Multi-shaft parallel-connection cutting machining device

A cutting processing and parallel connection technology, applied in metal processing equipment, metal processing machinery parts, turning equipment, etc., can solve the problems of unsuitable to ensure the dynamic balance of the water pump, the overall shape of the water pump is irregular, and the processing efficiency is not high, so as to improve the processing efficiency of the equipment , Improve processing flexibility, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means and creative features realized by the present invention easy to understand, the present invention will be further elaborated below.

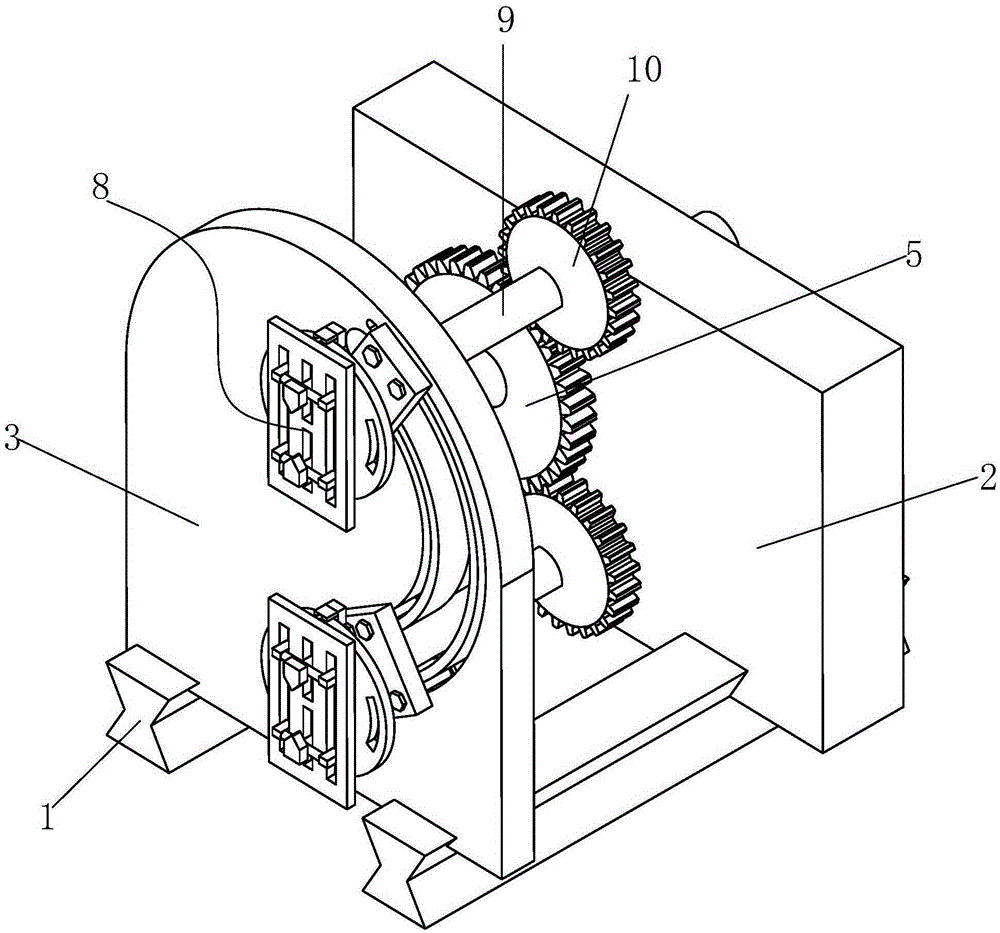

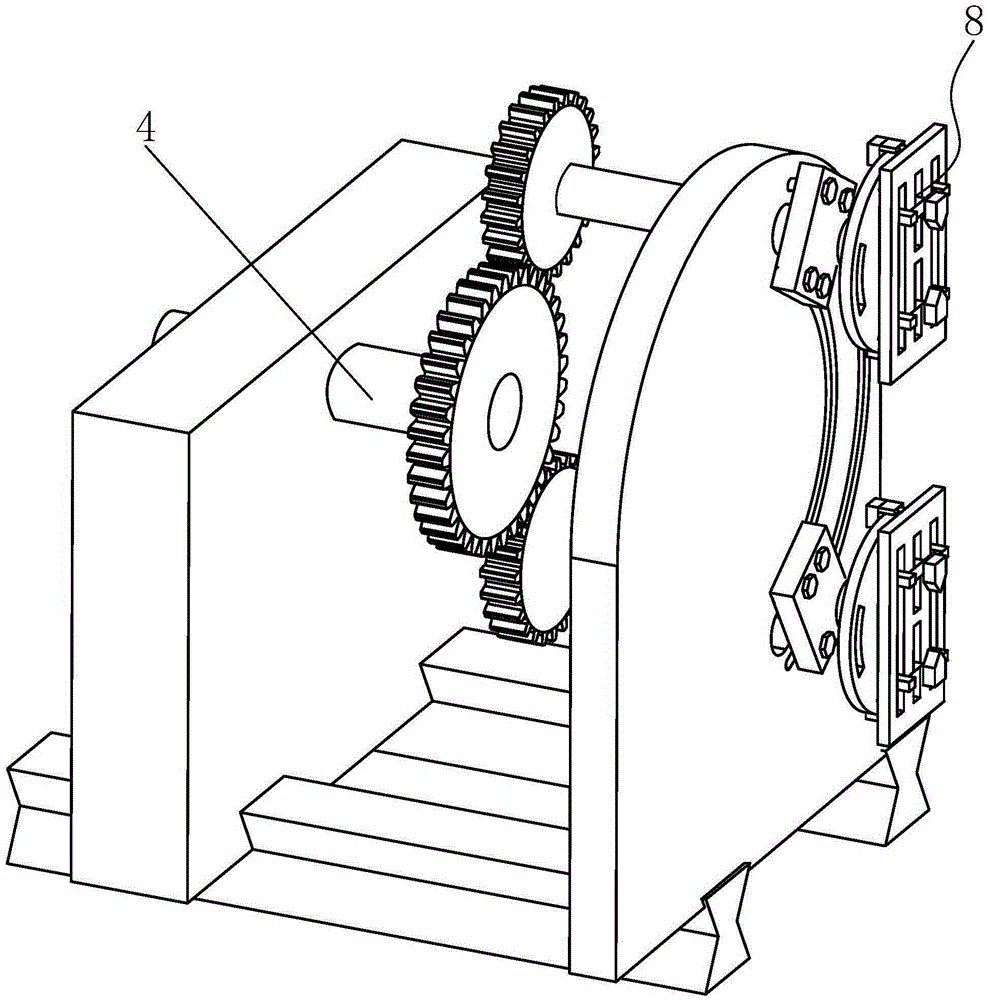

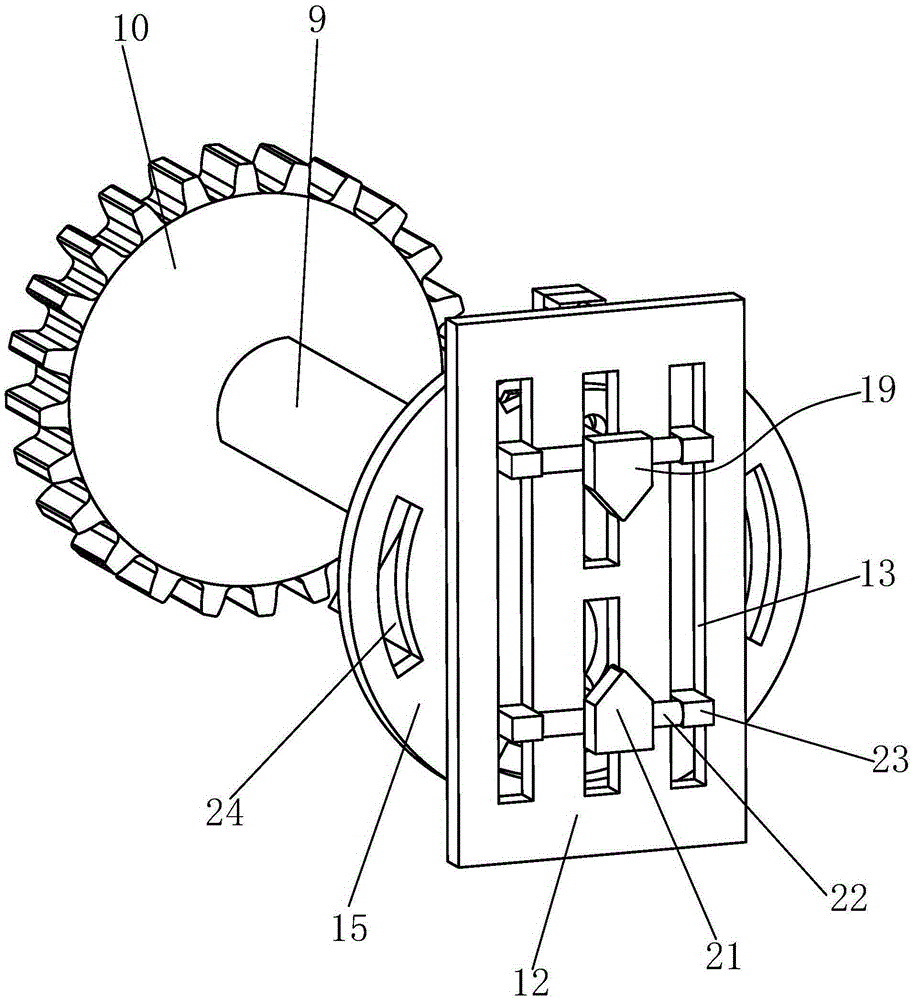

[0026] Such as Figure 1 to Figure 8 As shown, a multi-axis parallel cutting processing device includes a slide rail 1 on which a sliding support frame 2 and a sliding turntable 3 are matched.

[0027] A bearing sleeve is installed in the sliding support frame 2, and a transmission shaft 4 is connected inside the bearing sleeve, and a driving gear 5 is installed at the front end of the transmission shaft 4.

[0028] The sliding turntable 3 is provided with an arc-shaped slideway 6, the inside and outside of the arc-shaped slideway 6 are respectively provided with an arc-shaped positioning slideway 7, and there are two turning tool holders 8 in the arc-shaped slideway 6. . The arc-shaped slideway 6 is semicircular, so that the distance between the turning tool holders 8 in the arc-shaped slideway 6 ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com