Telescopic charging pipe for powder and granular tanker with positioning guidance

A charging pipe and material tank technology, which is applied to the field of telescopic charging pipes for powder and granular material tankers, can solve the problems of no positioning guide device, affecting the environmental sanitation of loading vehicles, residual pollution of materials, etc., so as to ensure food hygiene and safety and shorten the loading time. time, the effect of overcoming static friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

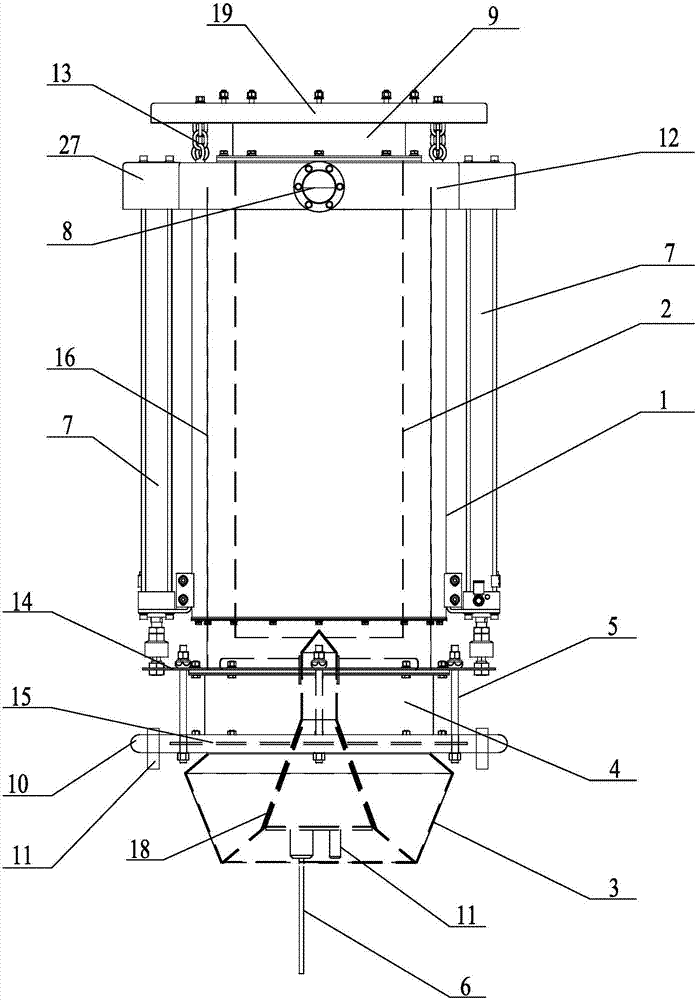

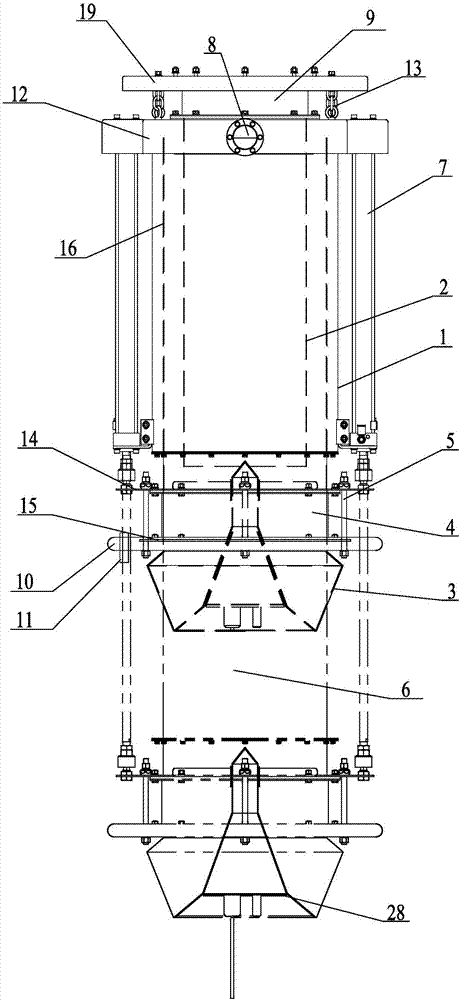

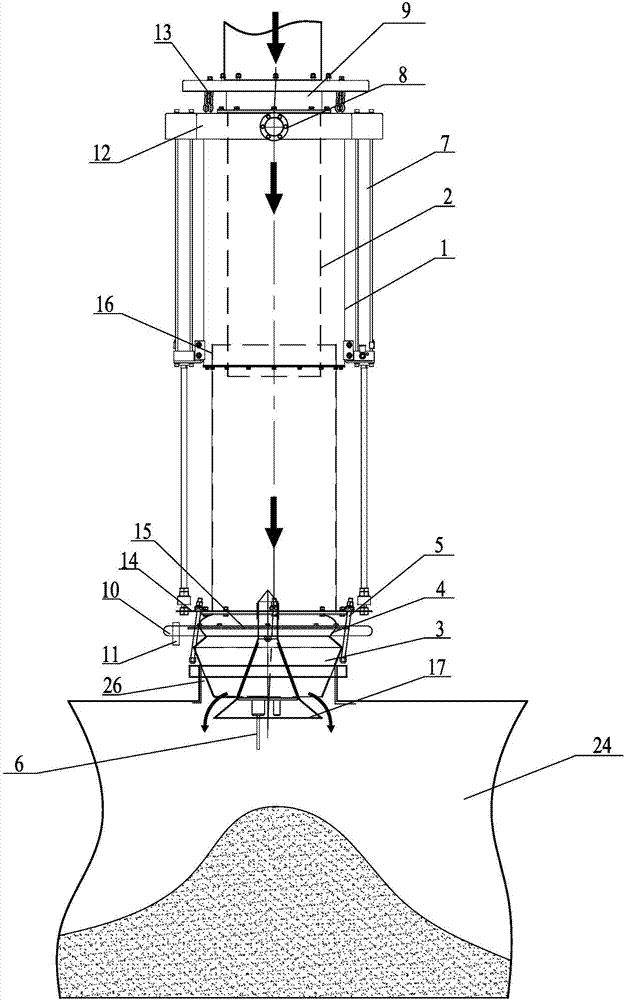

[0023] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0024] Such as figure 1 , figure 2 and image 3 Shown: in order to shorten the loading time and ensure the safety and sanitation of food, the present invention includes a charging pipe body 25; The tapered discharge pipe 3 located below the middle casing 16, the wide head end of the tapered discharge pipe 3 is sealed and connected with the lower end of the middle casing 16 through a deformable lower flexible connecting pipe 4, and the tapered discharge The feed pipe 3, the lower flexible connecting pipe 4, and the middle casing 16 are coaxially distributed with the outer casing 1, and the tapered discharge pipe 3 communicates with the outer casing 1 through the lower flexible connecting pipe 4;

[0025] Outer casing 1 is provided with a telescopic drive mechanism for driving the middle casing 16 to expand and contract in the outer casing 1. When the telesco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com