Water-based steel drum paint and preparation method thereof

A steel drum, water-based technology, applied in coatings, polyester coatings, etc., can solve the problems of reduced paint film performance, achieve good adhesion, improve wetting effect, and good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

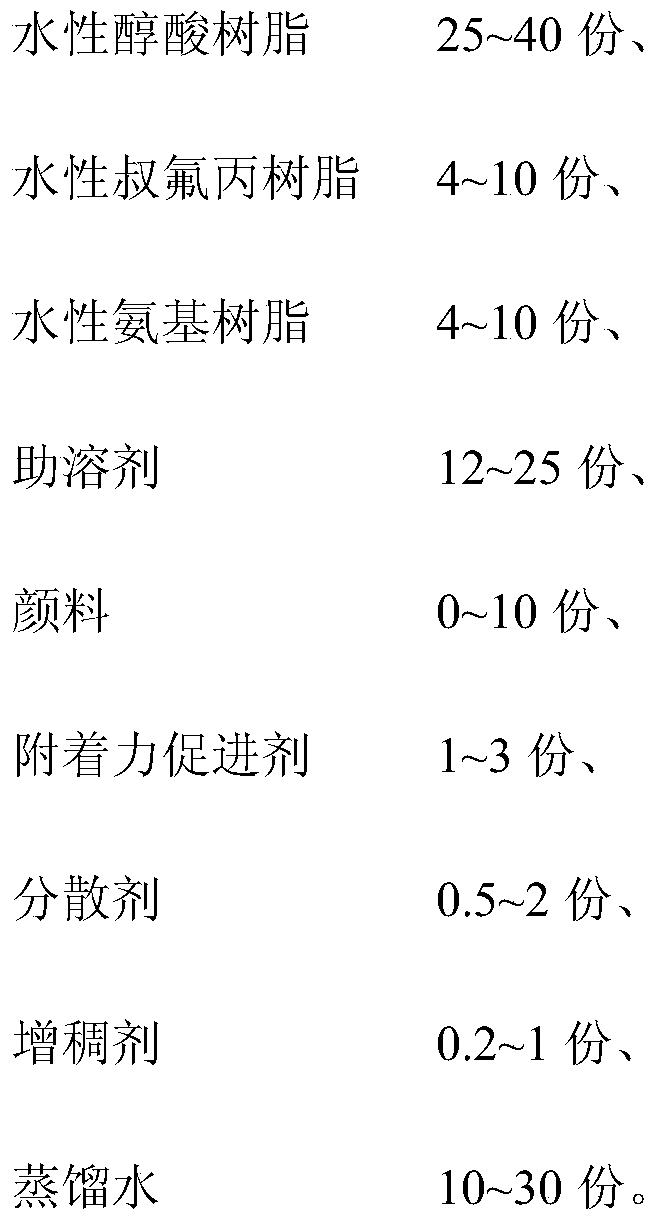

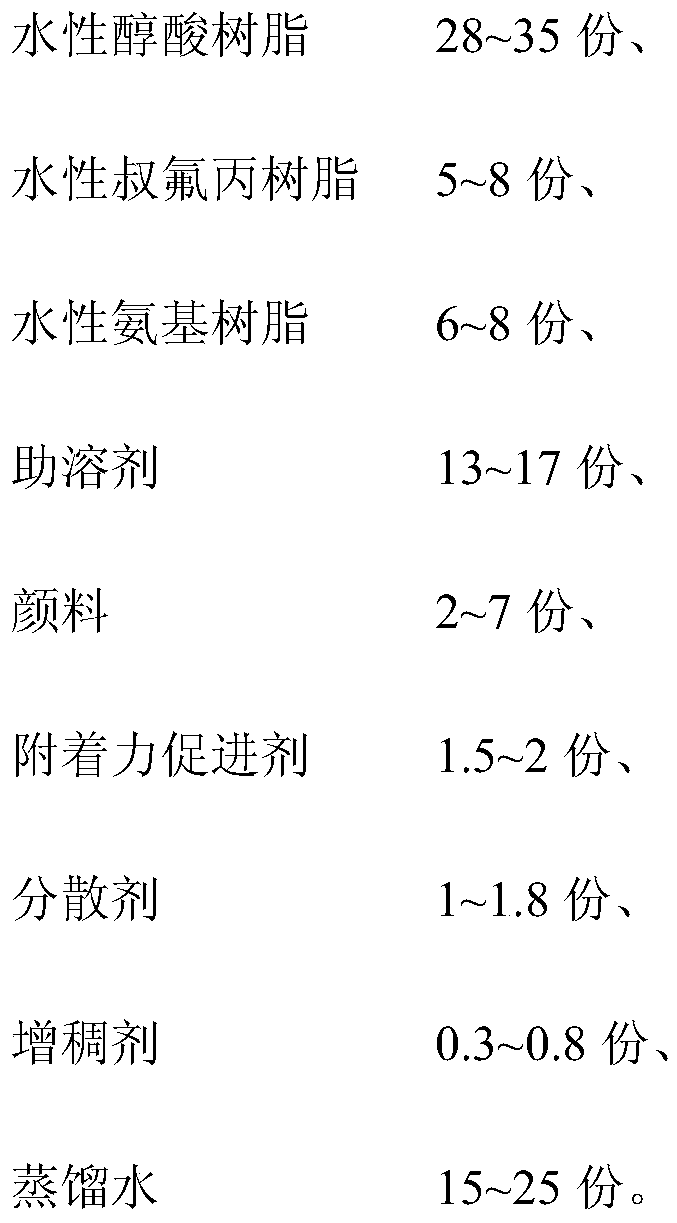

[0029] A kind of water-based steel bucket paint, comprises following raw material:

[0030] Water-based alkyd resin, water-based tertiary fluoroacrylic emulsion, water-based amino resin, cosolvent, pigment, adhesion promoter, dispersant, thickener and distilled water, of which,

[0031] The water-based alkyd resin is Foshan Tongde resin 27B,

[0032] The water-based tertiary fluoropropylene resin is Nantong Shengda Chemical SD-623,

[0033] The water-based amino resin is Allnex CYMEL-325 from the United States,

[0034] The auxiliary solvent is a mixture of ethylene glycol butyl ether, dipropylene glycol methyl ether and dipropylene glycol butyl ether in a weight ratio of 3:3:7,

[0035] The pigment is 2500-mesh iron red produced by LANXESS.

[0036] The adhesion promoter is Shanghai Nanbang Chemical NB-9997,

[0037] The dispersant is Matsuo 1252,

[0038] The thickener is Hemings R-299,

[0039] The parts by weight of each raw material are shown in Table 1 below;

[0...

Embodiment 2

[0046] A kind of water-based steel bucket paint, comprises following raw material:

[0047] Water-based alkyd resin, water-based tertiary fluoroacrylic emulsion, water-based amino resin, cosolvent, pigment, adhesion promoter, dispersant, thickener and distilled water, of which,

[0048] The co-solvent is a mixture of ethylene glycol butyl ether, dipropylene glycol methyl ether and dipropylene glycol butyl ether in a weight ratio of 5:5:7, and the manufacturer’s model or composition of the remaining raw materials is the same as in Example 1, and the parts by weight of each raw material are as follows As shown in Table 1;

[0049] The preparation method comprises the following steps:

[0050] (1) According to the dosage recorded in Table 1, take water-based alkyd resin, water-based tertiary fluoropropylene resin, water-based amino resin, cosolvent, pigment, adhesion promoter, dispersant, thickener, distilled water respectively;

[0051] (2) After mixing and stirring 16 parts o...

Embodiment 3

[0055] A kind of water-based steel bucket paint, comprises following raw material:

[0056] Water-based alkyd resin, water-based tertiary fluoroacrylic emulsion, water-based amino resin, cosolvent, pigment, adhesion promoter, dispersant, thickener and distilled water, of which,

[0057] The co-solvent is a mixture of ethylene glycol butyl ether, dipropylene glycol methyl ether and dipropylene glycol butyl ether with a weight ratio of 4:4:7. The manufacturer’s model or composition of the remaining raw materials is the same as in Example 1, and the parts by weight of each raw material are as follows As shown in Table 1;

[0058] The preparation method comprises the following steps:

[0059](1) According to the dosage recorded in Table 1, take water-based alkyd resin, water-based tertiary fluoropropylene resin, water-based amino resin, cosolvent, pigment, adhesion promoter, dispersant, thickener, distilled water respectively;

[0060] (2) After mixing and stirring 10 parts of w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com