Method for producing high-strength and elongation product automobile steel plate by continuous annealing technology

A technology of high-strength plastic product and annealing process, which is applied in the field of continuous annealing process to produce high-strength plastic-product automotive steel plates, to achieve the effect of accelerating enrichment speed, avoiding coarsening and good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

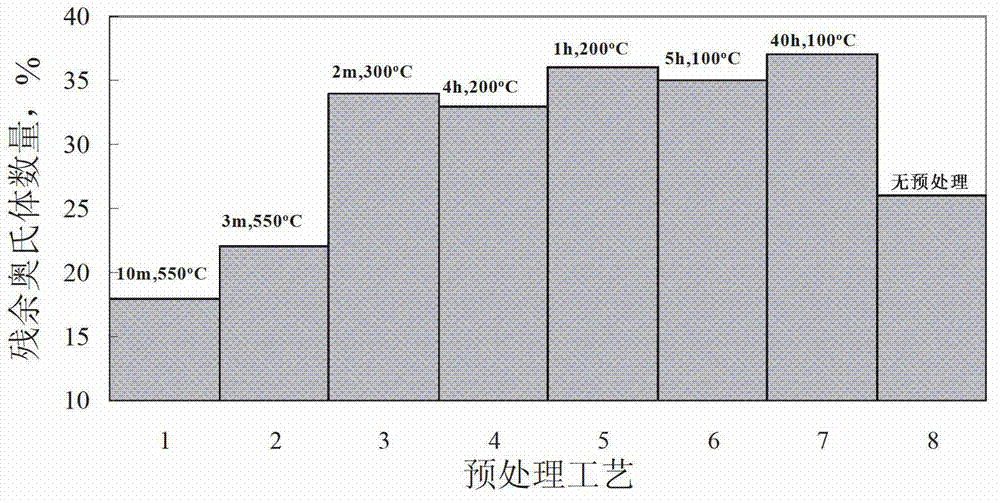

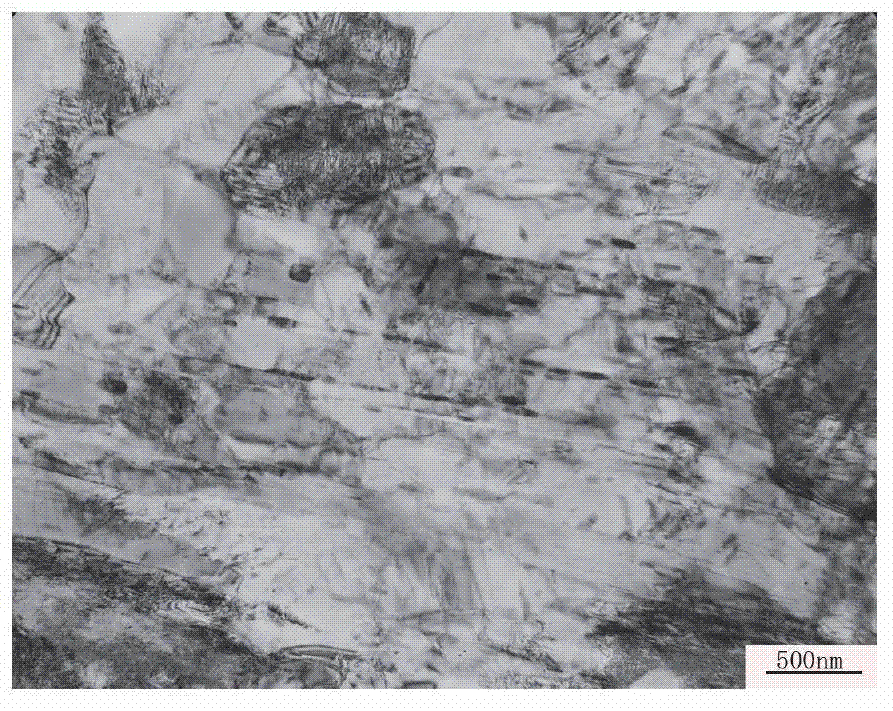

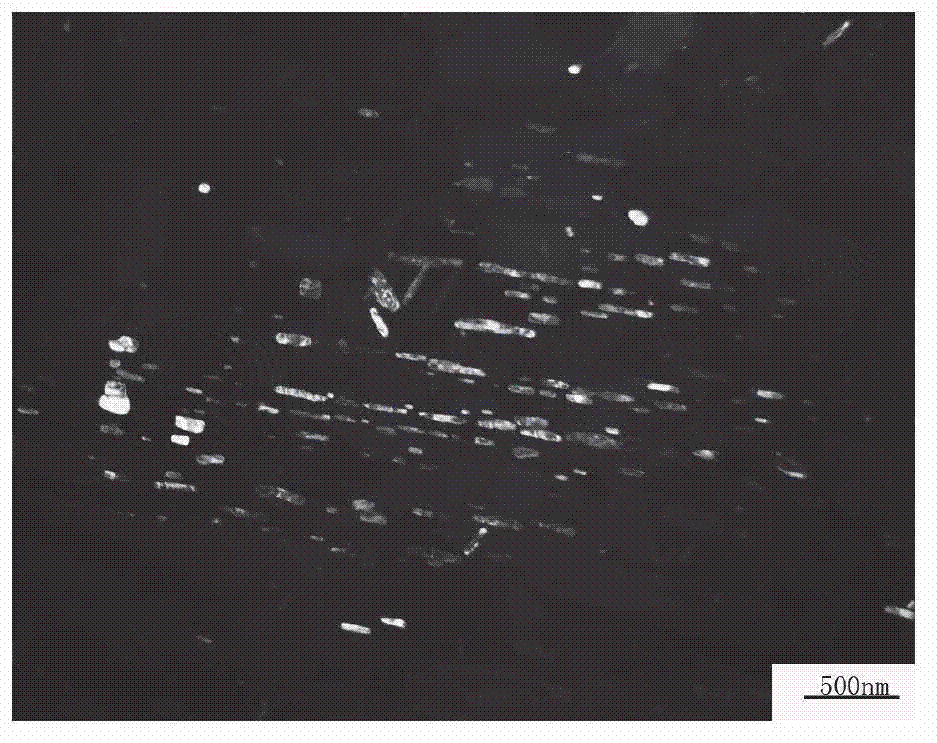

[0028] The test of this embodiment adopts the three chemical components of A, B, and C shown in Table 1, which are smelted by induction furnace, poured into ingots, hot forged into 50mm thick slabs, and then rolled to 6mm hot slabs by pilot single-stand rolling mill. Rolled coils, control the final rolling temperature at 750 o About C, coiling temperature > 600 o C. Put it into the holding furnace for 5 hours and then cool it to room temperature, then cold roll the hot rolled coil to 2mm through the cold rolling mill. Subsequent annealing of the cold-rolled sheet is done on an annealing simulator in the laboratory. Cold-rolled steel plate first in 780 o C annealed for 6 minutes to austenitize and dissolve carbides, according to not less than 20 o C / s is cooled to different temperatures, and the pretreatment is carried out according to the eight pretreatment processes shown in Table 2. 550 of them o C and the room temperature insulation process are comparative processes. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strong plastic product | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com