Automatic tightness adjusting type belt fastener capable of automatically adjusting tightness of belt

An automatic adjustment, belt buckle technology, applied in the direction of buckles, fasteners, clothing belts, etc., can solve the problems of fine adjustment of belt tightness, belt damage, inability to user experience, etc., to ensure integrity and avoid damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

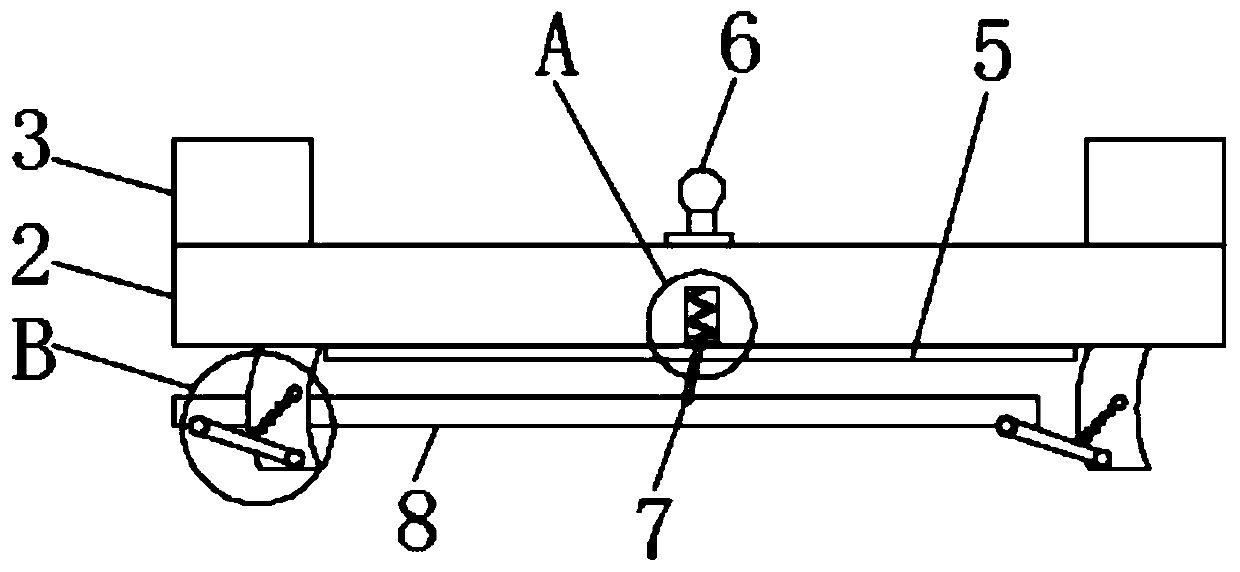

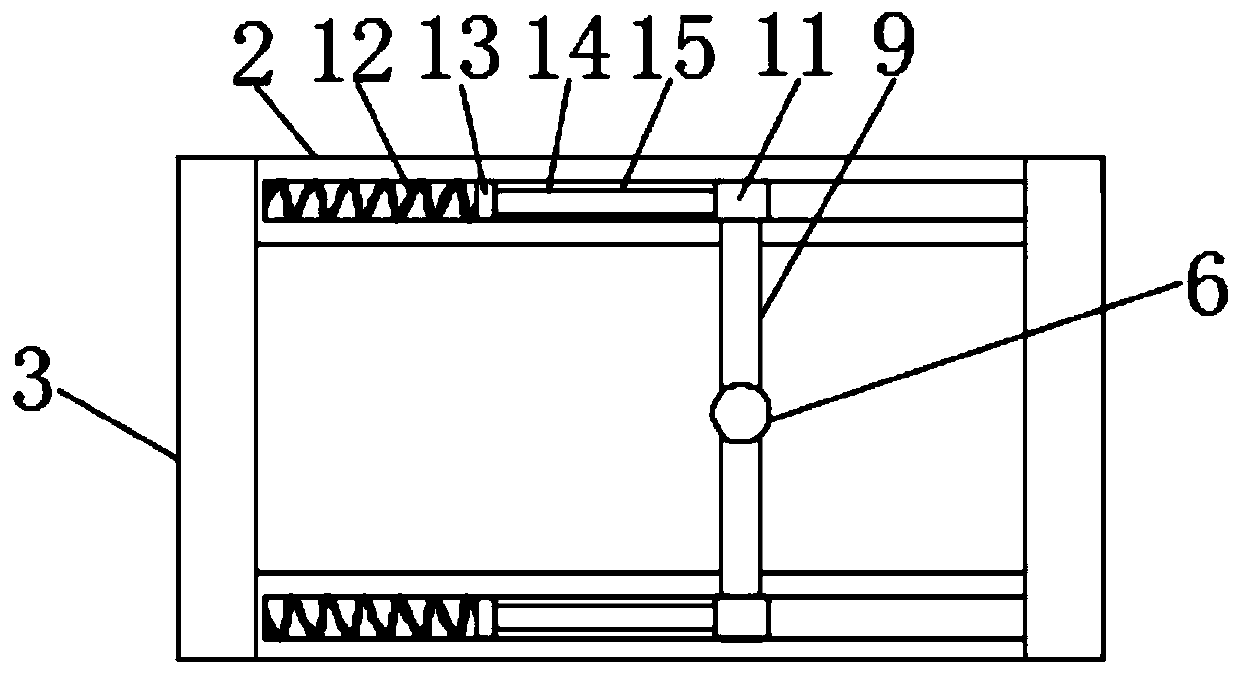

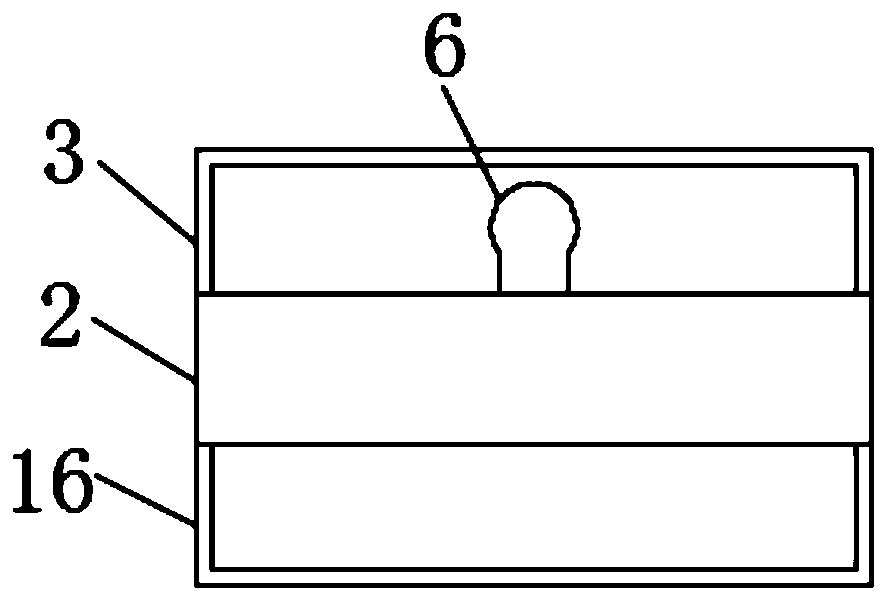

[0035]The difference between the second embodiment and the first embodiment is that the bottom end surface of the button body 2 is fixedly connected with an upper friction plate 5, the position of the upper friction plate 5 corresponds to the position of the lower friction plate 8 and the upper friction plate 5 is located at the bottom of the lower friction plate 8. Directly above, the opposite sides of the upper friction plate 5 and the lower friction plate 8 are provided with anti-skid lines, through the mutual cooperation between the upper friction plate 5 and the lower friction plate 8, the end of the belt without a belt hole can be firmly fixed in the middle There are two upper fixing sleeves 3 symmetrically and vertically fixedly connected to both sides of the upper end of the button body 2, and two sliding grooves 15 are provided on the upper end surface of the button body 2 transversely and symmetrically, and a slider 11 is slidably connected in each sliding groove 15, ...

Embodiment 3

[0037] The difference between the third embodiment and the first embodiment is that the bottom surface of the button body 2 is fixedly connected with the upper friction plate 5, the position of the upper friction plate 5 corresponds to the position of the lower friction plate 8 and the upper friction plate 5 is located at the bottom of the lower friction plate 8. Directly above, the opposite sides of the upper friction plate 5 and the lower friction plate 8 are provided with anti-skid lines, through the mutual cooperation between the upper friction plate 5 and the lower friction plate 8, the end of the belt without a belt hole can be firmly fixed in the middle There are two upper fixing sleeves 3 symmetrically and vertically fixedly connected to both sides of the upper end of the button body 2, and two sliding grooves 15 are provided on the upper end surface of the button body 2 transversely and symmetrically, and a slider 11 is slidably connected in each sliding groove 15, One...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com