Water treatment agent polyaluminum chloride waste residue comprehensive utilization method

A technology of polyaluminum chloride waste slag and water treatment agent, which is applied in the direction of aluminum chloride, aluminum halide, application, etc., can solve the problems of high energy consumption and incomplete treatment of water treatment agent polyaluminum chloride waste slag, etc., to reduce effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

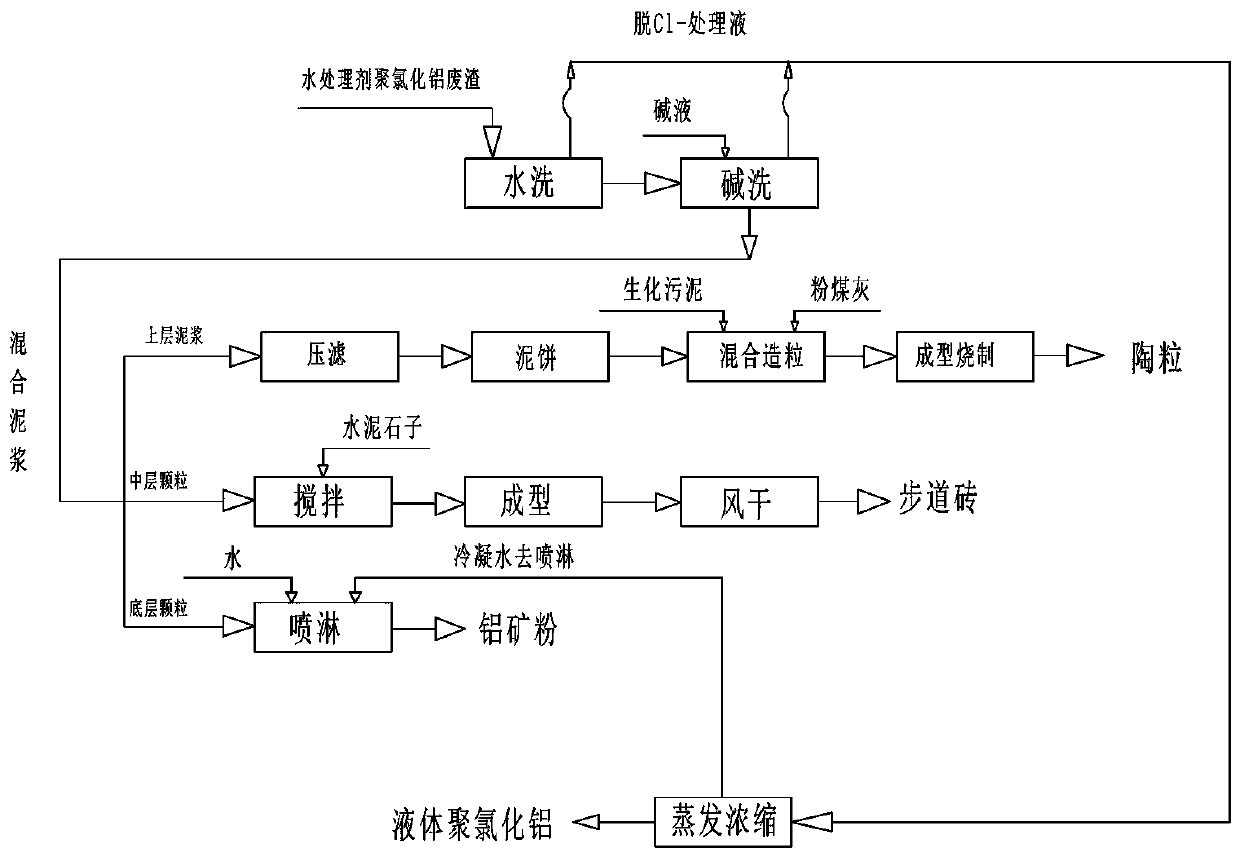

[0037] This embodiment provides a comprehensive utilization method of water treatment agent polyaluminum chloride waste residue, specifically, the flow chart of the method is as follows figure 1 As shown, it specifically includes the following steps:

[0038] DeCl - Firstly, the water treatment agent polyaluminum chloride waste slag is firstly washed with water to remove Cl - Treatment and base elution of Cl - treatment, get off Cl - Treatment liquid and mixed mud, wherein, the lye mass percentage concentration used when controlling described alkali washing is 10%, and described lye is sodium hydroxide solution; - Treatment and base elution of Cl - During processing, the water treatment agent polyaluminum chloride waste residue mud on the hydropulper is completely scattered until it can be left to stand for stratification; the decompression device is a hydropulper;

[0039] Static stratification The mixed mud is subjected to static sedimentation and stratification treatme...

Embodiment 2

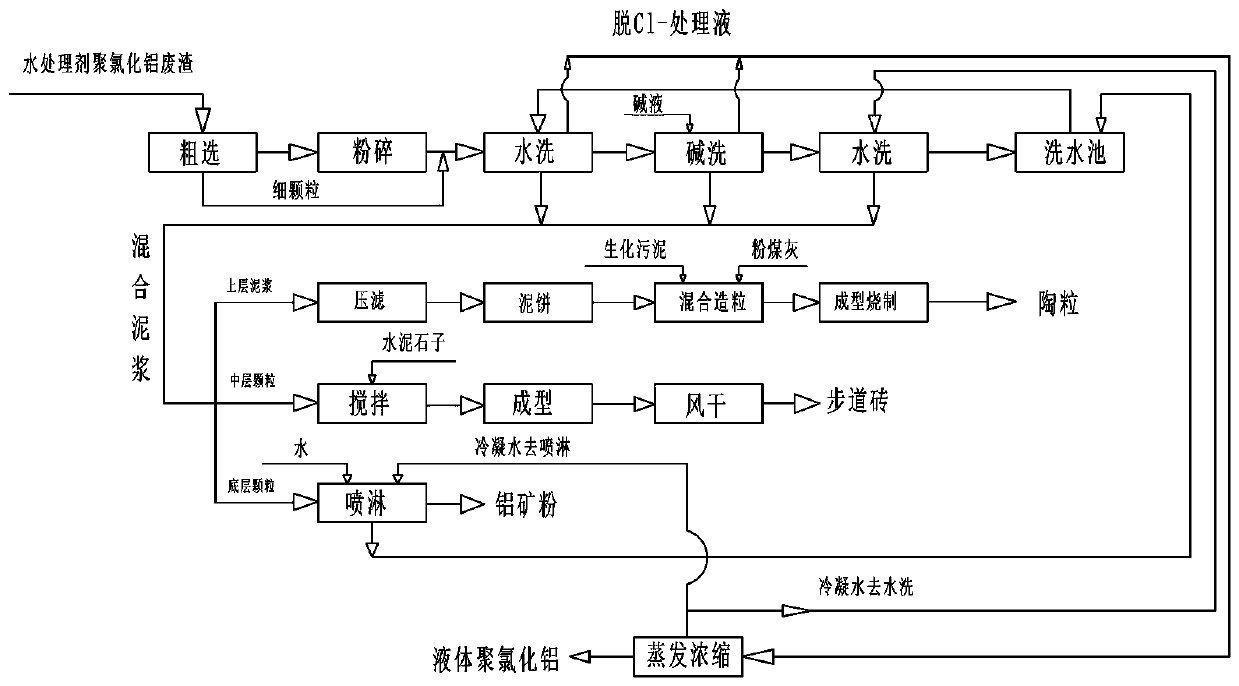

[0043] This embodiment provides a method for comprehensive utilization of water treatment agent polyaluminum chloride waste residue, the flow chart of the method is as follows figure 2 As shown, it specifically includes the following steps:

[0044] DeCl - Firstly, the water treatment agent polyaluminum chloride waste slag is roughly selected to obtain a water treatment agent polyaluminum chloride waste slag with a particle size greater than 15mm and a water treatment agent polyaluminum chloride waste slag with a particle size less than 15mm; using a differential speed pulverizer The water treatment agent polyaluminum chloride waste slag with a particle size greater than 15mm is crushed into a water treatment agent polyaluminum chloride waste slag with a particle size less than 15mm, and then the water treatment agent with a particle size of less than 15mm after rough selection and crushing is used The treatment agent polyaluminum chloride waste slag is washed with water for...

Embodiment 3

[0051] This embodiment provides a method for comprehensive utilization of water treatment agent polyaluminum chloride waste residue, the steps of which are roughly the same as those in Embodiment 2, except that in this embodiment: the mud cake is combined with the biochemical sludge and The mass-to-number ratio of the fly ash is 17:2:1.

[0052] The biochemical sludge used as the raw material for the preparation of ceramsite in the above-mentioned embodiments all comes from municipal sludge in Gongyi City. Since the sludge contains a large amount of organic matter, a large number of pores are formed after high-temperature carbonization, which is beneficial to the production of ceramsite. In addition, because the sludge itself has a certain calorific value, the amount of fuel used in the firing process is reduced, thereby realizing the comprehensive utilization method of polyaluminum chloride waste slag, a water treatment agent, which is convenient for local materials, and the g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com