Method for manufacturing seaweed seed bottom laying layer

A seed and bottom-laying technology, applied in botany equipment and methods, seaweed cultivation, climate change adaptation, etc., can solve the problems of heavy diving workload, high consumption of manpower and material resources, and inability to transport and store well for long distances. Achieve the effect of saving transportation cost, reducing labor intensity and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

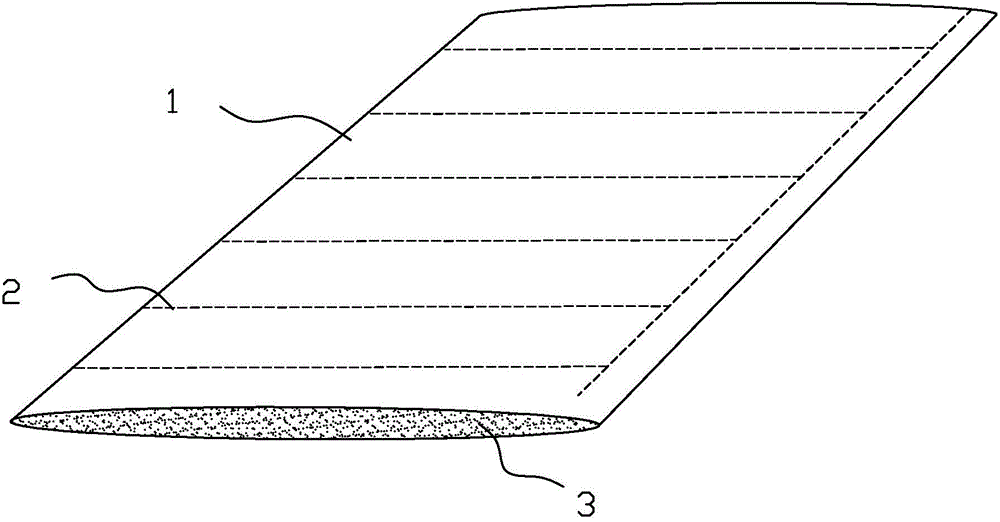

[0030] A method for making seaweed seed bottom layer, its seaweed bottom layer is shown in figure 1 , the method includes the following steps:

[0031] a. collecting seaweed seeds, and pretreating the seaweed seeds;

[0032] Cut the reproductive branches with mature seeds in the wild, put them in an incubator with ice and transport them to the pool of the nursery room or in the constant temperature incubator for temporary cultivation, let the seeds fall off naturally, change the water once a day, collect the scattered seeds, and store them for later use ;

[0033] The pretreatment is specifically to select mature and plump seeds from the collected seeds, soak them in 75% alcohol solution for 30 seconds, and rinse them with sterile seawater for 3 times; wherein, the mature and plump seeds are those with good maturity and will be extracted after dormancy. Seed individuals with bud limbs.

[0034] b. Evenly mix the pretreated seaweed seeds with the substrate to form a mixture ...

Embodiment 2

[0041] This embodiment is the implementation of the mixture prepared from seed and substrate, and the mixture is composed of the following components by weight:

[0042] Seeds 500 grains Ceramsite 800g

[0043] The preparation method is as follows: pour the ceramsite into the same container, slowly add the seeds in the weight part, and continue stirring for 4-8 minutes to obtain the seed bottom layer mixture.

Embodiment 3

[0045] This embodiment is another embodiment of the mixture prepared from seeds and substrates, and the mixture consists of the following components by weight:

[0046] 500 seeds, ceramsite 400g, sea sand 400g

[0047] The preparation method is as follows: pour the components of the ceramsite and the sea sand into the same container, fully stir, and at the same time slowly add the seeds in the weight part, and continue stirring for 5 minutes to obtain the mixture for the bottom layer of seeds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com