Echelon mounting method of oversized plane multi-layer steel truss electronic workshop steel structure

A technology for electronic workshops and installation methods, which is applied in building structures, industrial buildings, buildings, etc., can solve problems such as unsatisfactory construction period requirements, and achieve the effects of improving hoisting efficiency, speeding up construction progress, and improving risk resistance capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

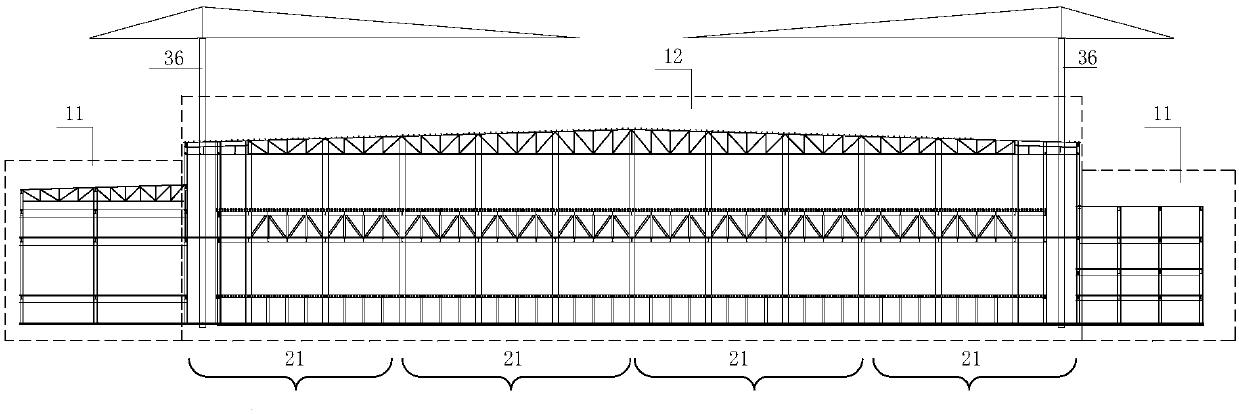

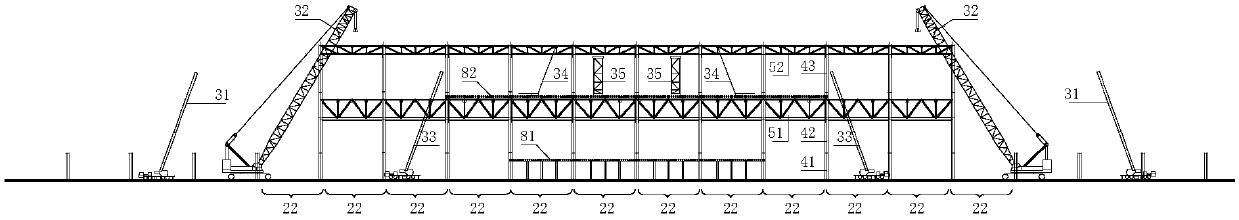

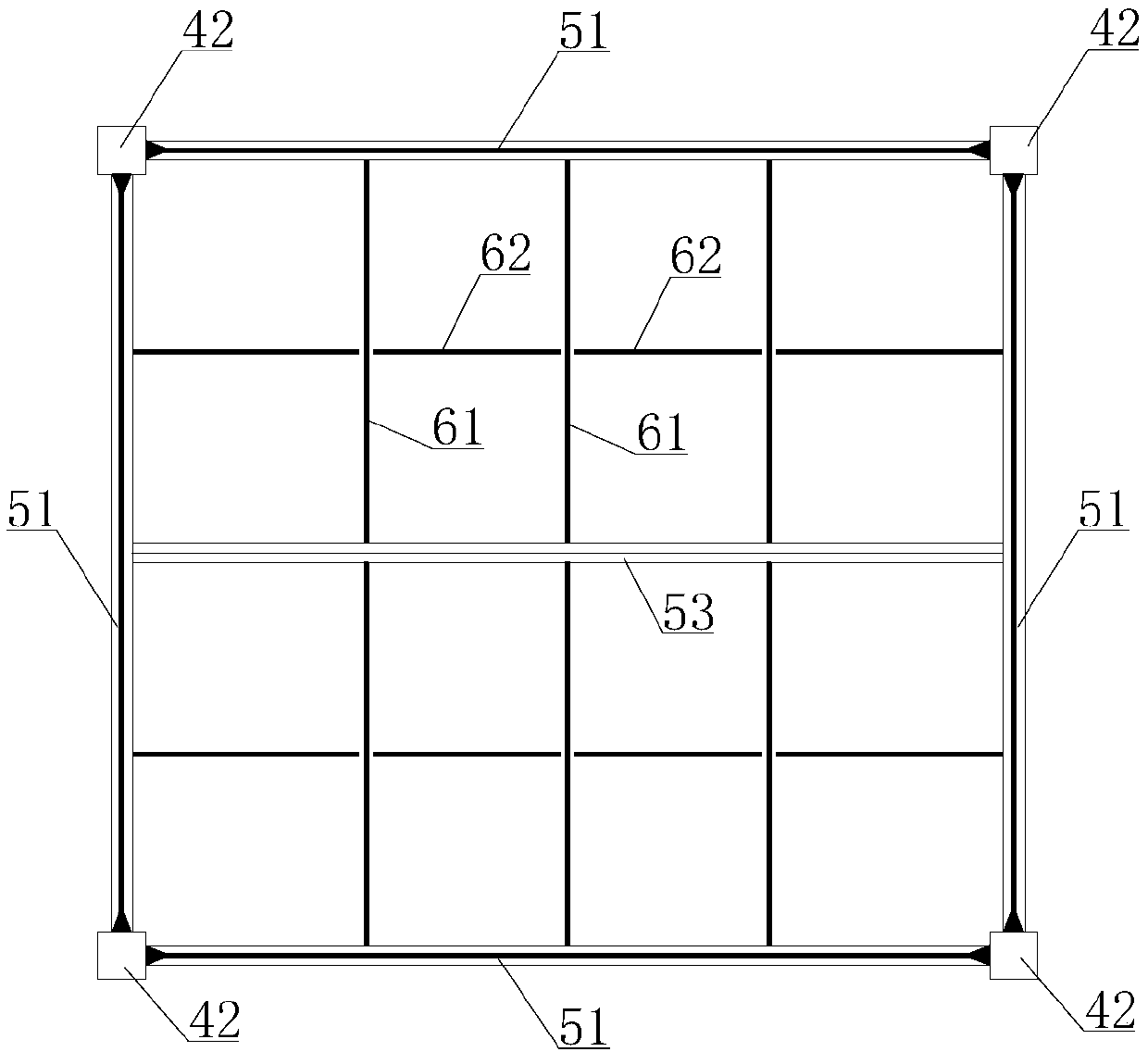

[0071] The following is an example of a large-scale electronic factory building project. The length of the project is 478 meters, the span is 258 meters, and the highest point is 42.5 meters above sea level. It is a steel truss structure (roof structure). The grid of steel structure columns is 18.6m*16.8m, and the supporting columns are plug-in. And in conjunction with accompanying drawing, technical scheme of the present invention is described further:

[0072] The step-by-step installation method of the steel structure of the super-large plane multi-layer steel truss electronic factory building is carried out according to the following steps:

[0073] (1) Division of plane hoisting areas and hoisting units:

[0074] Select the hoisting equipment according to the maximum weight of the hoisting components, and divide the construction area according to the turning radius of the hoisting equipment. The construction plane of the entire core area is divided into 4 construction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com