Cleaning method and cleaning system

A cleaning system and cleaning machine technology, applied in cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., can solve the problems of cleaning liquid waste, brush drying in the scrubbing room, and dust accumulation in the air supply pipeline, etc., to achieve Reduce the opening frequency, improve the wetting effect, and reduce the effect of gas consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

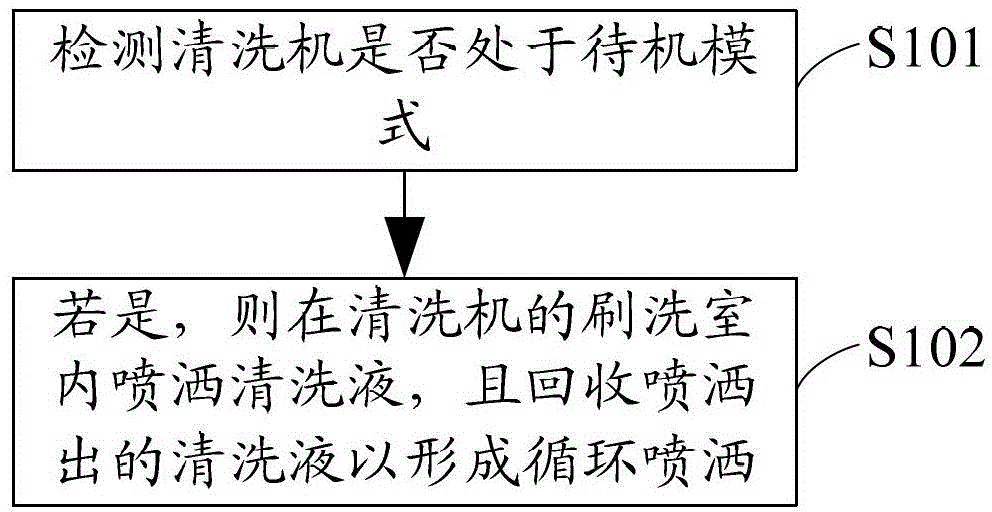

[0033] see figure 1 , the first embodiment of the cleaning method of the cleaning machine of the present invention is proposed, and the cleaning method includes:

[0034] Step S101, detecting whether the cleaning machine is in a standby mode.

[0035] When cleaning the glass substrate, the glass substrate enters from the inlet of the washing machine, changes from horizontal to inclined (the inclination angle is about 5°), and then enters the ultraviolet chamber, irradiates the glass substrate with ultraviolet rays, and decomposes the organic matter on the surface of the glass substrate; then passes through the isolation chamber (isolation dry process and wet process) into the scrubbing room, and the water spray pipe in the scrubbing room sprays cleaning liquid such as cleaning agent or deionized water onto the glass substrate, and uses a brush to scrub the glass substrate to remove large stain particles on the surface of the glass substrate (>5um) to realize the initial clean...

no. 2 example

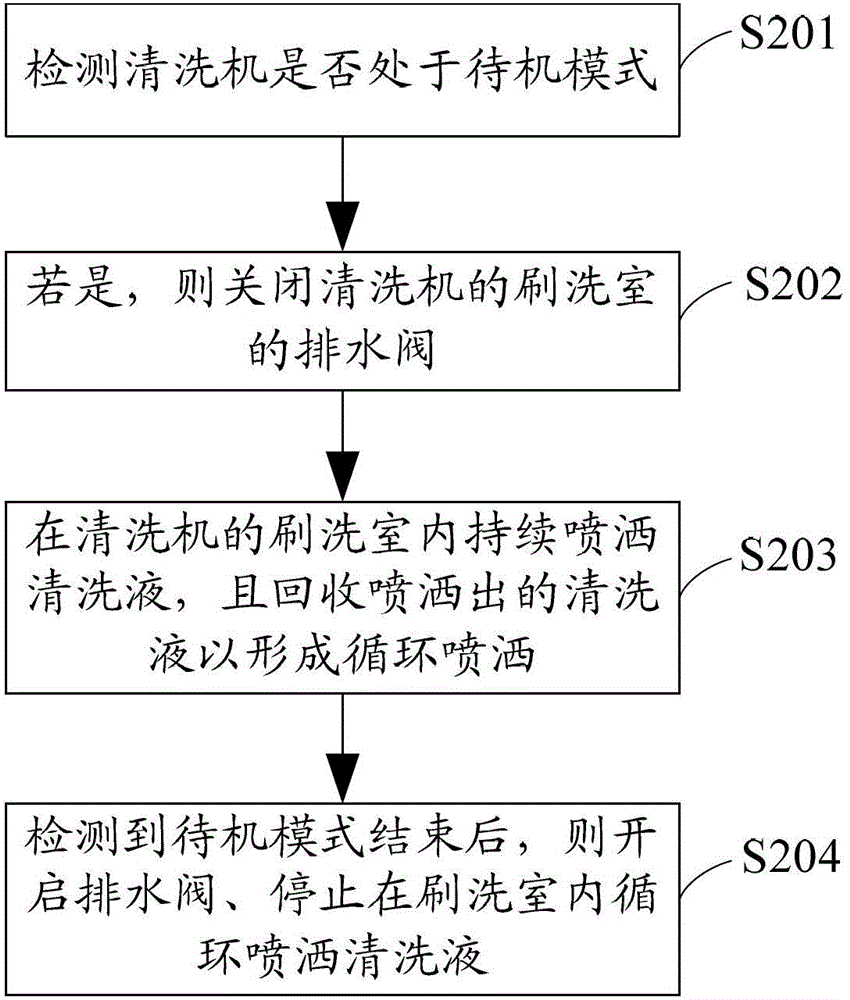

[0042] see figure 2 , the second embodiment of the cleaning method of the washing machine of the present invention is proposed, the cleaning method includes:

[0043] Step S201, detecting whether the cleaning machine is in standby mode.

[0044] When there is no glass substrate in the cleaning machine to be cleaned, in order to save energy, the cleaning machine will enter the standby mode, close the air supply and water supply pipelines, and stop spraying cleaning agents, deionized water or dry and clean air in each cleaning room, so this step S201 needs to detect in real time whether the washing machine is in standby mode.

[0045] Step S202, if yes, close the drain valve of the scrubbing chamber of the washing machine.

[0046] When the cleaning machine cleans the glass substrate, the drain valve is in an open state to discharge the cleaned waste liquid. If it is detected that the cleaning machine enters the standby mode, it means that the cleaning machine has not cleaned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com