Manufacturing method and production line for thermoset carbon fiber plate for wind vane

A carbon fiber board and wind blade technology, applied in the field of wind power generation, can solve problems such as heavy weight, achieve the effect of clean environment, reduce production cost, and solve environmental pollution of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

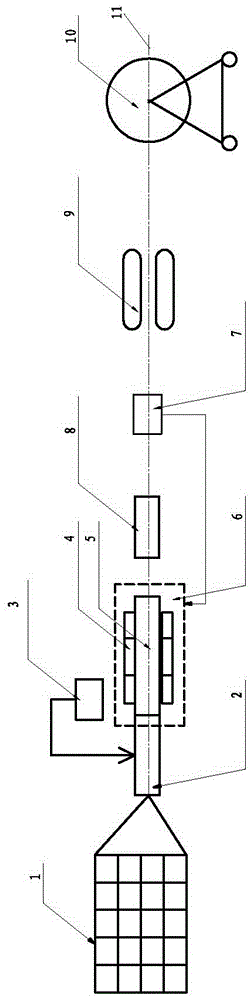

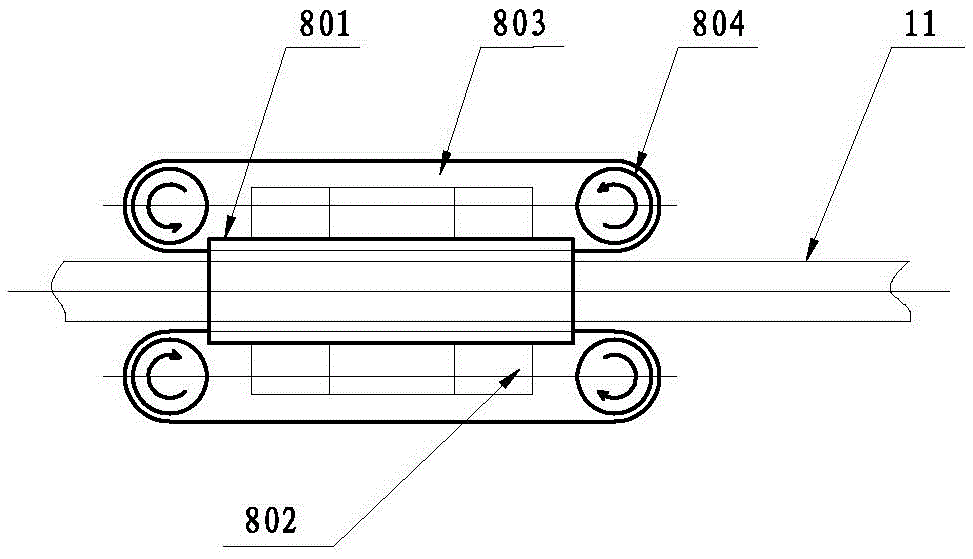

[0051] Such as Figure 1-4 shown.

[0052] A method for manufacturing a thermosetting carbon fiber plate for wind blades, such as figure 1 As shown, it includes the following steps:

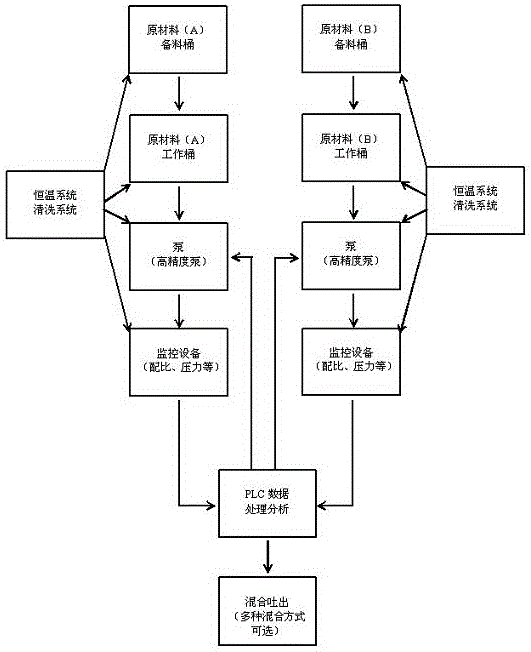

[0053] Firstly, the carbon fiber is introduced from the tension creel 1 into the sealing and dipping box 2 for impregnation. The sealing and dipping box has a fully automatic feeding device 3 that automatically injects glue according to the detected pressure and glue position in the sealing and dipping box. , to ensure that the carbon fiber is fully impregnated under the set pressure; the pressure in the sealed dipping box is 0.01-3.0MPA. The working principle of fully automatic feeding device 3 is as follows image 3 As shown, the mixing ratio of epoxy, polyurethane and thermoplastic resin is 100:20 to 100:200, and the feeding range is 0.01L~20.0L;

[0054] Secondly, the impregnated carbon fiber enters the curing mold 5 for three-stage heating and curing to obtain a carbon fiber plate, and a...

Embodiment 2

[0058] Such as Figure 1-4 shown.

[0059] A production line for manufacturing thermosetting carbon fiber panels for wind blades, such as figure 1 As shown, it includes:

[0060] A tension creel 1, the tension creel 1 is used to provide a continuous flow of raw materials for the manufacture of carbon fiber panels;

[0061] A sealed dipping box 2, the sealed dipping box 2 is used for dipping the carbon fibers drawn from the tension creel 1, so that the surface of the carbon fiber filaments is bonded with thermosetting adhesive, laying the foundation for the next step of thermosetting molding; By controlling the amount of glue in the sealed dipping box 2, the internal pressure is controlled between 0.01-3.0MPA;

[0062] A fully automatic feeding device 3 (according to image 3 self-designed and manufactured according to the requirements), the fully automatic feeding device 3 is used to inject the stirred heat-curing glue into the sealing dipping box 2, and realize the heat-c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com