Method for performing compatibilization treatment on vulcanized rubber powder produced by utilizing waste rubber

A technology of vulcanized rubber powder and waste rubber, which is applied in the fields of recycling technology, mechanical material recycling, plastic recycling, etc., can solve problems such as non-continuous operation, complex process, high surface tension, etc., and achieve continuous production, continuous production, process The effect of simplifying the process and improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

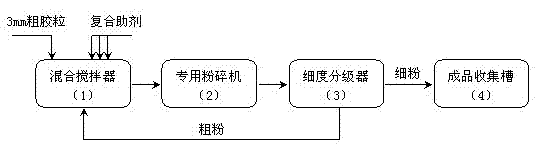

[0022] Embodiment 1: Compatibilization treatment of vulcanized rubber powder mixed with rubber products

[0023] After the waste rubber tires containing 30% (weight) of natural rubber, 35% (weight) of styrene-butadiene rubber and 35% (weight) of butadiene rubber are removed, they are cut into coarse rubber particles with a particle size of 2.5 mm ± 0.5 mm, and sent to Put into mixing agitator 1, drop into compound auxiliary agent according to the following proportion simultaneously: crushing auxiliary agent: hydrophobic silicon dioxide, 1.0%; Active dispersant: glyceryl monostearate, 1.0%, calcium stearate, 0.5%; The compatibilizing modifier is determined according to the blending purpose, and it is blended with non-polar rubber (such as natural rubber / NR, isoprene rubber / IR, styrene-butadiene rubber / SBR, butadiene rubber / BR, butyl rubber / IIR, Propylene rubber / EPM / EPDM), use C5 aliphatic hydrocarbon resin or C5 aliphatic hydrocarbon resin and C9 aromatic hydrocarbon resin

[...

Embodiment 2

[0027] Embodiment 2: Compatibilization treatment of vulcanized rubber powder mixed with plastic products

[0028] The raw material components of waste rubber tires contain 20% (weight) of natural rubber, 30% (weight) of styrene-butadiene rubber and 50% (weight) of butadiene rubber. The process operation steps are the same as in Example 1, the difference is the kind and proportioning of compounding additives. Grinding aid: sodium salt of maleic acid-acrylic acid copolymer, 1.0%; active dispersant: glyceryl tristearate, 1.0%, zinc stearate, 0.5%; compatibilizing modifier is determined according to the purpose of blending, For non-polar plastics (such as polyethylene / PE, polypropylene / PP, polystyrene / PS), use ethylene-methyl acrylate copolymer resin, or ethylene-ethyl acrylate copolymer resin, or ethylene- Butyl Acrylate Copolymer Resin, 3.0%. For polar plastics (such as vinyl polyvinyl chloride / PVC), use styrene-butadiene copolymer resin, or styrene-methyl methacrylate copolym...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com