High-concentration pressure feeding continuous in-bulk system

A high-concentration, high-pressure technology, applied in the direction of conveying bulk materials, conveyors, loading/unloading, etc., can solve the hidden dangers of the on-site loading personnel, the cumbersome on-site operation process, and the inability to solve problems such as flour, so as to save loading time , Simplify the distribution device, reduce the effect of safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] This embodiment is only a preferred technical solution, and the various components and connection relationships involved are not limited to the following implementation described in this embodiment. The configuration and connection relationship of the various components in the preferred solution can be Carry out arbitrary permutations and combinations to form a complete technical solution.

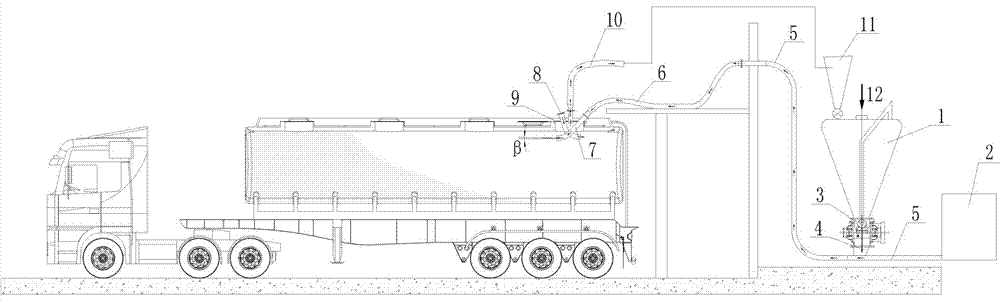

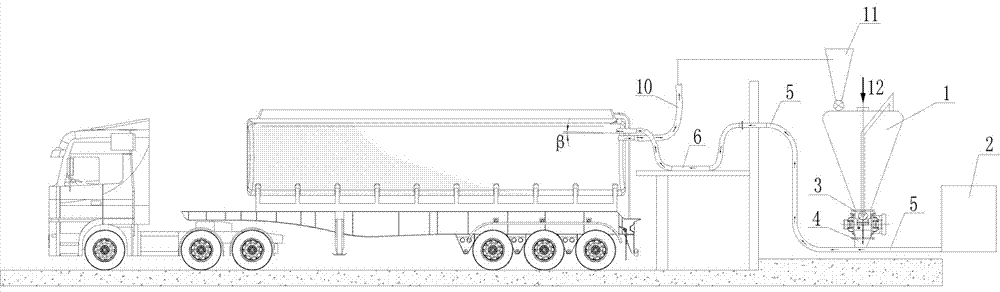

[0031] Combine below figure 1 Describe in detail the technical scheme 1 of the high-concentration pressure-feeding continuous bulk system that adopts the top feeding method of flour bulk tanker:

[0032] A high-concentration pressure-feeding continuous bulk system, including a feeding device and a dust removal device, the feeding device includes a high-pressure sending tank 1, an air compressor 2, a pressure-feeding pipeline, and a tanker inlet cover 9 located on the top of the flour bulk tanker compartment , one end of the pressure-feeding pipeline is respectively connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com