Panel overturning and micro-adjusting mechanism

A technology for fine-tuning mechanisms and panels, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of ineffective quality assurance, low production efficiency, high risk, and improve production efficiency and use. The effect of safety, compact structure, convenient production and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiments of the present invention will be described below in conjunction with the drawings.

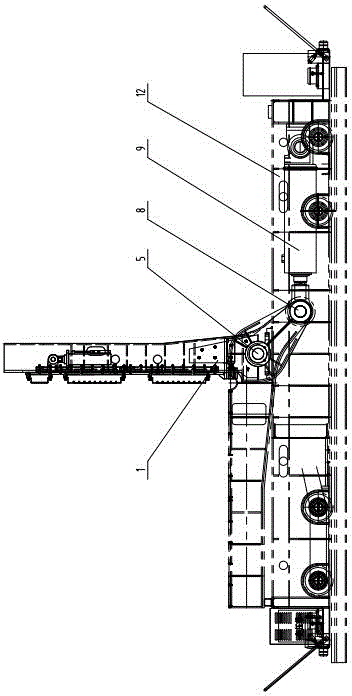

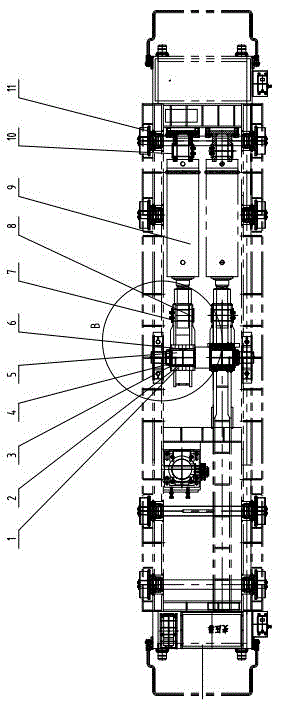

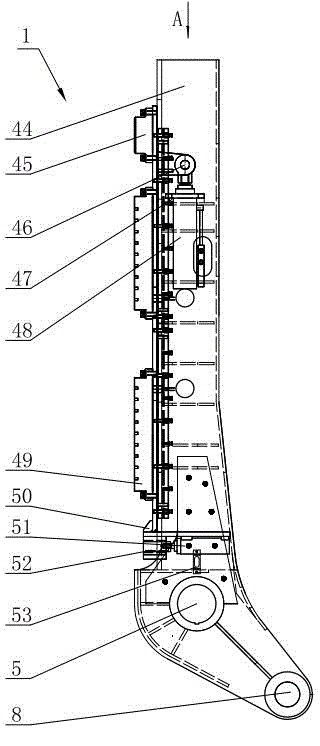

[0016] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, the panel turning and fine-tuning mechanism of this embodiment includes a frame 12 in which a cylinder base 11 is fixed through a second pin 10, and the output end of the cylinder base 11 is connected to the flip arm 1, and the structure of the flip arm 1 It includes a flip arm body 44, a bottom plate 47 is fixed in the flip arm body 44, a jacking cylinder 48 is installed on the bottom plate 47, and the top of the bottom plate 47 is connected to the side wall of the flip arm body 44 through a third pin 46; the flip arm body 44 A movable base 50 is fixed on the left arm of the middle part by a pressing block 57, an adjusting washer 58 and bolts. The movable base 50 is in a right-angled structure. The electromagnet 49 and a support block 45 are installed on the long right-angled side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com