A kind of gluing equipment and gluing process of reflective material

A reflective material and gluing technology, applied in coatings, devices for coating liquid on the surface, etc., can solve problems such as color inconsistency, product appearance color and surface uniformity, etc., to ensure uniformity, improve washing and Brightness performance, the effect of solving poor appearance color and surface uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

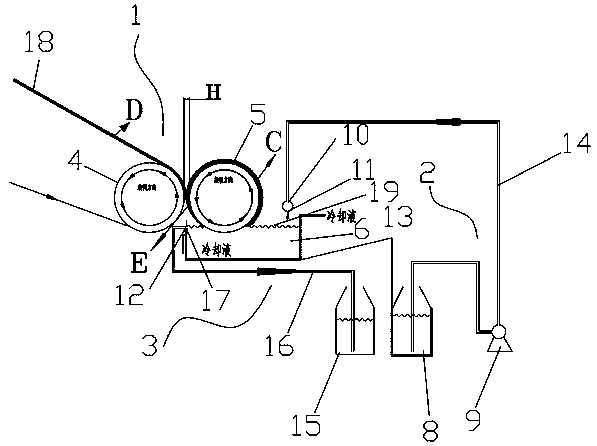

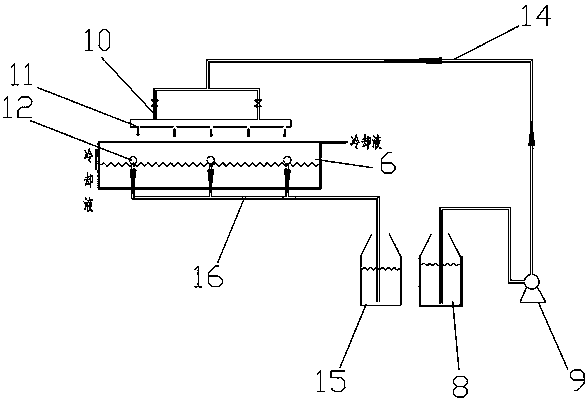

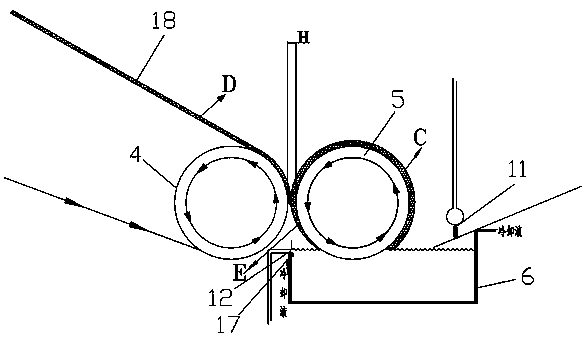

[0038] exist figure 1 , figure 2 , image 3 In the shown embodiment, a kind of gluing equipment of reflective material comprises:

[0039] Gluing system 1, a system for coating a uniform thin layer of glue on the surface of reflective material beads; Gluing system 1 includes a bottom roller 4, a rubber roller 5 and a trough 6, and the bottom roller 4 and the rubber roller 5 are arranged There is a gluing interval H, and there is a speed difference between the bottom roller 4 and the rubber roller 5; the speed difference between the bottom roller 4 and the rubber roller 5: when the two rollers rotate forward, the speed of the rubber roller is the speed of the bottom roller 110%~150%, the faster the speed of the rubber roller, the greater the amount of glue applied to the bead-planted film, and vice versa; the smaller the gap, the greater the amount of glue applied to the bead-planted film, and vice versa; when the two rollers are reversed, The speed of the belt roller is 50...

Embodiment 2

[0056] In embodiment 2, a kind of gluing equipment of reflective material comprises:

[0057] Gluing system 1, a system for coating a uniform thin layer of glue on the surface of reflective material beads; Gluing system 1 includes a bottom roller 4, a rubber roller 5 and a trough 6, and the bottom roller 4 and the rubber roller 5 are arranged There is a gluing interval H, and there is a speed difference between the bottom roller 4 and the rubber roller 5; the speed difference between the bottom roller 4 and the rubber roller 5: when the two rollers rotate forward, the speed of the rubber roller is the speed of the bottom roller 110%~150%, the faster the speed of the rubber roller, the greater the amount of glue applied to the beaded film, and vice versa; the smaller the gap, the greater the amount of glue applied to the beaded film, and vice versa. When the two rollers are reversed, the speed of the rubber roller is 50% to 150% of that of the bottom roller; the faster the spee...

Embodiment 3

[0073] exist Figure 5 In the shown embodiment 3, a kind of gluing process of reflective material comprises the following steps:

[0074] S1: The reflective material is a reflective cloth formed by the substrate and reflective beads arranged in a single layer on the substrate in the previous process;

[0075] S2: The reflective material is driven to move by the rotation of a bottom roller, and a non-contact gluing is carried out by the rotation of a rubber roller arranged inside the trough and in contact with the glue in the trough. The bottom roller and the There is a 0.5mm gluing interval between the rubber rollers, and there is a speed difference between the bottom roller and the rubber rollers; the two rollers are reversed, and the speed of the rubber rollers is 50% of the bottom roller; The faster the speed, the greater the amount of glue applied, but the amount of glue applied to the beaded film depends on the size of the gap; the smaller the gap, the smaller the amount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com