Gantry type combined cutting tool

A cutting tool and gantry-type technology, applied in the field of cutting tools for refrigerated car insulation boards, can solve problems such as difficulty in improving production efficiency, difficulty in ensuring machining accuracy, and high labor intensity of workers, so as to reduce labor intensity, improve labor production efficiency, and design The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

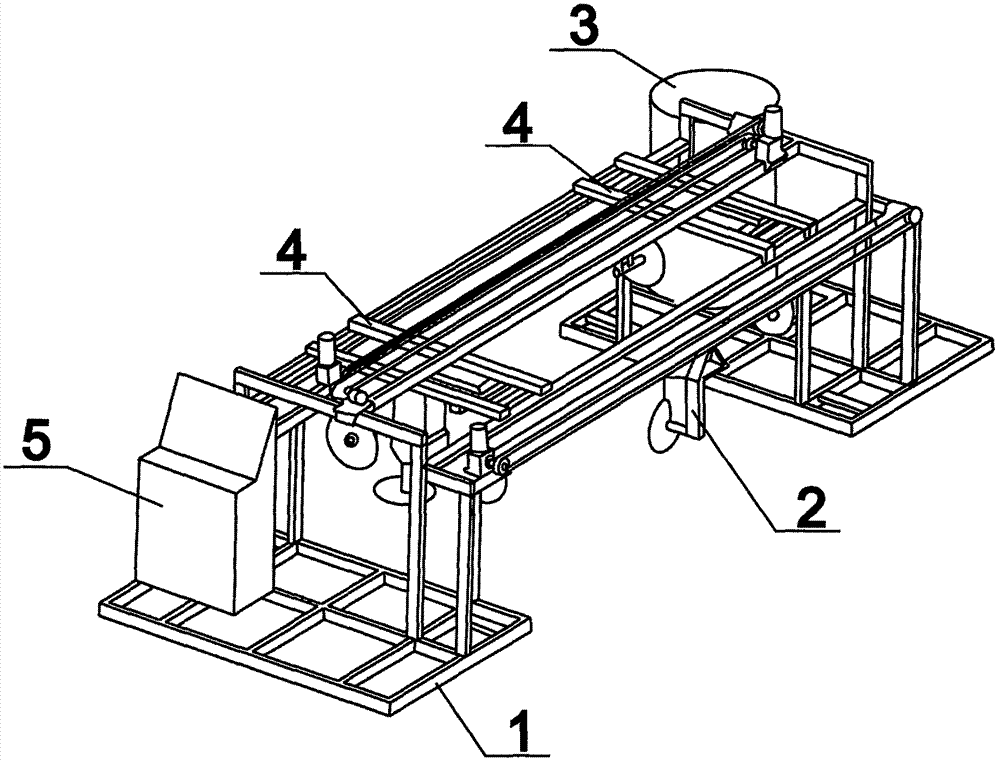

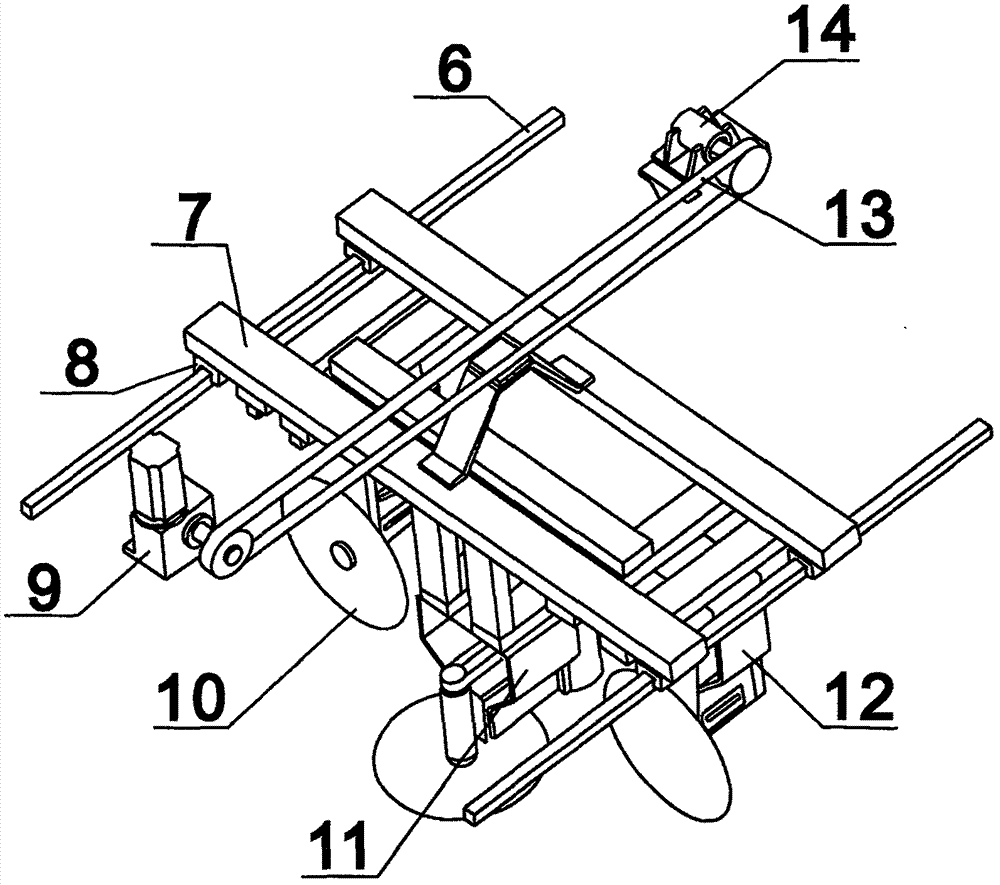

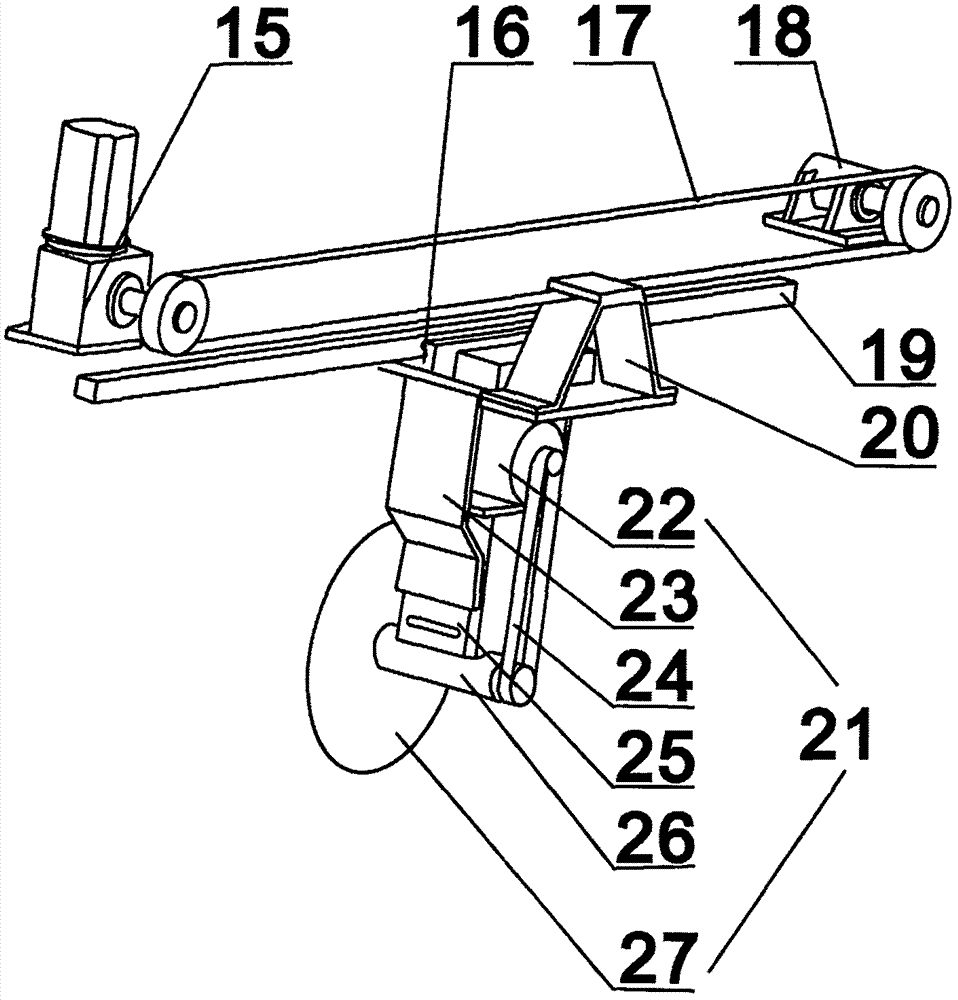

[0022] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0023] As shown in the figure, a gantry-type combined cutting tool includes a support frame 1, a control system 5 and a dust collection system 3. The control system 5 is fixedly installed on one side of the support frame 1, and the dust collection system is installed on the other side of the support frame 1. 3. There are two sets of unilateral slitting knife systems 4 installed opposite to each other on both sides above the support frame 1. The unilateral slitting knife system 4 includes a combined cutter holder 7, a width cutter 10, a step groove cutter 11, Width step cutter 12, the first guide rail 6, the first slide block 8, the first drive reduction motor 9, the first conveyor belt 13 and the first driven pulley assembly 14, the combined cutter rest 7 below is fixedly connected with a width Cutter 10, step groove cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com