Production method and production equipment for small piece of calcium carbide

A production method and production equipment technology, applied in the calcium carbide method PVC production field, can solve problems such as calcium carbide dust, achieve the effects of reducing pollution, reducing production costs, and improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

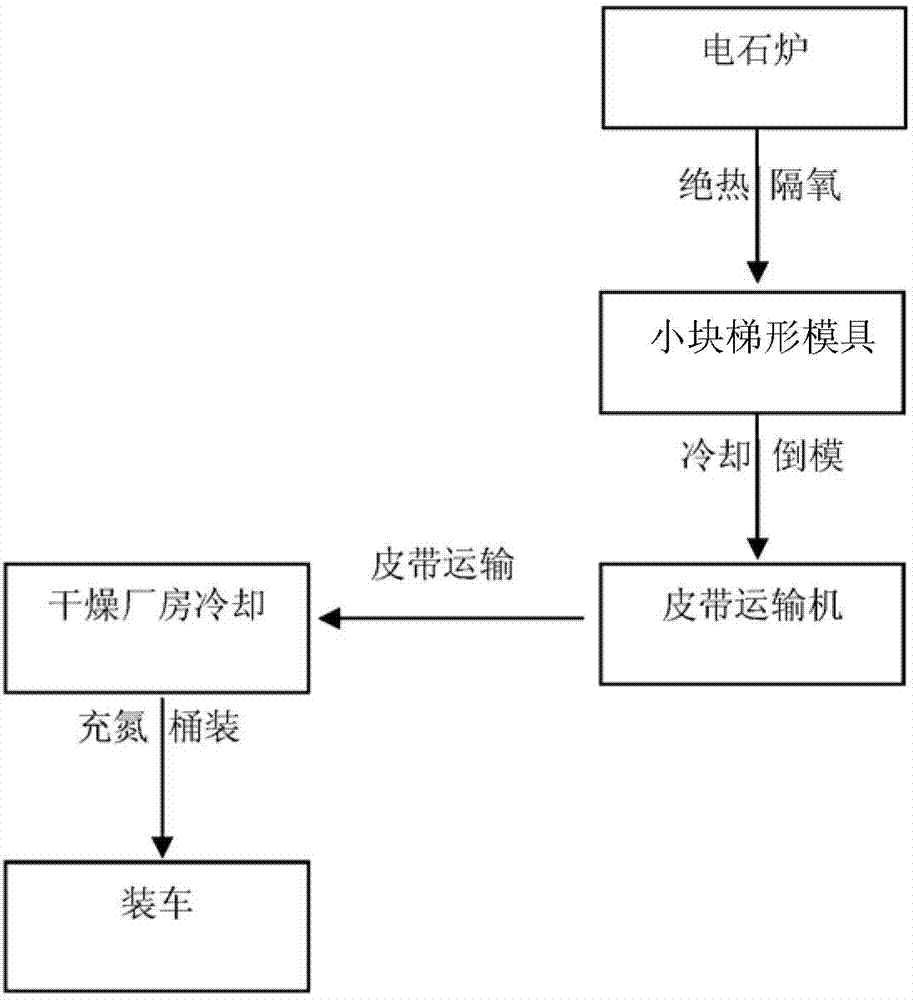

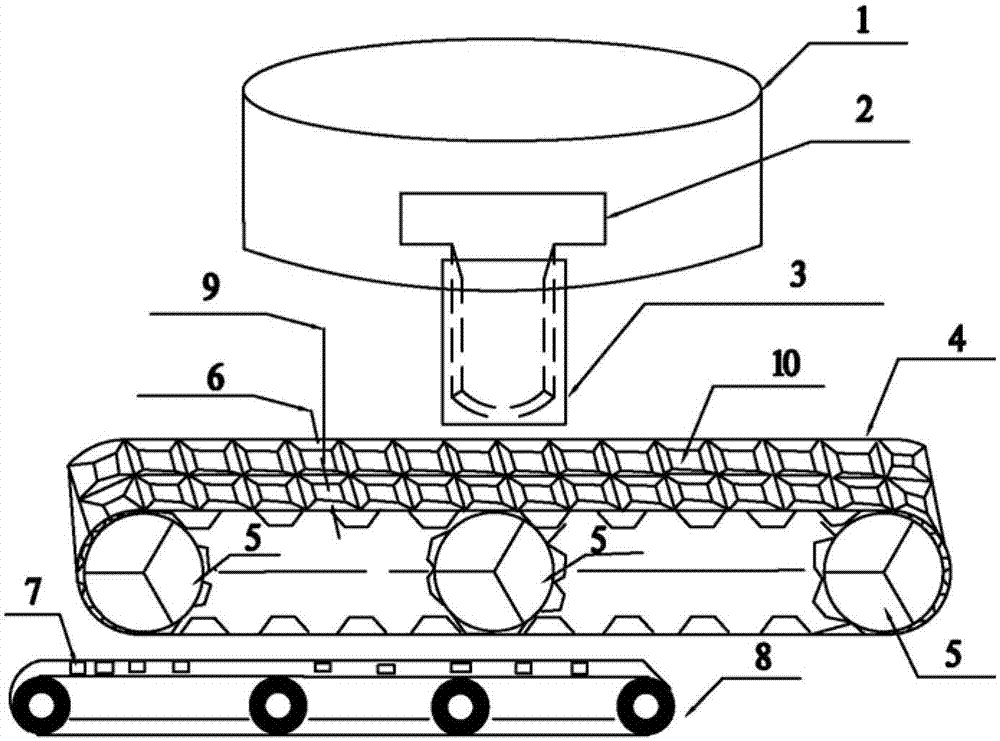

[0029] Such as figure 1 Shown, be the production process flowchart of small calcium carbide of the present invention, this method may further comprise the steps:

[0030] 1) Add mud balls (made from red clay in Dalat Banner, Inner Mongolia) with a water content of about 10% (w / w) in the calcium carbide furnace (the furnace hole is blocked), and the quality standard is to fix carbon > 82%, volatilize Anthracite 3500μΩM, particle size 5-25mm, maximum 30mm anthracite and quality standard CaO≥90%, MgO≤ 1.8%, SiO 2 ≤1.1%, quicklime with a particle size of 10-50mm;

[0031] 2) The anthracite and quicklime react under high temperature environment to generate calcium carbide slurry (carbon and calcium oxide undergo a chemical reaction to generate calcium carbide);

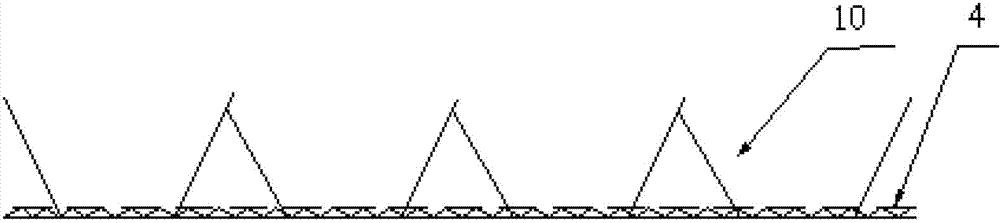

[0032] 3) The calcium carbide slurry is injected into a small trapezoidal mold under the condition of heat and oxygen insulation, and cooled to shape.

[0033] Wherein in the above step 2), the anthracite and quicklime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com