Conveying structure

A conveyor belt and sliding frame technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of large space occupied by telescopic devices, low work efficiency, and uncompact structure, and achieve compact conveying structure, fast movement, and convenience The effect of connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

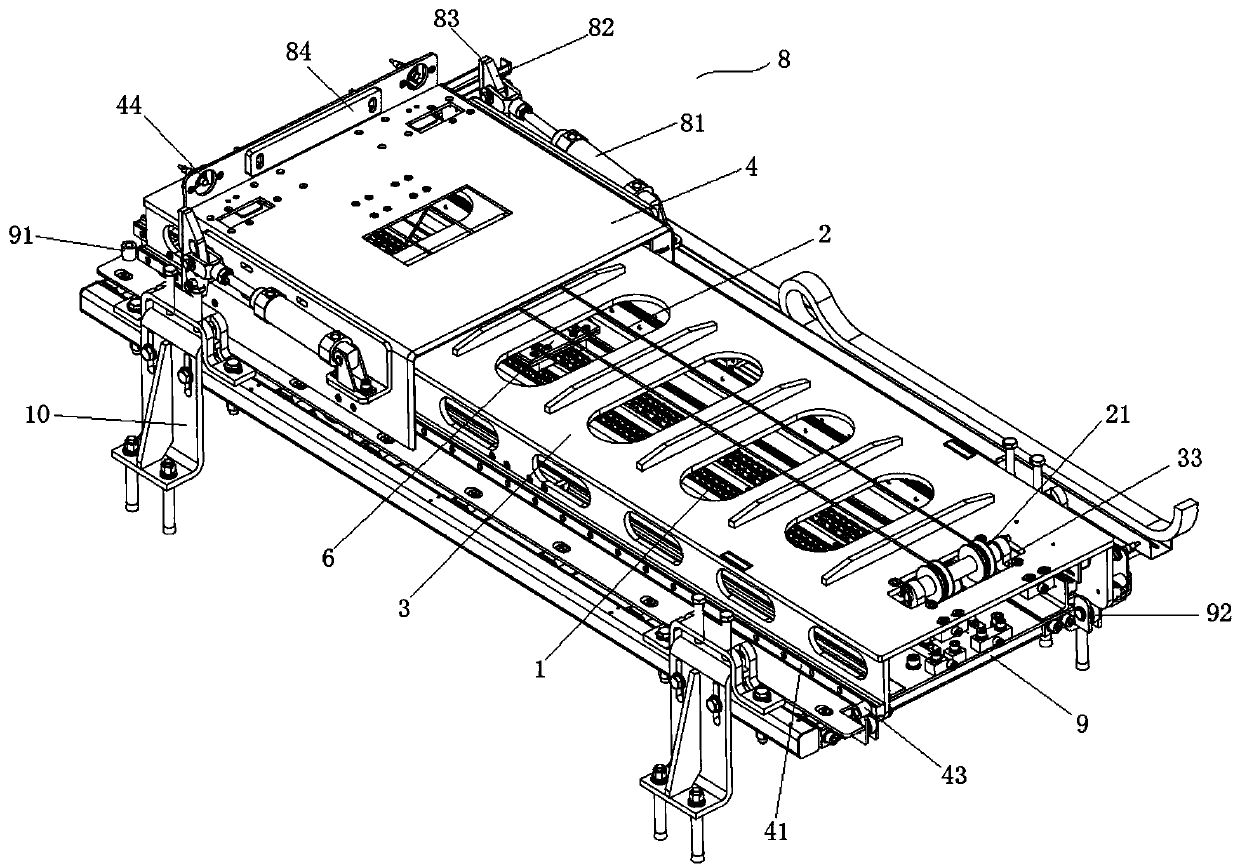

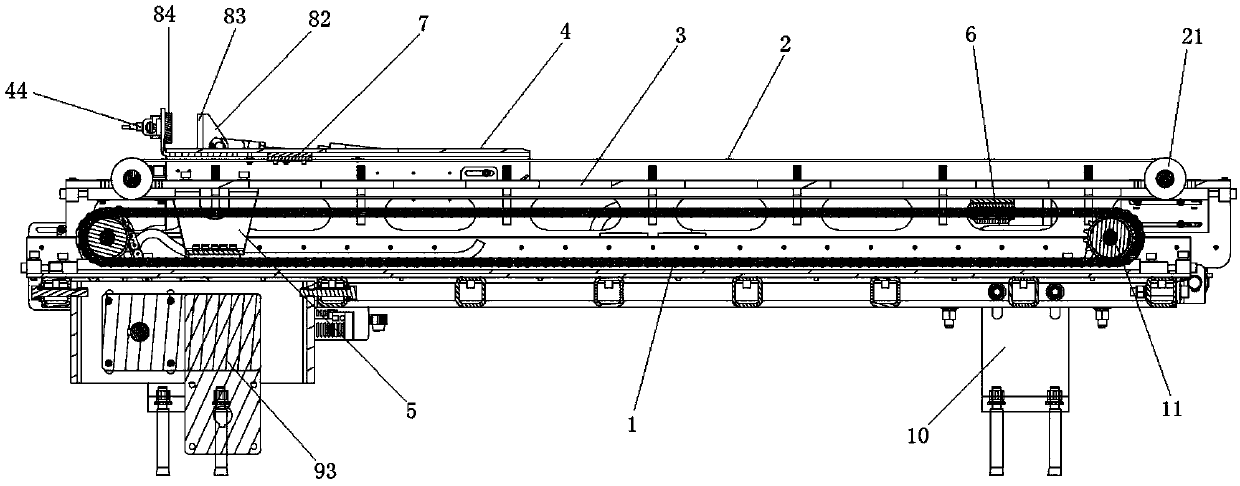

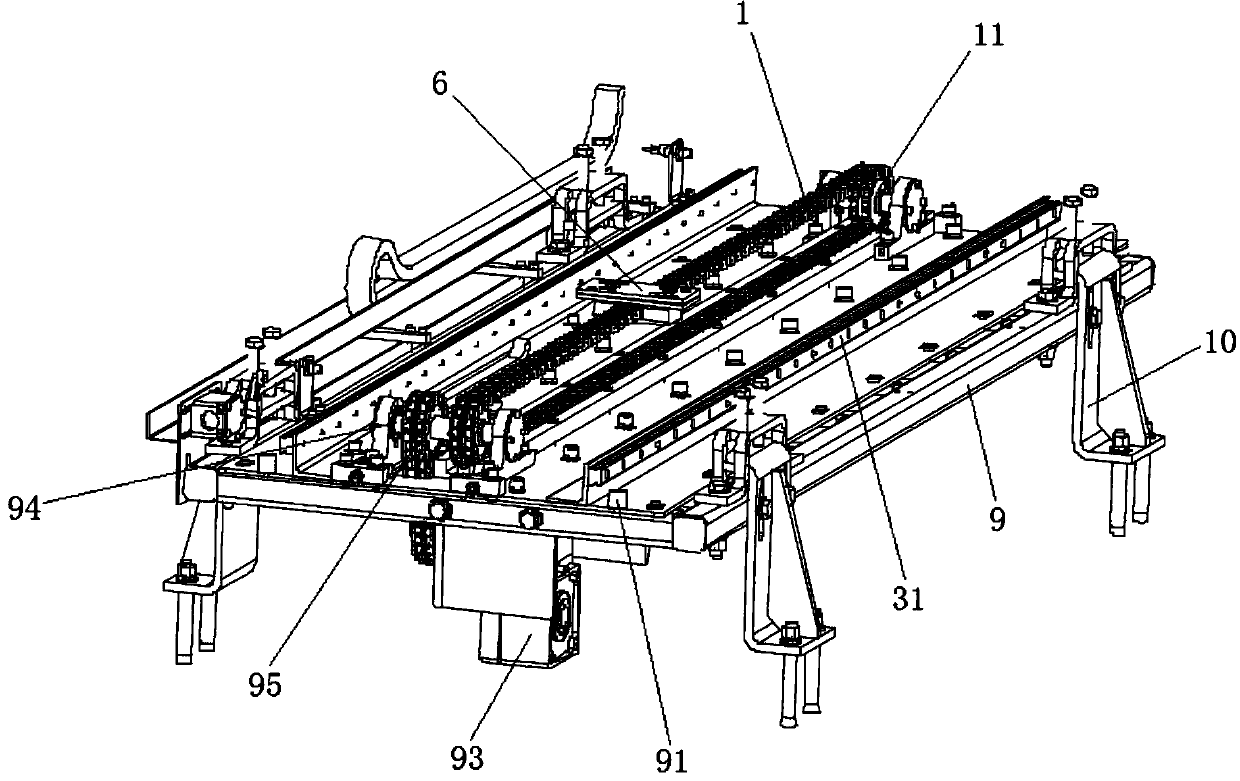

[0064] This embodiment provides a transport structure, such as figure 1 As shown, it includes a base 9 , a first conveyor belt 1 , a second conveyor belt 2 , a first sliding frame 3 and a second sliding frame 4 . Wherein the first conveyor belt 1 and the second conveyor belt 2 are respectively closed and looped on the respective corresponding roller sets, and the second conveyor belt 2 is stacked on the top of the first conveyor belt 1 at the required interval, and the second conveyor belt 2 The lower end is fixedly connected with the upper end of the first conveyor belt 1, the first conveyor belt 1 is driven by the first driver 93 to reciprocate and slide, the first carriage 3 is fixed on the lower end of the first conveyor belt 1, and the second conveyor belt 2 is wound around The second roller group 21 is fixed on the first sliding frame 3, the second sliding frame 4 is fixed on the upper end of the second conveyor belt 2, and the first sliding frame 3 is at the junction of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com