Air purification composition, preparation and preparation method thereof

A technology of air purification and composition, which is applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve problems that cannot meet actual needs, release polluted gases, and have no persistence of adsorption, so as to promote the process of photocatalytic oxidation degradation , Improve the purification efficiency, and the effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

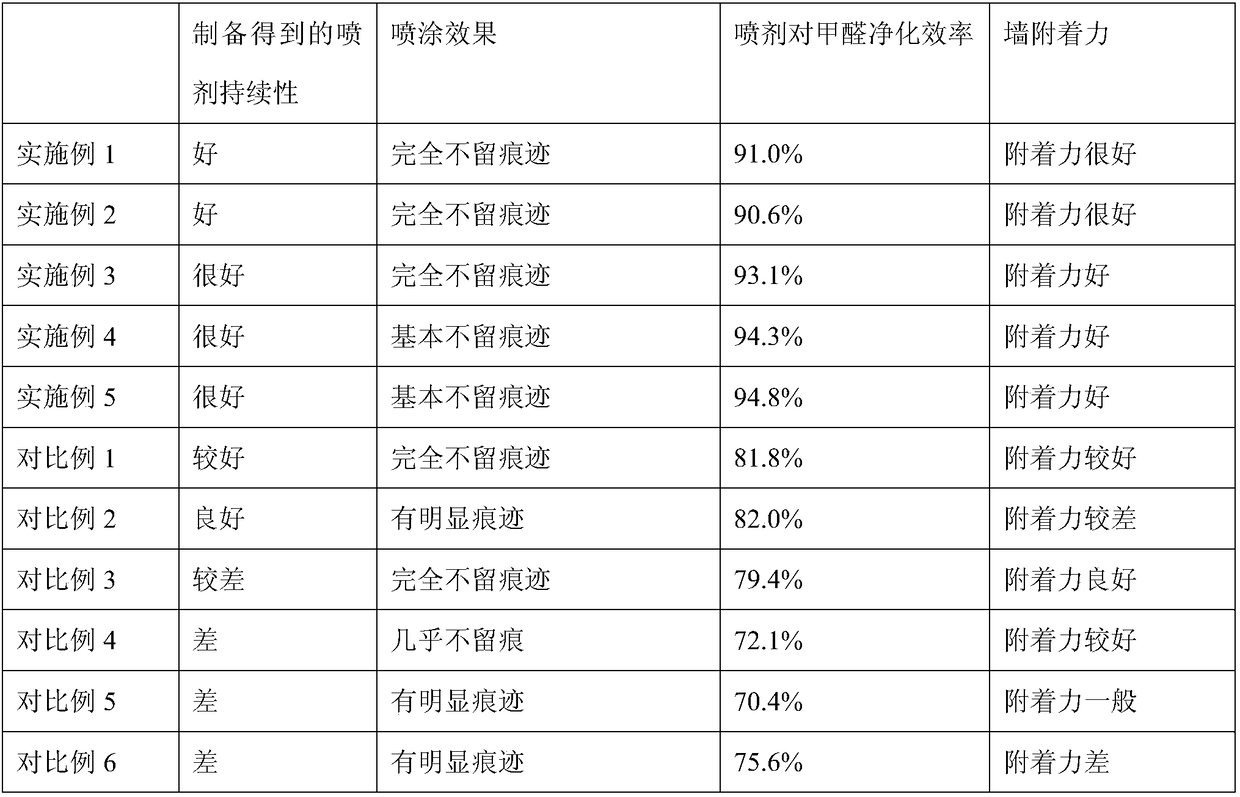

Examples

Embodiment 1

[0031] An air-purifying composition, whose raw materials include the following components by weight: 5 parts of formaldehyde scavenger, 2 parts of zeolite, 1.5 parts of diatomite, 0.5 part of bentonite, and 1 part of carbon nitride.

Embodiment 2

[0033] An air-purifying composition, whose raw materials include the following components by weight: 8 parts of formaldehyde scavenger, 3 parts of diatomaceous earth, and 1.5 parts of carbon nitride.

Embodiment 3

[0035] An air purification composition, the raw material of which comprises the following components by weight: 10 parts of formaldehyde scavenger, 2 parts of zeolite, 2 parts of diatomite, 0.5 part of bentonite, 0.5 part of hydroxyapatite, and 2 parts of carbon nitride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com