Method for preparing ceramsite by utilizing water treatment agent polyaluminium chloride residue

A polyaluminum chloride waste slag and water treatment agent technology, applied in applications, household utensils, clay products, etc., can solve the problems that cannot be fully realized, and achieve the effect of simple steps, easy industrialization, and rough surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

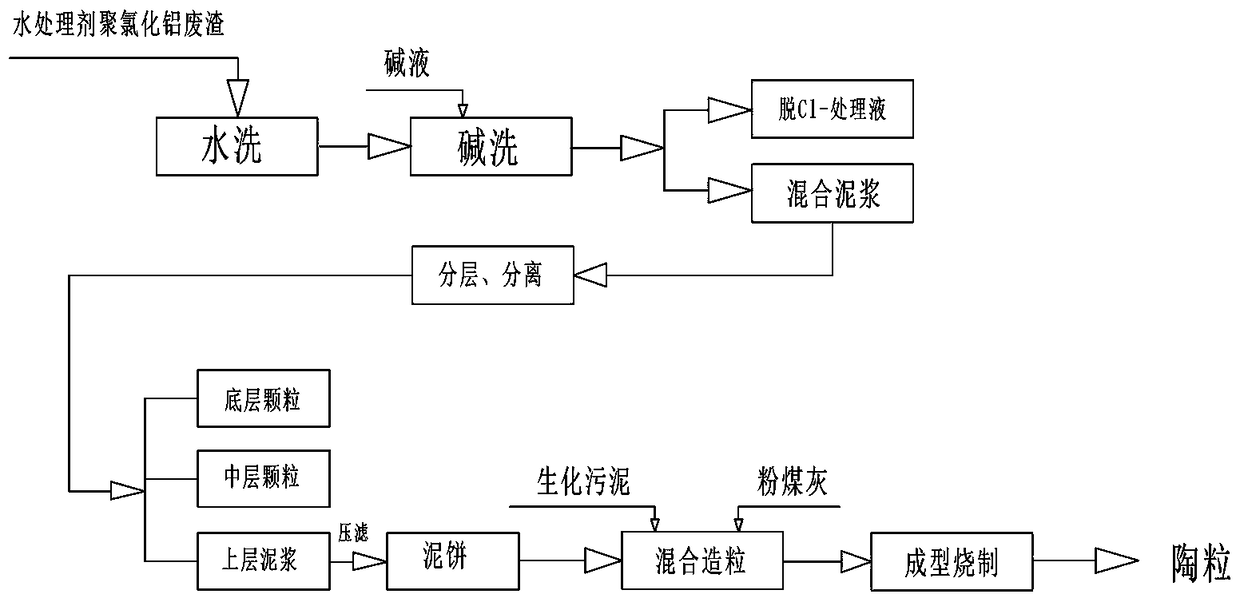

[0041] This embodiment provides a method for producing ceramsite by utilizing waste residue of water treatment agent polyaluminum chloride, such as figure 1 As shown, it specifically includes the following steps:

[0042] DeCl - Treatment Utilize the decomposer to carry out water elution of Cl - Treatment and use of lye for deCl - treatment, get off Cl - Treatment liquid and mixed mud; the mass percent concentration of the lye is 10%; the lye is a sodium hydroxide solution; the decompelling device is a hydropulper;

[0043] Static stratification The mixed mud is subjected to static sedimentation and stratification treatment to obtain a mixture containing bottom particles, middle layer particles and upper layer mud;

[0044] Waste slag separation: Separating the middle layer particles and the upper layer mud sequentially from the mixture containing the bottom layer particles, middle layer particles and upper layer mud; the upper layer mud is filtered to obtain a mud cake; ...

Embodiment 2

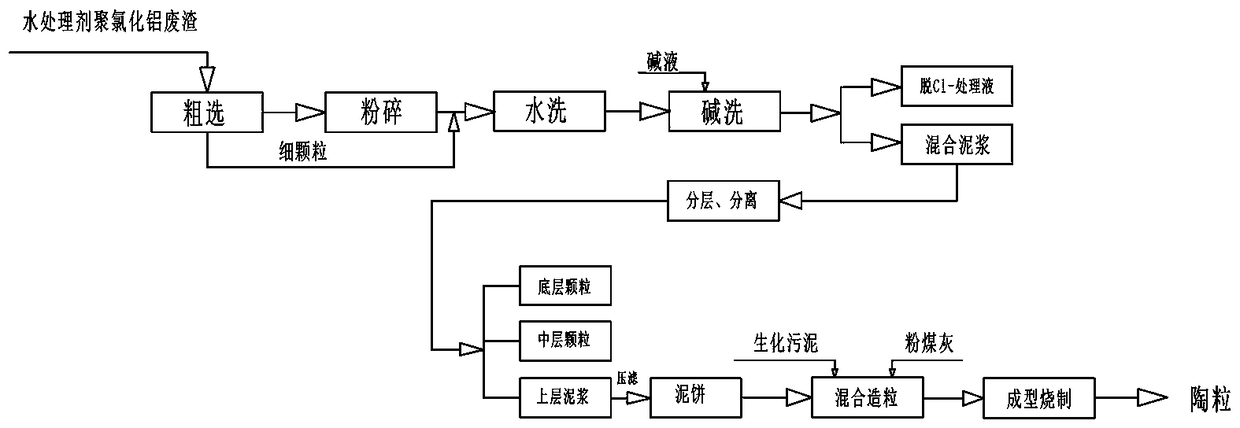

[0048] This embodiment provides a method for producing ceramsite by utilizing waste residue of water treatment agent polyaluminum chloride, such as figure 2 As shown, it specifically includes the following steps:

[0049] DeCl - Firstly, the water treatment agent polyaluminum chloride waste slag is roughly selected to obtain the water treatment agent polyaluminum chloride waste slag with a particle size greater than 15mm and the water treatment agent polyaluminum chloride waste slag with a particle size less than 15mm; The water treatment agent polyaluminum chloride waste slag with a particle size greater than 15mm is crushed into a water treatment agent polyaluminum chloride waste slag with a particle size less than 15mm, and then the water treatment with a particle size of less than 15mm after rough selection and crushing is performed using a decomposer. The waste slag of polyaluminum chloride was washed with water for the first time in sequence - Treatment, alkaline elut...

Embodiment 3

[0055] This embodiment provides a method for producing ceramsite by utilizing waste slag of polyaluminum chloride, a water treatment agent, the steps of which are roughly the same as those in Example 2, except that:

[0056] In this embodiment, the mass-number ratio of mud cake to biochemical sludge and fly ash is 85:10:5; the temperature for firing the pellets to be fired is 1300°C, and the firing time is 30min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com