Soldering tin forming device, method and continuous plating device

A soldering and area technology, which is applied in the field of soldering area forming devices, can solve problems such as the fracture of the electroplating layer, and achieve the effect of improving mechanical strength and improving joint reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

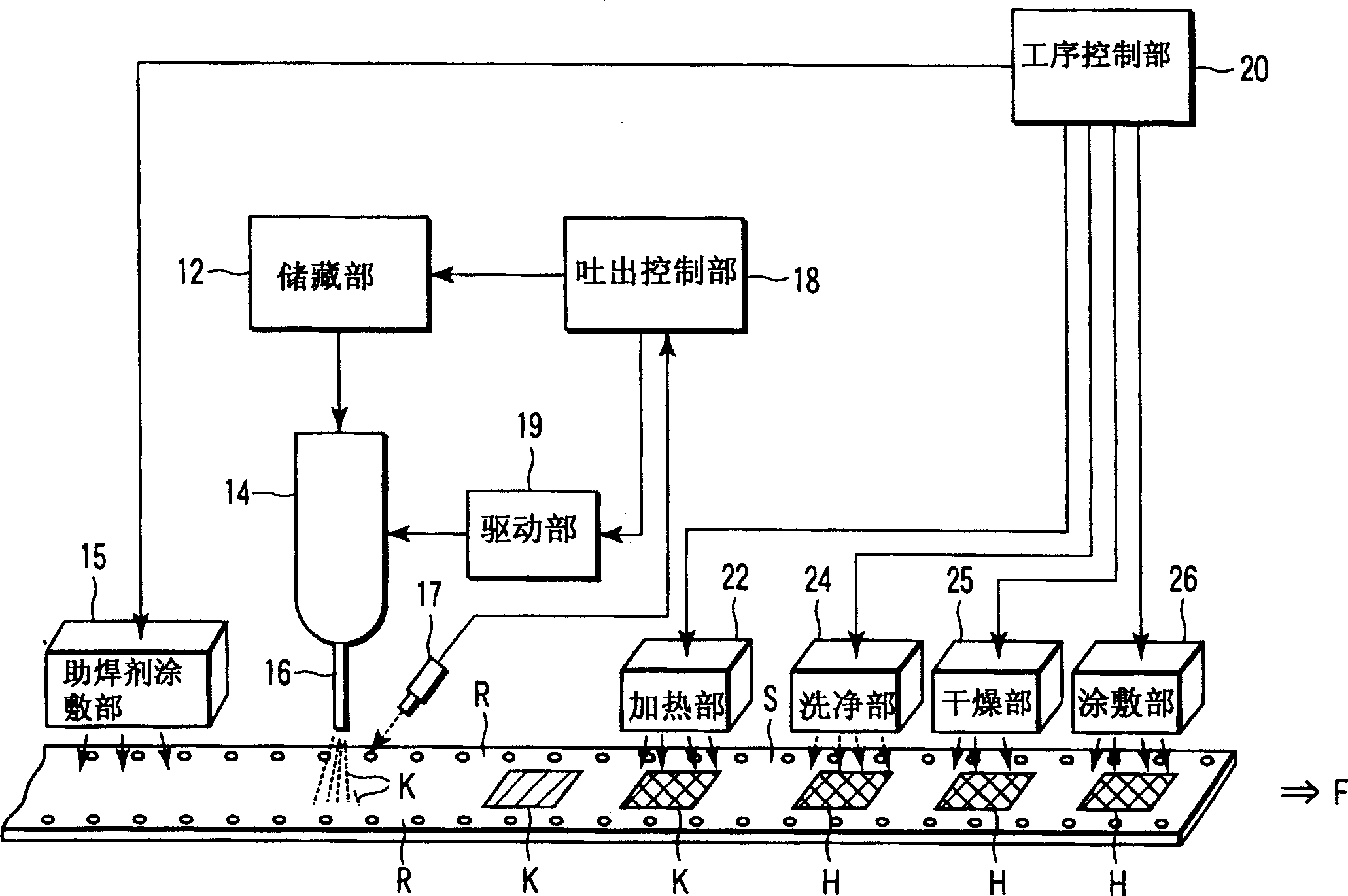

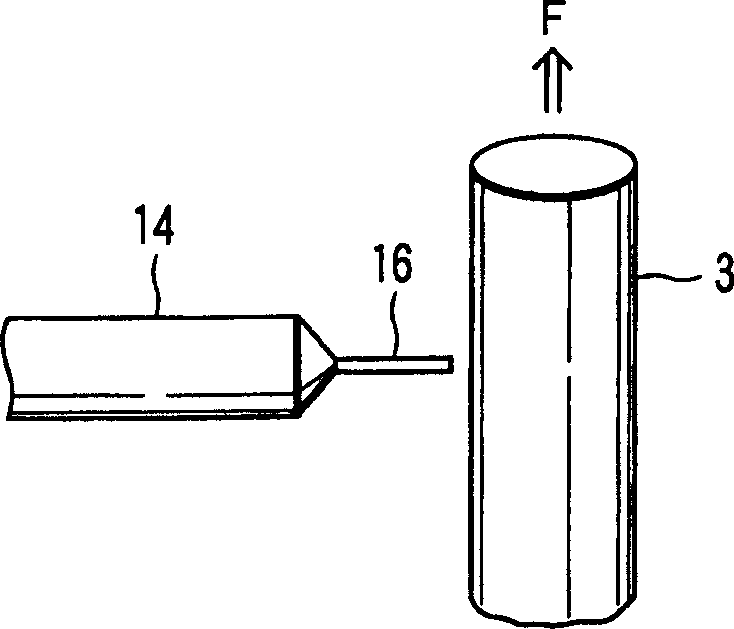

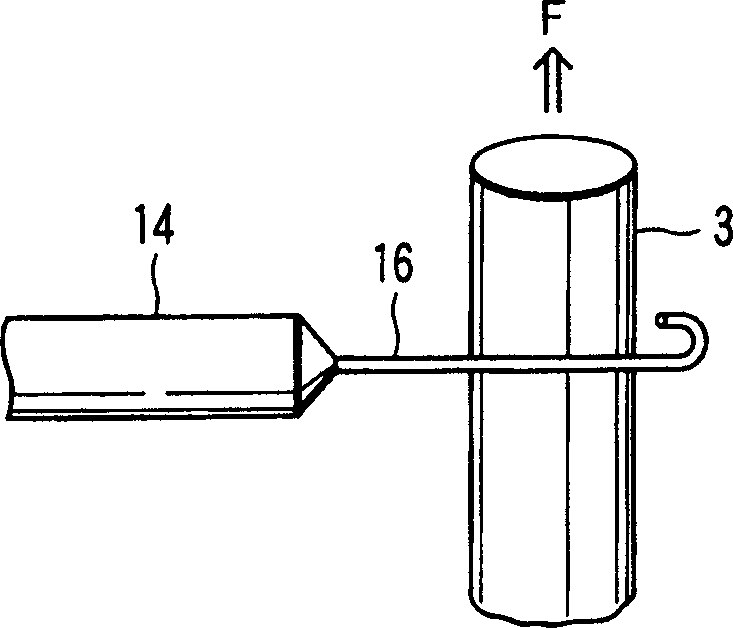

[0053] Regarding the first implementation mode, use Figure 1 to Figure 7 Be explained.

[0054] figure 1 It is a structural conceptual diagram showing an example of a solder forming apparatus to which the solder region forming method of the first embodiment is applied.

[0055] That is, the solder region forming apparatus is an apparatus for forming a solder region H on components S such as film carrier tapes, connector components, and lead frames, and includes a storage unit 12, a dispenser 14 provided with a nozzle 16 at the tip, and a flux Coating unit 15, position sensor (sensor) 17, discharge control unit 18, drive unit 19, process control unit 20, heating unit 22, cleaning unit 24, drying unit 25, coating unit 26, and conveyance unit (not shown) .

[0056] Process control unit 20 controls flux application unit 15 , heating unit 22 , cleaning unit 24 , drying unit 25 , and application unit 26 .

[0057] The flux application unit 15 applies a flux that promotes solder...

Embodiment approach 2

[0094] Referring to Figure 8, Figure 9 Embodiment 2 will be described. Embodiment 2 is a modified example of Embodiment 1. Therefore, only the differences are described here, and repeated descriptions are avoided.

[0095] FIG. 8 is a conceptual diagram showing the configuration of an example of a solder region forming apparatus to which the method of forming a solder region according to Embodiment 2 is applied.

[0096] That is, this solder region forming apparatus differs from Embodiment 1 only in that a plurality of distributors 14 and nozzles 16 are provided. The plurality of dispensers 14 and nozzles 16 also supply the solder paste K from the storage unit 12 . In addition, FIG. 8 shows the structure in this case: the solder paste K is supplied from the same storage part 12 to a plurality of distributors 14, but as Figure 9 As shown, a storage portion 12 corresponding to each dispenser 14 may also be provided.

[0097] In addition, Figure 8 and Figure 9 In the fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com