Prefabricated corner wall and construction method

A corner and wall technology, used in buildings, building components, building structures, etc., can solve problems such as troublesome operation and hidden dangers, and achieve the effect of high safety, eliminating hidden dangers and reducing working time at heights.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

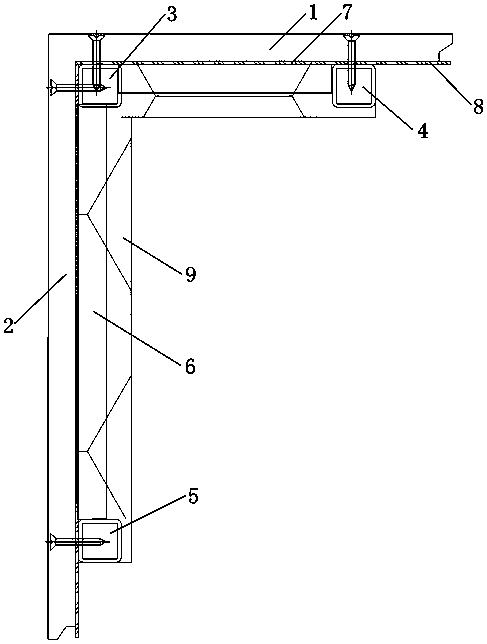

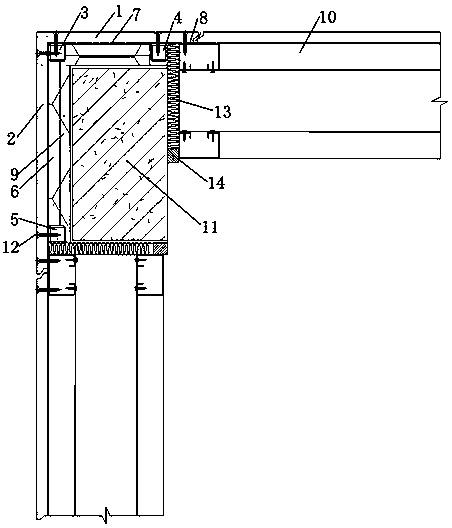

[0012] The prefabricated corner wall of the present invention is such as figure 1 As shown, there are a first wall panel 1 and a second wall panel 2 that are vertically connected, and the first wall panel 1 and the second wall panel 2 can be a cement fiber board with an integrated structure, and the ends thereof are of a tongue-and-groove structure. The inner side of the connecting end of the first wall panel 1 and the second wall panel 2 is connected to the two sides of the first vertical tube 3 respectively, and the inner side of the first wall panel 1 is connected to the side surface of the second vertical tube 4 by screws. , The inner side of the second wall panel 2 is in contact with the side surface of the third vertical square tube 5, and the second vertical square tube 4 and the third vertical square tube 5 are respectively separated from the 1 end of the first wall panel and the 2 end of the second wall panel. The horizontal distance of the head is 60mm, the first ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com