Oil and gas well fracturing flow-back fluid treatment method

A technology for fracturing flowback fluid and treatment methods, which is applied in earthwork drilling, wellbore/well components, production fluids, etc., and can solve problems such as limited single treatment volume, poor water quality, and difficulty in reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A method for treating oil and gas well fracturing flowback fluid. The fracturing flowback fluid discharged through the wellhead of the oil well is put into a buffer tank for oxidation treatment, and a regulator is added to the oxidized fracturing flowback fluid. Adjust the pH of the fracturing flowback fluid after oxidation treatment to 7.5-9, send the adjusted fracturing flowback fluid into the reactor through the lift pump, and add treatment chemicals to the fracturing flowback fluid in the reactor, Make it fully mixed and react to form flocs. When the flocs no longer increase, the reacted mixture is pumped into the solid-liquid separation device (centrifugal separator) for solid-liquid separation. The separated solid phase is directly The solid-liquid separation device is discharged, and the separated liquid phase is refined for recycling or directly discharged to complete the treatment of fracturing flowback fluid; the refined treatment includes three methods:

[00...

Embodiment 2

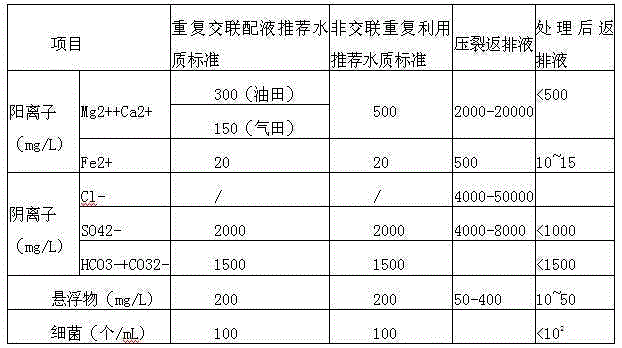

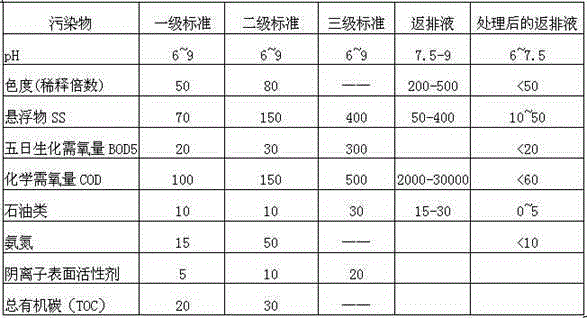

[0026] On the basis of Example 1, the regulator is sodium hydroxide; the treatment agent includes the following ingredients: oxidant, flocculant, coagulant, bactericide; The dosing amount is: oxidant 1-2kg / square, flocculant 2-10kg / square, coagulant aid 1-3kg / square, fungicide 0.05-0.1kg / square, using the agents in this example to achieve rapid flocculation and sedimentation , more than 95% of the flocculation and sedimentation process can be completed in 10 minutes. After 10 minutes of flocculation and settling time, the treatment result can reach more than 80% of the 6-hour treatment effect of traditional chemical treatment agents. Filter the residue, filter out the incompatible solid phase, that is, perform solid-liquid separation, conduct ion detection on the liquid phase, and perform refined treatment according to the results, mainly to remove various ions and suspended solids, chroma, and COD in the water. After refined treatment, the ion content of the liquid is detect...

Embodiment 3

[0028] On the basis of implementation 2, the treatment agents are hydrogen peroxide, polyaluminum chloride, polyacrylamide, and dodecyldimethylbenzyl ammonium chloride, which are added according to the following dosage per cubic meter of fracturing flowback fluid, Hydrogen peroxide 1kg / square, polyaluminum chloride 2kg / square, polyacrylamide 1kg / square, dodecyl dimethyl benzyl ammonium chloride 0.05kg / square, the chromaticity (dilution factor) is 30 after the reaction is completed, The suspended matter SS is 50, the chemical oxygen demand is 80mg / L, and the petroleum is 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com