Method for recovering aluminum resources from water treatment agent polyaluminum chloride waste slag

A technology of polyaluminum chloride waste slag and water treatment agent, which is applied to the removal of solid waste, etc., and can solve the problems of high roasting temperature, energy consumption of pickling waste slag, and difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

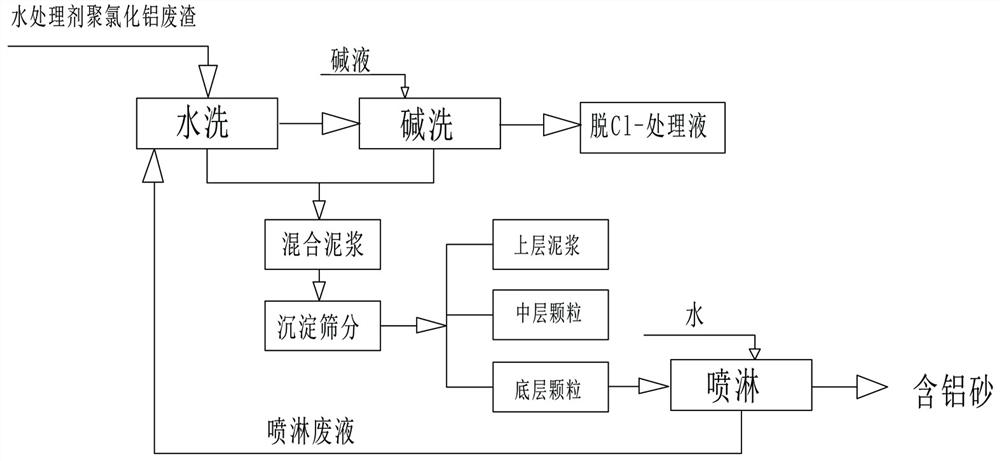

[0031] This embodiment provides a method for recycling aluminum resources from water treatment agent polyaluminum chloride waste slag, the specific flow chart is as follows figure 1 As shown, it specifically includes the following steps:

[0032] DeCl -Treatment The water treatment agent polyaluminum chloride waste slag is washed with water and alkaline washed with lye to obtain the de-Cl - Treatment fluid and mixed mud; among them, Cl in mixed mud - Concentration is 0.2%, water soluble Al 3+ Concentration is 0.4%, deCl - Al in the treatment solution 2 o 3 The mass percentage content is 5%;

[0033] Spray treatment The mixed mud is subjected to static sedimentation and sieving treatment to obtain the upper mud, middle layer particles and bottom layer particles, and the bottom layer particles are sprayed to obtain aluminum-containing sand and spray waste liquid, and the spray is recovered. Spraying the waste liquid and using the spraying waste liquid as a water source wh...

Embodiment 2

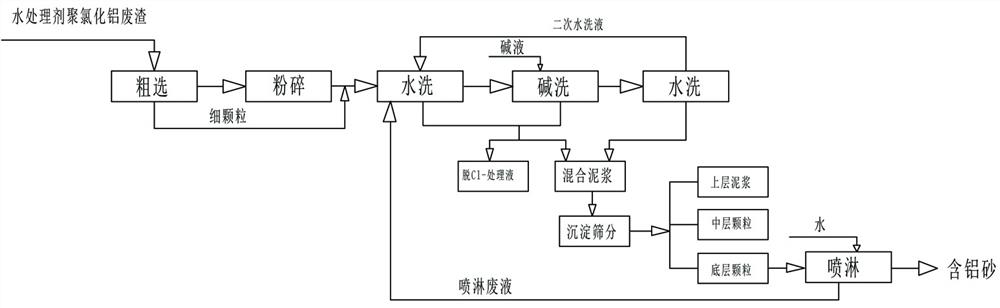

[0036] This embodiment provides a method for recycling aluminum resources from water treatment agent polyaluminum chloride waste slag, the specific flow chart is as follows figure 2 As shown, it specifically includes the following steps:

[0037] DeCl - Firstly, the waste slag of water treatment agent polyaluminum chloride is roughly selected to obtain the waste slag of water treatment agent polyaluminium chloride with a particle size greater than 15mm and the waste slag of water treatment agent polyaluminium chloride with a particle size of less than 15mm; The water treatment agent polyaluminum chloride waste slag with a particle size greater than 15 mm is crushed into a water treatment agent polyaluminum chloride waste slag with a particle size less than 15 mm;

[0038] Utilize the disintegration device to carry out the water treatment agent polyaluminum chloride waste slag of water treatment agent less than 15mm successively after coarse selection and through pulverizing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com