Degradable environment-friendly efficient dust suppressant and preparation method and use method thereof

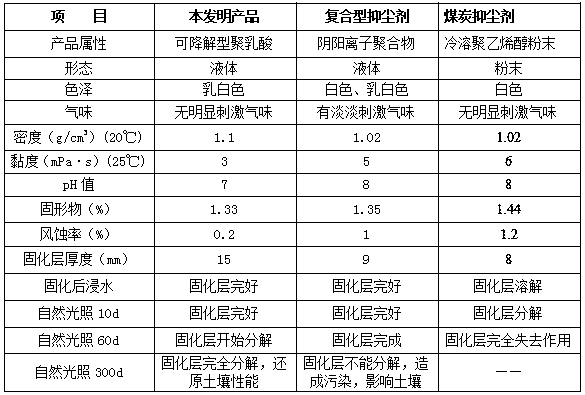

A dust suppressant and high-efficiency technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of photolysis resistance, degradation resistance, water resistance, etc., achieve good water retention capacity, excellent compatibility, and increase fluidity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Weigh 440g of water and heat it to 30°C, start stirring at 150r / min, slowly add 30g of hydroxypropyl starch, and stir for 7min. After uniformity, adjust the rotation speed to 110r / min, gradually raise the temperature to 73°C, the color gradually changes from white to transparent, and stir for 3 minutes to obtain the modified starch paste.

[0031] Weigh 80g of hydroxyl-terminated polylactic acid emulsion and 440g of water and put them in a stirrer, start stirring at a speed of 150r / min, then add 3g of carboxymethylcellulose, 3g of polycarboxylate sodium salt, and 4g of sodium alkylarylsulfonate respectively , and kept stirring for 15 minutes at a rotating speed. Adjust the rotation speed to 120r / min, gradually add 470g of the modified starch paste prepared above, and stir for 10min to ensure uniform mixing, and then it is obtained after discharging.

[0032] During construction, use a sprayer to spray the liquid directly on the surface of the dust source.

Embodiment 2

[0034] Weigh 445g of water and heat it to 32°C, start stirring at 180r / min, slowly add 30g of modified starch (a mixture of hydroxypropyl starch and carboxymethyl starch, the ratio is 1:1~1:1.5), and stir for 8 minutes. After uniformity, adjust the rotation speed to 120r / min, gradually raise the temperature to 70°C, the color gradually changes from white to transparent, stir for 5min, and obtain the modified starch paste.

[0035] Weigh and weigh 90g of degradable vinyl acetate emulsion and 445g of water and put them in a stirrer, start stirring at a speed of 130r / min, then add 4g of modified cellulose (a mixture of hydroxypropylmethylcellulose and methylcellulose, The ratio is 1:1~1:1.8), 3g of polyalkoxy compound, 3g of phosphoric acid ester, and keep stirring at the rotating speed for 12min. Adjust the rotation speed to 100r / min, gradually add 475g of the modified starch paste prepared above, and stir for 6min to ensure uniform mixing, and then it will be obtained after dis...

Embodiment 3

[0038] Weigh 436.5g of water and heat it to 35°C, start stirring at 120r / min, slowly add 20g of modified starch (a mixture of hydroxypropyl starch and acetate starch, the ratio is 1:1~1:1.5), and stir for 5 minutes. After uniformity, adjust the rotation speed to 80r / min, gradually raise the temperature to 64°C, the color gradually changes from white to transparent, stir for 5min, and obtain the modified starch paste.

[0039] Weigh and weigh 100g of a degradable emulsion composition such as hydroxyl-terminated polylactic acid emulsion and 475g of water in a stirrer, start stirring at a speed of 200r / min, and then add 5g of modified cellulose (cellulose inorganic acid ester and micro Crystalline cellulose mixture, the ratio is 1:1~1:1.8), 1g of partially saturated carboxylate, 1g of polyether polyol, and keep stirring for 10min at the rotating speed. Adjust the rotating speed to 80r / min, gradually add 456.5g of the modified starch paste prepared above, and stir for 8min to ensu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com