Humidifying device capable of controlling water quantity for non-woven fabric processing

A technology of non-woven fabrics and water volume, which is applied in the processing of textile materials, equipment configuration, textiles and papermaking, and textile materials. Better effect, even wetting, improved quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

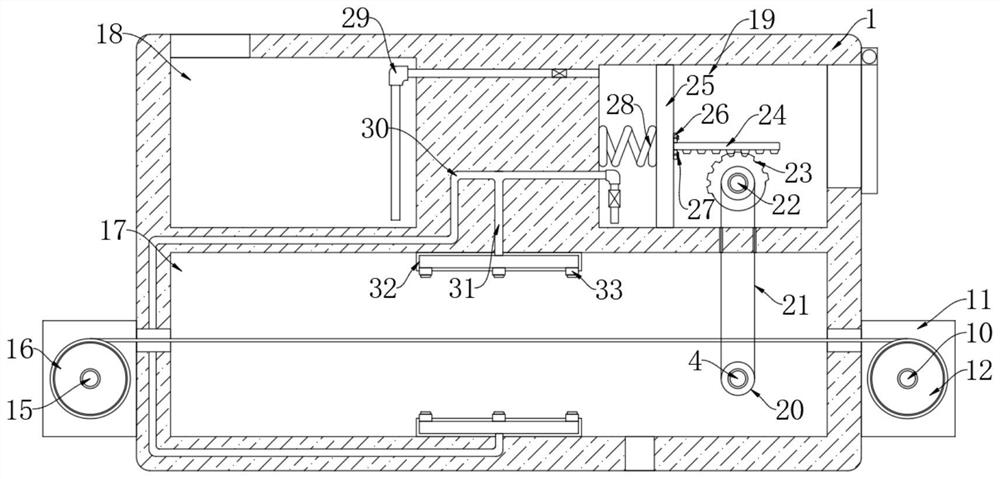

[0021] refer to Figure 1-2 , a wetting device for non-woven fabric processing that can control the amount of water, including a box body 1, a spray chamber 17 is arranged in the box body 1, a water storage chamber 18 and a rotating chamber 19 are arranged in the box body 1 from left to right , the water storage chamber 18 and the rotating chamber 19 are all located above the spraying chamber 17, the inner top of the water storage chamber 18 is provided with a water inlet communicating with the outside world, and the right side inner wall of the rotating chamber 19 is provided with an opening communicating with the outside world, on the opening Sliding doors are installed;

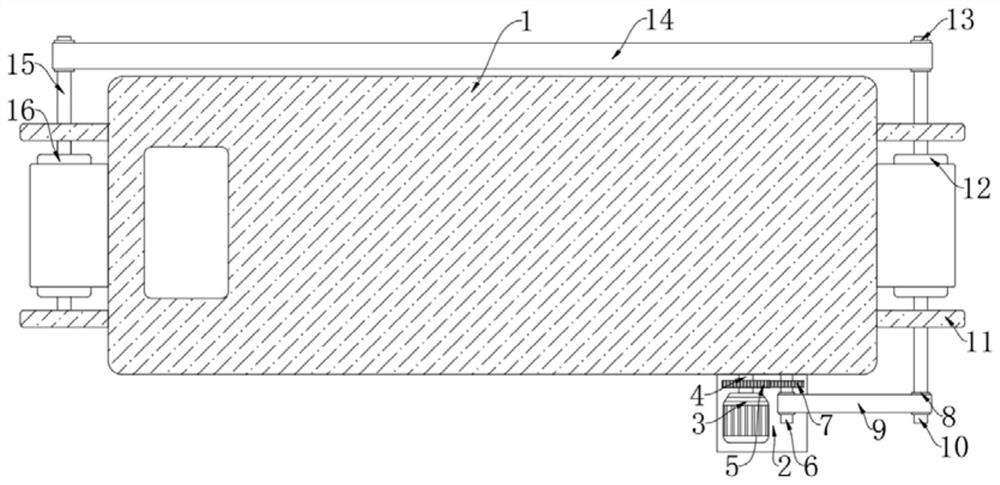

[0022] Trigger mechanism, the trigger mechanism includes a mounting block 2 fixedly connected to the front side of the box body 1, a motor 3 is installed on the upper end of the mounting block 2, and the end of the output shaft of the motor 3 is fixedly connected to the first rotating rod 4, and the first ...

Embodiment 2

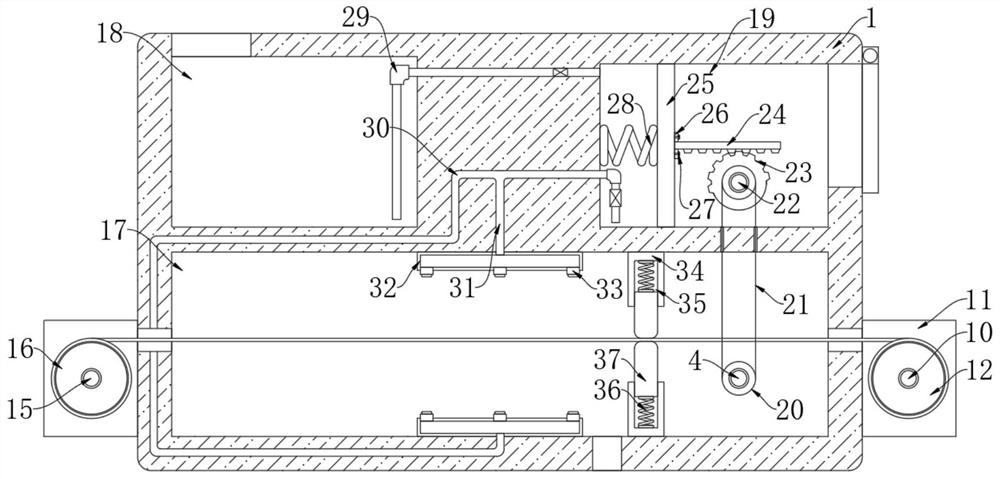

[0030] refer to image 3 The difference between this embodiment and Embodiment 1 is that the upper and lower inner walls of the spray chamber 17 are fixedly connected with fixed blocks 34, and the adjacent ends of the two fixed blocks 34 are provided with telescopic slots 35, and the two telescopic slots 35 are provided with block 37 for moving up and down, and the two block 37 and the inner wall of the corresponding telescopic groove 35 away from the notch are elastically connected by the second spring 36, and the non-woven fabric is connected by the two block 37. Squeeze to make the moisture in the non-woven fabric more uniform.

[0031] In this embodiment, the two resisting blocks 37 press the non-woven fabric through the elastic action of the corresponding second spring 36. When the non-woven fabric is wet, some parts may still have more water, and some parts may still be wet. In the case of less water, at this time, by squeezing the non-woven fabric, the excess water in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com