Method for separating and purifying boron-10 and boron-11

A technology of boric acid and ionized water, which is applied in the field of separation and purification of boron-10 and boron-11, can solve the problems of increasing production costs, taking a long time, and long chromatographic columns, and achieves increasing single-stage separation factors and rich The effect of fast settling speed and enhanced separation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

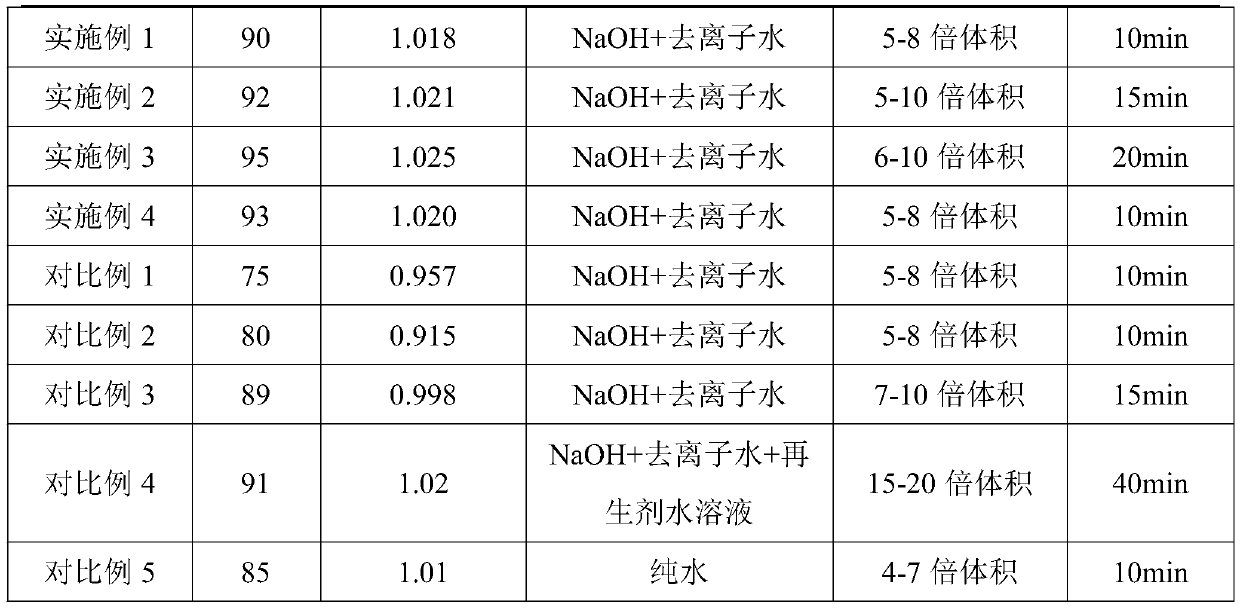

Embodiment 1

[0028] Weigh the boric acid solid and dissolve it in pure water to prepare a boric acid aqueous solution containing a boron isotope concentration of 0.5mol / L, adjust the pH value to 4 with hydrochloric acid; add 1.0g / L mannitol to the boric acid aqueous solution, and then use a filter membrane Filter to remove impurities in the solution, and then degas it with ultrasound for 15 minutes to obtain the sample solution of the simulated moving bed;

[0029] Amberlite IRA 743 resin, soak Amberlite IRA 743 resin with deionized water for 24 hours, then wash with 5 times the volume of 0.1mol / L hydrochloric acid, treat the resin as a chlorine-type resin, and then wash with deionized water until neutral, and at least Stable for 8 hours without changing, so as to achieve the activation effect;

[0030] The activated Amberlite IRA 743 resin was packed in 25 chromatographic columns in the four zones of the simulated moving bed by wet packing method. %, positive pressure recoil method is us...

Embodiment 2

[0039] Compared with Example 1, the chromatographic column filling resin uses Diaion CRB 02 resin, the eluent uses nitric acid aqueous solution, and the operating temperature is 30 ° C, and other conditions are the same as in Example 1.

Embodiment 3

[0041] Compared with Example 1, Zone I and Zone III are each composed of two ZXC 700 resin columns, Zone II is composed of 20 Amberlite IRA743 resin columns, Zone IV is composed of one D 564 resin column, and the eluent First use sulfuric acid aqueous solution, then use hydrochloric acid aqueous solution, the operating temperature is 28°C, other conditions are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com