Fully-automatic grinder

A fully automatic, grinding machine technology, applied in the field of machinery, can solve the problems of large floor space and potential safety hazards, and achieve the effects of small floor space, reduced defective rate, and uniform distribution of clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

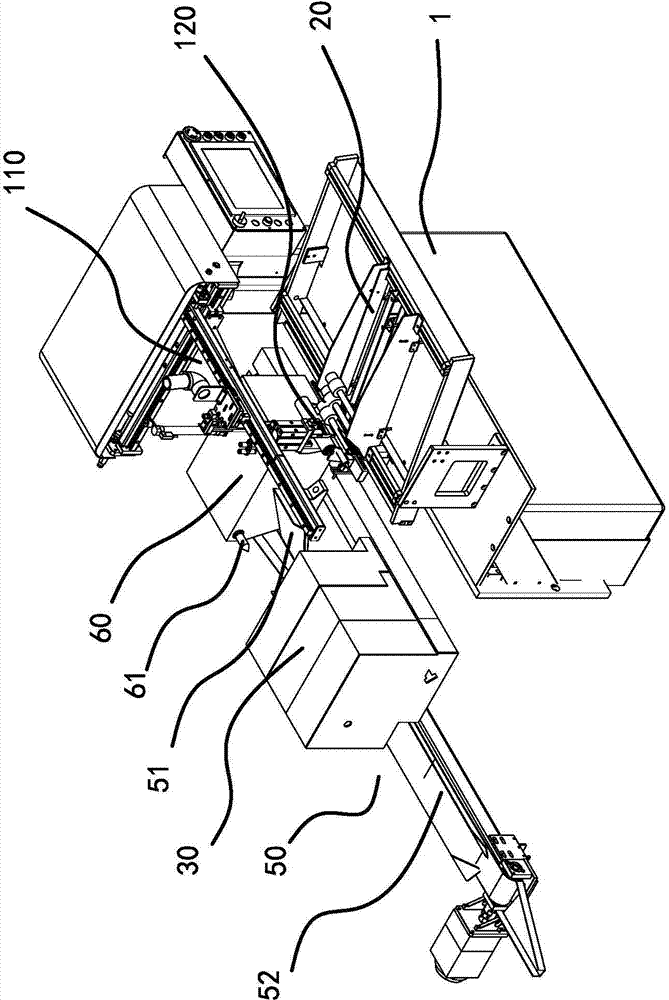

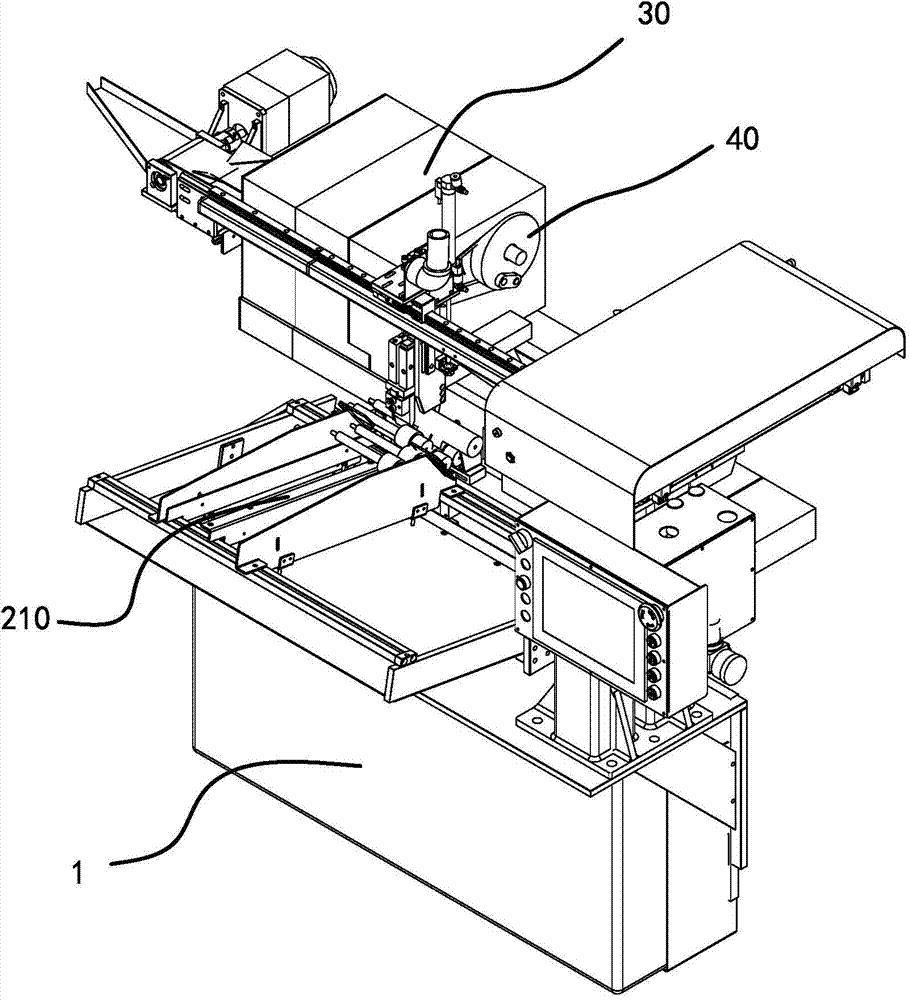

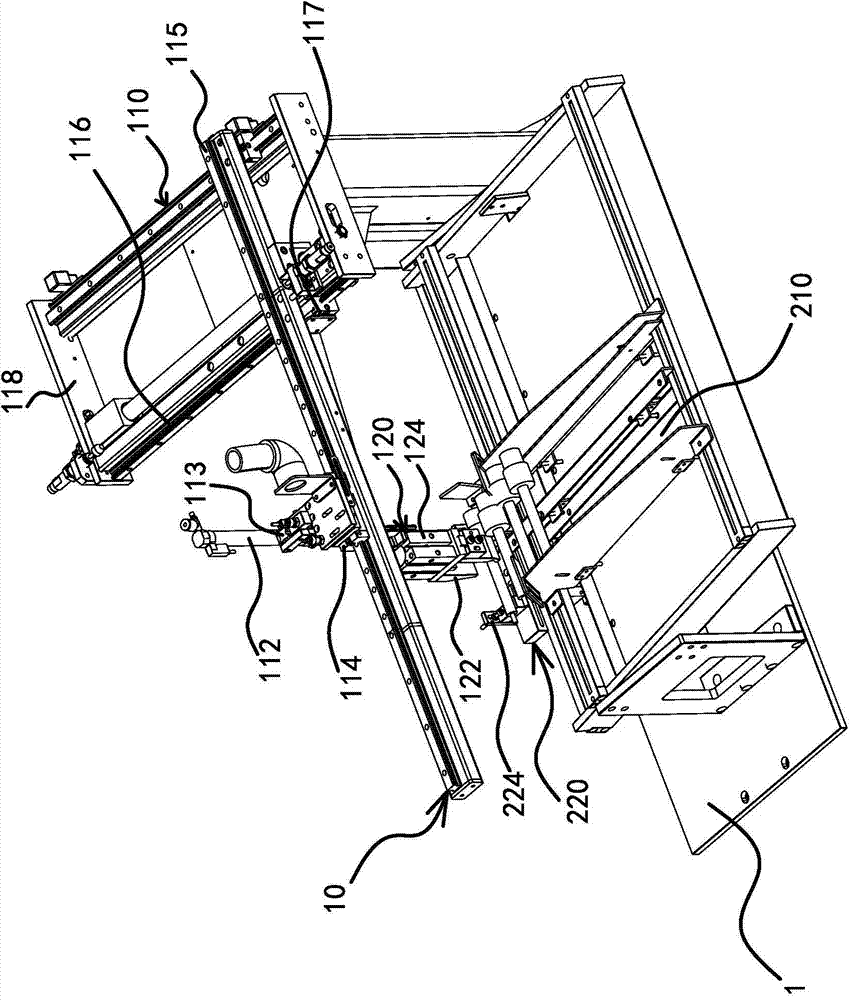

[0036] Such as Figure 1 to Figure 14 As shown, the fully automatic grinding machine includes a frame 1, and the frame 1 is divided into a feeding area and a processing area from front to back in turn, and an incoming material mechanism 10 and a feeding mechanism 20 are arranged in the feeding area, and a spindle is arranged in the processing area The box 30 and the unloading mechanism 50, the unloading mechanism 50 and the incoming material mechanism 20 are respectively arranged on both sides of the spindle box 30, and the feeding mechanism 10 is arranged above the incoming material mechanism 20 and can reciprocate in a straight line between the incoming material mechanism 20 and the spindle box 30 Movement, a floating ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com