Pressure-control drilling system utilizing automatic shunt manifold for pressure-control drilling and pressure-control drilling method

It is a technology of managed pressure drilling and automatic flow diversion, which is applied in wellbore/well components, earthwork drilling, flushing wellbore, etc. It can solve the problems of occupying, increasing the cost of wellhead back pressure pump and its ancillary equipment, large site space, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the following embodiments in no way limit the present invention.

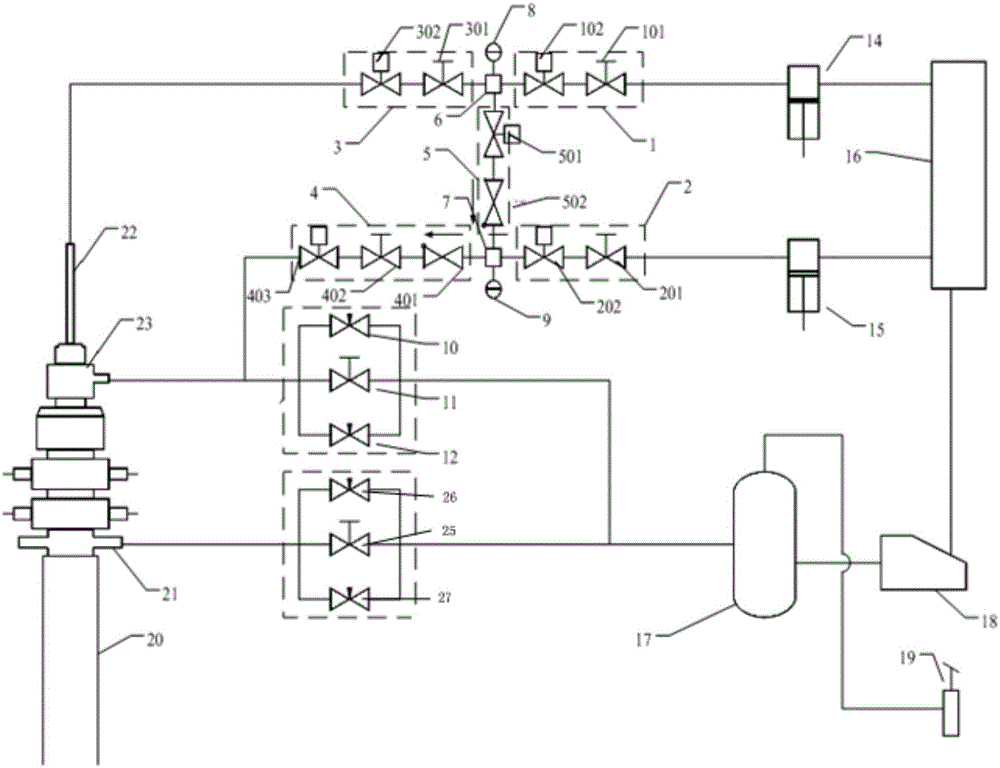

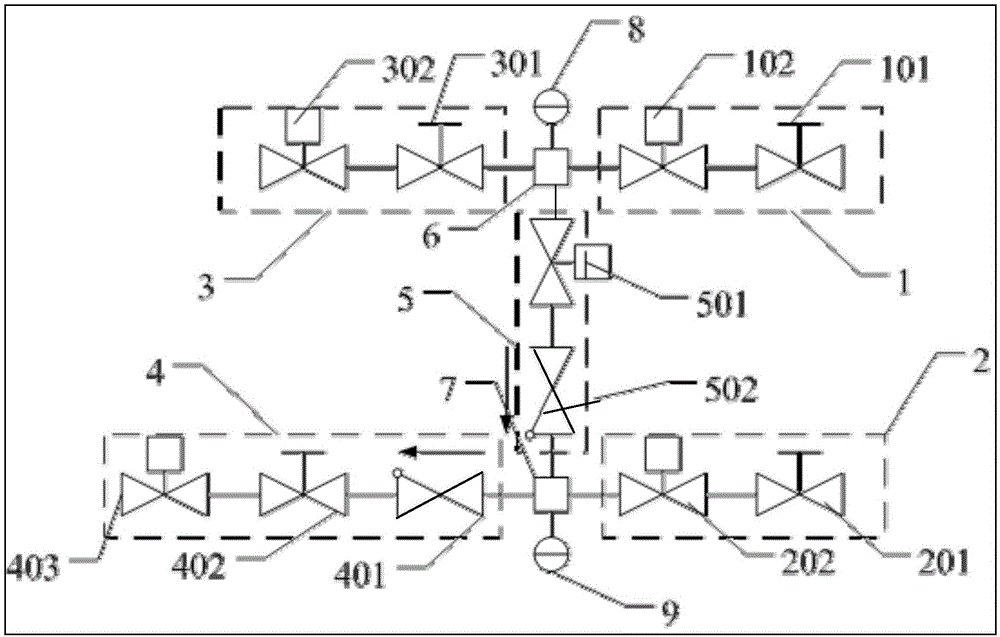

[0022] Such as Figure 1~2 As shown, the managed pressure drilling system includes a drilling spool 21 arranged at the upper wellhead of the wellbore 20, a rotary control head 23 and a drill string 22, and bypass pipes connected to the drill string 22 and the rotary control head 23 respectively. The automatic diverter manifold, the automatic throttling manifold and the throttling manifold that communicate with the bypass pipeline in the blowout direction of the drilling spool 21; specifically,

[0023] The automatic distribution manifold includes a first inflow path 1, a second inflow path 2, a first outflow path 3, a second outflow path 4 and a conversion path 5; the first inflow path 1, the The first outflow path 3 and the conversion path 5 are respectively connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com