Tobacco stem classifying and processing method

A processing method and technology for tobacco stems, which are applied in the field of tobacco stem processing in tobacco production and processing, can solve the problems of uneven cut stems after cutting, too many stems, increased consumption, etc., and achieve uniform moisture content and silking rate of cut stems. High, improve the effect of puffing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

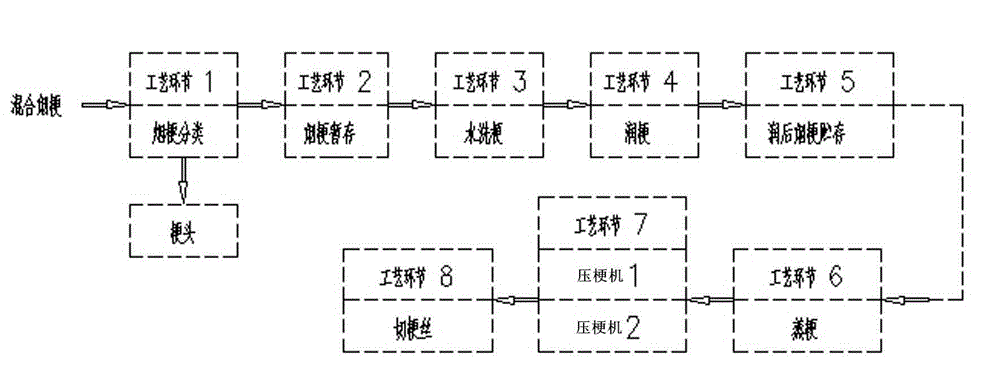

[0016] Such as figure 1 Shown, the steps of tobacco stem classification processing method are as follows:

[0017] (1) After feeding the tobacco stems, first enter the tobacco stem classification link. Due to the different physical properties of tobacco stems of different grades, the tobacco stems are classified according to the diameter of the tobacco stems (process step 1), and the stem heads of the tobacco stems with heavier wood gas are removed. The method of classifying the tobacco stems can be as follows One or a combination of methods in spectral imaging classification, multi-stage vibrating screening classification, winnowing classification:

[0018] 1) Spectrum camera classification: first thin the tobacco stems to a single layer, then use a high-speed camera device to capture images and perform image analysis to identify tobacco stems with different diameters, and then use compressed air to blow the tobacco stems. Tobacco stems are sprayed to different positions to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com