Environment-friendly mural

A kind of mural painting and environmental protection technology, applied in the field of decorations, can solve the problems of indoor air without benefits, achieve the effect of improving the quality of healthy life and purifying the air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] The preparation process of nano opal powder and micron opal powder is as follows:

[0064] The raw ore is crushed to about 100 microns and then crushed to 10 microns by airflow to obtain micron opal powder, and then the nano-opal powder is prepared by hydrothermal method. Nano-powder materials are produced by hydrothermal method. 10-micron protein powder is reacted for two hours in a reaction kettle at a temperature of 180°C and a water-solid ratio of 20:1. Nano colloidal particles, stir and age for 1 hour, control the pH value and temperature to ensure that the colloidal particles are evenly dispersed. Dry powder can be obtained by spray drying after separating excess water. That is, the 10-micron protein powder is hydrolyzed into a sol by adding alkali at high temperature, aging treatment under acidic conditions, controlling temperature, ph value, time, and finally filtering and drying to obtain nano powder. The specific process is as follows:

[0065] Raw ore—coar...

Embodiment 1

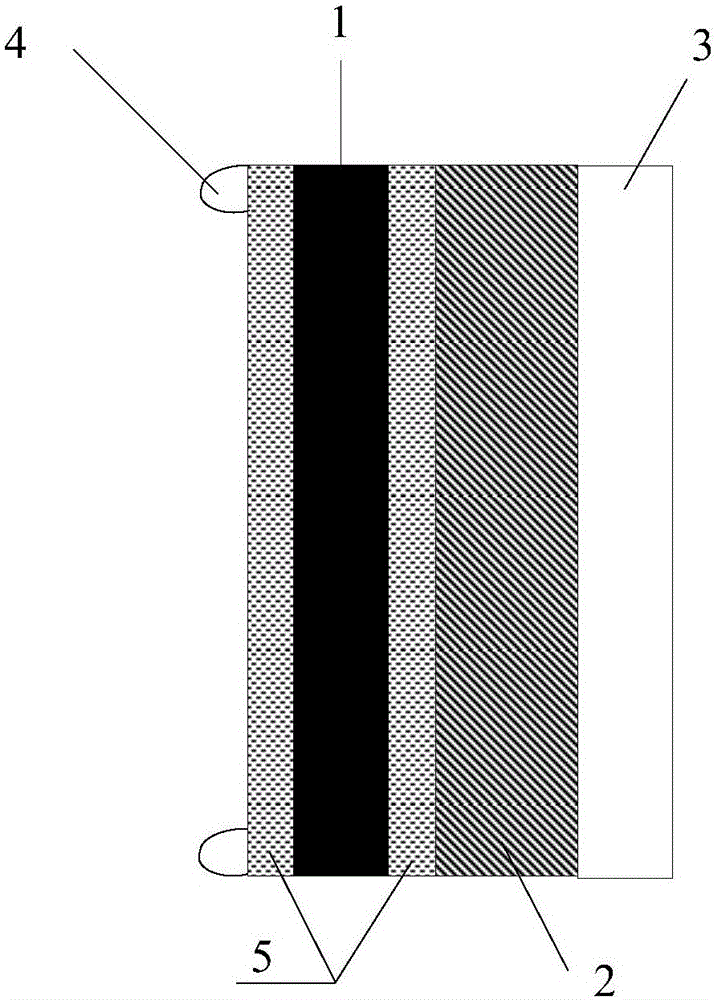

[0085] Such as figure 1 and figure 2 As shown, the environment-friendly mural provided by the embodiment of the present invention includes a canvas 1 and a canvas support 2, and the canvas 1 is fixed on the canvas support 2, wherein the surface of the canvas 1 includes a nano-opal powder coating 5. It should be noted that the canvas 1 is fixed on the canvas support 2, and the fixing methods include bonding and gluing. The nano-opal powder coating 5 can be applied to the front surface of the canvas 1 by brushing or spraying, and can also be coated on both the front and back surfaces. The thickness of the nano-opal powder coating 5 is 0.1-0.3 mm. Further, the canvas 1 is fixed on the canvas support body 2 by bonding, and the nano-opal powder coating 5 is coated on the front and back surfaces of the canvas 1 by spraying, and the thickness of the nano-opal powder coating 5 is 0.2mm.

[0086] Preferably, the canvas support 2 includes main materials and a curing agent. The main ...

Embodiment 2

[0099] Canvas preparation process:

[0100] Step 200, preparing nano-opal powder, the specific process refers to the preparation process of nano-powder above.

[0101] Step 202, spraying or brushing nano opal powder coating on the surface of the canvas.

[0102] Step 204, drying and flattening the canvas.

[0103] Step 206, drawing or engraving pictures on the canvas.

[0104] Step 208, corona treatment is performed on the canvas.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface area | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com