Water spraying transport case

A transport box and water spray technology, applied in the field of transport, can solve the problems of transport loss, labor and labor, increase the mortality rate of living aquatic products, etc., and achieve the effect of improving shock absorption and better soaking effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

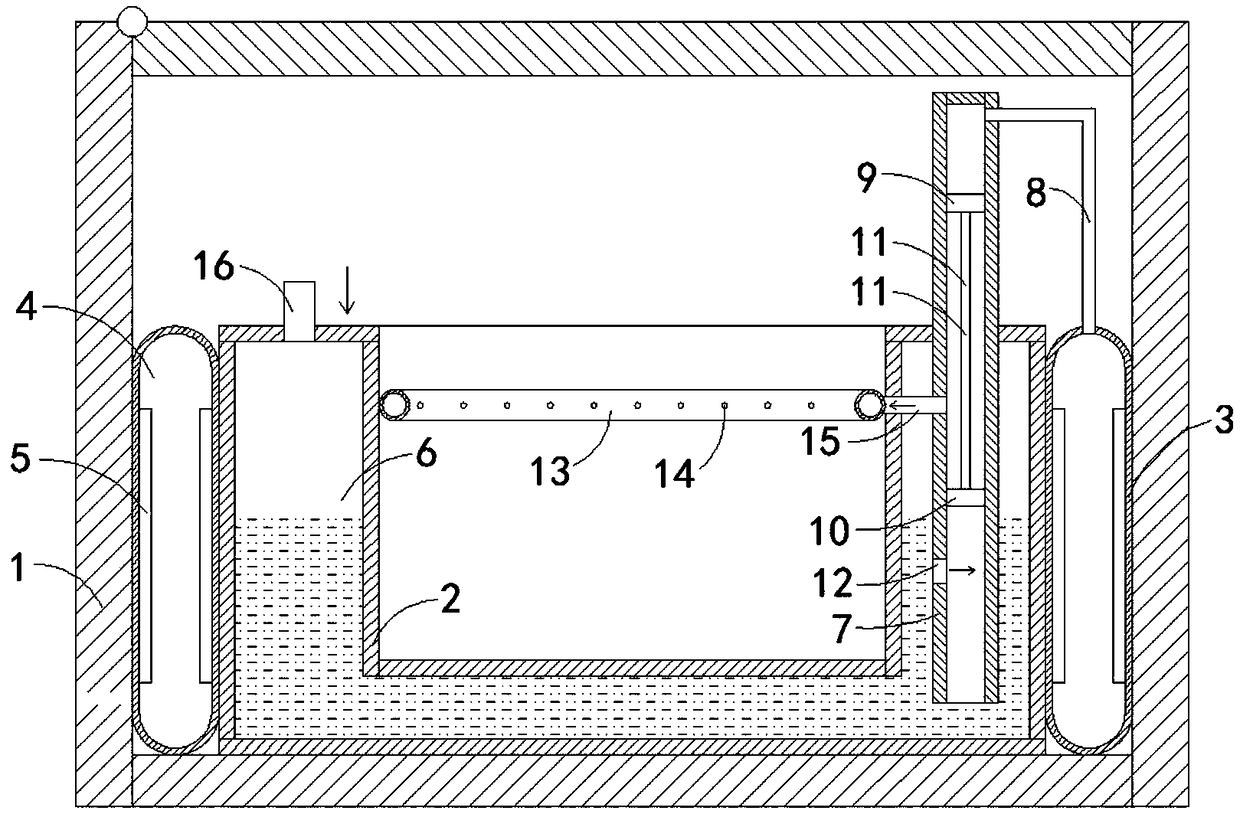

[0016] Such as figure 1 As shown, a water spraying transport box includes a fixed box 1, and a movable box 2 is arranged in the fixed box 1. The movable box 2 can move back and forth in the fixed box 1, and the front and rear ends of the movable box 2 pass through the first air bag 3 respectively. and the second air bag 4 is fixedly connected with the inner side wall of the fixed box 1, the first air bag 3 and the second air bag 4 all adopt elastic materials such as silica gel, etc., and the front and rear inner walls of the first air bag 3 and the second air bag 4 are all fixedly connected with The opposite sex repels the permanent magnet block 5, and two permanent magnet blocks 5 are facing to each other, and the recovery ability of the first air bag 3 and the second air bag 4 is improved by setting the permanent magnet block 5, and the surrounding side walls and the bottom side walls of the movable box 2 There are interconnected cavities 6 inside, and water is stored in the...

Embodiment 2

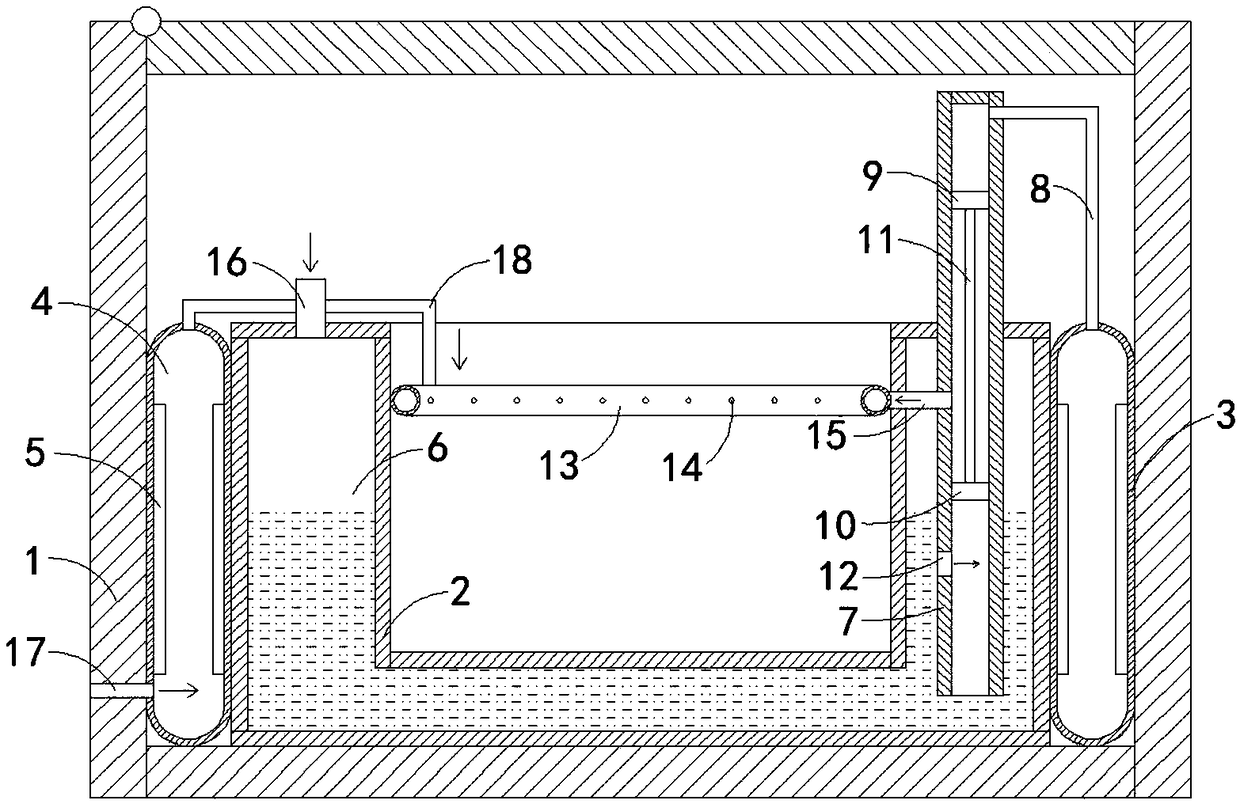

[0020] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that: the side wall of the second airbag 4 is fixedly connected with an air inlet pipe 17, and the end of the air inlet pipe 17 away from the second airbag 4 is set through the fixed box 1, and the air inlet pipe 17 A fourth one-way valve is fixedly connected inside (the allowed passage direction of the one-way valve is shown by the arrow in the figure), and the second air bag 4 communicates with the shower pipe 13 through the exhaust pipe 18, and the exhaust pipe 18 is fixedly connected with a single To the pressure valve (the allowable direction of the one-way valve is shown by the arrow in the figure).

[0021] In this embodiment, when the transport vehicle decelerates, the volume of the second airbag 4 will increase, and external air will be sucked in from the intake pipe 17. When the transport vehicle returns to normal driving, the second airbag 4 will be compressed. Under the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com