Glue injecting production line for loudspeaker

A loudspeaker and production line technology, applied in sensors, electrical components, etc., can solve the problems of increasing labor costs, affecting production cycles, and low automation, and achieving the effects of improving automation performance, reducing labor costs, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical solution of the present invention is further described below in conjunction with the examples, but the scope of protection is not limited to the description.

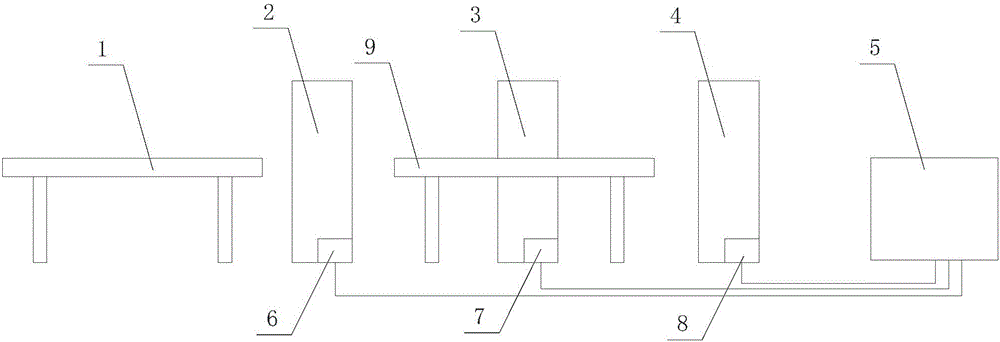

[0012] Such as figure 1 , which includes a first working platform 1, an oven 2, a second working platform 9, a dispensing machine 3, a UV energy lamp 4 and a control host 5 arranged in sequence, wherein the dispensing machine 3 is a double-syringe dispensing machine, and the second Both the first working platform 1 and the second working platform 9 are provided with positioning tooling for fixing loudspeakers, the oven 2 is provided with a temperature controller 6, the glue dispenser 3 is provided with a flow controller 7, and the UV energy lamp 4 is provided with a time The signal input terminals of the controller 8 , the temperature controller 6 , the flow controller 7 and the time controller 8 are respectively connected with the signal output terminals of the control host 5 .

[0013] The glue d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com