High-silicon and high-copper aluminum alloy and preparation method thereof

A technology of aluminum alloy and aluminum alloy ingot casting, which is applied in the field of aluminum alloy to achieve the effect of high mechanical properties, uniform internal structure and elimination of internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention also provides a method for preparing a high-silicon and high-copper aluminum alloy, comprising the following steps:

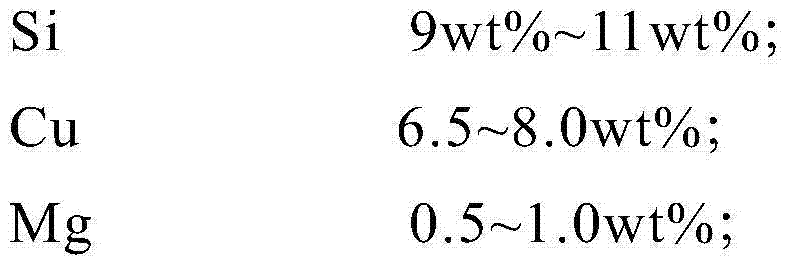

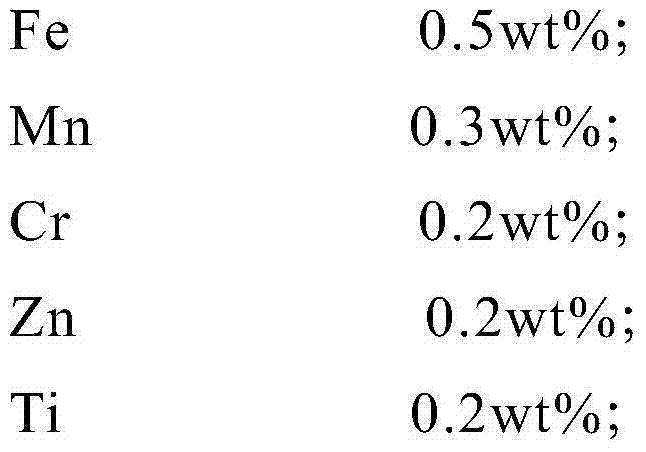

[0034] Cast aluminum alloy ingots with the following composition: 9wt%-11wt% Si, 6.5-8.0wt% Cu, 0.5-1.0wt% Mg, 0.5wt% Fe, 0.3wt% Mn, 0.2wt% Cr , the Zn of 0.2wt%, the Ti of 0.2wt%, the aluminum of balance;

[0035] hot extruding the aluminum alloy ingot;

[0036] Quenching the hot-extruded aluminum alloy ingot at a temperature of 480°C to 510°C;

[0037] The quenched aluminum alloy ingot is subjected to aging treatment, and the temperature of the aging treatment is 155-200°C.

[0038] According to the present invention, an aluminum alloy ingot is first cast, and the method for preparing the aluminum alloy ingot is not particularly limited in the present invention, and it can be a method well known to those skilled in the art.

[0039] After the aluminum alloy ingot is prepared, the aluminum alloy ingot is hot-extruded to make the...

Embodiment 1

[0045] An 800-ton induction furnace is used to cast aluminum alloy ingots. The composition of the aluminum alloy ingots is: 9wt% Si, 6.5wt% Cu, 0.5wt% Mg, 0.5wt% Fe, 0.3wt% Mn, 0.2wt% % Cr, 0.2wt% Zn, 0.2wt% Ti and the rest of the aluminum;

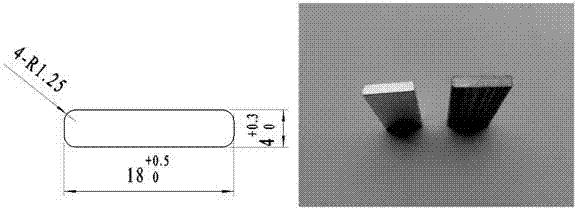

[0046]The aluminum alloy ingot is extruded in an 800-ton extrusion machine. The extrusion temperature is 390°C, the extrusion coefficient is 44.94, and the extrusion speed is 1.0m / min. The aluminum alloy ingot is extruded into a specification of EL4465 aluminum alloy profiles, such as figure 1 as shown, figure 1 It is the appearance and size drawing of EL4465 aluminum alloy profile;

[0047] Place the extruded aluminum alloy profiles in a salt bath furnace for quenching at a temperature of 490°C for 20 minutes;

[0048] The quenched aluminum alloy is stretched and straightened, and the head of the stretched and straightened aluminum alloy profile is cut to 400mm, and the tail is cut to 1m to sample, and then cut into two evenly; after ...

Embodiment 2

[0050] An 800-ton induction furnace is used to cast aluminum alloy ingots. The composition of the aluminum alloy ingots is: 11wt% Si, 7wt% Cu, 0.6wt% Mg, 0.5wt% Fe, 0.3wt% Mn, 0.2wt% The Cr of 0.2wt%, the Zn of 0.2wt%, the Ti of 0.2wt% and the aluminum of balance;

[0051] The aluminum alloy ingot is extruded in an 800-ton extrusion machine. The extrusion temperature is 400°C, the extrusion coefficient is 44.94, and the extrusion speed is 0.8m / min. The aluminum alloy ingot is extruded into a specification of EL4465 aluminum alloy profiles, such as figure 1 as shown, figure 1 It is the appearance and size drawing of EL4465 aluminum alloy profile;

[0052] Place the extruded aluminum alloy profiles in an air furnace for quenching at a temperature of 490°C for 30 minutes;

[0053] The quenched aluminum alloy is stretched and straightened, and the head of the stretched and straightened aluminum alloy profile is cut to 400mm, and the tail is cut to 1m to sample, and then cut int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com