A kind of fluorine-containing color-fixing agent and preparation method thereof

A technology of color fixing agent and perfluorooctanol, used in the field of textile auxiliaries, can solve the problems of no effect on wet rubbing fastness, affecting the light fastness, and inability to dissolve silicone oil in the same way, and achieves wet rubbing and light fastness. Improved effect, low surface tension, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

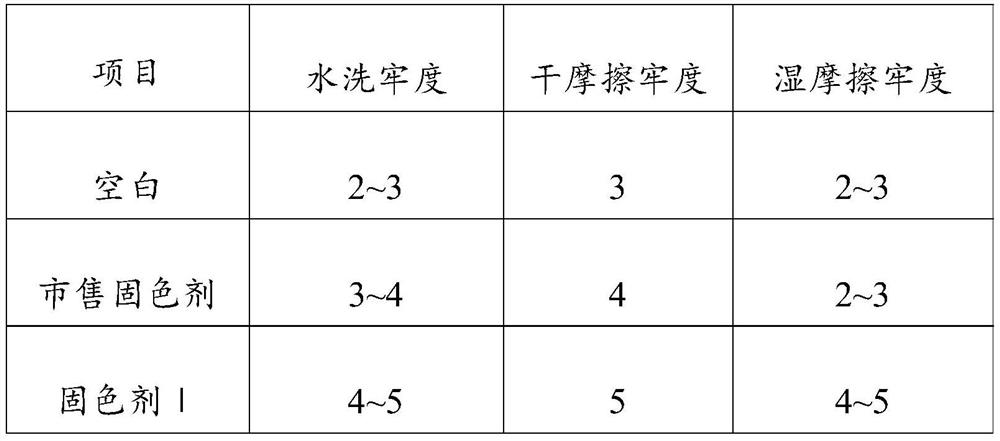

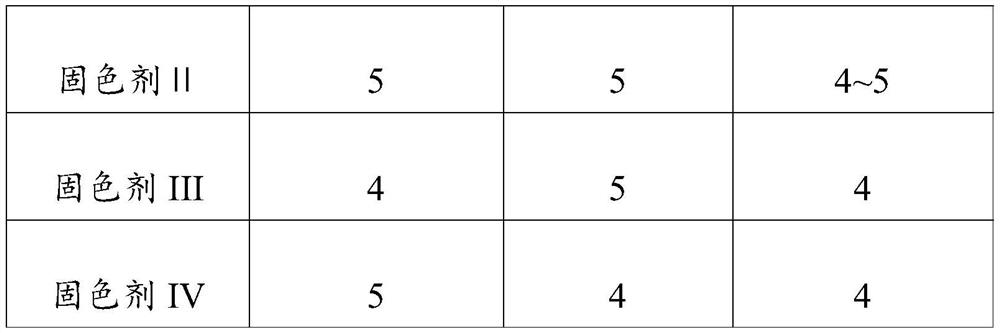

Examples

Embodiment 1

[0016] In a four-necked flask with a stirring cooling device, add 1 mol of perfluorooctyl alcohol, add 0.1 mol of triethylamine, and dropwise add acryloyl chloride with the same molar weight as perfluorooctyl alcohol from the separatory funnel, and the rate of addition makes the reaction temperature Keep the temperature below 20°C. After adding acryloyl chloride dropwise, react at a temperature below 20°C for 60 minutes to obtain a light-colored liquid, that is, allyl perfluorooctyl ether, which is ready for use.

[0017] Take by weighing 55 parts by weight of dimethyl diallyl ammonium chloride, 10 parts by weight of diallylamine hydrochloride, 2 parts by weight of allyl perfluorooctyl ether, and 32.5 parts by weight of deionized water are added to the In a four-necked flask with a stirring and heating device, heat up to 80-90°C and keep stirring for 30 minutes, add 5 parts by weight of ammonium persulfate solution with a concentration of 10%, and keep it at 80-90°C for 120 min...

Embodiment 2

[0019] In a four-necked flask with stirring heating and a water separator device, add 1mol perfluorooctyl alcohol, 0.1mol p-toluenesulfonic acid, 0.01mol hydroquinone, and acrylic acid of equal molar weight with perfluorooctyl alcohol, and heat up to 160~180℃, the calculated time from the water in the water separator is about 2~3hrs, until there is no more water in the water separator, stop heating, continue to stir to room temperature, and obtain light-colored perfluorooctyl alcohol acrylate, which is ready for use .

[0020] Take by weighing 60 parts by weight of dimethyl diallyl ammonium chloride, 15 parts by weight of diallyl sulfate, 4 parts by weight of perfluorooctyl alcohol acrylate, and 20 parts by weight of deionized water, add to the tank with stirring and heating In the four-necked flask of the device, stir and heat to 80-90°C, keep warm for 60min, add dropwise 10 parts by weight of sodium persulfate solution with a concentration of 10%, and initiate polymerization...

Embodiment 3

[0022] In a four-necked flask with stirring heating and a water separator device, add 1mol perfluorooctyl alcohol, 0.1mol p-toluenesulfonic acid, 0.01mol hydroquinone, and acrylic acid of equal molar weight with perfluorooctyl alcohol, and heat up to 160~180℃, the calculated time from the water in the water separator is about 2~3hrs, until there is no more water in the water separator, stop heating, continue to stir to room temperature, and obtain light-colored perfluorooctyl alcohol acrylate, which is ready for use .

[0023] Take by weighing 40 parts by weight of dimethyl diallyl ammonium chloride, 5 parts by weight of diallyl sulfate, 1 part by weight of perfluorooctyl acrylate, and 53 parts by weight of deionized water, and add to the In the four-necked flask of the device, stir and heat to 80-90°C, keep warm for 60min, add dropwise 10 parts by weight of sodium persulfate solution with a concentration of 10%, and initiate polymerization. After dropping the sodium persulfat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com