Fine-adjustment level tripod

A tripod and leveling technology, applied in the field of tripods, can solve problems such as difficult to guarantee accuracy, time-consuming process, poor support stability, etc., and achieve the effect of good accuracy and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

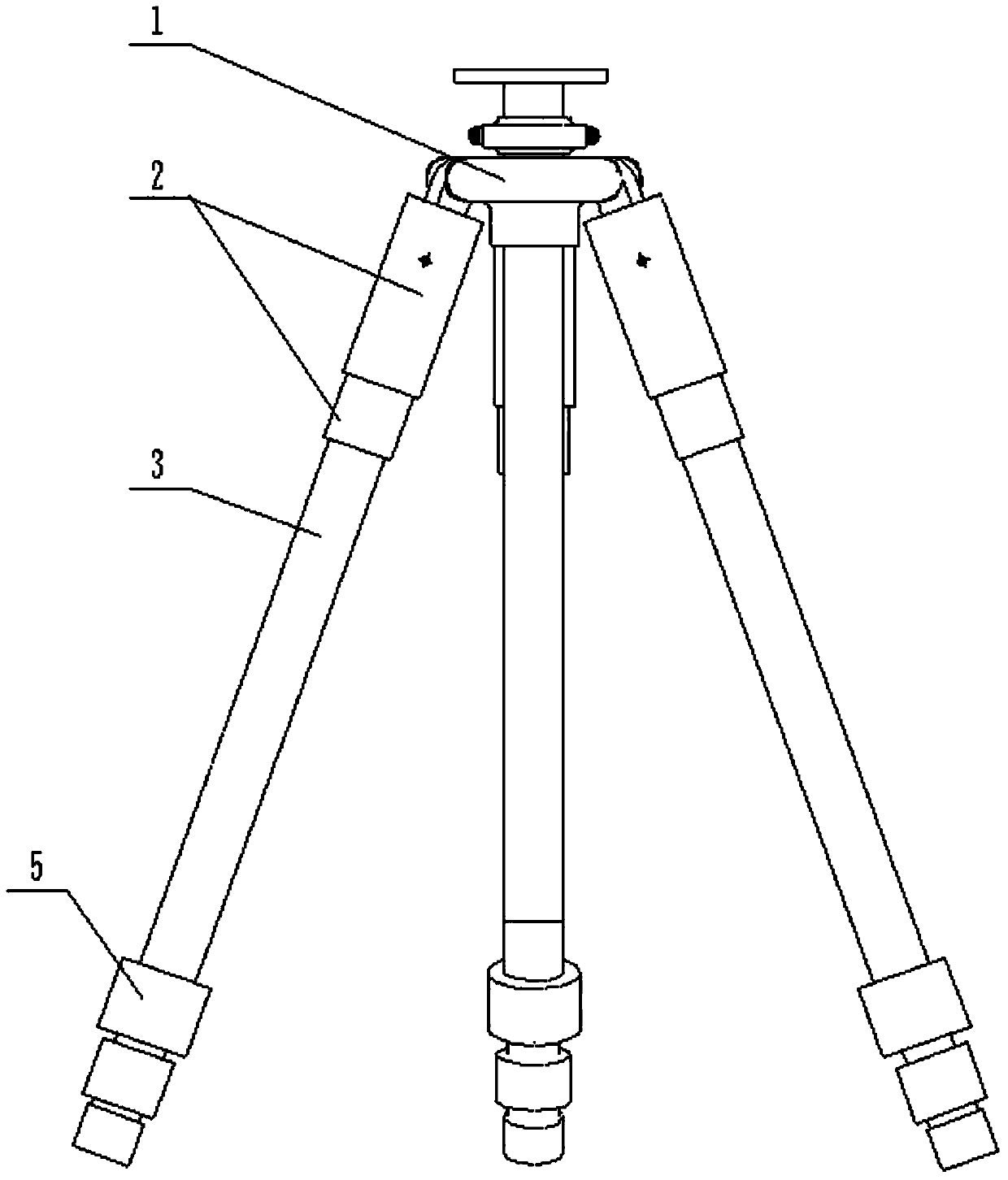

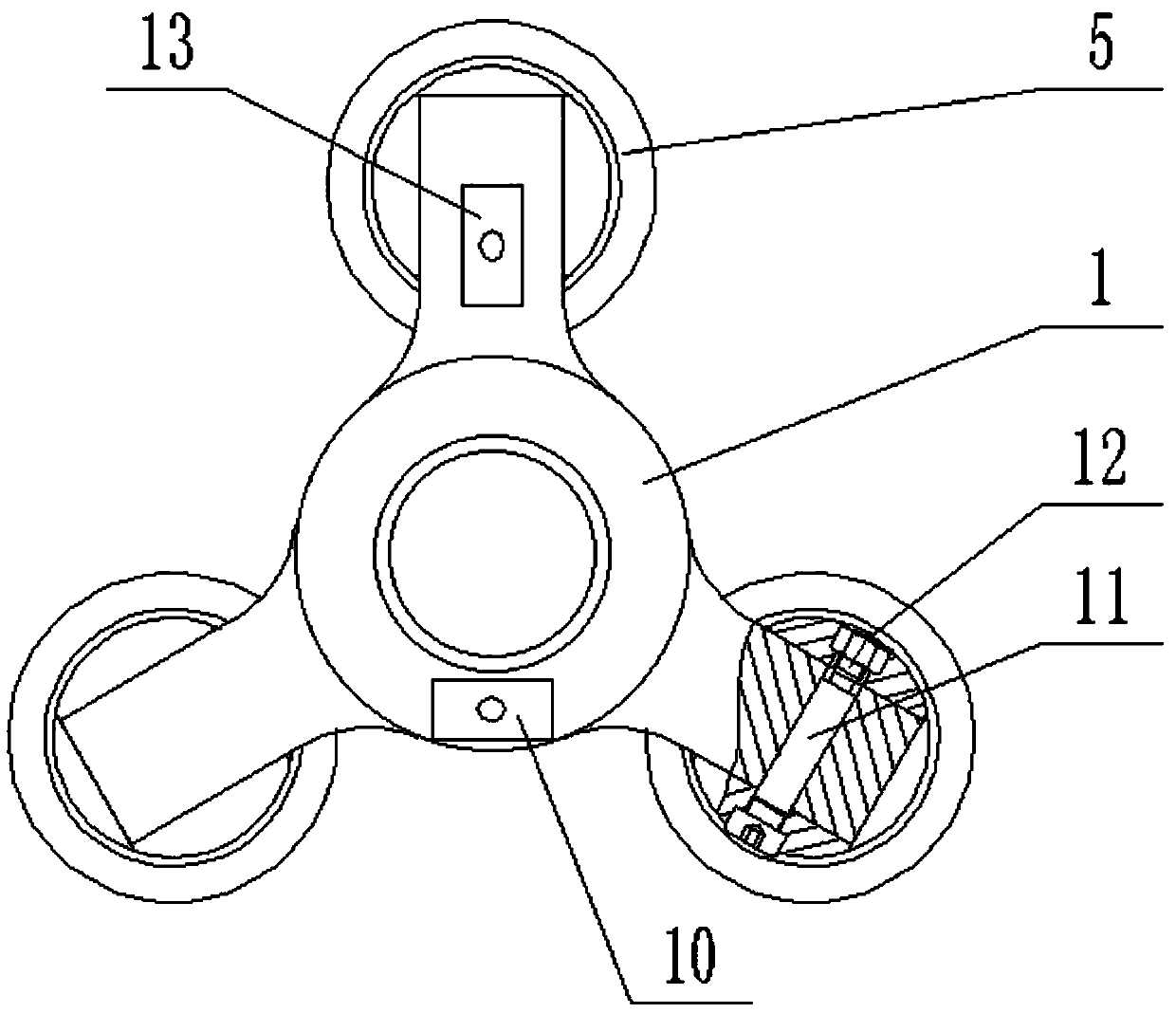

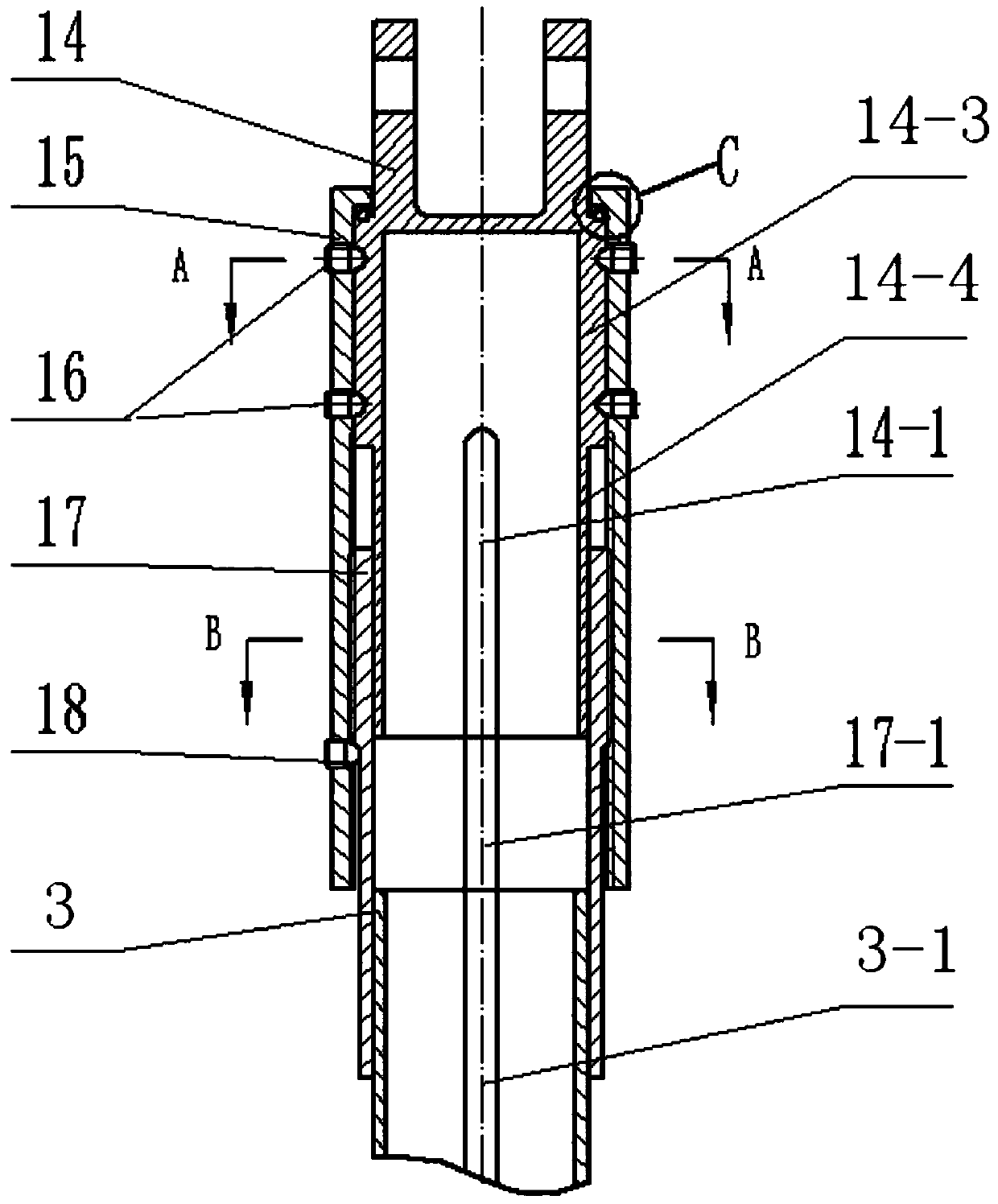

[0036] like figure 1 , 3 , 4, and 5. The invention discloses a fine-tuning horizontal tripod, comprising a tripod 3, a connecting piece 1, and a connecting end 14, one end of the connecting end 14 is connected to the connecting piece 1 (connected by a bolt 11 and a nut 12), and the other end is connected to the tripod 3 connection, a fine-tuning mechanism 2 for adjusting the telescoping ratio of the tripod 3 is also provided between the tripod 3 and the connector 1;

[0037] The fine-tuning mechanism 2 includes a fine-tuning coil 15 and a fine-tuning conduit 17;

[0038] The upper end of the fine-tuning coil 15 is movably sleeved on the outer peripheral wall of the upper connector 14-3 of the connecting terminal 14;

[0039] The lower end of the fine-tuning coil 15 is sleeved on the upper end of the fine-tuning conduit 17, and the fine-tuning coil 15 and the fine-tuning conduit 17 are connected by internal and external threads;

[0040] The upper end of the tripod 3 extend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com