Method for extracting lead, zinc and silver in lead-zinc-silver composite sulfide minerals

An extraction method, a technology of sulfide ore, which is applied in the extraction of zinc and silver directly converted into metallic lead-zinc-silver, and in the field of lead in composite lead-zinc-silver ore, which can solve the problems of lengthy process, large amount of pollutants, and many processes. , to achieve the effect of improving separation and extraction efficiency, fast enrichment speed and short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

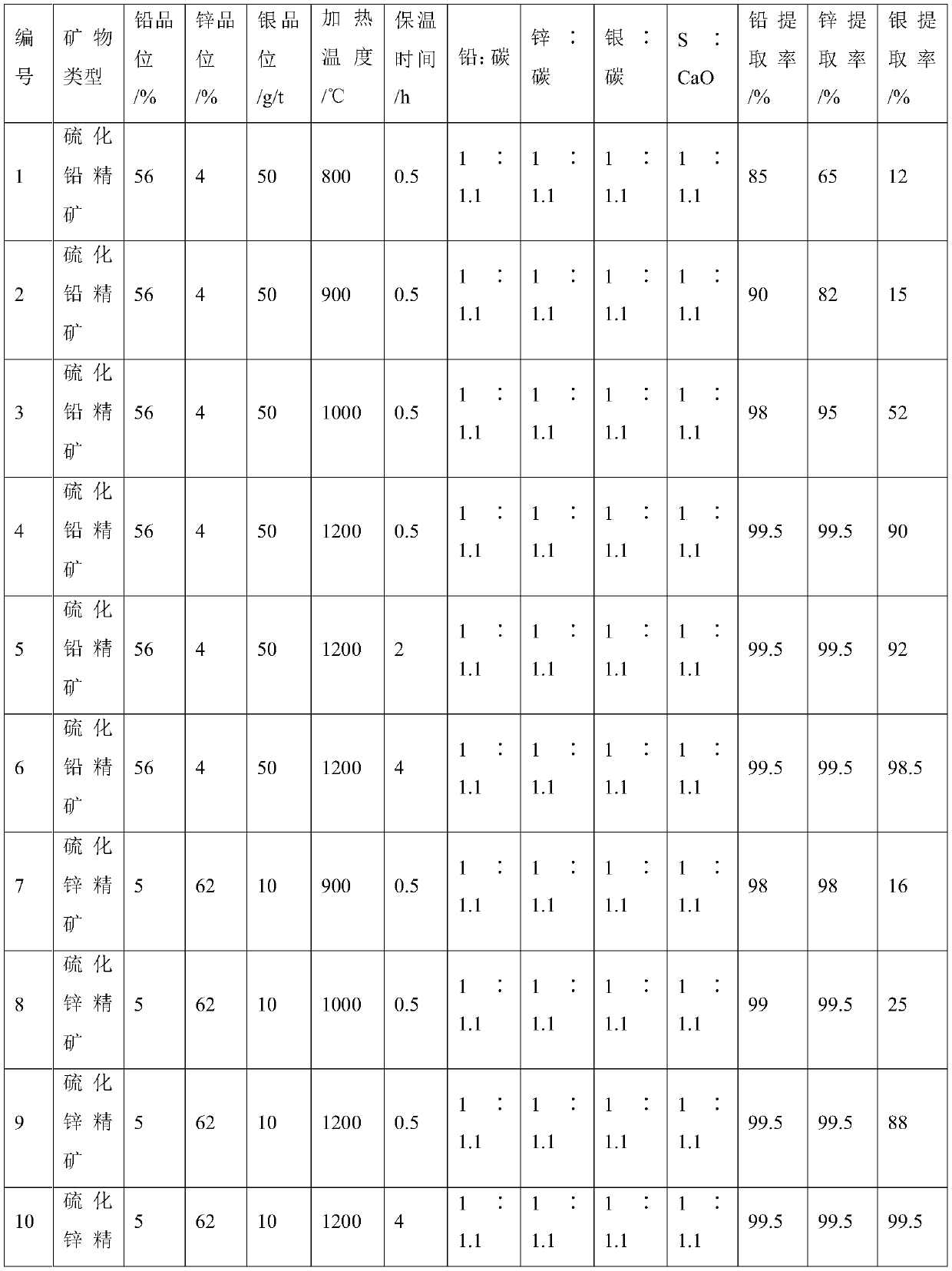

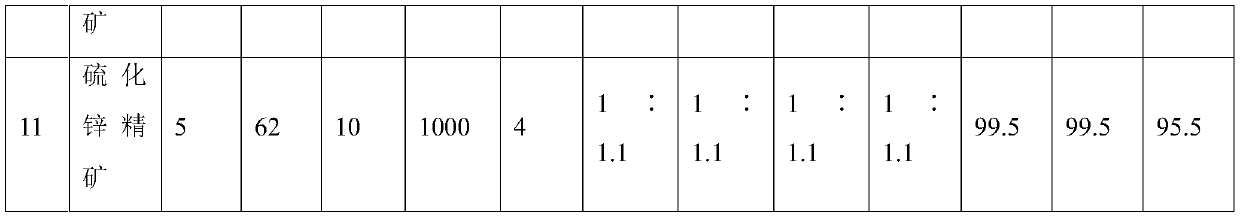

[0038] The specific content of the present invention will be described in further detail below in conjunction with the examples.

[0039] The invention discloses a method for extracting lead-zinc-silver in a lead-zinc-silver composite ore. Coal powder and quicklime powder are added to the composite ore, fully mixed to form a mixture, the mixture is briquetted, and then the briquetted mixture is subjected to vacuum heating and reduction. The heating temperature is controlled separately according to the components extracted from the minerals. The extraction control temperature of lead in lead sulfide minerals is 800-1000 °C, the control temperature of zinc extraction in zinc sulfide minerals is 900-1000 °C, and the control temperature of silver extraction in minerals is 1100 °C. Between -1200°C, keep warm for 0.5-4 hours, and collect the metal vapors of lead, zinc, and silver obtained by heating and reducing by condensation, and the collected condensate is a mixture of lead, zinc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com