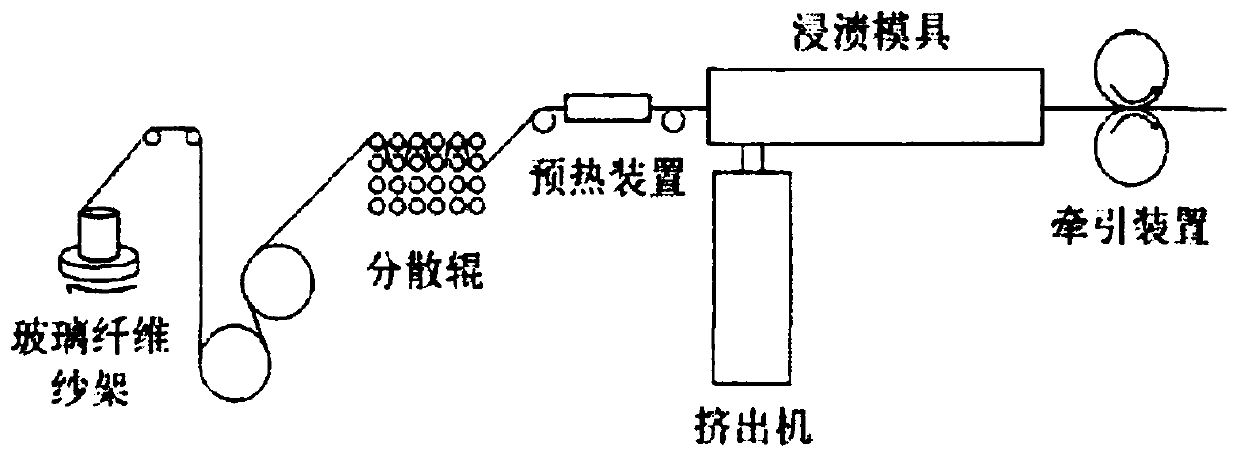

Long fiber reinforced thermoplastic composite material wetting mold and wetting process

A technology for strengthening thermoplastic and composite materials, applied in the field of fiber infiltration, can solve the problems of lack of infiltration of fibers, easy damage to the inner wall of the mold, affecting the quality of the masterbatch, etc., so as to avoid material oxidation, save time and labor, and improve the infiltration effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

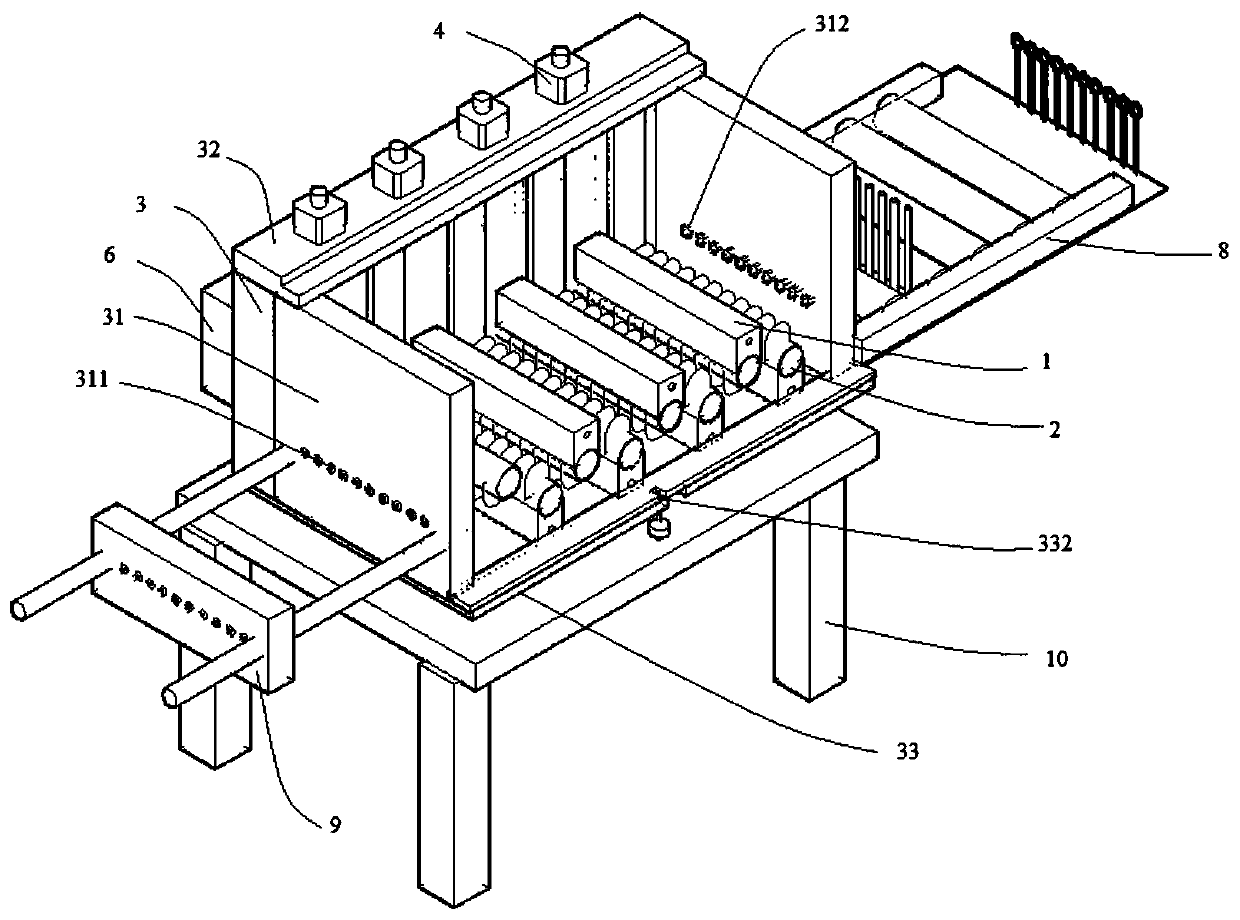

[0057] Embodiment 1: the mold structure provided by the present invention.

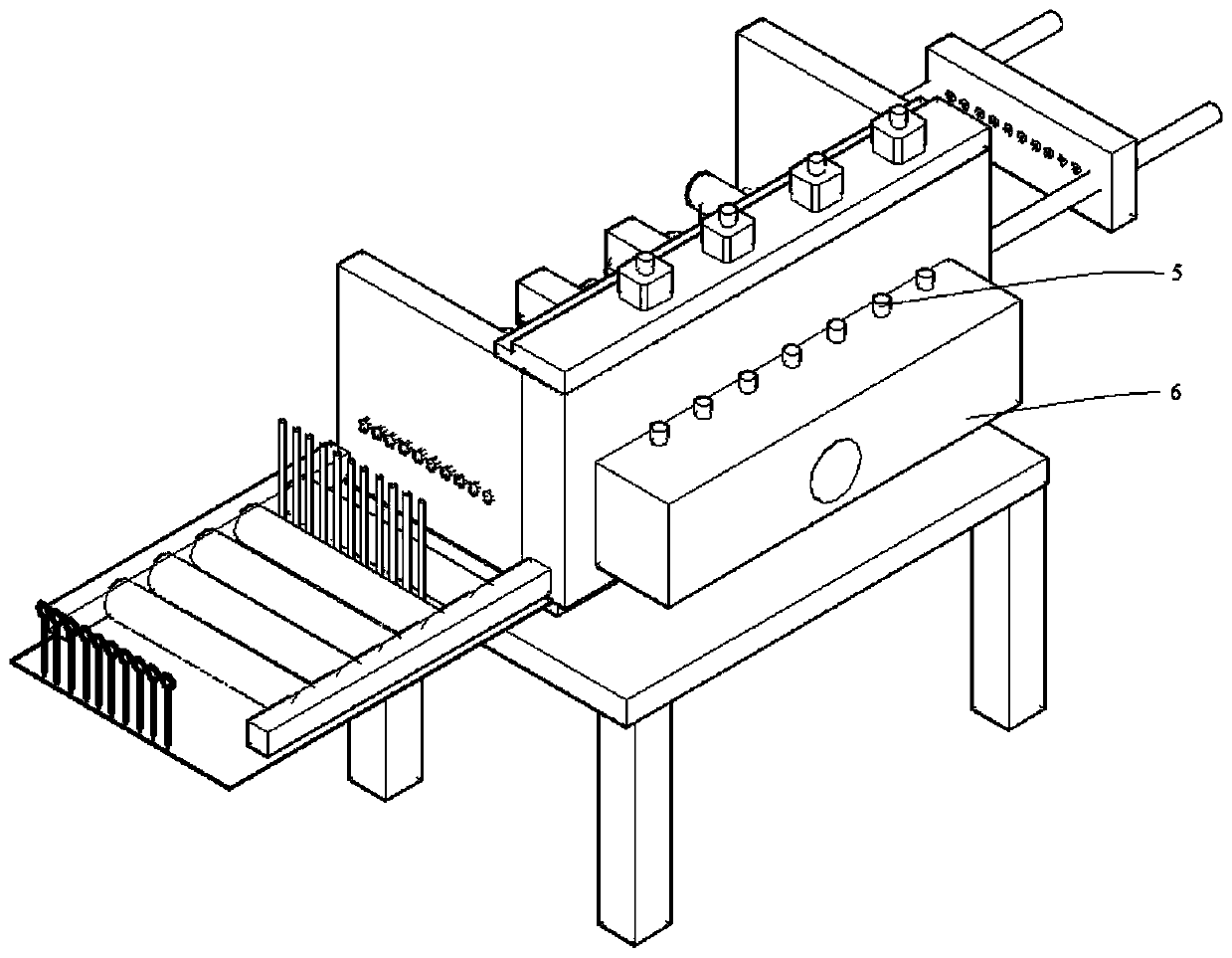

[0058] A long fiber reinforced thermoplastic composite infiltration mold such as figure 2 , image 3 with Figure 8 As shown, it includes upper pressure roller 1 and its fixed assembly, lower pressure roller 2 and its fixed assembly, mold shell 3, lifting mechanism 4, heating mechanism 5, molten pool transition section 6 and connecting flange 7;

[0059] The mold shell 3 includes a mold side wall 31, a mold upper cover plate 32 and a mold lower cover plate 33;

[0060] The upper pressing roller and the lower pressing roller are arranged parallel to each other and at intervals;

[0061] The lower pressure roller 2 is a static pressure roller, and the lower pressure roller is fixed on the side wall of the mold through a fixing assembly;

[0062] The upper pressure roller 4 is a dynamic pressure roller, and the upper pressure roller is connected with the lifting mechanism through a fixed assembly, a...

Embodiment 2

[0085] Example 2: An infiltration process for long fiber reinforced thermoplastic composites

[0086] The present invention also provides a long-fiber-reinforced thermoplastic composite material infiltration process, using the mold provided by the present invention, comprising the following steps:

[0087] Step 1, opening the mold, passing the fiber through the yarn inlet hole and the yarn outlet hole of the mould;

[0088] Step 2: Close the mold, turn on the electric heater, and heat the mold to a specified temperature, which is at least equal to or higher than the melting temperature of the resin used; adjust the lifting mechanism of the upper pressing roller to lower the upper pressing roller, so that the fibers are pressed on the upper pressing roller. A uniform wave shape is formed between the roller and the lower pressure roller; the greater the wave amplitude, the greater the tension on the fiber and the better the fiber impregnation effect. However, excessive tension ...

Embodiment 3

[0097] Example 3: A glass fiber reinforced polypropylene composite material was prepared using the mold and process provided in this application.

[0098] Set the heating temperature to 180°C. Using the mold provided in Example 1 and the process provided in Example 2, a composite material was prepared using glass fiber and polypropylene as raw materials. Except for the infiltration process, other preparation processes were the same as those of traditional composite materials.

[0099] Figure 10 It is a cross-sectional scanning electron microscope photo of glass fiber reinforced polypropylene composite material masterbatch, in which the round material is glass fiber, and the gray part is polypropylene resin. It can be seen from the figure that the glass fibers are evenly distributed in the resin matrix without agglomeration, indicating that the infiltration effect of the fibers is very good.

[0100] The mechanical properties of the prepared glass fiber reinforced polypropyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com