Unlimited compatible method for producing cement clinker by using carbide slag and limestone as raw material

A cement clinker and calcium carbide slag technology, applied in clinker production, cement production and other directions, can solve the problem of incompatible calcium raw materials using calcium carbide slag and limestone, etc., to achieve resource utilization, reduce fuel consumption, solve The effect of polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

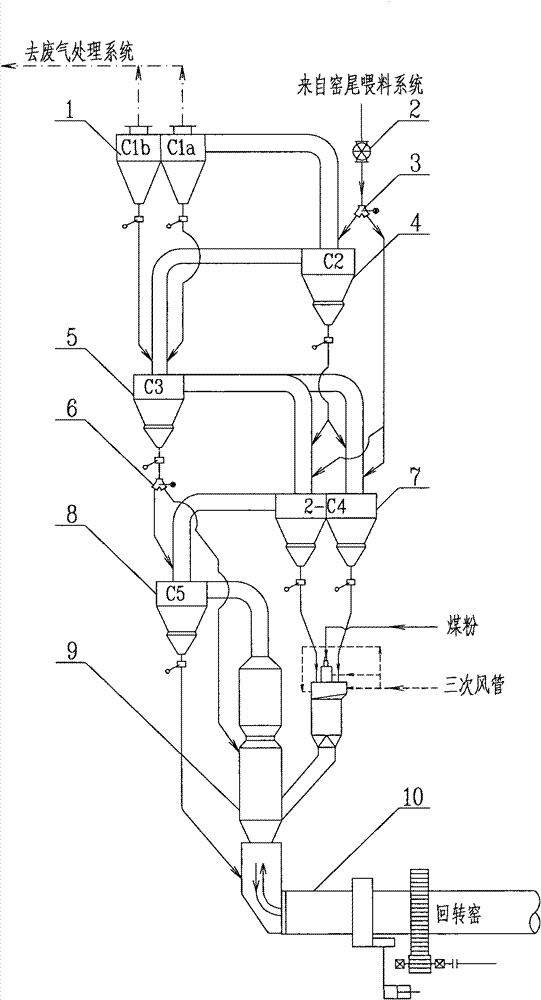

[0030] Refer to attached figure 1

[0031] The new dry cement carbide slag technology is also compatible with limestone as a calcareous raw material. Its working process includes:

[0032] (1) Feeding at the kiln tail

[0033] The raw material at the kiln tail first passes through the rotary feeder 2 and then enters the three-way valve 3, and the three-way valve is connected to two feeding pipes: one feeds into the air pipe between cyclone preheater 1 and cyclone preheater 4; The air duct between the cyclone preheater 5 and the cyclone preheater 7. The feeding pipe under the cyclone preheater 5 is provided with a material distribution valve 6 to divide the material into two parts, one part enters the air pipe between the cyclone preheater 7 and the cyclone preheater 8, and the other part enters the calciner 9 for mixing. middle of the room. When limestone is used as the calcareous raw material, the raw meal passes through the three-way valve 3 and then fed into the air duc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com