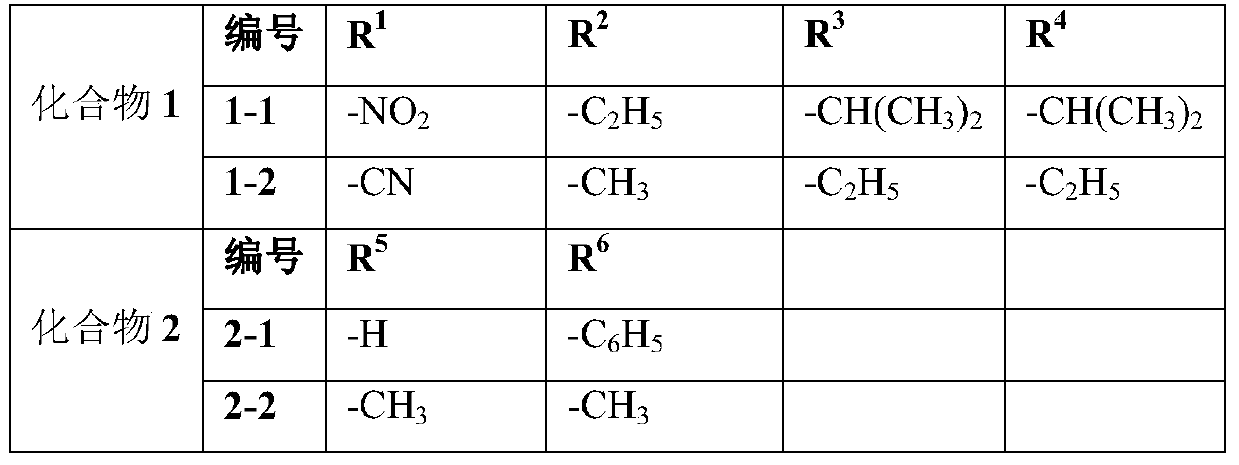

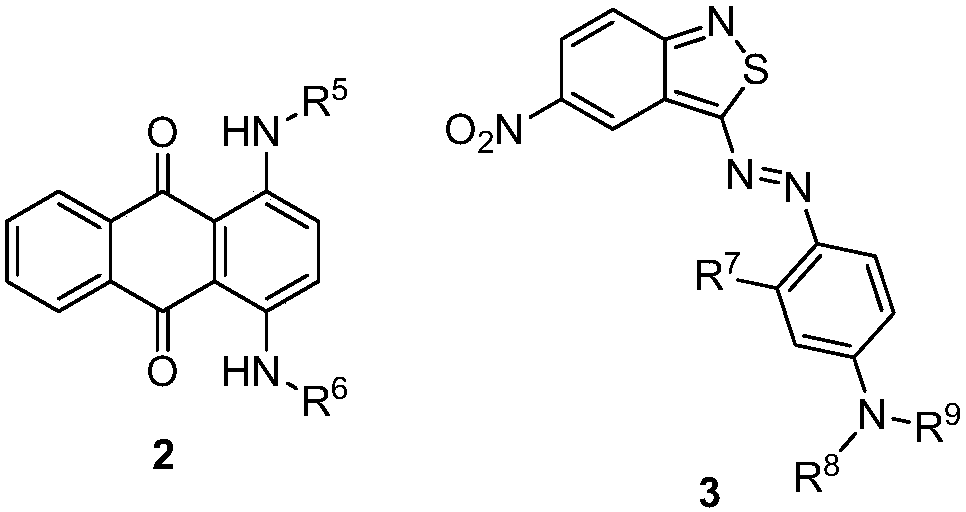

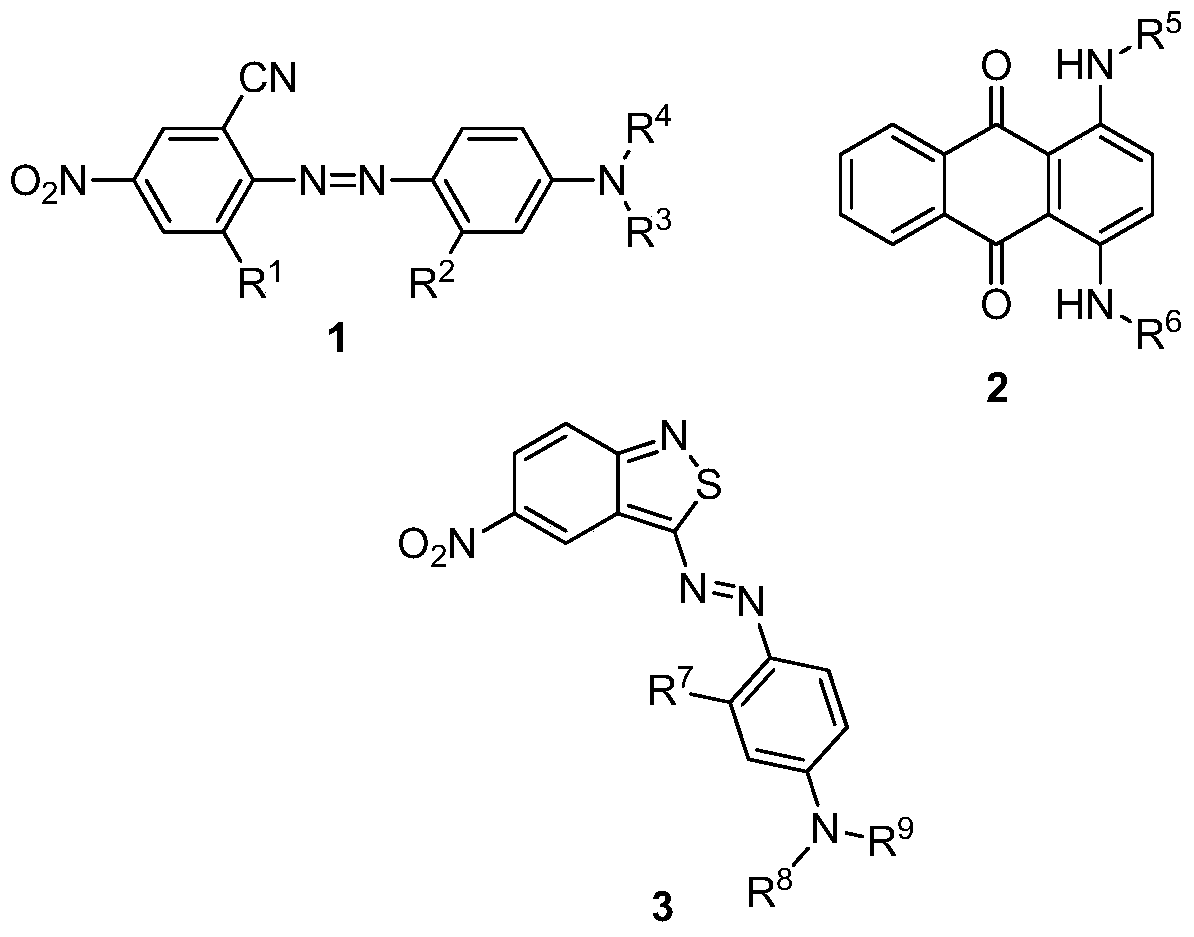

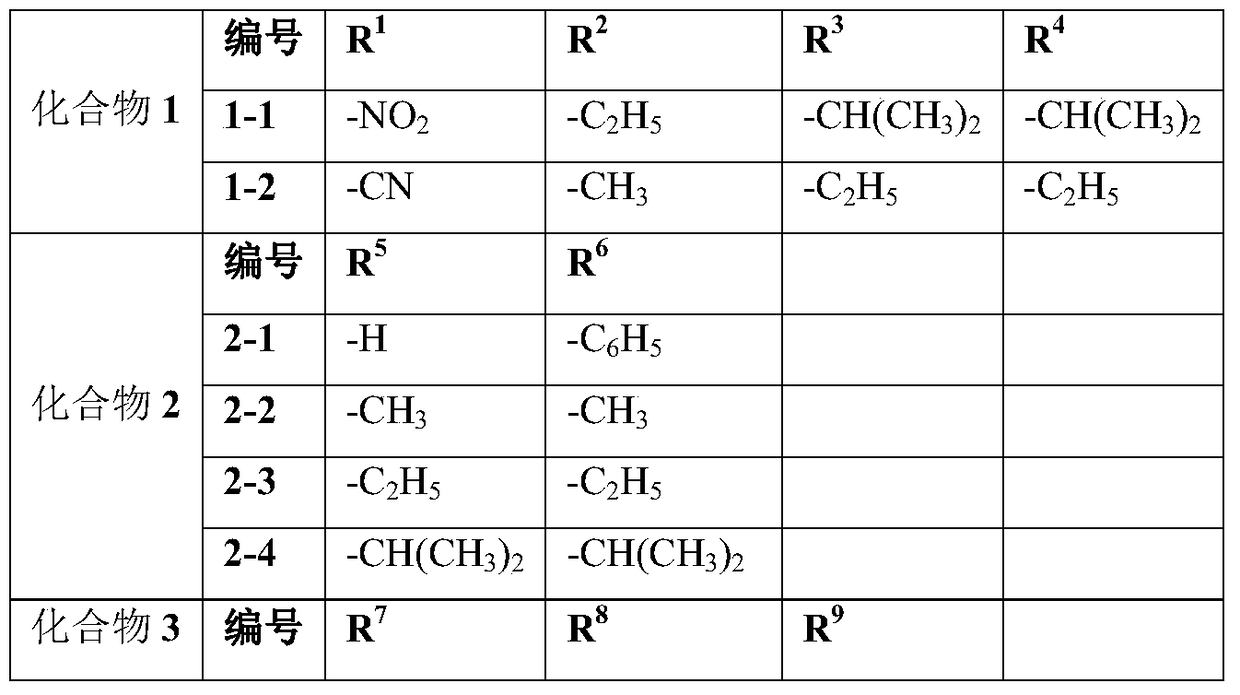

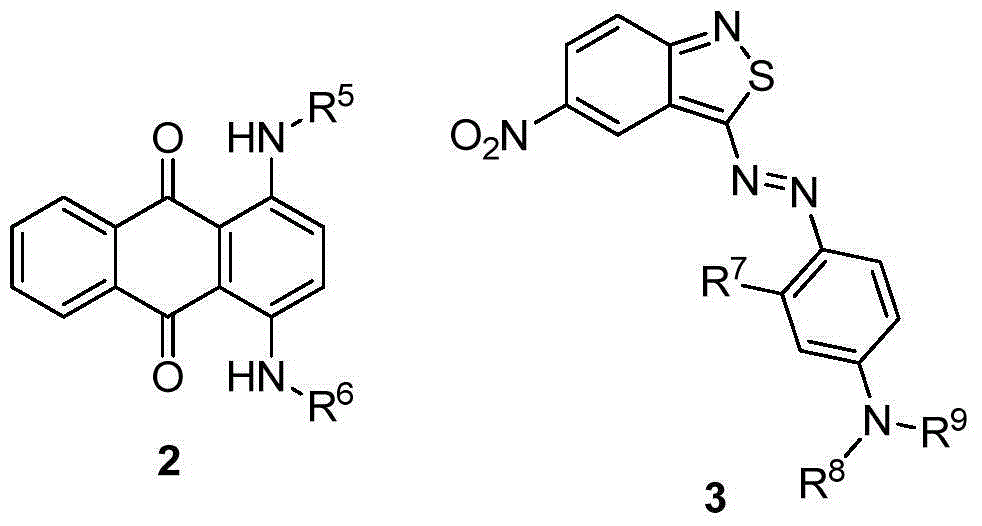

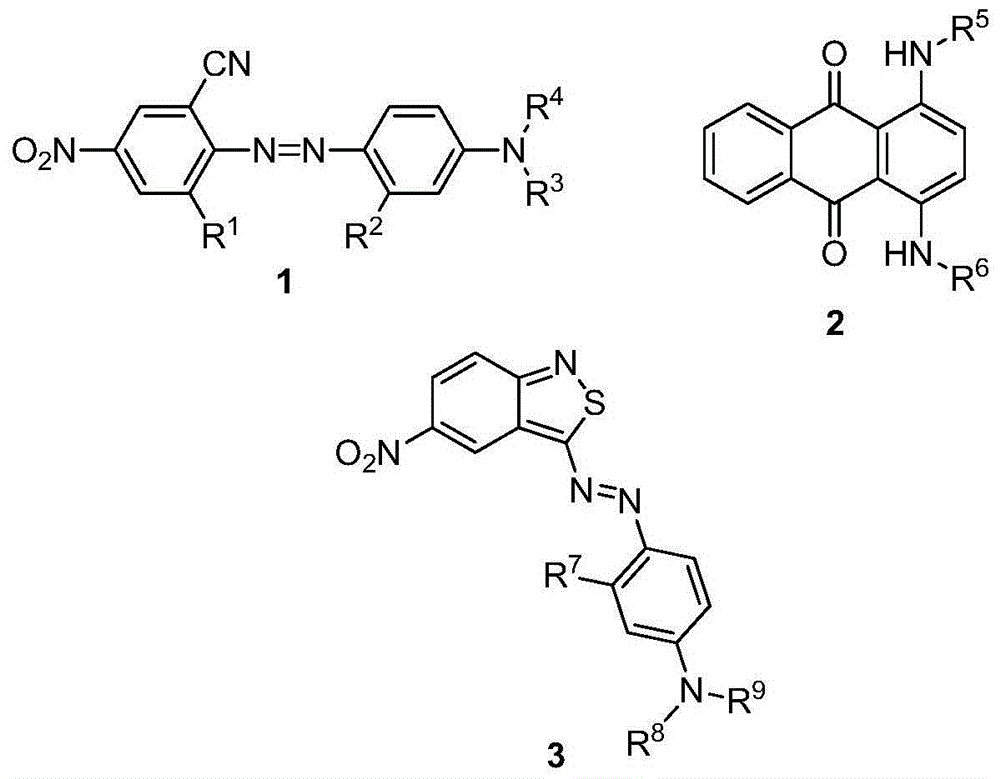

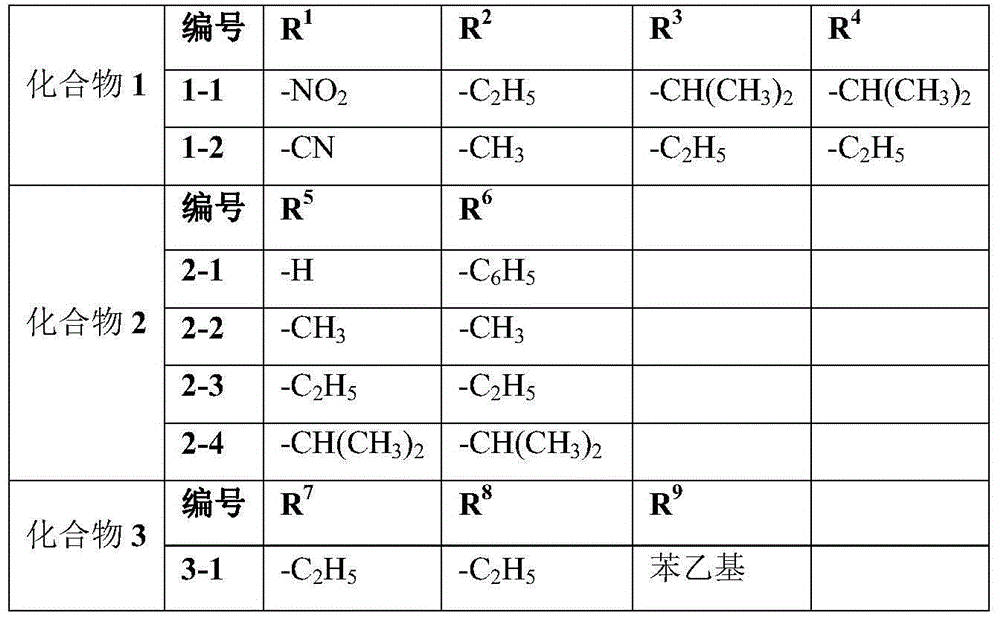

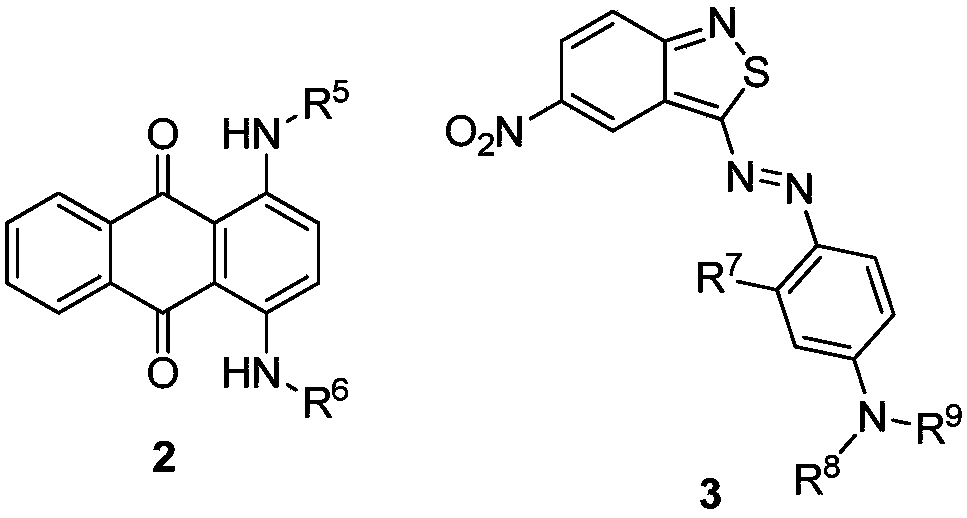

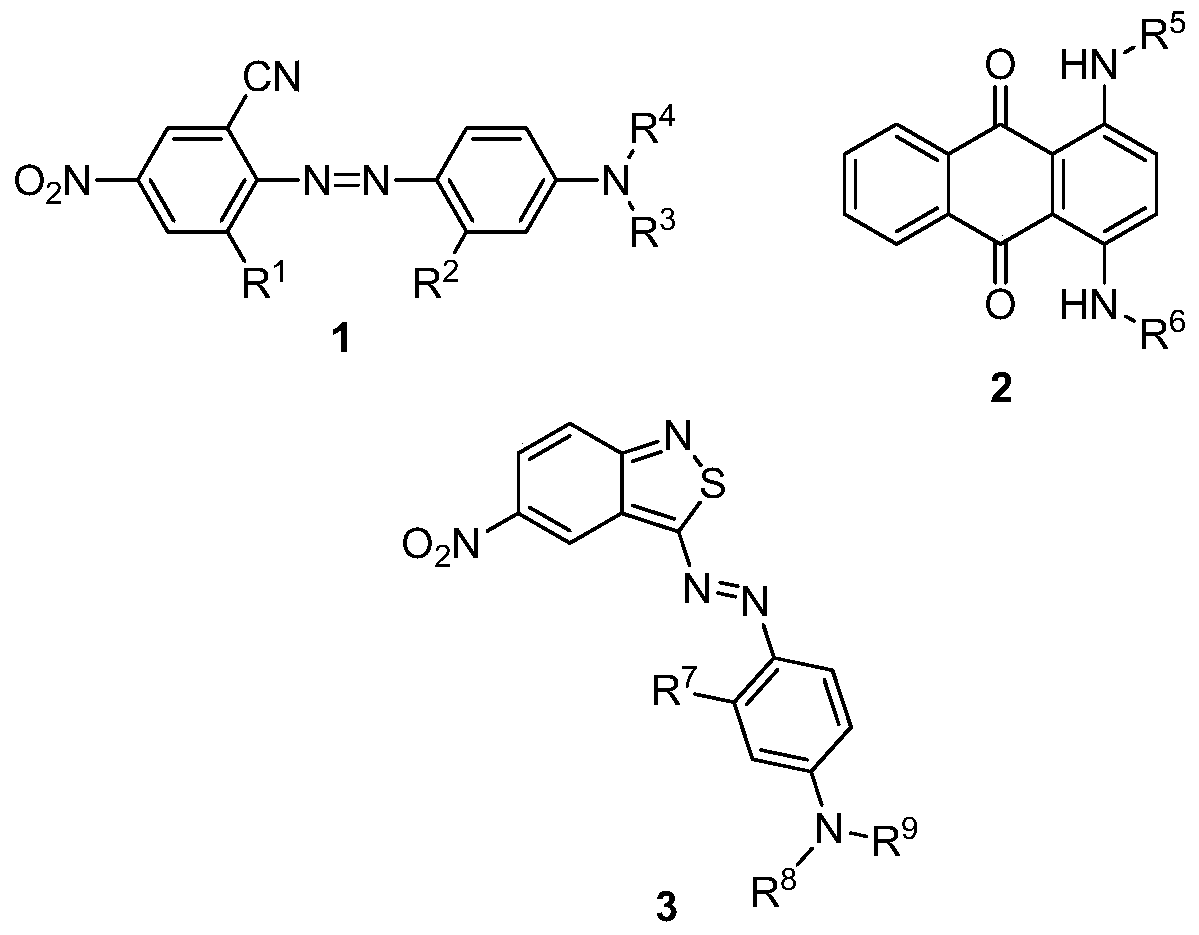

Preparation method of blue disperse dye composition

The invention discloses a preparation method of a blue disperse dye composition. The method can be conducted according to a method I or a method II. The method I comprises mixing a dye, a dispersant, and water, performing micro-granulation, and performing spray-drying to obtain the composition. The method II comprises micro-granulating components of the dye in the presence of a dispersant and water, performing spray-drying, and performing mixing to obtain the composition. The mass ratio of the dispersant to the dye is in a range from 0.35:1 to 5.0:1. The dye comprises 15-85% of a component B and 15-85% of a component C. The percentage of each component is a mass percentage of each component to the dye. The component B is one or more kinds of a compound 2, and the component C is one or more kinds of a compound 3, wherein the compound 2 and the compound 3 are shown in the description. The preparation method is simple to operate, and the prepared composition is bright-colored, is excellent in alkali resistance and light fastness, and can be used for a strong-base-resistant and super-base-resistant dyeing and one-bath scouring method or bleaching and dyeing and one-bath scouring method, a disperse / reactive printing process in one paste, and an alkaline burnt-out printing process.

Owner:浙江名毅新能源股份有限公司

Application of blue disperse dye composition

The invention discloses an application of a blue disperse dye composition as blue disperse dye. The composition comprises dye and a dispersant. A ratio of the mass of the dispersant to the mass of the dye is 0.35:1-5.0:1. The dye comprises, by weight, 15-85% of a component B and 15-85% of a component C. The component B is one or more of compounds 2. The component C is one or more of compounds 3. The composition is bright in color and light, extremely good in alkali resistance and good in light fasteness and can be used for strong-base resistant and superstrong-base resistant scouring-dyeing one bath processes or bleaching-dyeing one-bath processes, disperse / active one-emulsion printing processes and alkaline burn-out printing processes.

Owner:浙江名毅新能源股份有限公司

Method for preparing polyaluminum chloride from water treatment agent polyaluminum chloride waste slag dechlorination treatment liquid

ActiveCN109336153BUniform compositionEvenly heatedAluminium chloridesWater/sewage treatment by flocculation/precipitationAluminium chlorideResource recovery

The invention provides a method for preparing PAC (polyaluminum chloride) from a dechlorination treatment liquid of water treatment agent PAC waste residues. The method mainly comprises the steps as follows: performing water washing treatment and alkali washing tretament on water treatment agent PAC waste residues to obtain the dechlorination treatment liquid and mixed mud; placing the dechlorination treatment liquid in triple-effect and four-body forced circulation evaporation equipment or an MVR forced circulation evaporator for circulation evaporation concentration treatment to prepare liquid PAC and condensate water. By means of the method, PAC can be recycled from the dechlorination treatment liquid of water treatment agent PAC waste residues, waste can be changed into wealth, resource recycling is realized, the process comprises simple steps and facilitates industrial promotion.

Owner:河南省福可思环保科技有限公司

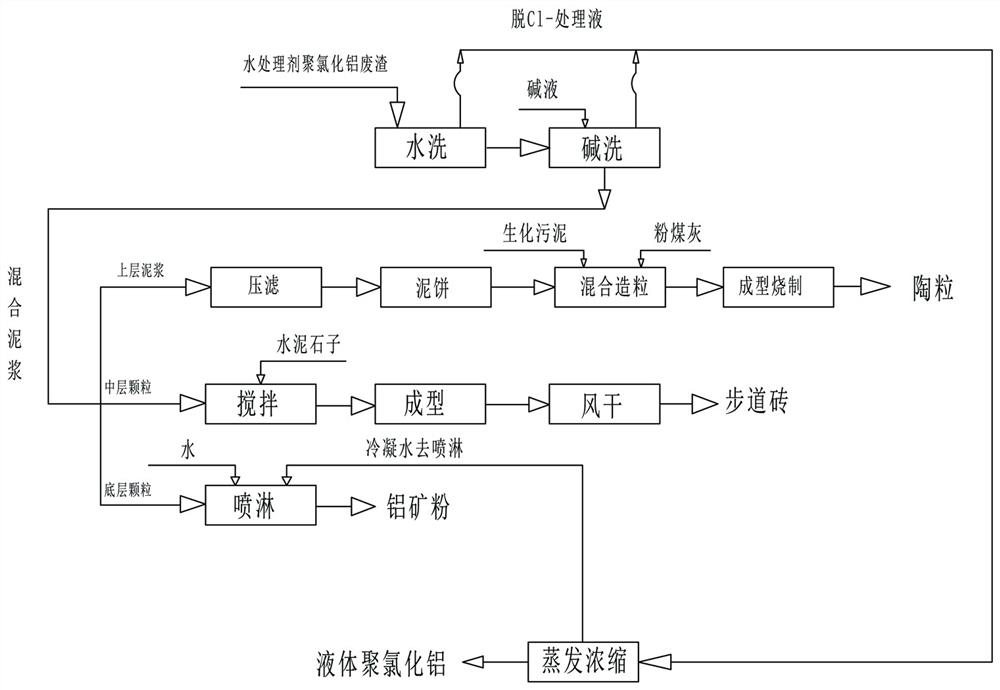

Water treatment agent polyaluminum chloride waste residue comprehensive utilization method

ActiveCN109650426ASolve the problem of stacking and polluting the environmentThe process steps are simpleAluminium chloridesCeramic materials productionAluminium chlorideSludge

The invention provides a water treatment agent polyaluminum chloride waste residue comprehensive utilization method. The method includes performing Cl<-> removing treatment on water treatment agent polyaluminum chloride waste residue to obtain a Cl<-> removing treatment solution and mixed slurry; performing static sedimentation layering treatment on the mixed slurry to obtain bottom particles, middle layer particles and upper layer slurry; obtaining mud cakes after clear liquid is filtered by pressing the upper layer slurry, and performing mixed granulation and sintering on the mud cakes, biochemical sludge and fly ash so that ceramsite can be prepared; placing the dechlorination treatment solution in three-effect four-body forced circulation evaporation equipment or MVR forced circulationevaporation equipment to perform cyclic evaporation concentration treatment so that liquid polyaluminium chloride can be prepared; and performing spraying treatment on the bottom particles so that aluminized sand can be obtained. The method can make each component in the water treatment agent polyaluminum chloride waste residue fully recycled, and no new waste is discharged during the whole process, so that the pollution problem of everywhere stacking of the water treatment agent polyaluminum chloride waste residue can be solved, and resource recycling can be realized as well. The method is simple in technology step and easy to industrialize and popularize.

Owner:河南省福可思环保科技有限公司

Dyeing and finishing processing method of natural vegetable dyes for cellulose loose fibers

Owner:苏州麻朵纺织科技有限公司

A kind of preparation method of silane modified moisture curing polyurethane hot melt adhesive

ActiveCN104449535BEnhanced van der Waals forceImprove wetting effectNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterSilanes

The invention discloses a preparation method for a silane-modified moisture-curable polyurethane hot melt adhesive. The method comprises the following steps: (1) heating and mixing polyester polyol, polyether polyol, tackifying resin, an antioxidant and a fluorescent whitening agent at a certain temperature, performing reduced pressure degassing for 2 hours, and cooling to 90 DEG C; (2) adding isocyanate and a catalyst into a reaction system under the nitrogen protection, and reacting at 85-95 DEG C for 45 minutes; (3) adding a chain extender and a silane coupler under the nitrogen protection, and reacting at 85-95 DEG C for 1 hour to obtain a prepolymer; (4) transferring a reaction mixture into an aluminum foil bag under the nitrogen protection, sealing, and curing at 85 DEG C for 6 hours to obtain the silane-modified moisture-curable polyurethane hot melt adhesive with excellent performance.

Owner:SHANGHAI TIANYANG HOT MELT ADHESIVE CO LTD +2

Method for recovering aluminum resources from water treatment agent polyaluminum chloride waste slag

ActiveCN109701991BAvoid it happening againReduce pollutionSolid waste disposalAluminium chloridePolyaluminium chloride

The invention provides a method for recovering aluminum resources from the polyaluminum chloride waste slag of the water treatment agent, which comprises washing the polyaluminum chloride waste slag of the water treatment agent with water and carrying out alkaline washing treatment with lye to obtain Cl removal ‑ treatment liquid and mixed mud; the mixed mud is subjected to static sedimentation and sieving treatment to obtain upper mud, middle layer particles and bottom layer particles, and the bottom layer particles are sprayed to obtain aluminum-containing sand and spray waste liquid. The method realizes the recovery of aluminum resources from the polyaluminum chloride waste slag of the water treatment agent, reduces waste of resources, and at the same time, the method is easy to be popularized in an industrialized manner.

Owner:河南省福可思环保科技有限公司

A blue disperse dye composition

A blue disperse dye composition is disclosed and comprises dye and a dispersant. A ratio of the mass of the dispersant to the mass of the dye is 0.35:1-5.0:1. The dye comprises, by weight, 15-85% of a component B and 15-85% of a component C. The component B is one or more of compounds 2. The component C is one or more of compounds 3. The composition is bright in color and light, extremely good in alkali resistance and good in light fasteness and can be used for strong-base resistant and superstrong-base resistant scouring-dyeing one bath processes or bleaching-dyeing one-bath processes, disperse / active one-emulsion printing processes and alkaline burn-out printing processes.

Owner:SHANGHAI ANOKY GRP

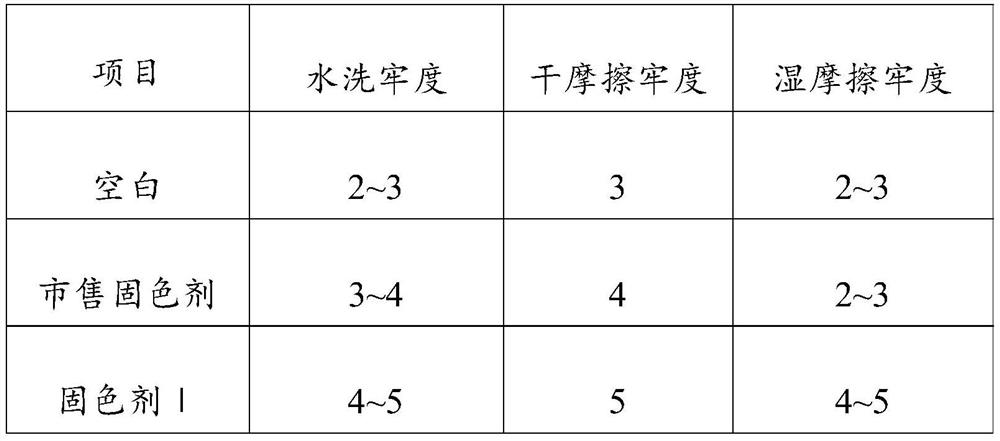

A kind of fluorine-containing color-fixing agent and preparation method thereof

The invention discloses a fluorine-containing color fixing agent and a preparation method thereof. It consists of the following components in percentage by weight: 40-60% dimethyl diallyl ammonium chloride, 5-25% diallylamine Salt, 1-5% allyl perfluorooctyl ether or ester, 0.5-1% peroxide and the remainder of deionized water; the fluorine-containing color fixing agent of the present invention is yellow and sticky, compared with the existing Color agent, the color fixing agent of the present invention has better stability and can be dissolved with various finishing agents such as silicone oil; and the fabric fastness to washing, dry wiping, wet wiping and sunlight has been significantly improved. The preparation process of the fluorine-containing color-fixing agent of the present invention is simple and convenient, and provides a choice of color-fixing agent with better performance.

Owner:广东灵捷制造化工有限公司

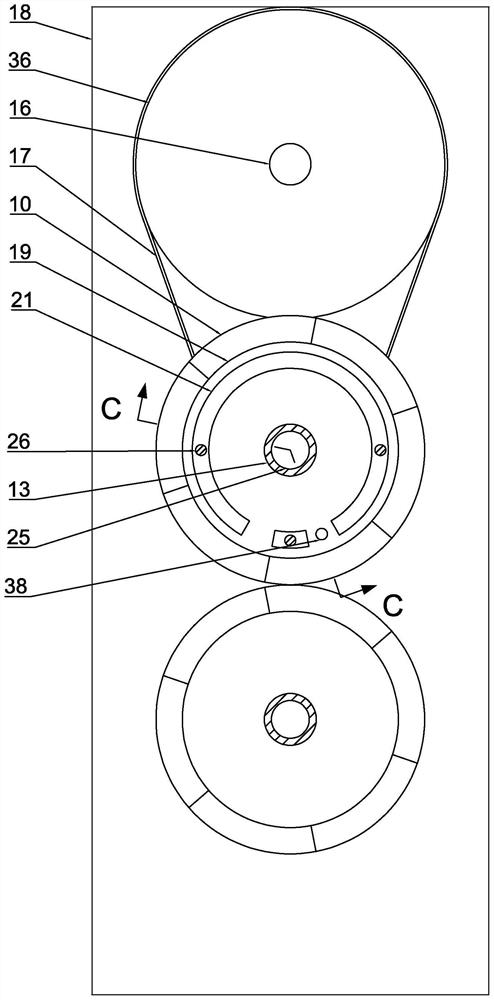

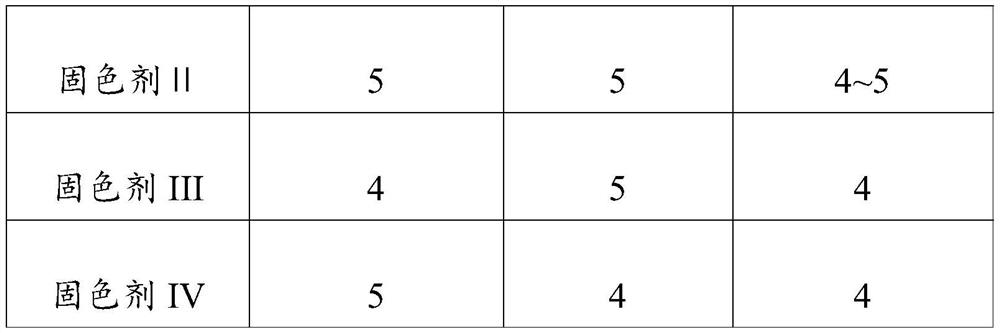

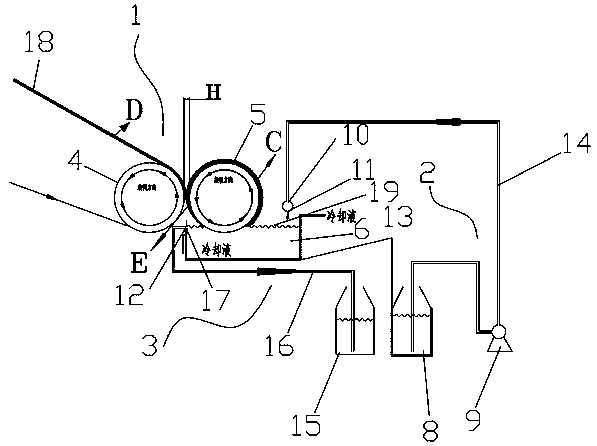

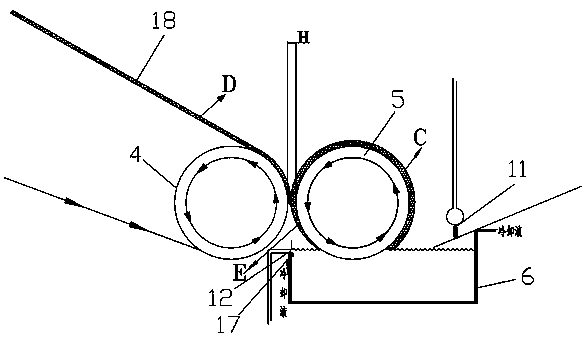

A kind of gluing equipment and gluing process of reflective material

ActiveCN108940715BRealize non-contact glue applicationSolve for uniformityLiquid surface applicatorsCoatingsAdhesive glueEngineering

The invention discloses gluing equipment of a reflecting material. The gluing equipment comprises a gluing system, a glue supply system and a overflow system, wherein the gluing system comprises a bottom roller, a glue roller and a material groove; a gluing gap is formed between the bottom roller and the glue roller; a speed difference is formed between the bottom roller and the glue roller; the glue roller is arranged in the material groove, and is contacted with glue in the material groove; the glue supply system comprises a storage device, a metering device and a glue unloading device communicating with each other; the glue unloading device is arranged above the material groove, and is provided with multiple glue unloading ports uniformly distributed; and the overflow system is providedwith multiple overflow ports uniformly distributed in the material groove. The invention further discloses a gluing process. In the gluing equipment of the reflecting material, a certain speed difference between the bottom roller and the glue roller and the gap between the two rollers are controlled; and through a non-contact gluing mode, the uniform gluing is realized, and the problems of weak appearance color and surface shape uniformity of the reflecting material caused by nonuniform gluing are solved.

Owner:HANGZHOU CHINASTARS REFLECTIVE MATERIAL

Method for preparing ceramsite from waste slag of polyaluminum chloride as water treatment agent

ActiveCN109437960BUniform internal organizationLarge specific surface areaCeramic materials productionCeramicwareAluminium chlorideSludge

The invention provides a method for preparing ceramsite by utilizing polyaluminum chloride waste slag of a water treatment agent. ‑ treatment, get off Cl ‑ Treatment liquid and mixed mud, the mixed mud is subjected to static sedimentation and sieving treatment to obtain bottom layer particles, middle layer particles and upper layer mud; the upper layer mud is filtered to obtain a mud cake after filtering out the clear liquid, according to the ratio of parts by mass The ratio of (80-100): (0-20): (0-20) is used to mix and granulate the mud cake with biochemical sludge and fly ash to obtain pellets to be burned, and then granulate them at a temperature of 1000°C The granules to be fired are fired at ~1300° C. and cooled to room temperature to obtain ceramsite. The internal structure of the ceramsite prepared by this method is uniform, which can not only make full use of the polyaluminum chloride waste residue resource of the water treatment agent, but also solve the problem of random stacking of biochemical sludge to pollute the environment, and also utilize the heat of combustible components in the biochemical sludge . The method has simple steps and is easy to be popularized industrially.

Owner:河南省福可思环保科技有限公司

blue disperse dye composition

A blue disperse dye composition is disclosed and comprises dye and a dispersant. A ratio of the mass of the dispersant to the mass of the dye is 0.35:1-5.0:1. The dye comprises, by weight, 15-85% of a component B and 15-85% of a component C. The component B is one or more of compounds 2. The component C is one or more of compounds 3. The composition is bright in color and light, extremely good in alkali resistance and good in light fasteness and can be used for strong-base resistant and superstrong-base resistant scouring-dyeing one bath processes or bleaching-dyeing one-bath processes, disperse / active one-emulsion printing processes and alkaline burn-out printing processes.

Owner:SHANGHAI ANOKY GRP

Chemiluminescence immunoassay analyzer incubator

ActiveCN104655865BGuaranteed washing effectSpeed up the washing processMaterial analysisBiochemical engineeringChemiluminescence immunoassay

The invention discloses an incubator for a chemiluminescence immunoassay analyzer, which comprises a box body, one side opening of the box body, and a plurality of parallel partitions are arranged on the upper surface of the bottom plate of the box body, and the partition boards are connected with the box body. The base plate is vertical, and a cuvette holder installation groove is formed between two adjacent partitions, and one end of the cuvette holder installation groove communicates with the opening on the side of the box body. The remarkable effect of adopting the present invention is that it can ensure the stable placement of the strip-shaped cuvettes, and by maintaining the constant temperature in the incubator and shaking the box, the blood and reaction reagents in the cuvettes in the box can be quickly and fully reaction to ensure the accuracy and reliability of the detection and analysis results, and timely washing and substrate filling can improve the accuracy of the detection results and improve the detection and analysis efficiency.

Owner:CHONGQING KEYSMILE BIOLOGICAL TECH CO LTD

Comprehensive utilization method of water treatment agent polyaluminum chloride waste residue

ActiveCN109650426BSolve the problem of stacking and polluting the environmentThe process steps are simpleAluminium chloridesCeramic materials productionAluminium chlorideSludge

The invention provides a comprehensive utilization method of polyaluminum chloride waste slag of water treatment agent, which comprises declination of polyaluminum chloride waste slag of water treatment agent ‑ treatment, get off Cl ‑ treatment liquid and mixed mud; the mixed mud is subjected to static sedimentation and layered treatment to obtain bottom layer particles, middle layer particles and upper layer mud; the upper layer mud is filtered to obtain a mud cake, and the mud cake is mixed with biochemical waste Mud and fly ash are mixed, granulated and sintered to obtain ceramsite; the dechlorination treatment liquid is placed in a three-effect four-body forced circulation evaporator or an MVR forced circulation evaporator for circulation evaporation and concentration treatment to obtain a liquid polymer Aluminum chloride; spraying the bottom particles to obtain aluminum-containing sand. The method enables each component in the polyaluminum chloride waste slag of the water treatment agent to be fully recycled, and no new waste is discharged in the whole process, which not only solves the pollution problem of the polyaluminum chloride waste slag of the water treatment agent piled up everywhere, but also realizes resource recovery. The process has simple steps and is easy to be popularized industrially.

Owner:河南省福可思环保科技有限公司

Preparation of white titanium pigment double action crystal seed from metatitanic acid

ActiveCN101565201BFast phase changeSimplify operating proceduresPigmenting treatmentTitanium dioxideDiffractometerPhysical chemistry

The invention relates to a preparation of white titanium pigment double action crystal seed from metatitanic acid, which is characterized in the process of (1) alkali dissolving, boiling the metatitanic acid purified by water washing with thermokalite; (2) water washing, removing residue sodium hydroxide and generated sodium sulfate thereby; (3) neutralizing and acid dissolving, neutralizing by hydrochloric acid and acid solution; (4) peptizing to generate a seed suspension, evaporating the suspension at a temperature from 105 to 300 DEG C., grinding, measuring the rutile microcrystalline withweight percentage over 90-98% by a X-ray diffractometer. The preparation uses metatitanic acid produced during sulphuric acid production process as raw material, adopts sol-gel process, with the produced rutile microcrystalline is safe and non-toxic, simple and easy to get raw material, low in cost, thus capable of evidently improving quality of product, enhancing stability of product quality andmarket competitiveness.

Owner:江西添光钛业有限公司

A carbon fiber washing machine for washing carbon fiber precursors

InactiveCN106521848BIncrease washing timeSmall footprintSucessive textile treatmentsTextile treatment containersWater useFiber

The invention relates to a carbon-fiber washing machine for carbon fiber precursor washing. A multilevel washing trough is installed at the front portion of a machine frame 1, a driving roller and a guiding roller are installed on the machine frame 1, and two transmission systems are installed at the back portion of the machine frame 1. The carbon-fiber washing machine is superposed by five-level water troughs in a dislocation mode, the washing time is prolonged, and the occupied area of the device is saved to a maximum degree. As liquid level plates, flow stopping plates and overflowing plates are designed in the washing troughs, the washing process is intensified; as the two ends of the washing troughs are distributed in a dislocation mode, the number of driving roller is reduced, the contact area of fibers and rollers is reduced, and the broken filament generating probability caused by friction is reduced; deionized water used by the carbon-fiber washing machine flows to the next washing trough from the last washing trough and is recycled, and the cost is reduced while the washing effect is improved. The carbon-fiber washing machine has the advantages of being simple in structure and convenient to daily maintain and operate.

Owner:THE NORTHWEST RES INST OF CHEM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com