Modified aramid fiber and processing technology thereof

A technology for modifying aramid fiber and aramid fiber, which is applied in the direction of fiber type, fiber treatment, dry cleaning fiber products, etc. Thoroughness and other issues to achieve the effect of improving the washing effect, high strength and corrosion resistance, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

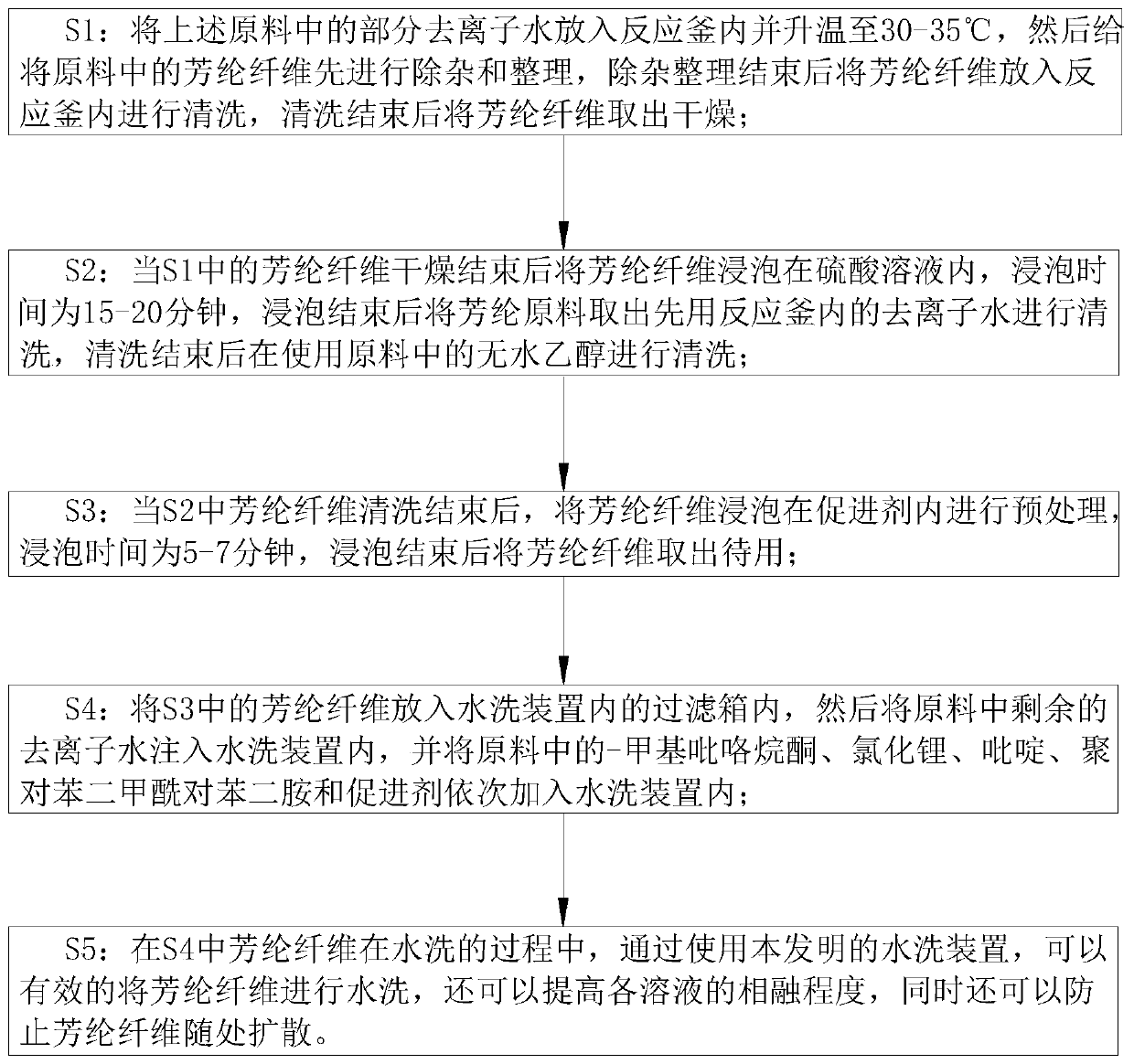

Method used

Image

Examples

Embodiment approach

[0036] As an embodiment of the present invention, the accelerator contains 20-25% of high-strength carbon fibers and high-strength boron fibers;

[0037] The high-strength carbon fiber contained in the accelerator is a new fiber material with high strength and high modulus fiber with a carbon content of more than 95%, and has higher strength and corrosion resistance. In the present invention, when aramid fiber and After the high-strength carbon fiber is mixed, the impact strength of the aramid fiber can be greatly improved, and the bending strength of the aramid fiber can also be effectively improved. The accelerator contains high-strength boron fiber, which is an inorganic fiber formed by depositing boron on the metal wire. And the breaking strength of boron fiber, after aramid fiber and boron fiber are mixed in the present invention can further improve the strength of modified aramid fiber, can also improve the modulus of elasticity of modified aramid fiber simultaneously, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com