A kind of preparation method of silane modified moisture curing polyurethane hot melt adhesive

A polyurethane hot melt adhesive and silane modification technology, which is applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the limitation of the application field and development space of polyurethane melt adhesive products, and the inability of polyurethane hot melt adhesives Full response, low wettability of waterproof fabrics and other issues, to achieve the effect of improving washing and peeling resistance, improving van der Waals force, broadening application fields and development space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

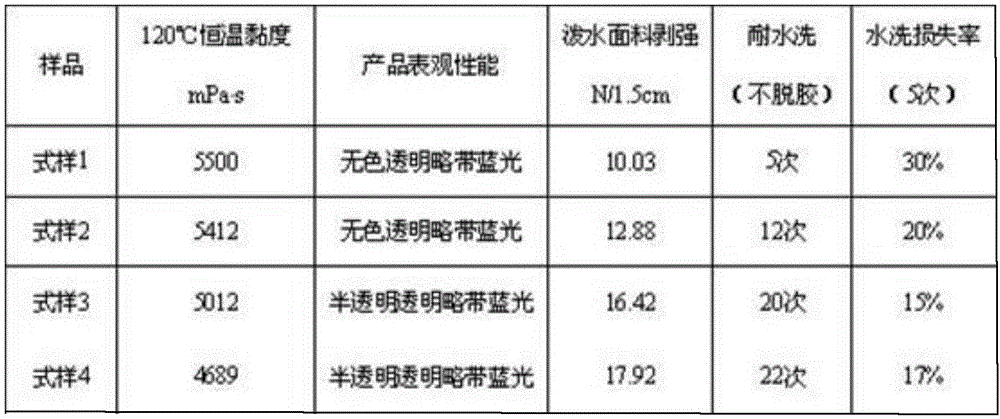

Embodiment 1

[0027] On the four-necked flask of 1000mL, a thermometer, a mechanical stirrer, a condenser and a nitrogen inlet tube are installed, and 160 g of polyoxypropylene diol (number-average molecular weight 1000) and polyethylene adipate diol (number-average molecular weight 4000) are weighed. ) 45.25g, acrylic resin 60g, antioxidant 10100.64g, sodium distyryl biphenyl disulfonate 0.8g, then heated to 120-140°C, stirred and mixed, and degassed under reduced pressure for 2h (absolute pressure 100Pa), cooled to 90°C; under nitrogen protection, add 62.5g of 4,4′-diphenylmethane diisocyanate, 0.1g of the compound of stannous octoate and bismorpholine diethyl ether in a mass ratio of 1:1, at 85-95°C Next, react for 45min. Under the protection of nitrogen, 2.4 g of 1,4-butanediol was added, and the reaction was stirred at 85-95° C. for 1 h at high speed. The above prepolymer was discharged under the protection of nitrogen, sealed and packaged, and aged at 85°C for 6 hours to obtain the p...

Embodiment 2

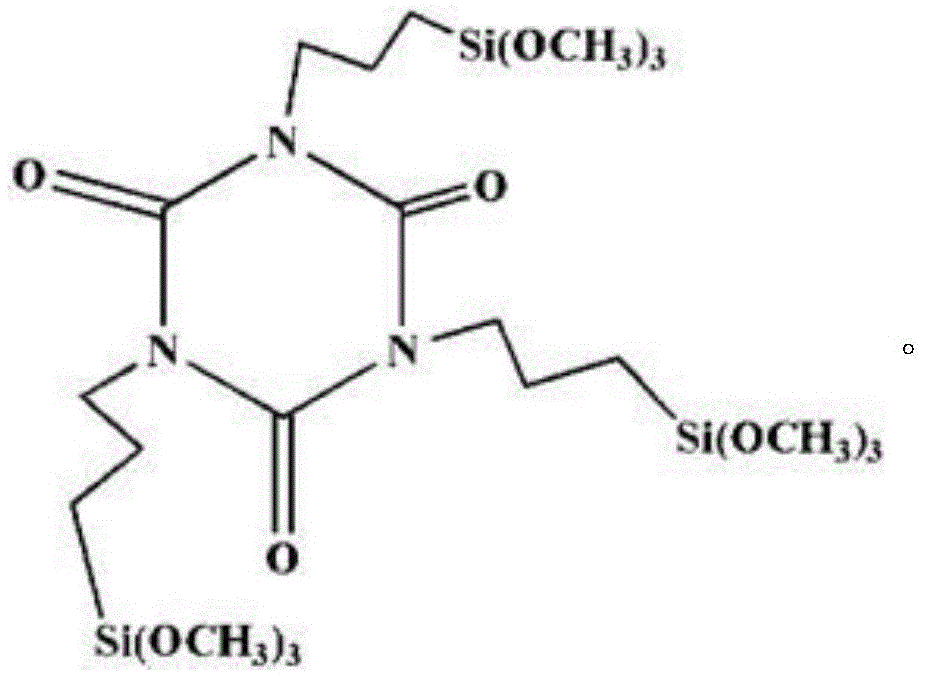

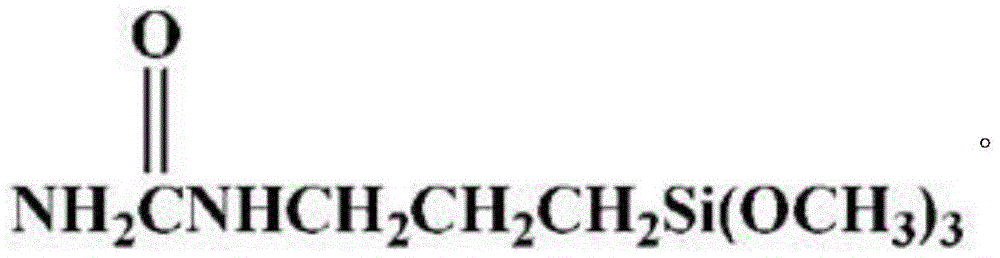

[0029] Install a thermometer, a mechanical stirrer, a condenser and a nitrogen inlet tube on a 1000mL four-necked flask, weigh polyethylene glycol (number average molecular weight 1250) 160g, polybutylene adipate diol (number average molecular weight 1000) 45.25g, phenolic resin 60g, antioxidant 10100.64g, triazineaminostilbene 0.8g, then heated to 120-140°C, stirred and mixed, and degassed under reduced pressure for 2 hours (absolute pressure 100Pa), cooled to 90°C; Under protection, add 62.5g of 2,4′-diphenylmethane diisocyanate, 0.1g of the compound of stannous octoate and bismorpholine diethyl ether in a mass ratio of 1:1, and react for 45min at 85-95°C . Under the protection of nitrogen, add 2.4g of 1.6-hexanediol, and 2g of 3-trimethoxysilylpropyl isocyanurate, stir and react at a high speed at 85-95°C for 1h and discharge the material, and put the above prepolymer under the protection of nitrogen Discharge and seal the package, and ripen at 85°C for 6 hours to obtain t...

Embodiment 3

[0031] On the 1000mL four-necked flask, a thermometer, a mechanical stirrer, a condenser and a nitrogen inlet tube are installed, and polytetrahydrofuran ether glycol (number-average molecular weight 2000) 160g, polyhexamethylene terephthalate glycol (number-average molecular weight 2000) are weighed 4000) 16g, C 5 -C 9 Petroleum resin 32g, antioxidant 10100.32g, phthalimide 0.08g, then heated to 120-140°C, stirred and mixed, while degassing under reduced pressure for 2h (absolute pressure 300Pa), cooled to 90°C; 16g of 2,2'-diphenylmethane diisocyanate, 0.08g of a compound of stannous octoate and bismorpholine diethyl ether in a mass ratio of 1:1, and reacted for 45 minutes at 85-95°C. Under the protection of nitrogen, add 1.6g of glycerin and 4g of 3-ureapropyltrimethoxysilane, stir and react at a high speed for 1h at 85-95°C and discharge the material, discharge the above prepolymer under the protection of nitrogen and seal the package. ℃ environment for 6 hours to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com