Modified nonmetallic reclaimed material of printed circuit board and preparation method thereof

A technology of non-metallic recycled materials and printed circuit boards, which is applied in chemical recycling, chemical instruments and methods, fibrous fillers, etc., can solve the problem of poor dispersion of PCB non-metallic recycled materials, inability to effectively improve the blending application effect, and interphase Low adhesion and other problems, to achieve the effect of improving the use value, improving physical and mechanical properties, and thickening the phase interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

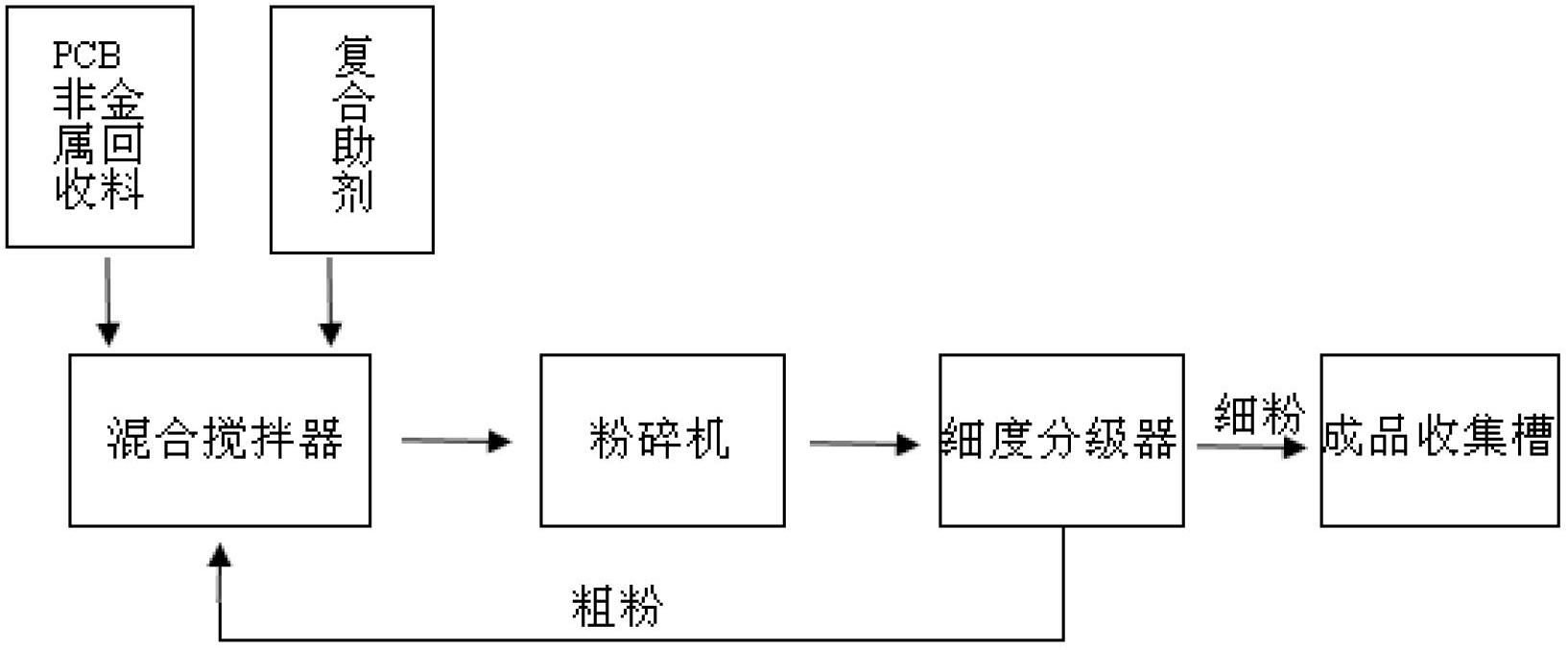

Method used

Image

Examples

Embodiment 1

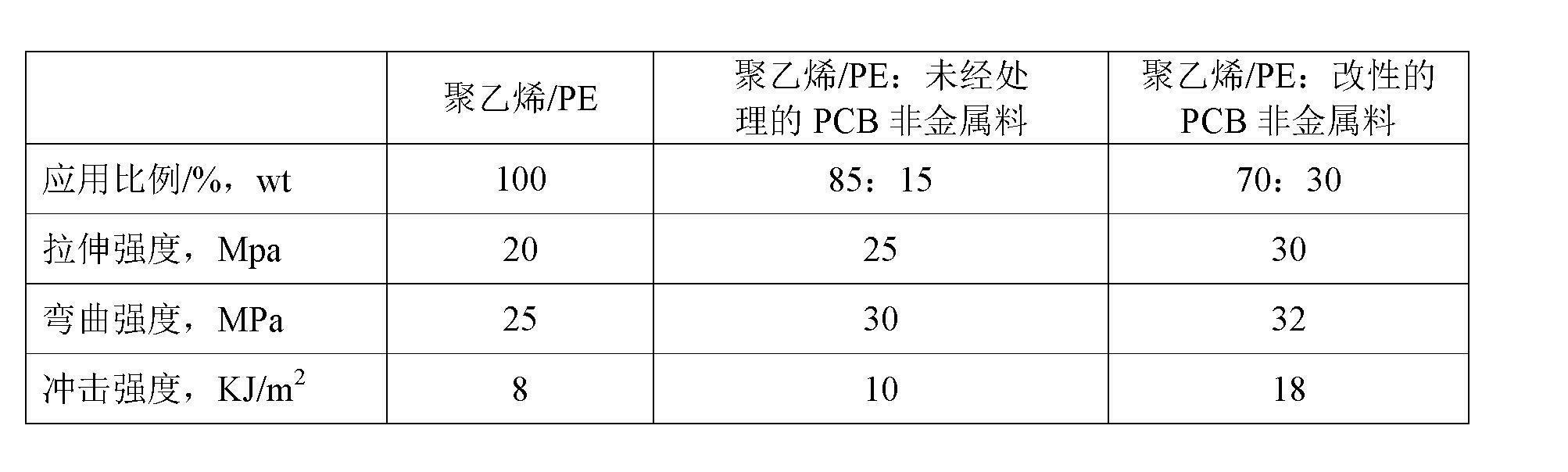

[0029] Example 1 Modification of PCB non-metallic recycled materials applied to polyethylene / PE profiles and processing of composite materials

[0030] 1000Kg of PCB non-metallic recycled material with a particle size of 200μm-500μm separated from the metal-rich body is sent to the mixer, and compound additives are added according to the following ratio:

[0031] Grinding aid: Sodium lignosulfonate 10 Kg (the dosage of sodium lignosulfonate is 1% of the weight of PCB non-metallic recycled materials);

[0032] Active dispersant: glyceryl monostearate (Wuhan Jinnuo Chemical Co., Ltd.) 10 Kg, zinc stearate (Nantong Huizhi Chemical Co., Ltd.) 5Kg (the amount of active dispersant is 1.5% of the weight of PCB non-metallic recycled materials );

[0033] Compatibility modifier: polyethylene oligomer (produced by Jiande Huachen Chemical Co., Ltd., white powder, softening point ℃: 55 ℃, viscosity CPS 140 ℃ 40MAX, penetration 25 ℃: 3~8, average Molecular weight: 2000-5000, thermal weig...

Embodiment 2

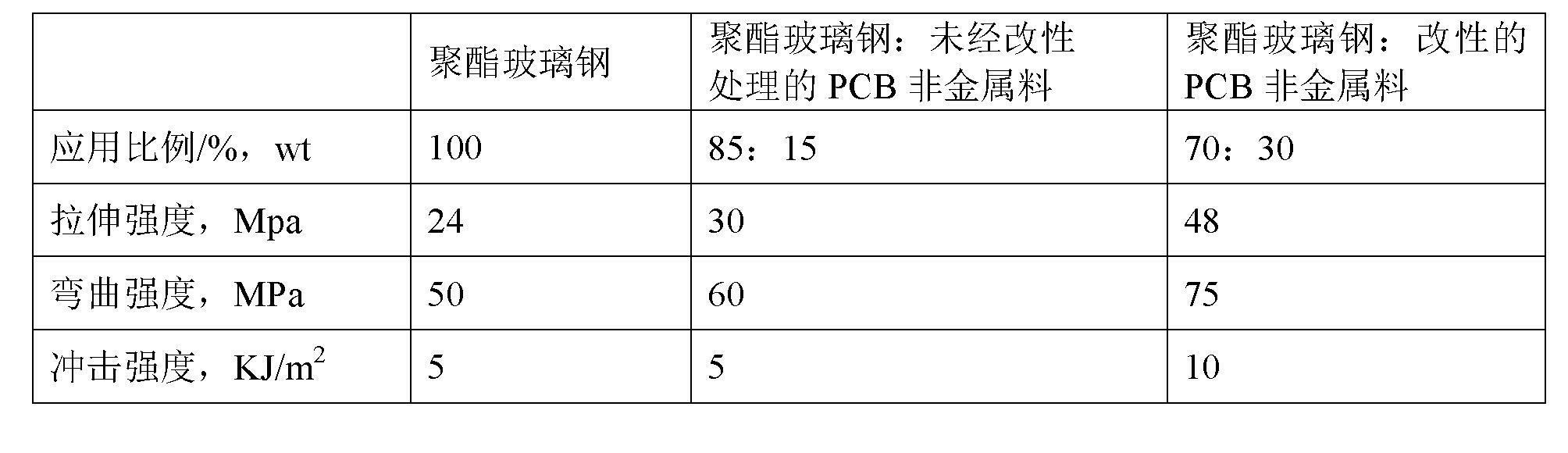

[0039] Example 2: Compatibility treatment of PCB non-metallic recycled materials applied to polyester FRP profiles and processing of composite materials

[0040] 1000Kg of PCB non-metallic recycled material with a particle size of 200μm-500μm separated from the metal-rich body is sent to the mixer, and compound additives are added according to the following ratio:

[0041] Grinding aid: 10 Kg of sodium silicate (the dosage of the grinding aid sodium silicate is 1% of the weight of PCB non-metallic recycled materials);

[0042] Active dispersant: sodium tripolyphosphate 10Kg (the amount of active dispersant sodium tripolyphosphate is 1% of the weight of PCB non-metallic recycled materials);

[0043] Compatibility modifier: vinyl acetate 30Kg, unsaturated polyester resin (Shenzhen Yoshida Chemical Co., Ltd., 191#) 10Kg (the amount of compatibilization modifier is 4% of the weight of PCB non-metallic recycled materials).

[0044] After uniform stirring, the material is discharge...

Embodiment 3

[0049] Example 3: Compatibility treatment of PCB non-metallic recycled materials applied to polyester FRP profiles and processing of composite materials

[0050] 1000Kg of PCB non-metal reclaimed material with metal-enriched bodies with a particle size of 200μm-500μm has been separated, sent to the mixer, and compound additives are added according to the following ratio:

[0051] Grinding aid: 50 Kg of sodium silicate (the dosage of the grinding aid sodium silicate is 5% of the weight of PCB non-metal recycled materials);

[0052] Active dispersant: sodium tripolyphosphate 30Kg (the amount of active dispersant sodium tripolyphosphate is 3% of the weight of PCB non-metallic recycled materials);

[0053] Compatibility modifier: phenolic resin (Wuxi Guangming Chemical Co., Ltd., 2124) 50Kg (the amount of phenolic resin used as a compatibilizing modifier is 5% of the weight of PCB non-metallic recycled materials).

[0054] After uniform stirring, the material is discharged into t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com