Electric control self-walking packer for horizontal well

A packer and self-propelled technology, applied in sealing/isolation, drilling equipment, wellbore/well components, etc., can solve problems such as operational safety risks, downhole string safety failures, and complex operating processes, and simplify operations process, reduce operating and supporting costs, and improve the effect of safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

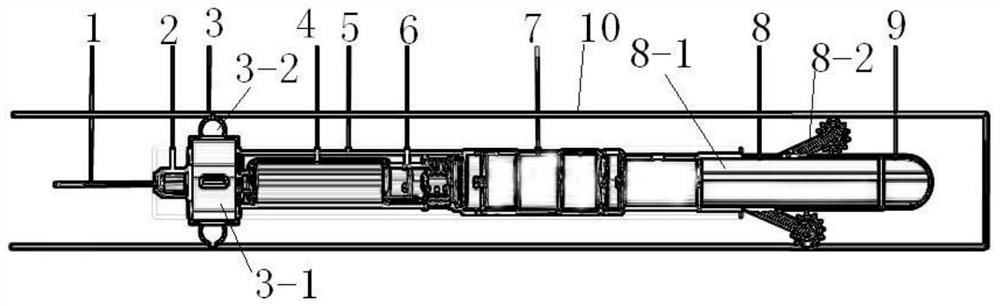

[0019] Such as figure 1 As shown, an electronically controlled self-propelled packer for horizontal wells, including cable 1, centralizer 3, oil bag 4, setting mechanism 6, rubber tube 7, crawling mechanism 8 and guide head 9, cable 1, centralizer 3 , oil bag 4, setting mechanism 6, rubber tube 7, crawling mechanism 8 and guide head 9 are connected sequentially from left to right.

[0020] Realize the power supply and signal transmission of the electronically controlled self-propelled packer through the cable 1; realize the self-propelled self-propelled electronically controlled self-propelled packer in the wellbore position of the horizontal well through the crawling mechanism 8; determine the crawling position of the crawling mechanism through the steering head 9 to realize The precise positioning of the electronically controlled self-propelled packer in the horizontal well; the repeated setting and unsealing of the electronically controlled self-propelled packer at any posi...

Embodiment 2

[0022] On the basis of Embodiment 1, further, the cable 1 is an armored cable. Cable 1 is connected to the wellhead power supply, and is mainly responsible for supplying power to the electronically controlled self-propelled packer. It is also the control signal transmission channel of the electronically controlled self-propelled packer. Packing, unpacking and other actions are controlled; the armored cable can well adapt to the environment of horizontal wells, prevent external jamming, pressure, collision, etc., and has good waterproof performance, which can well ensure the power supply of the electronically controlled self-propelled packer And the stability of signal transmission performance, strong adaptability, and prolong service life.

[0023] Further, it also includes a cable joint 2 through which the cable 1 is connected to the centralizer 3 . The armored cable is connected to the electronically controlled self-propelled packer of the horizontal well through the cable ...

Embodiment 3

[0025] On the basis of Example 2, the centralizer 3 is a roller centralizer. The centralizer 3 is mainly to ensure that the electronically controlled self-propelled packer is axially centered in the casing of the horizontal well, and at the same time adopts a roller design to reduce frictional resistance during the reciprocating movement of the electronically controlled self-propelled packer in the casing.

[0026] Further, the roller bearing of the roller centralizer is provided with an elastic mechanism. The elastic mechanism is an existing structure. When encountering debris or scaling on the inner wall of the casing, it can overcome obstacles to a certain extent and improve the self-propelled adaptability of the electronically controlled self-propelled packer.

[0027] The roller centralizer includes a centralizer body 3-1 and a direction scroll wheel 3-2, the number of direction scroll wheels 3-2 is multiple, and the plurality of direction scroll wheels 3-2 are distribute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com