Self-bearing type preprocessing component, self-bearing type preprocessing concrete structure and construction method thereof

A concrete structure and construction method technology, applied in the direction of structural elements, building components, building reinforcements, etc., can solve the problems of high-altitude operations, difficult on-site construction, frequent safety accidents, etc., so that the construction quality is easy to control and reduce Effects of reducing construction risks and safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

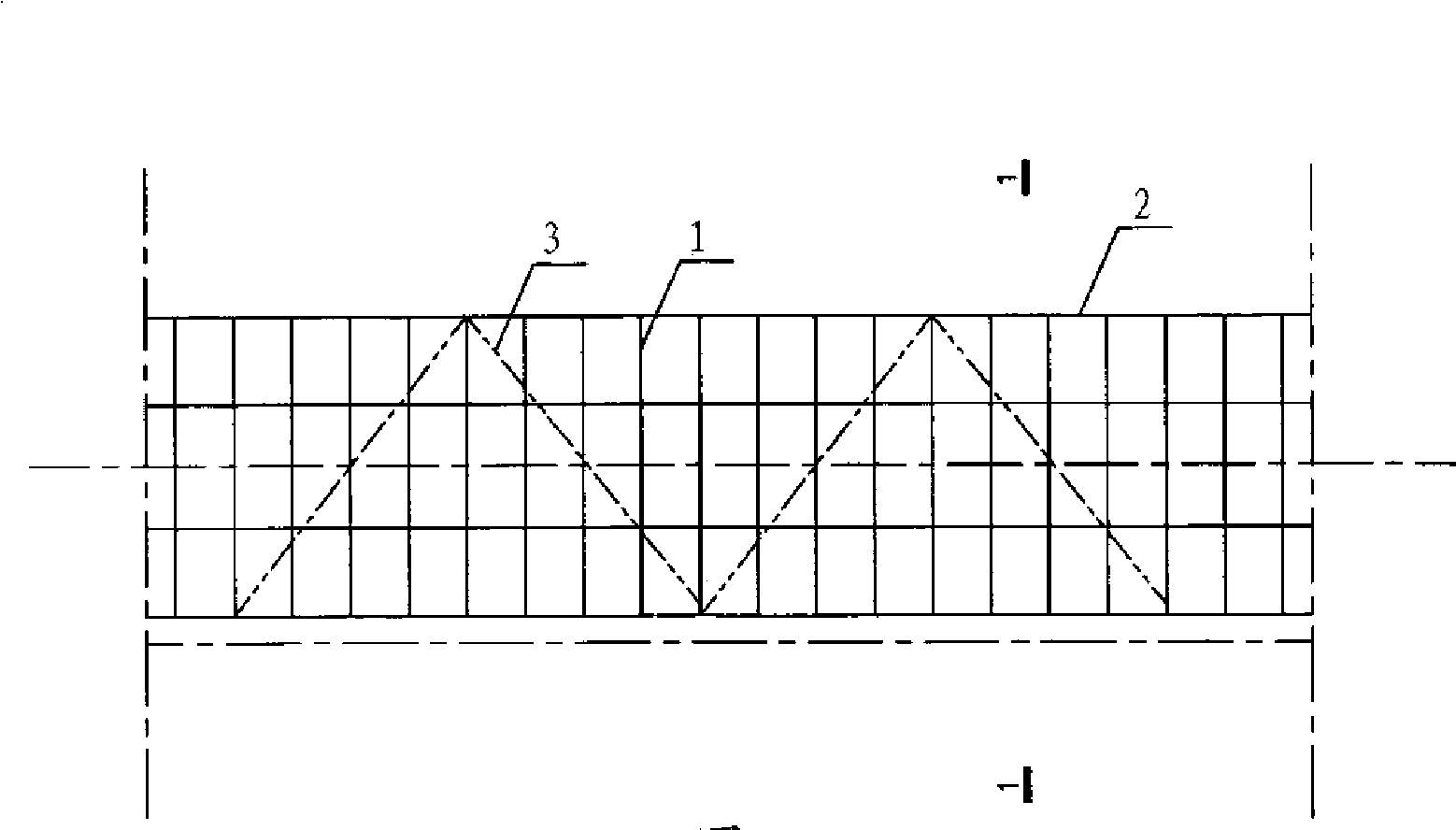

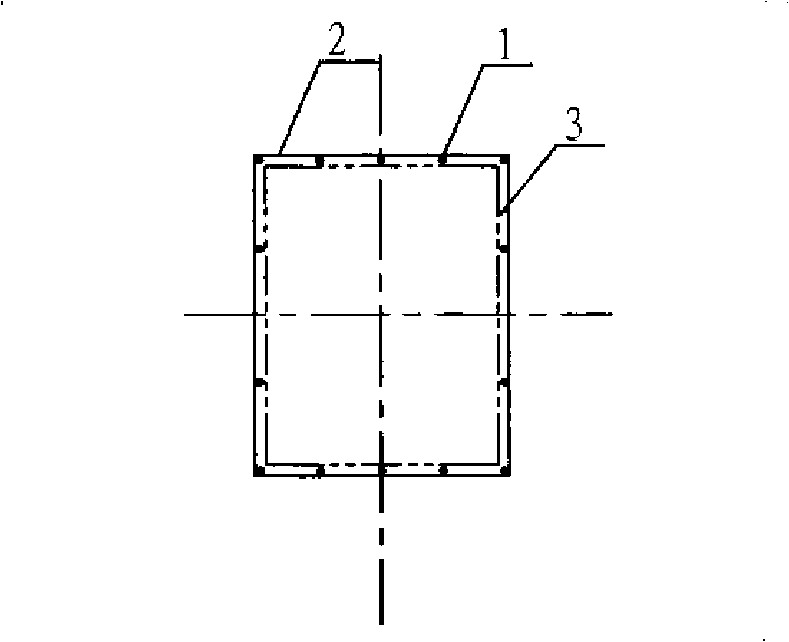

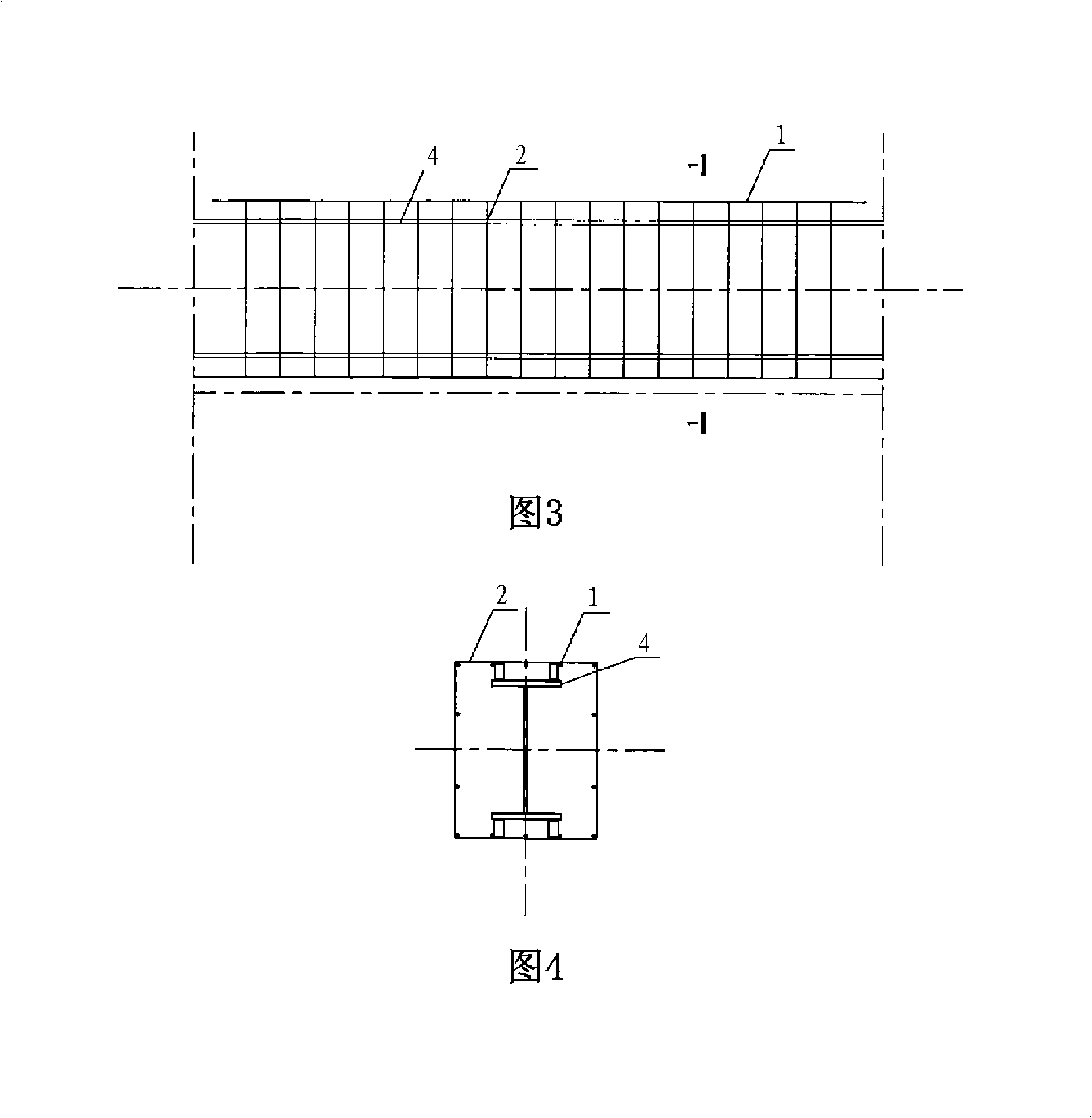

[0078] Examples see Figure 1-Figure 25 , this self-supporting prefabricated component is characterized in that it is a stable structure that is connected by a pre-assembled steel skeleton and supporting components and has a load-bearing structure that relies on its own material. The longitudinal reinforcement in the above-mentioned three-dimensional steel skeleton has at least four root.

[0079] see Figure 1-Figure 26 The above-mentioned three-dimensional reinforced skeleton is a combination of steel bar, section steel, prestressed steel bar or any two or three of the above-mentioned. The longitudinal bars of the above-mentioned steel bar grid are connected with stirrups at intervals along the length. , Horizontal bars and tension bars. Steps for Tensioned Reinforcement with Prestressed Reinforcement.

[0080] The above-mentioned supporting parts are one or more combinations of diagonal rods, steel frames or templates, wherein the diagonal rods and steel frames are steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com