Patents

Literature

31results about How to "Avoid glue opening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

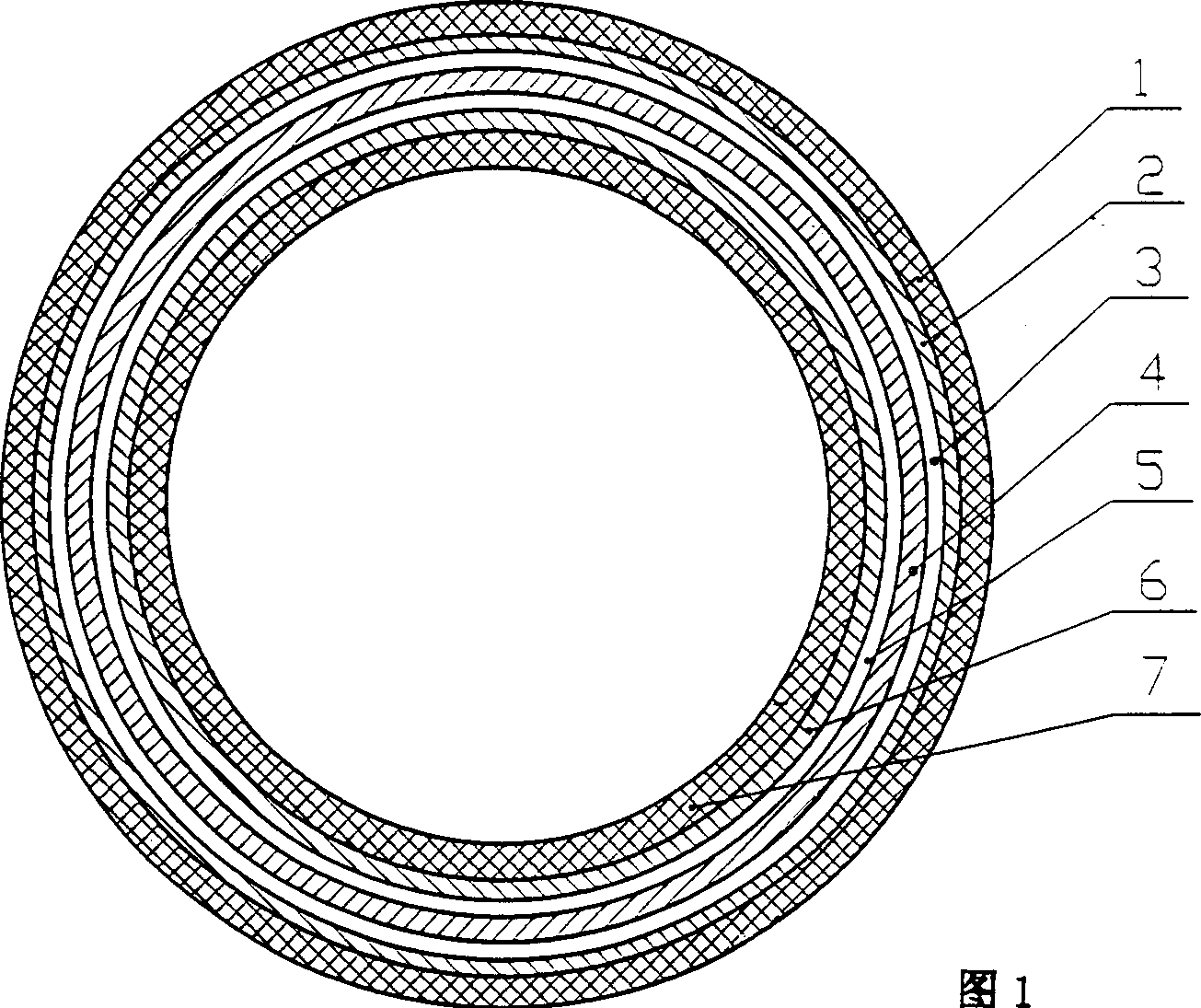

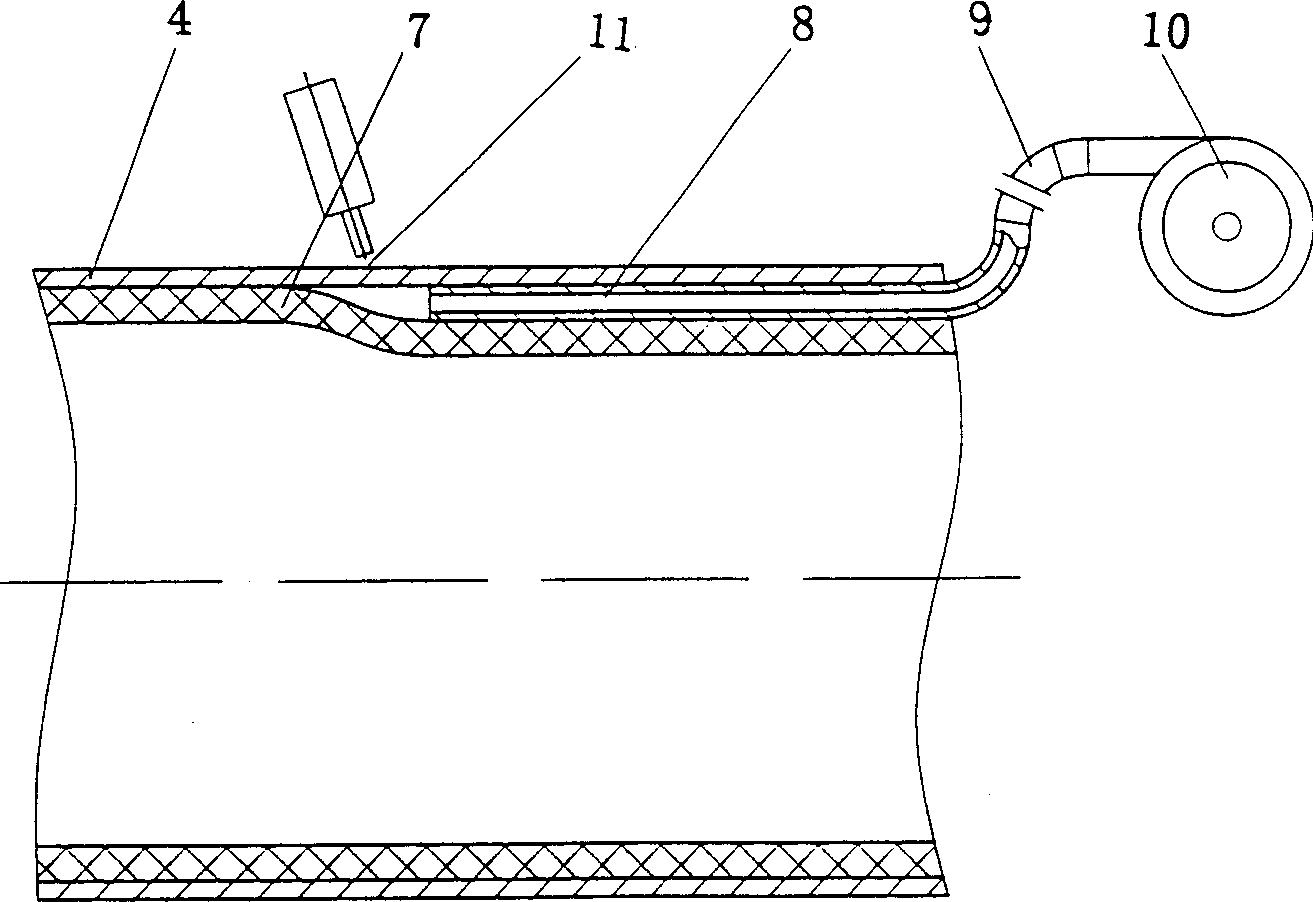

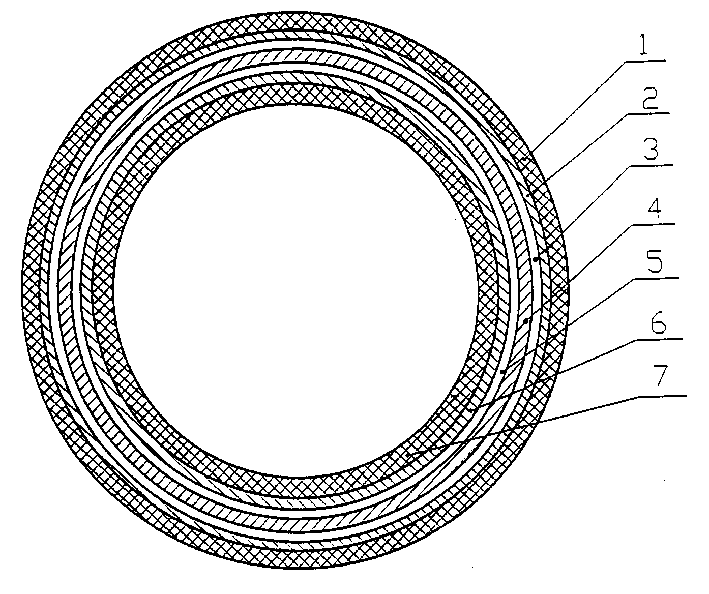

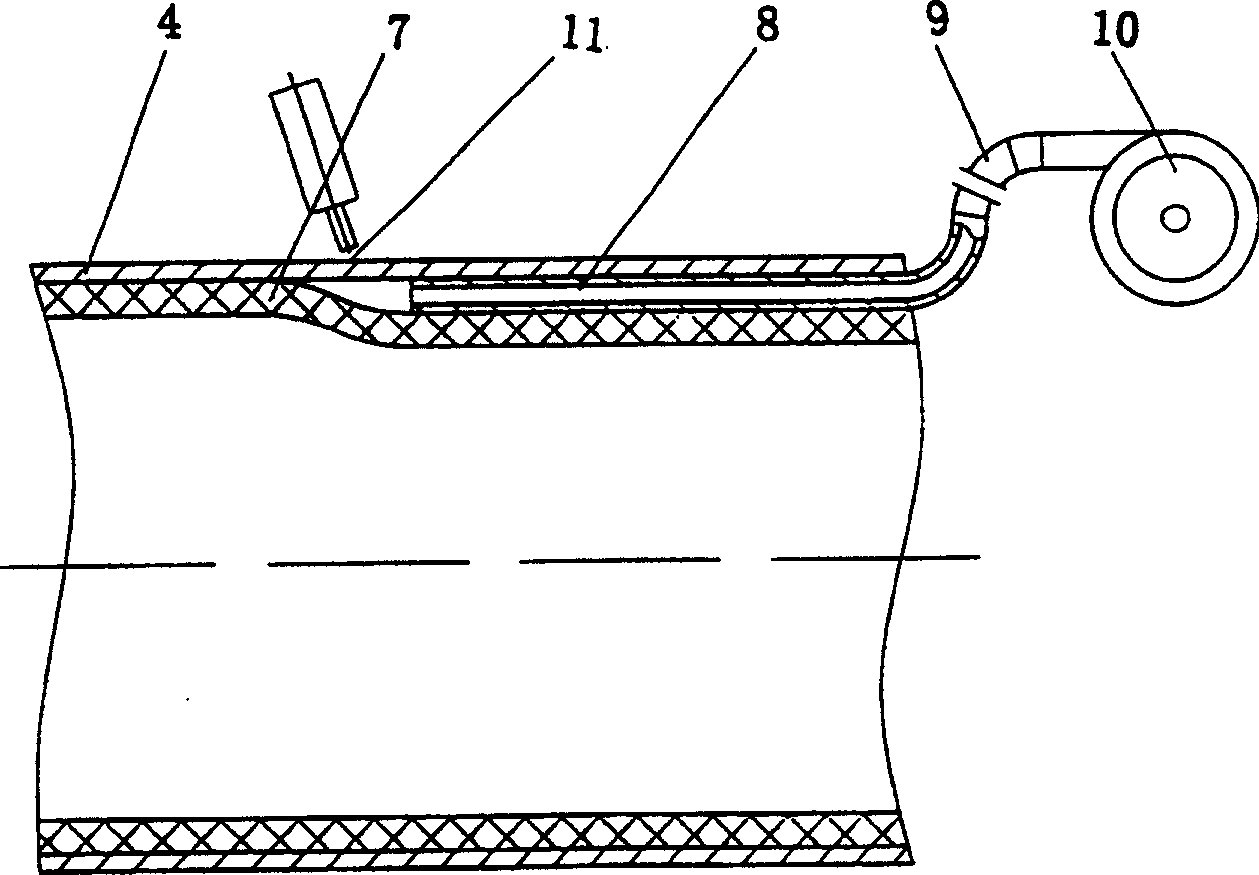

Steel-plastics composite pressure pipe and its production method

The steel plastics composite pressure pipe includes external plastic layer, external adhesive layer, internal adhesive layer and internal plastic layer, between external adhesive layer and internal adhesive layer there is a galvanized or aluminium-plated steel tape. Its production method includes the following steps: preparing steel pipe, blanking, cleaning welded two edges, removing aluminium and zinc, at the same time of extruding to obtain formed pipe, coating thermal sol, high-frequency heating, pressing and coating external plastic layer for resisting corrosion so as to obtain the invented steel plastic composite pressure pipe.

Owner:XINXING DUCTILE IRON PIPES CO LTD +2

One-piece formed sole processing process

InactiveCN102406282AAvoid glue openingImprove production environmentShoe gluingRubber materialMixed materials

The invention relates to a one-piece formed sole processing process, in particular to a processing process for forming sole sand insoles. The processing process comprises: performing a manufacturing process of wear-resistance rubber material soles; performing a manufacturing process of elastic ethylene vinyl acetate (EVA) insoles; mixing the EVA material and rubber material in a certain ratio, wherein the content of EVA is 30 to 40 percent; forming shoe-shaped cover pieces; placing the cover pieces on the soles; placing the insoles made by the EVA manufacturing process on the cover pieces; and performing thermocompression of the soles and the insoles by heating a template and applying die compression, wherein the heating temperature is 150 to 165 DEG C, and the applied die pressure is 70 to 80KG / CM2. Because the cover pieces made of the mixed material, after undergoing thermocompression with the soles and insoles, have a very big adhering force, the soles and the insoles are combined, the separating phenomenon is eliminated, lots of labor cost can be saved in a production process, the dangers caused by the conventional production process to the health of human body are eliminated, and the production environment of the plant is improved.

Owner:东莞市义丰鞋材有限公司

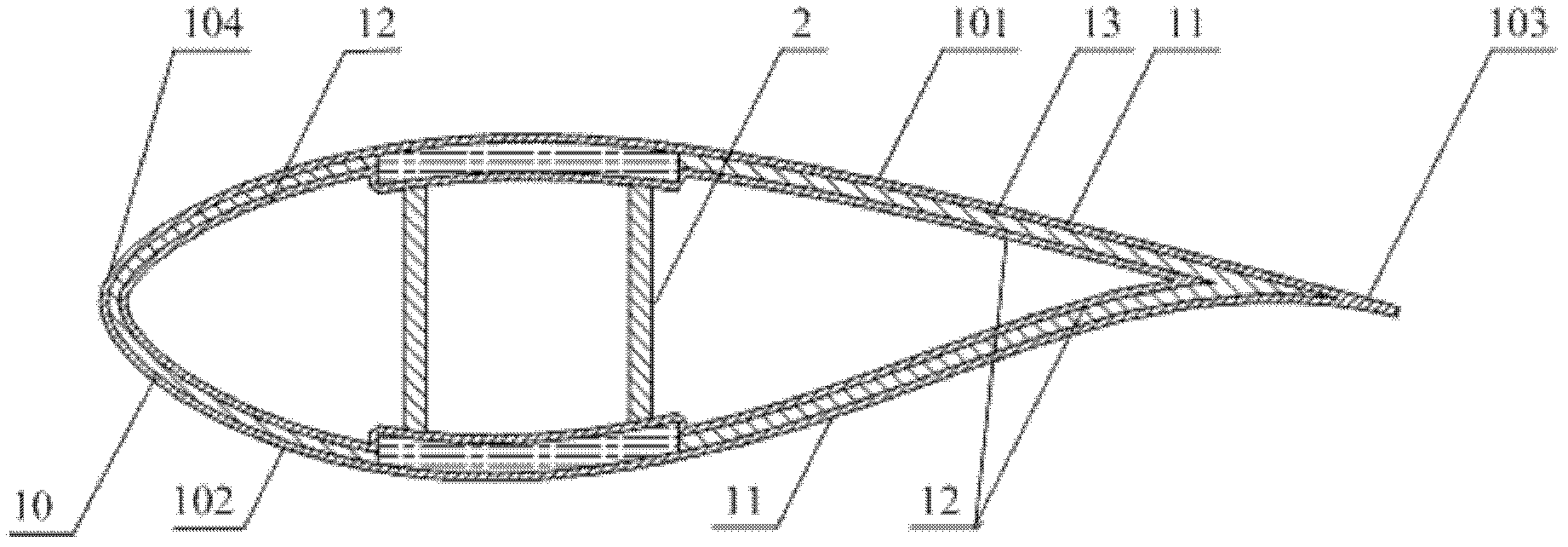

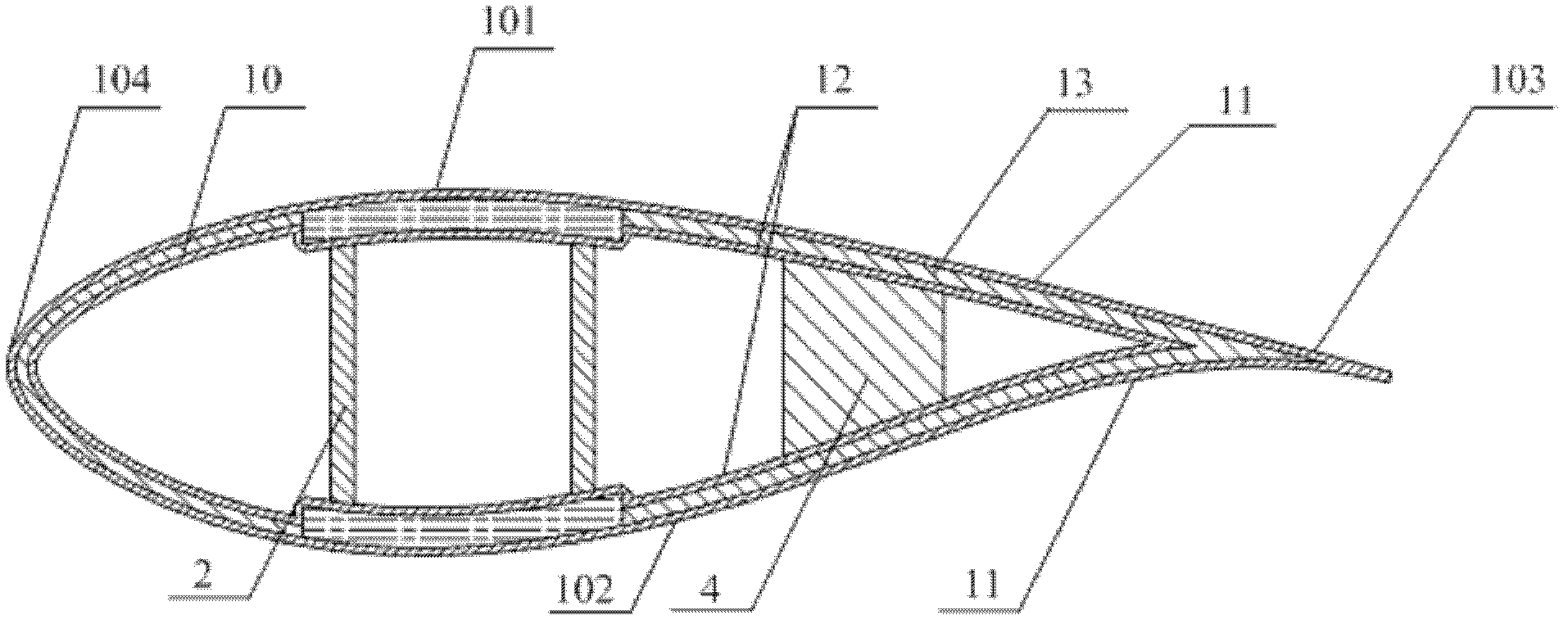

Fan blade

InactiveCN103174600AImprove structural performanceImprove buckling resistanceWind motor componentsButt jointBulk resistance

The invention provides a fan blade which comprises a sealed fan shell body. The fan shell body is formed by an upper shell and a lower shell in a butt joint mode. A shearing resistance web is arranged inside a cavity formed by the fan shell body. The top end and the bottom end of the shearing resistance web are respectively and fixedly connected with a beam cap on the upper shell and a beam cap on the lower shell. A connecting body is arranged between the shearing resistance web and the rear edge of the fan blade inside the cavity, and the connecting body is respectively and fixedly connected with the upper shell and the lower shell. The fan blade improves the bulking resistance capacity of the rear edge of the fan blade, the tackless phenomenon at the position of the rear edge of the fan blade is effectively avoided through fixed connection between the upper shell and the connecting body and the fixed connection between the lower shell and the connecting body, failures caused by insufficient stability of the rear edge of the fan blade are prevented, and therefore normal power generation of a wind turbine generator is guaranteed.

Owner:SINOVEL WIND GRP

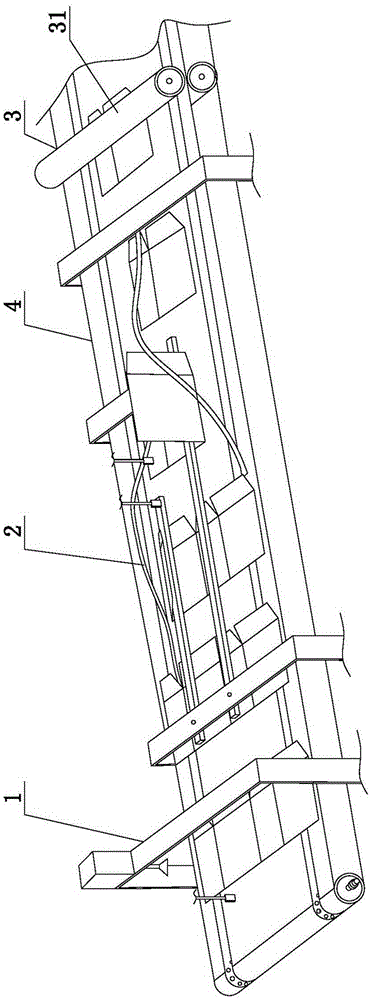

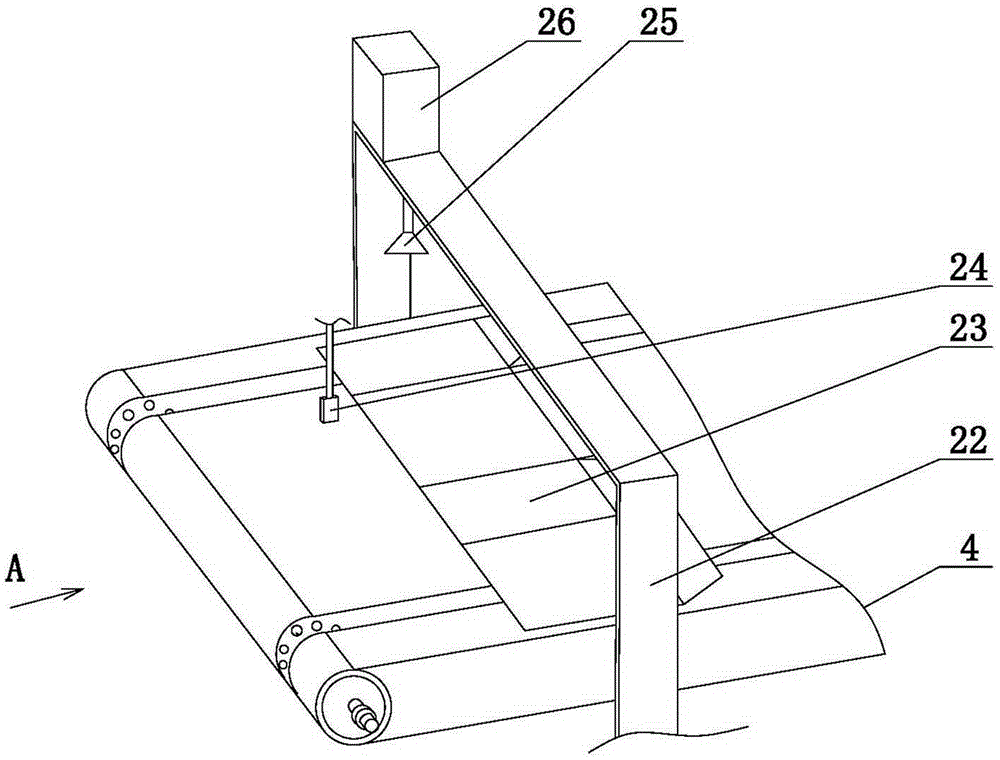

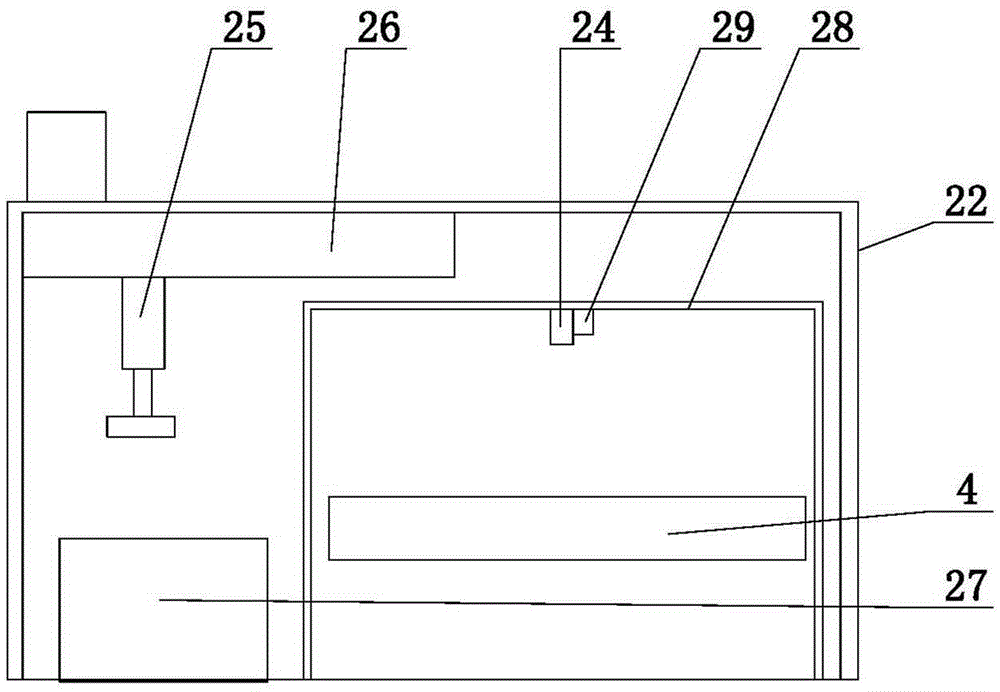

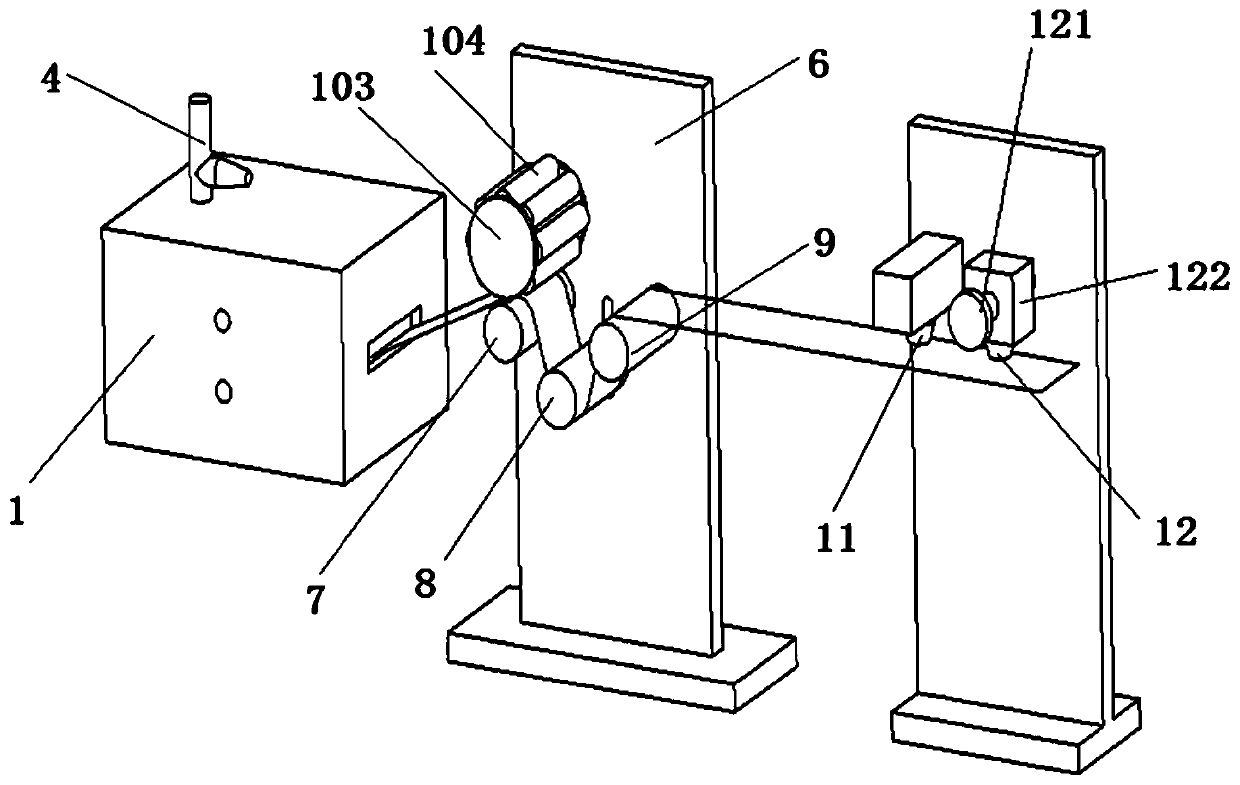

Automatic carton folding production line

InactiveCN106739140AImprove reliabilityImprove pass rateBox making operationsPaper-makingProduction lineCardboard

The invention provides an automatic carton folding production line and relates to an improvement in the structure of the automatic carton folding production line. The automatic carton folding production line provided by the invention has the advantages that the reliability is high, the degree of automation is high, and the product quality is guaranteed. The automatic carton folding production line comprises a carton folding-forming mechanism, and is characterized in that a carton raw-material cardboard automatic detecting device is arranged at the front end of the carton folding-forming mechanism; a rolling mechanism is arranged at the rear end of the carton folding-forming mechanism; the carton folding-forming mechanism comprises a conveying belt; and a left folding belt and a right folding belt are arranged on the conveying belt. The carton folding-forming mechanism is characterized in that a front mounting frame, a middle supporting frame and a rear mounting frame are arranged above the conveying belt; the tail end of the left folding belt is arranged on the middle supporting frame; a left pressing rod corresponding to the left folding belt is arranged on the front mounting frame; a gluing nozzle is arranged at the position, corresponding to the tail end of the left folding belt, above the conveying belt; a drying air duct is arranged at the back of the gluing nozzle; and the rear mounting frame is connected with the tail end of the right folding belt.

Owner:沈阳恒德包装制品股份有限公司

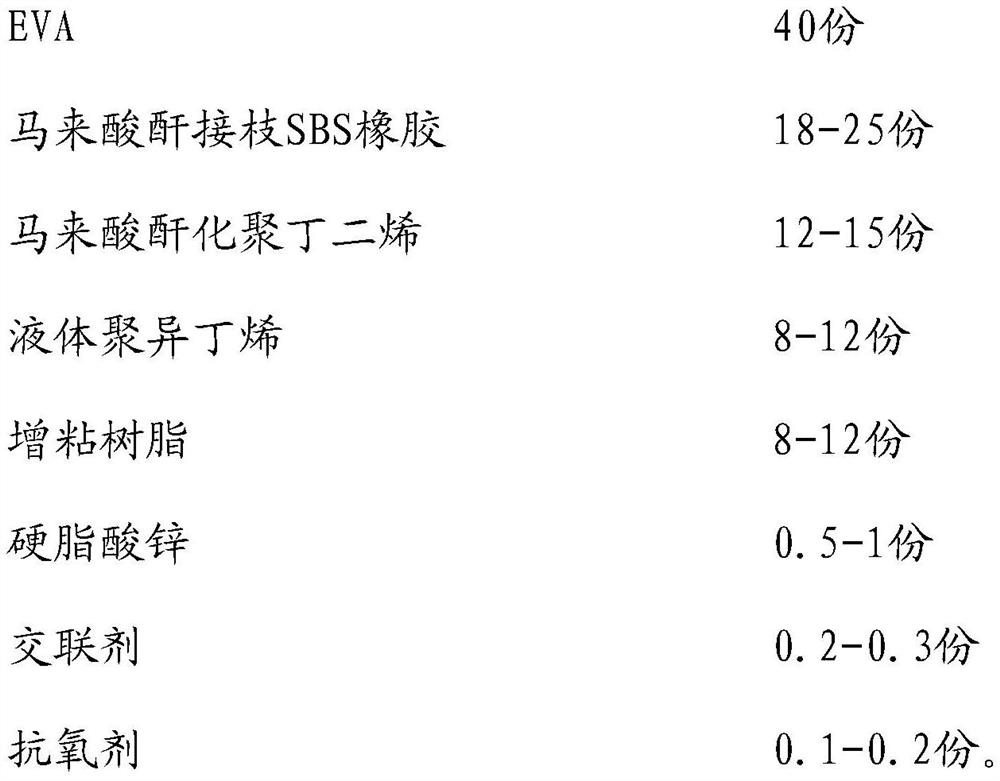

Adhesive film, preparation method of adhesive film and shoe sole comprising adhesive film

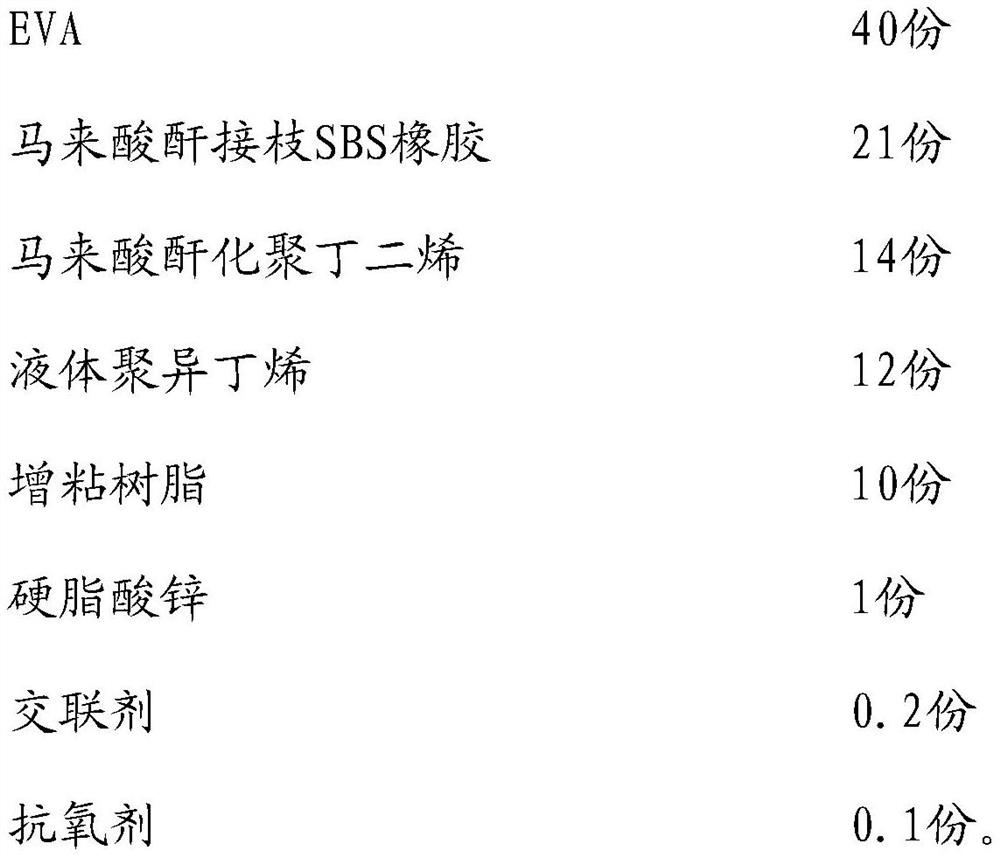

ActiveCN111004584ASolve the problem of obvious drop in viscosityHigh bond strength requirementsSolesNon-macromolecular adhesive additivesPolymer scienceAdhesive

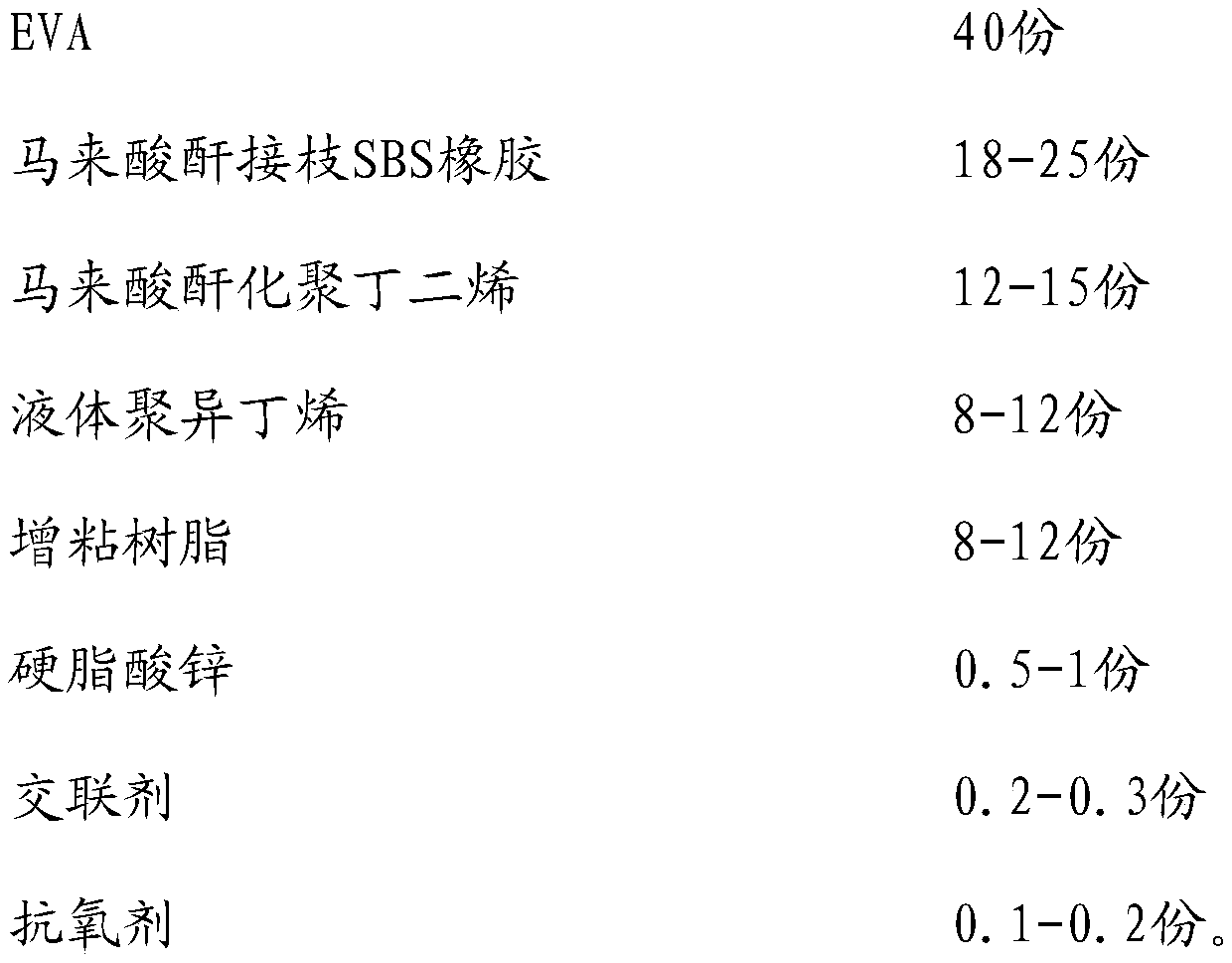

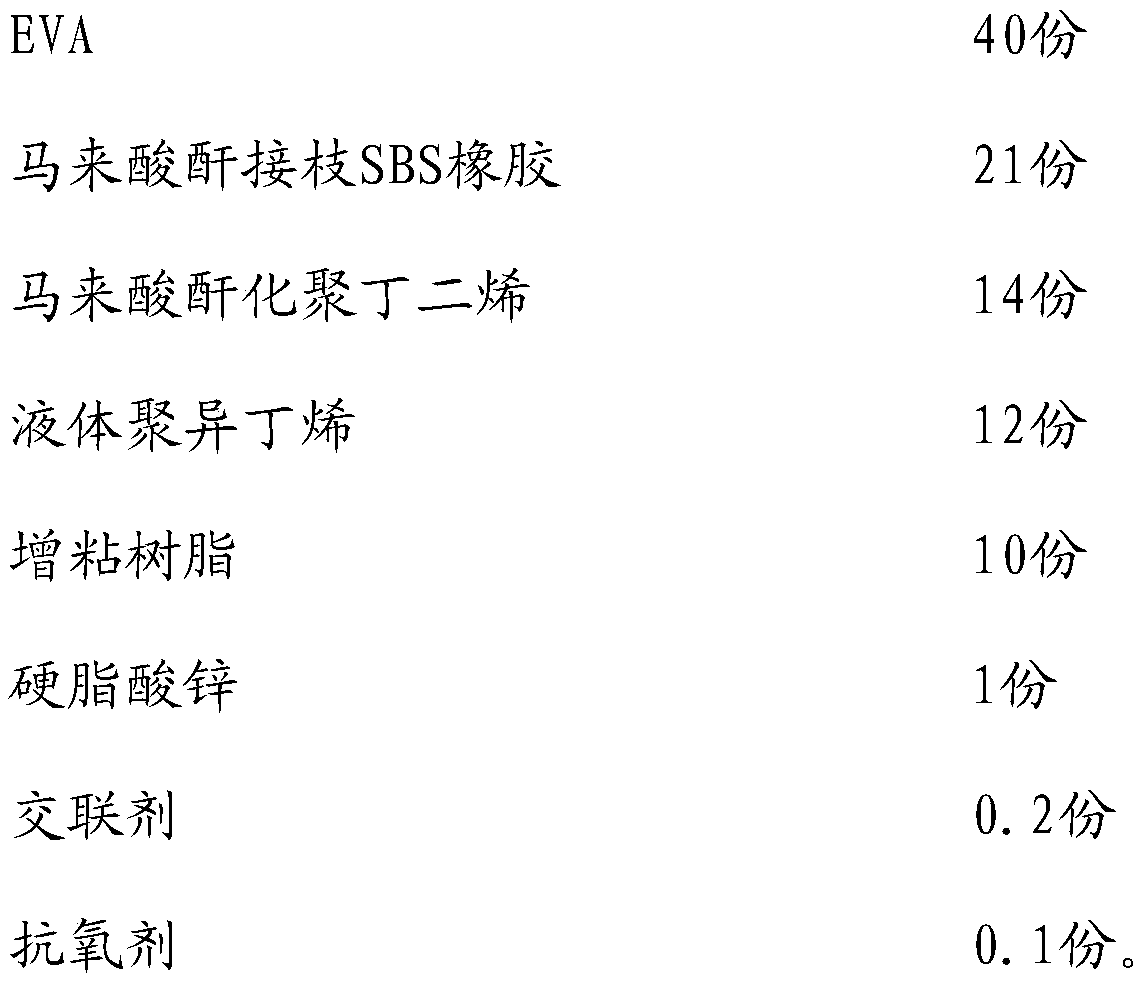

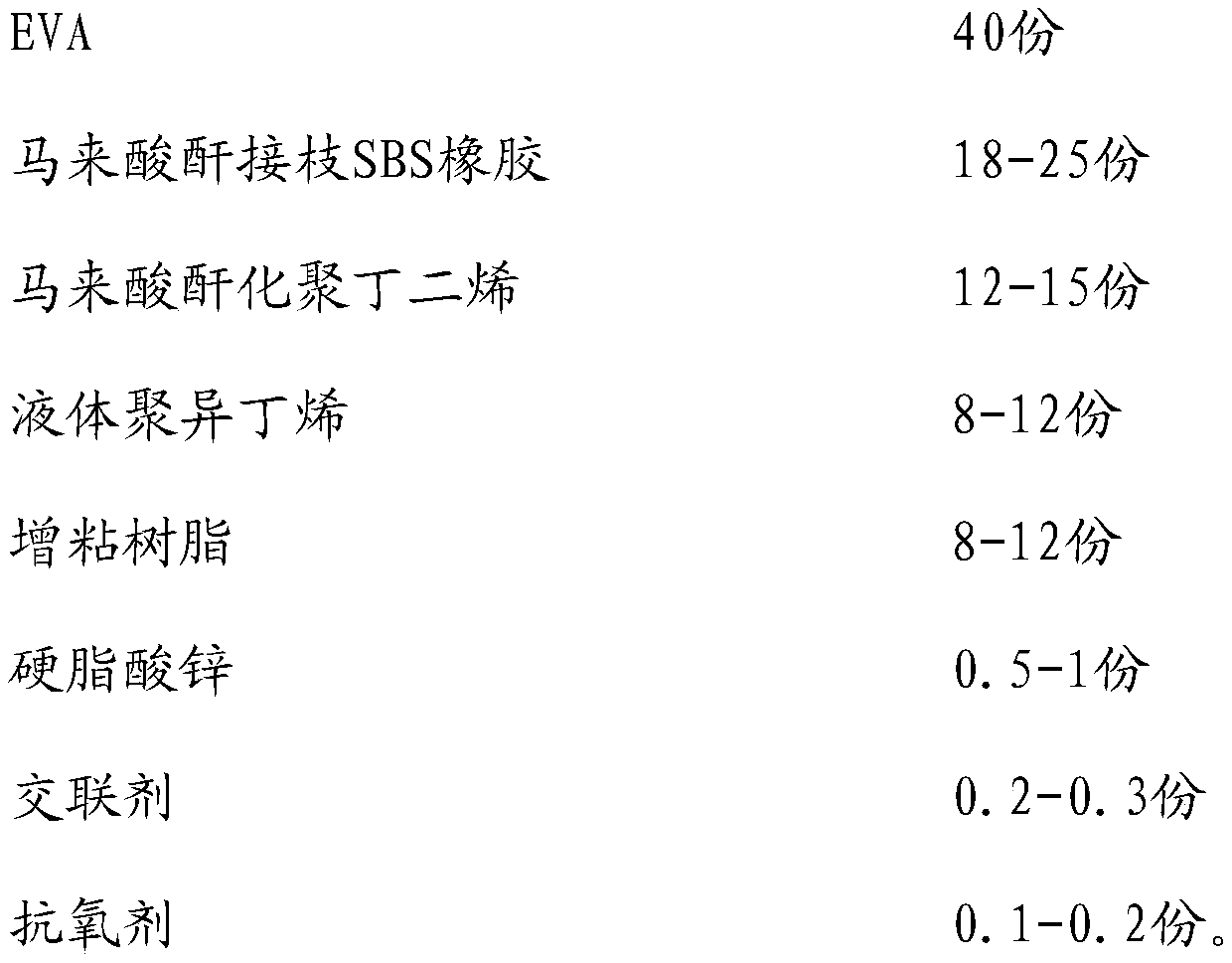

The invention discloses an adhesive film, a preparation method of the adhesive film and a shoe sole comprising the adhesive film. The adhesive film is prepared from the following components in parts by weight: EVA, maleic anhydride grafted SBS rubber, maleic anhydride polybutadiene, liquid polyisobutene, a tackifying resin, zinc stearate, a cross-linking agent and an antioxidant. The adhesive filmdisclosed by the invention is a cross-linked adhesive film; the cross-linking agent is decomposed in the compression molding process to generate active free radicals, so that free radical cross-linking occurs among EVA, maleic anhydride grafted SBS rubber, maleic anhydride polybutadiene and saturated hydrocarbon in a liquid polyisobutene molecular structure in the adhesive film to form a net-shaped structure, and the cohesion of the adhesive film is improved; meanwhile, the saturated hydrocarbon structure in the adhesive film and the saturated hydrocarbon structure in an EVA midsole are subjected to free radical crosslinking, and the saturated hydrocarbon structure in the adhesive film and the saturated hydrocarbon structure in a thermoplastic rubber bottom sheet are subjected to free radical crosslinking, so that the interaction force between the adhesive film and the EVA midsole and the interaction force between the adhesive film and the thermoplastic rubber bottom sheet are enhanced, and the bonding strength is improved.

Owner:MAOTAI FUJIAN SOLES CO LTD

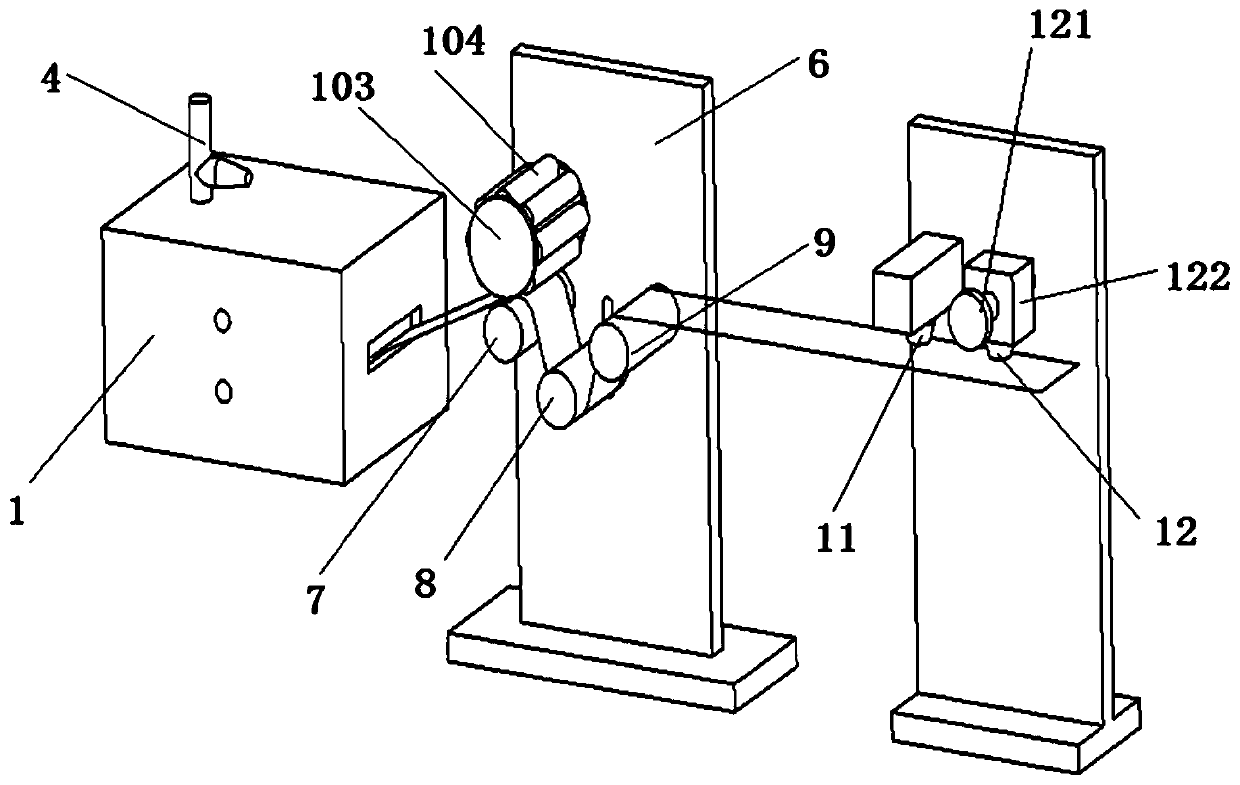

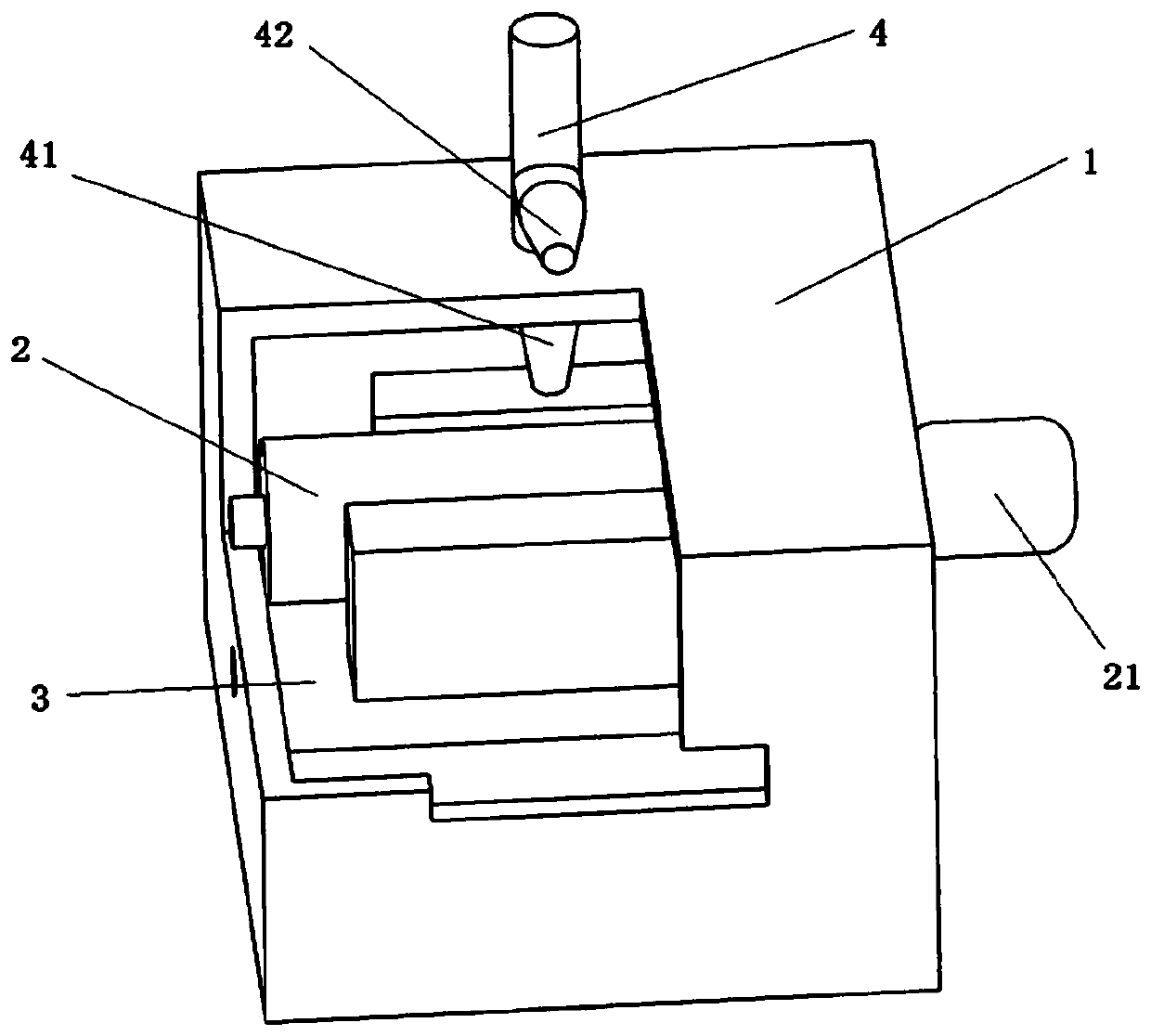

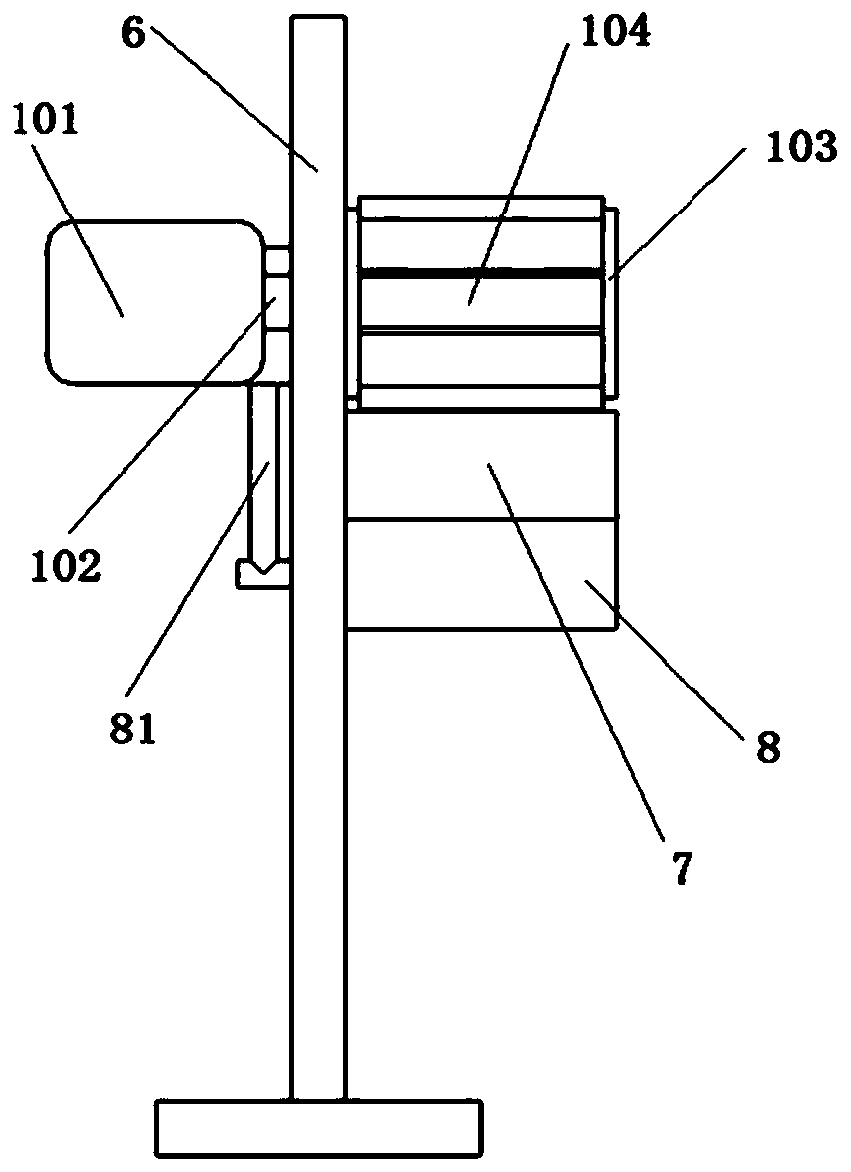

Code spraying system and method for glued surface printing label

The invention provides a code spraying system and method for a glued surface printing label. The system comprises a solidifying unit, a leveling unit and a detecting and code spraying unit; the solidifying unit is used for improving the bonding strength of the glued surface printing label and preventing the label from being unglued; the leveling unit is arranged on the outlet side of the solidifying unit and is used for preventing edges of the glued surface printing label from being folded; and the detecting and code spraying unit is arranged on the outlet side of the leveling unit and is usedfor performing identification and sequence code spraying on the glued surface printing label. By the aid of the code spraying system and method for the glued surface printing label, the sequence codespraying accuracy of the glued surface printing label can be improved, and the phenomena of code spraying errors can be avoided.

Owner:天津英友标贴科技有限公司

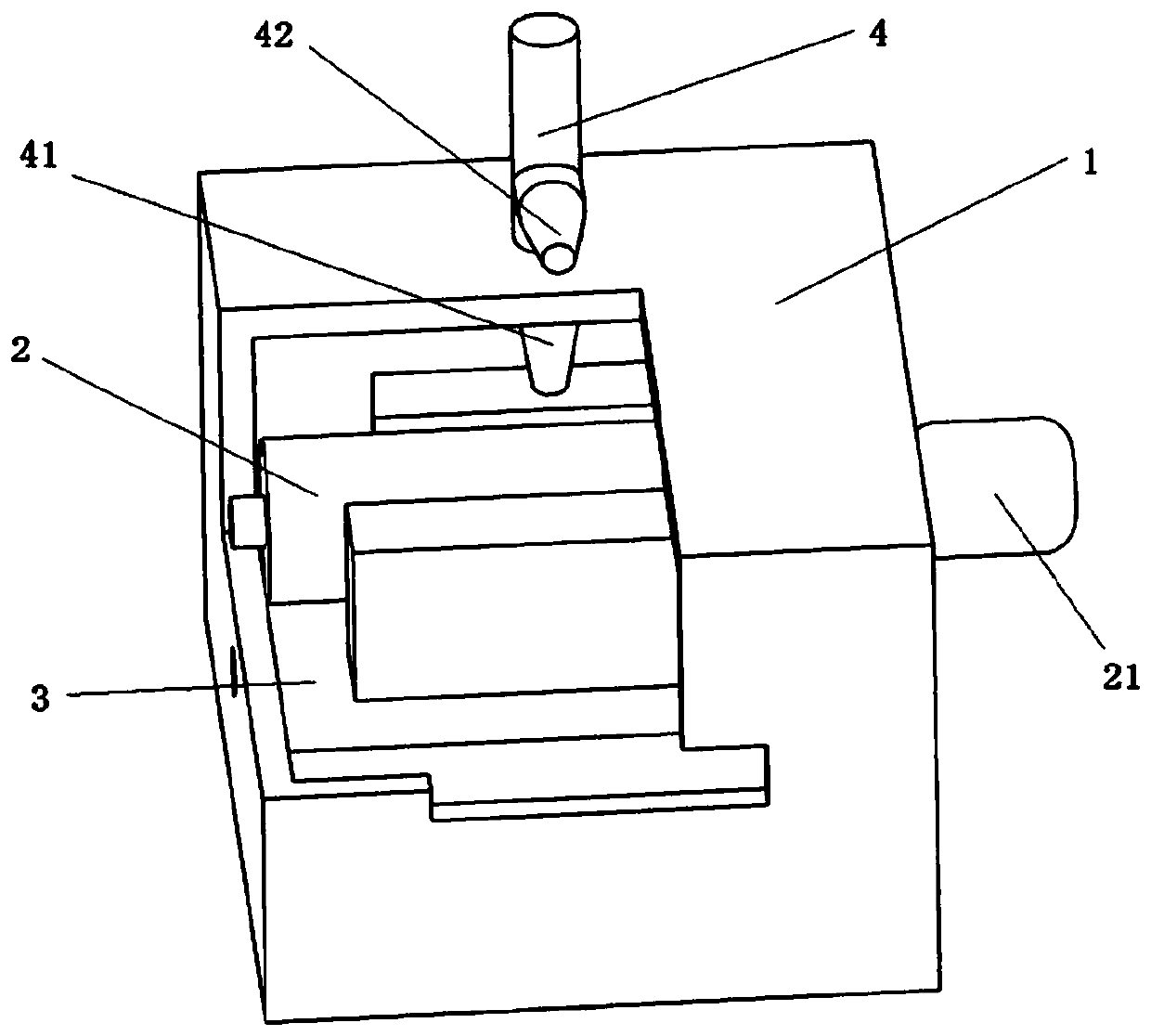

Heelpiece setting machine for cement shoes

PendingCN108771305AAccurate bonding positionPaste effect is goodShoe gluingMotor driveReciprocating motion

The invention discloses a heelpiece setting machine for cement shoes. The heelpiece setting machine comprises a bottom plate, wherein a U-shaped support plate is arranged on one side of the top of thebottom plate; a first cylinder is mounted at the top of the U-shaped support plate; a first push rod penetrating to the top end of the inner side of the U-shaped support plate is arranged at the output end of the first cylinder; a scraper is arranged at the bottom of the first push rod; a storage box is arranged on one side of the U-shaped support plate; a glue pump is mounted at the top of the storage box. According to the heelpiece setting machine for the cement shoes, a motor drives a rotating shaft to rotate so as to drive the support plate to rotate; a second cylinder pushes a second push rod to perform left-right reciprocating motion, therefore, a heel on the support plate is pushed out and sticks to a shoe sole, furthermore, by means of a limit plate arranged on the support plate,the sticking position of the heel is more accurate, errors are reduced, and the sticking effect of the heel is better; by means of mutual cooperation of the motor and the second cylinder, the stickingspeed is increased, and the working efficiency is improved.

Owner:衡东县鑫德成鞋业有限公司

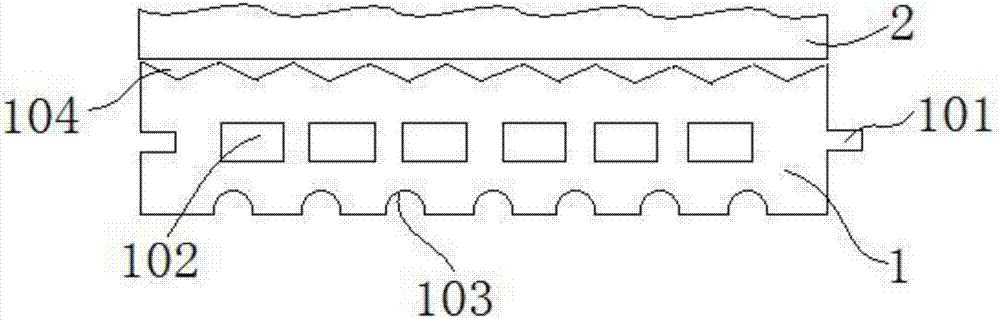

Environment-friendly formaldehyde-free flame-retardant plywood and preparation process thereof

ActiveCN113977710AImprove flame retardant performanceFirmly connectedWood compressionLaminationWood veneerSingle plate

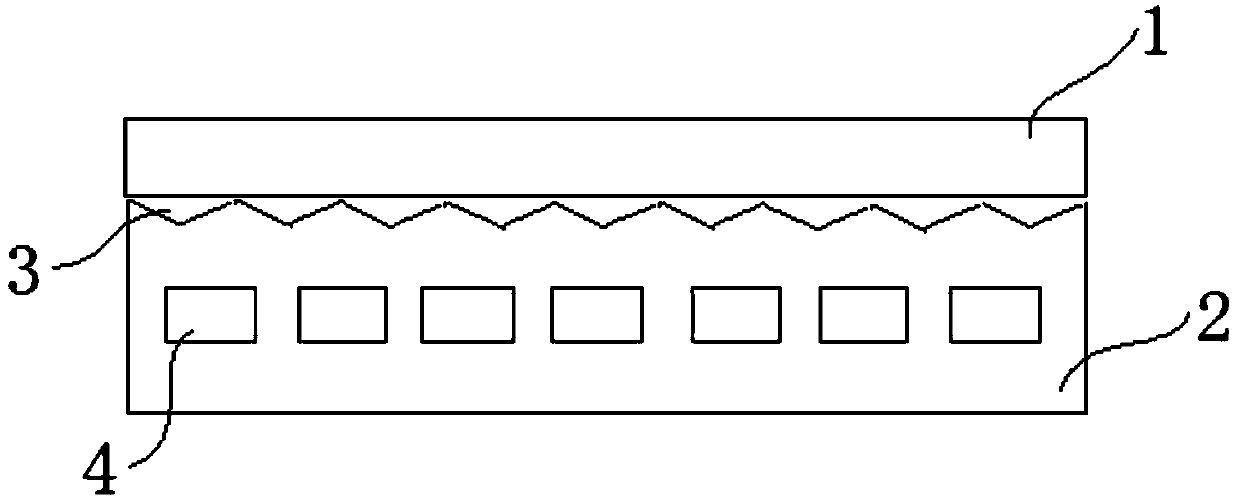

The invention relates to the technical field of plywood, and discloses environment-friendly formaldehyde-free flame-retardant plywood, which comprises a lower-layer wood veneer, wherein a plywood layer is arranged at the top of the lower-layer wood veneer, an upper-layer wood veneer is arranged at the top of the plywood layer, an outer film aluminum foil layer is arranged at the top of the upper-layer wood veneer, adhesive film layers are sprayed between the plywood layer and the lower-layer wood veneer and between the plywood layer and the upper-layer wood veneer, filler grids are uniformly distributed in the plywood layer, and fireproof film bags are adhered to the inner walls of the filler grids. According to the invention, fireproof film bags are attached to the inner side of filler grids on a plywood layer, the filler grids are filled with gluing filler blocks to form a plywood interlayer, when the plywood is burned, the fireproof film bags are damaged, fire-fighting dust blocks are thermally decomposed to generate fire-fighting dust, and pressure bubble particles on the surface of the fireproof film bags explode, so that the dust is dispersed, open fire on the plywood is extinguished, and the flame retardant effect of the plywood is improved.

Owner:TAOJIANG HONGSEN WOOD IND

Adhesive film and preparation method thereof, and shoe sole comprising adhesive film

ActiveCN111019571ASolve the loss of bond strengthHigh bond strength requirementsMineral oil hydrocarbon copolymer adhesivesSolesPolymer scienceAntioxidant

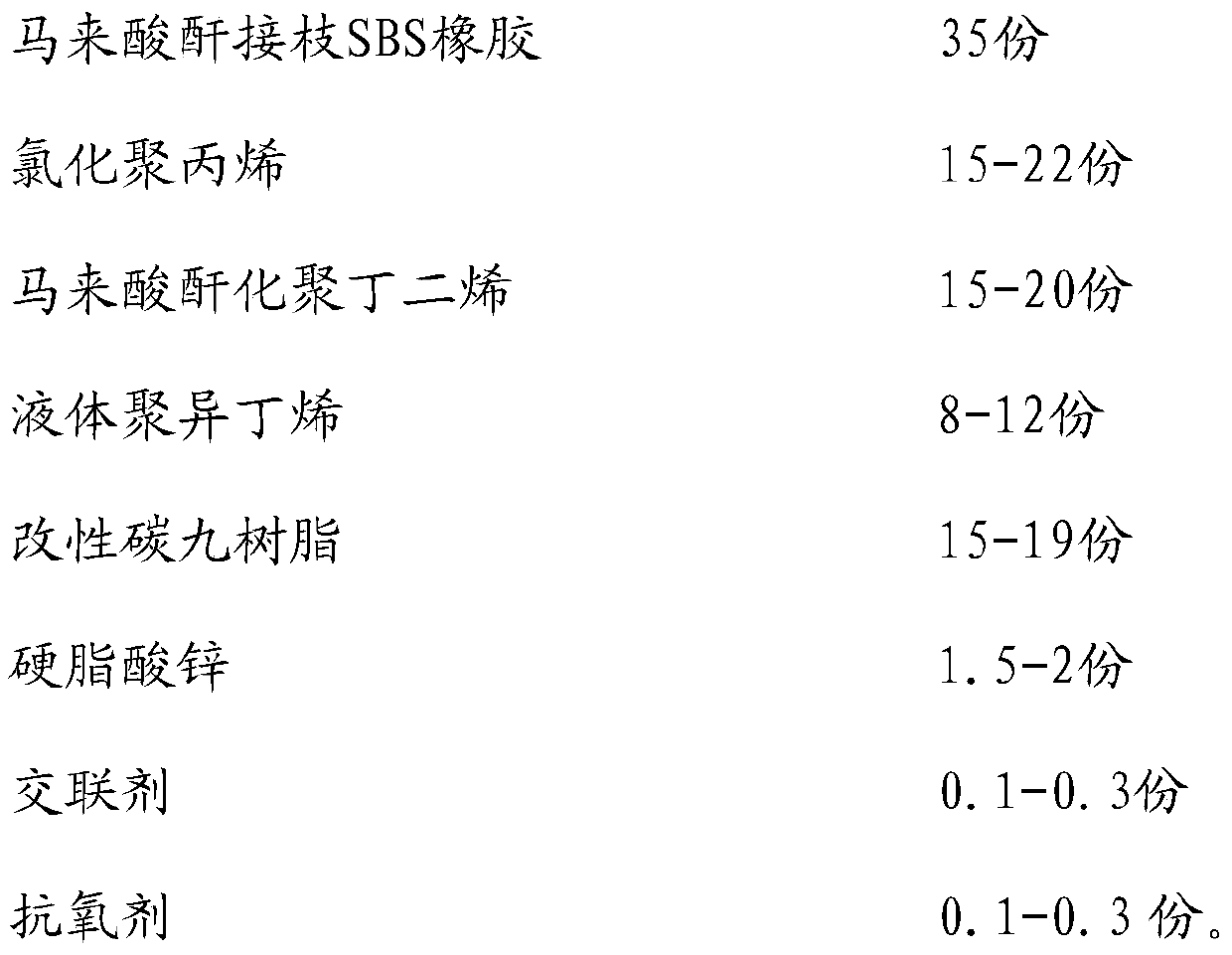

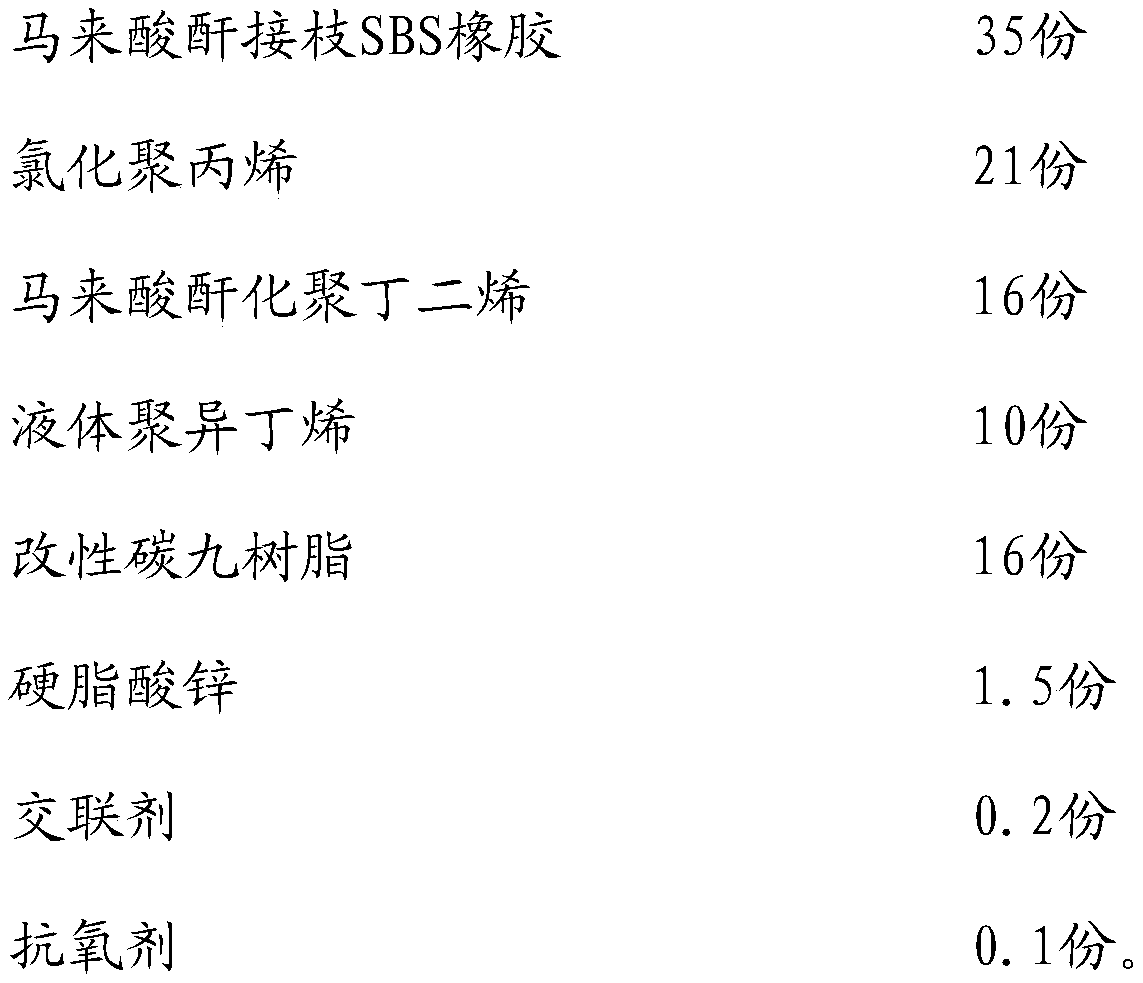

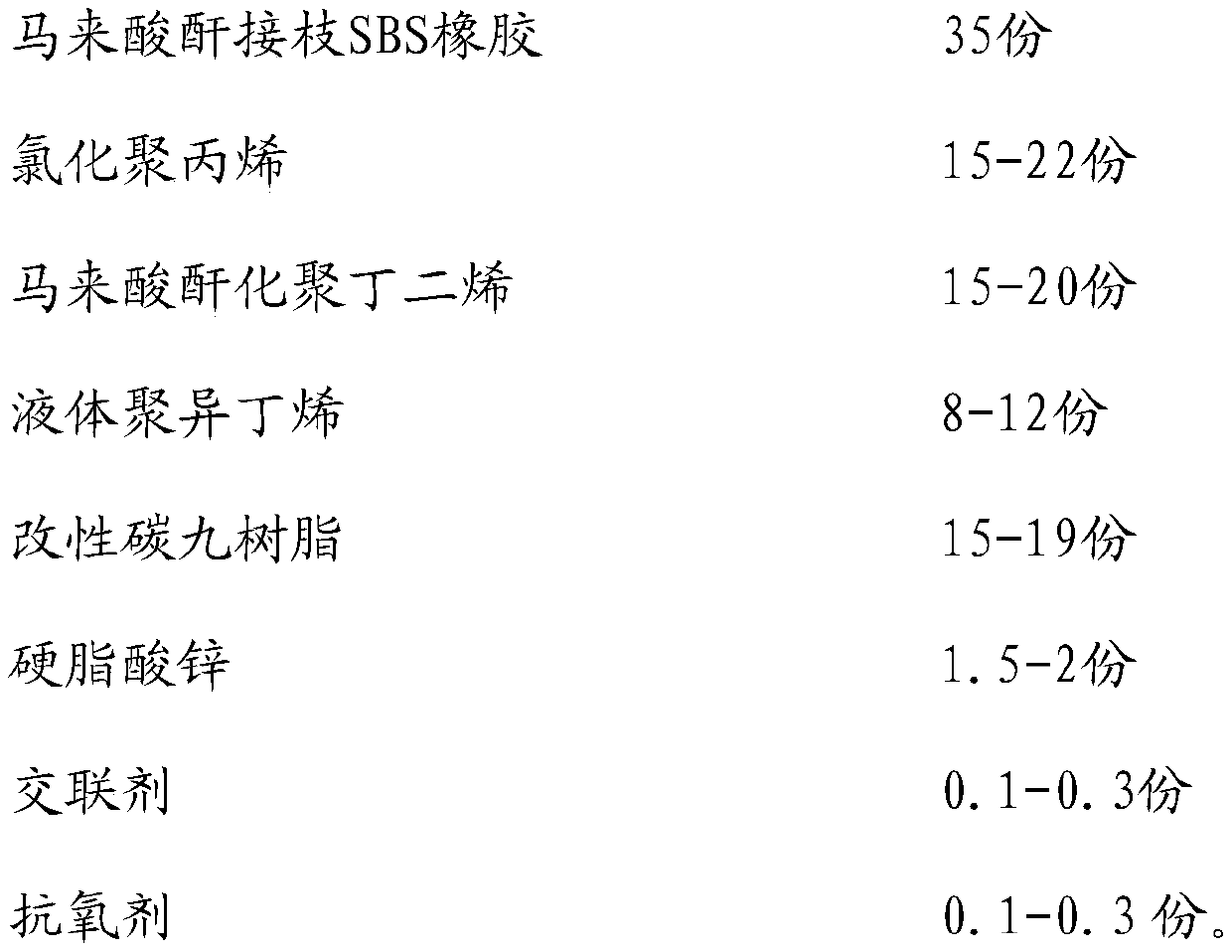

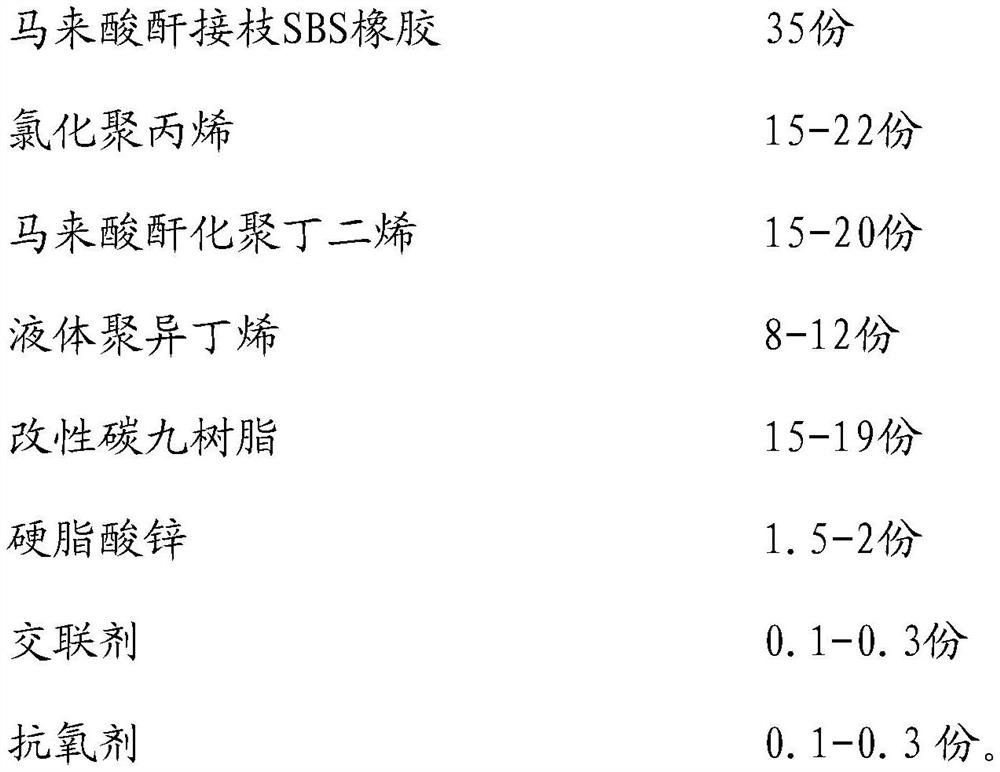

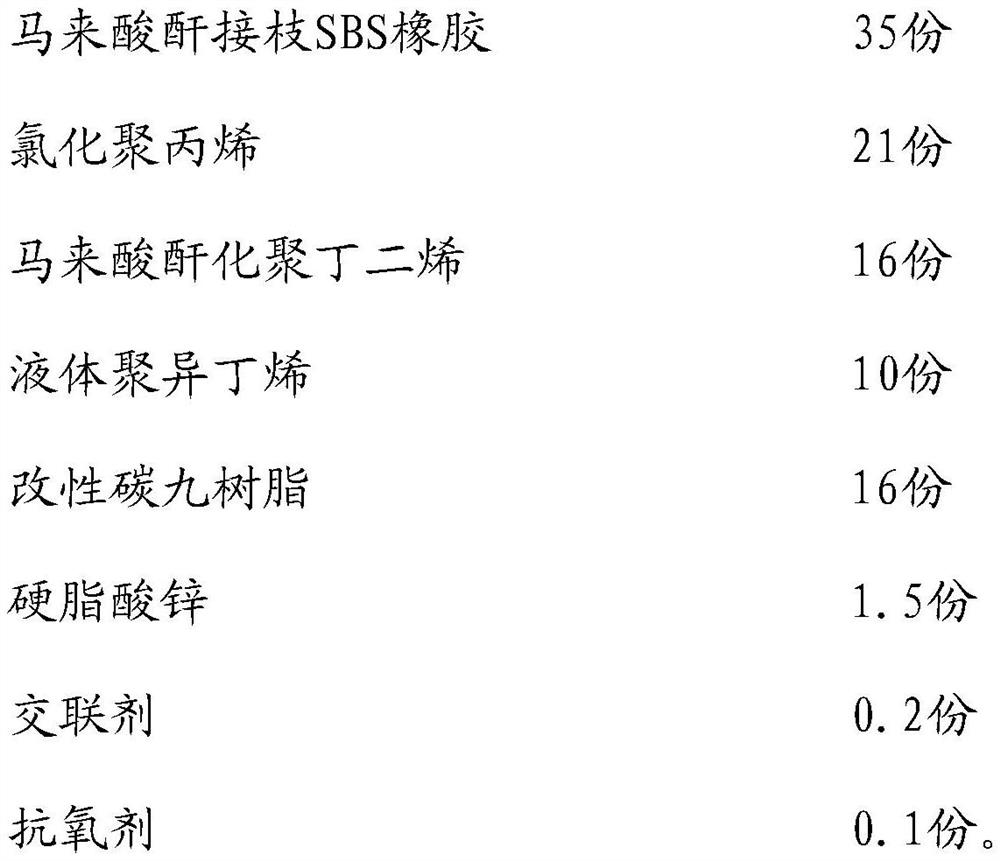

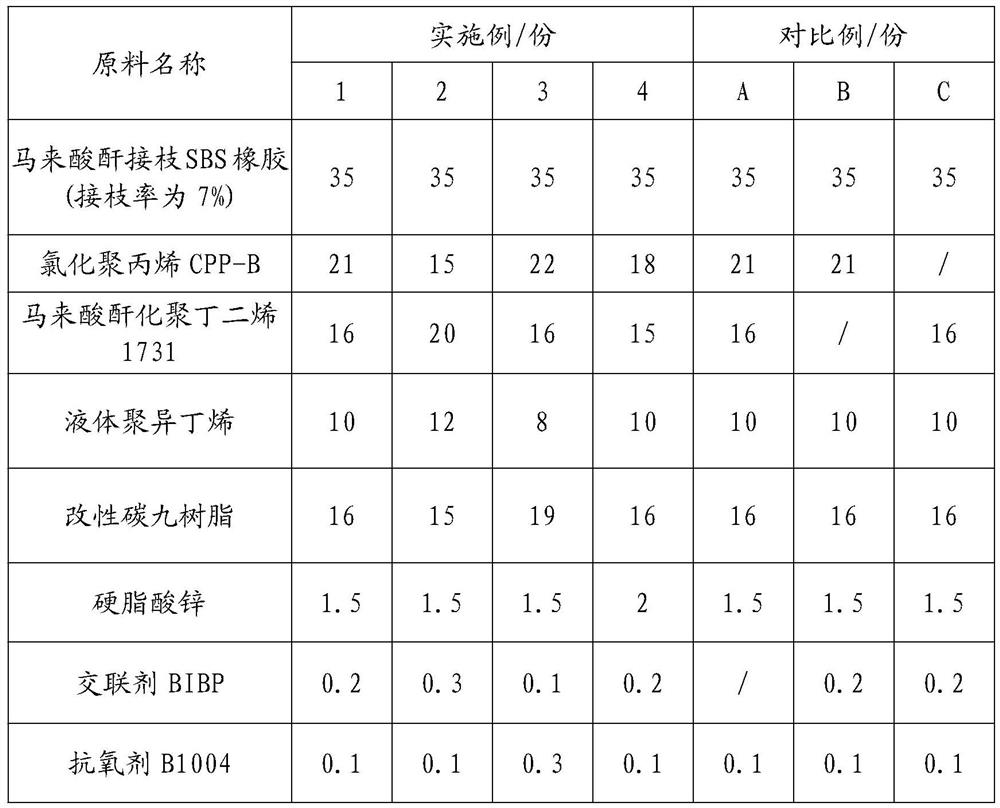

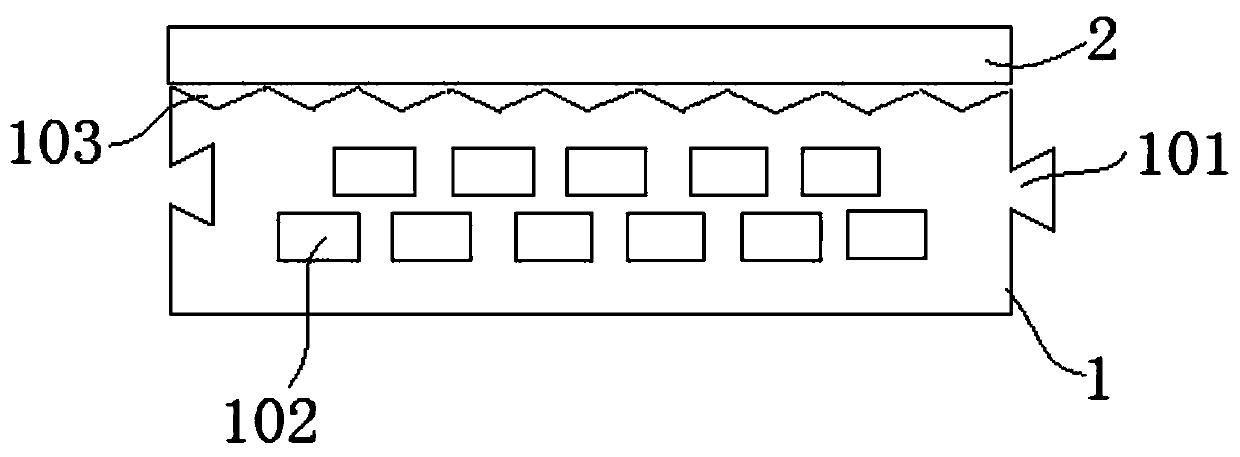

The invention discloses an adhesive film and a preparation method thereof, and a shoe sole comprising the adhesive film, wherein the adhesive film is prepared from the following raw materials in partsby weight: 35 parts of a maleic anhydride grafted SBS rubber, 15 to 22 parts of chlorinated polypropylene, 15 to 20 parts of maleic anhydride polybutadiene, 8 to 12 parts of liquid polyisobutene, 15to 19 parts of a modified C9 resin, 1.5 to 2 parts of zinc stearate, 0.1 to 0.3 part of a cross-linking agent and 0.1 to 0.3 part of an antioxidant. According to the invention, the adhesive film is across-linking type adhesive film containing a peroxide cross-linking agent, is subjected to chemical cross-linking effect with a vulcanized rubber and a foaming insole in a heating forming process, ishigh in adhesive force and good in heat resistance and water resistance, can effectively avoid the phenomenon of adhesive failure of a combined shoe sole due to wet aging and thermal aging, and improves the brand effect of products.

Owner:MAOTAI FUJIAN SOLES CO LTD

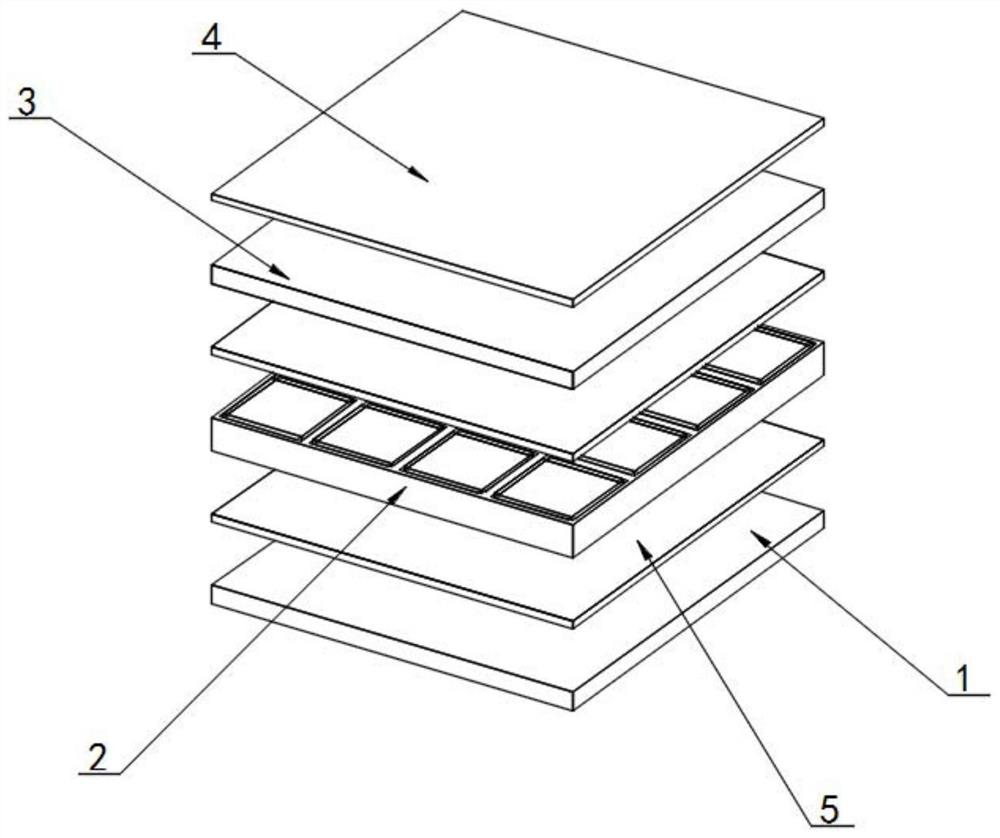

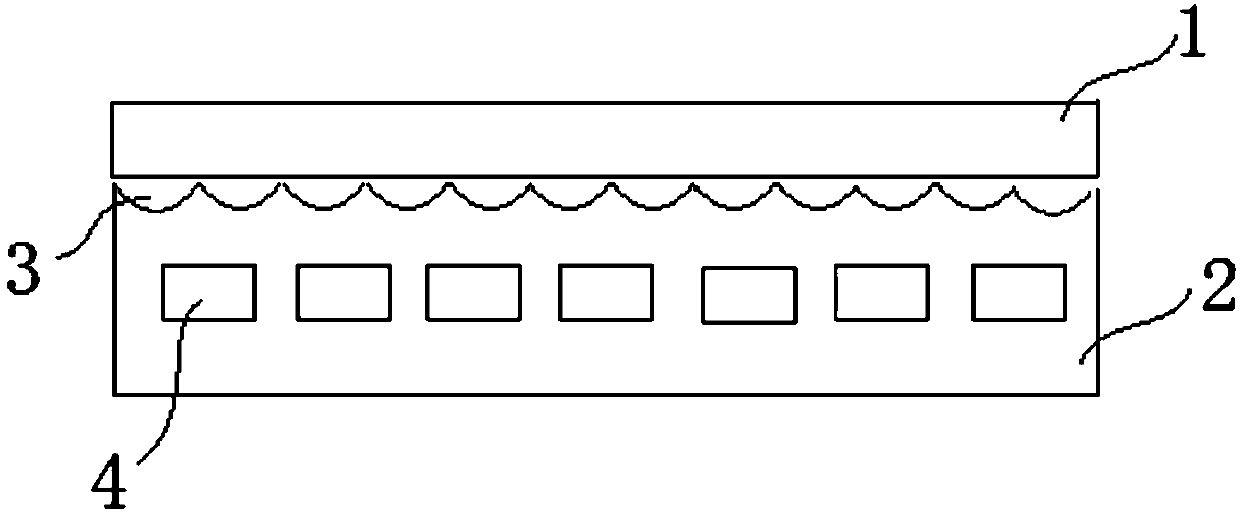

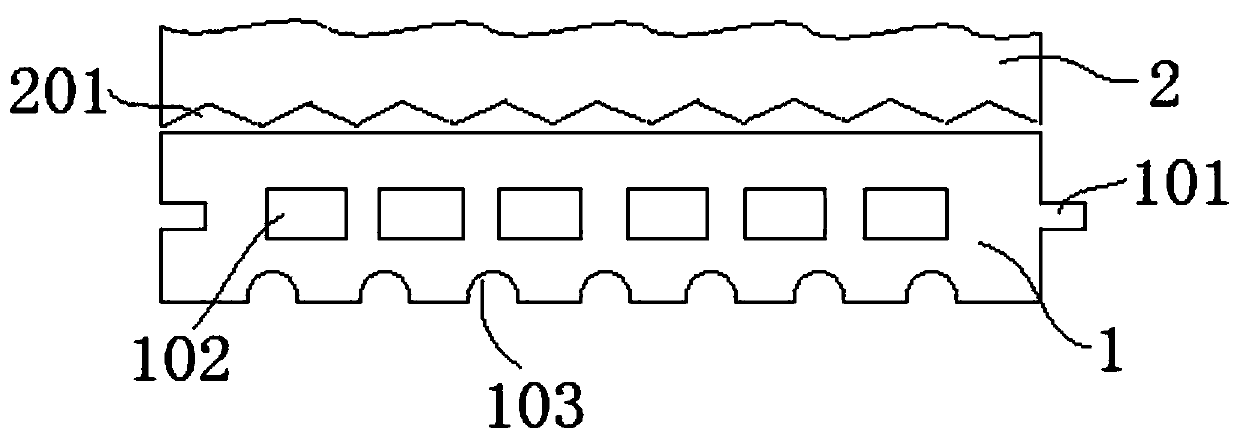

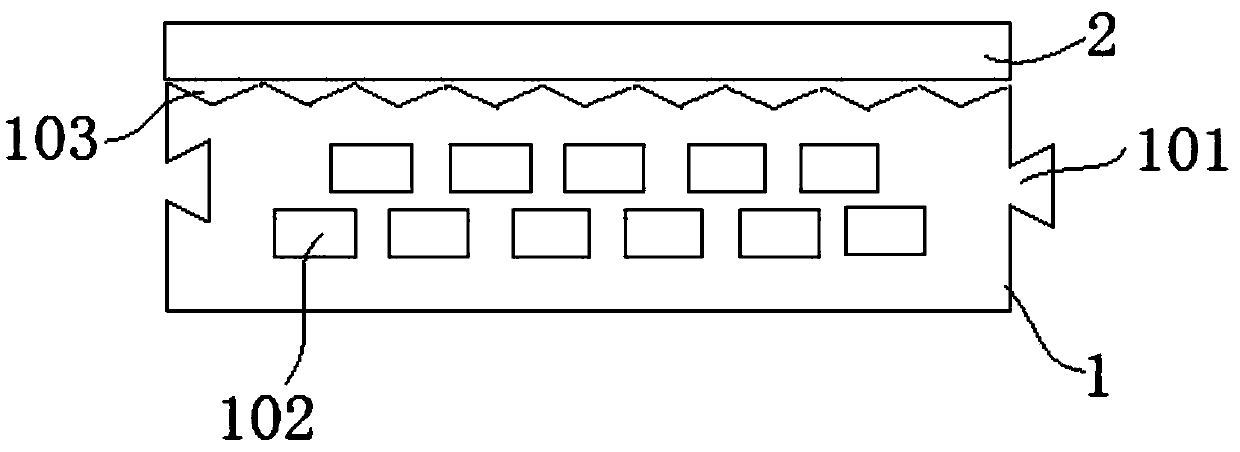

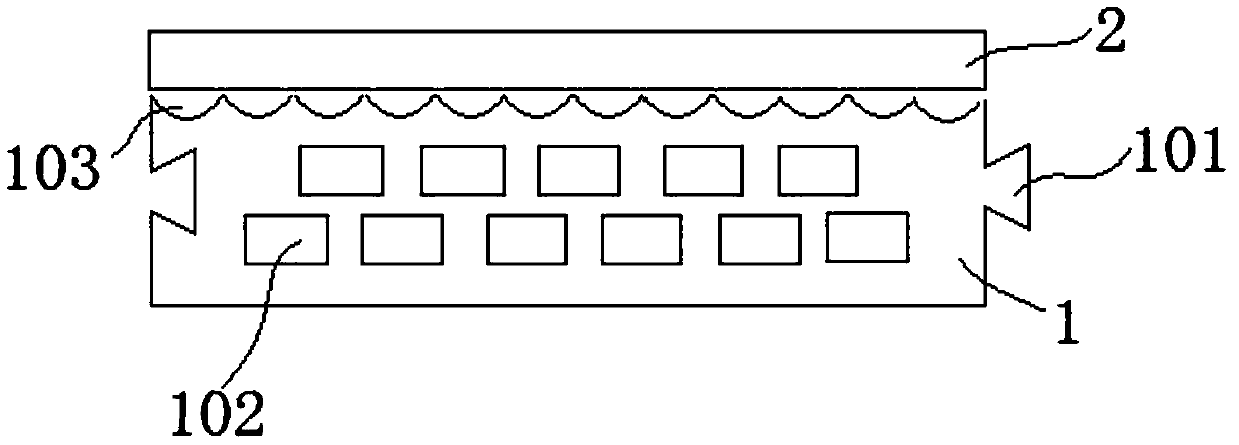

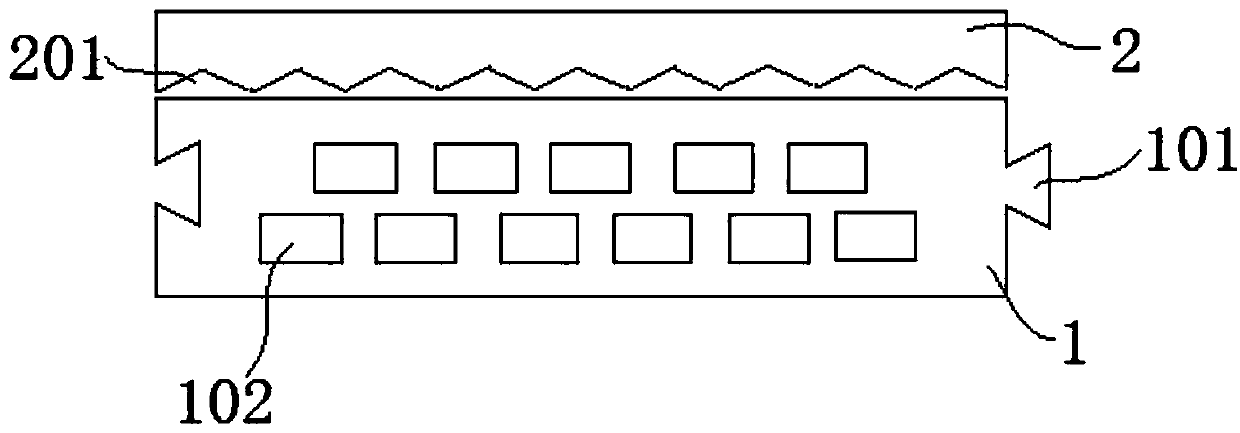

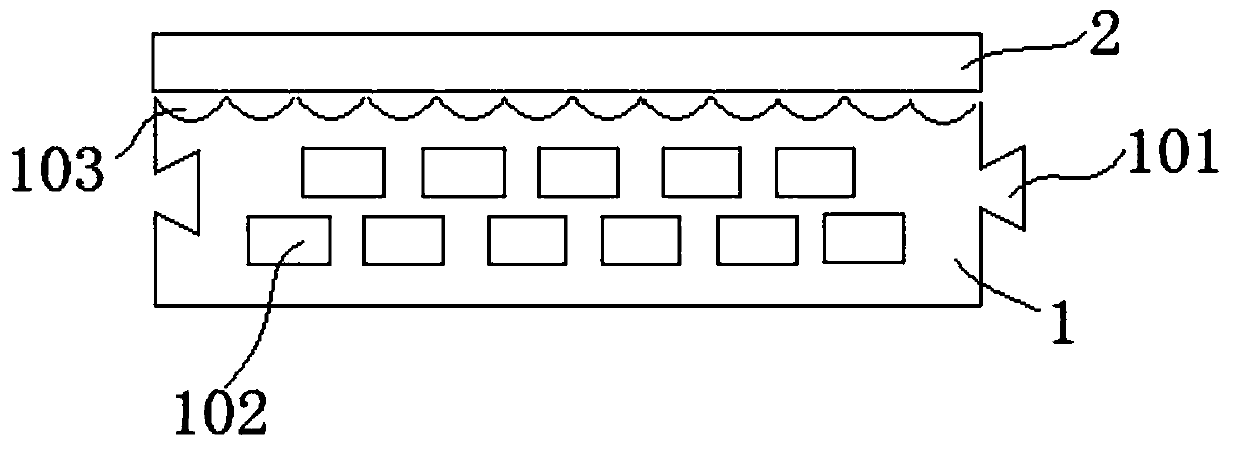

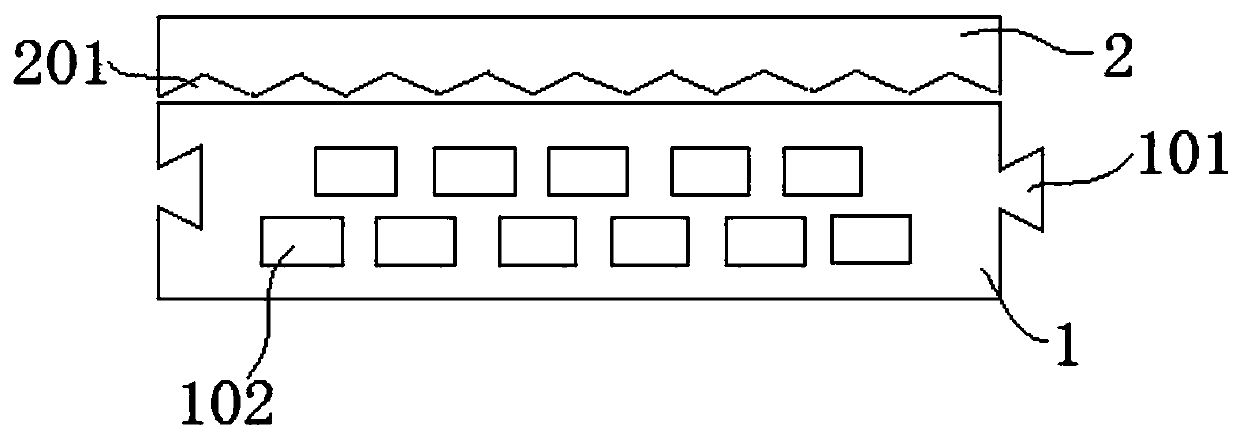

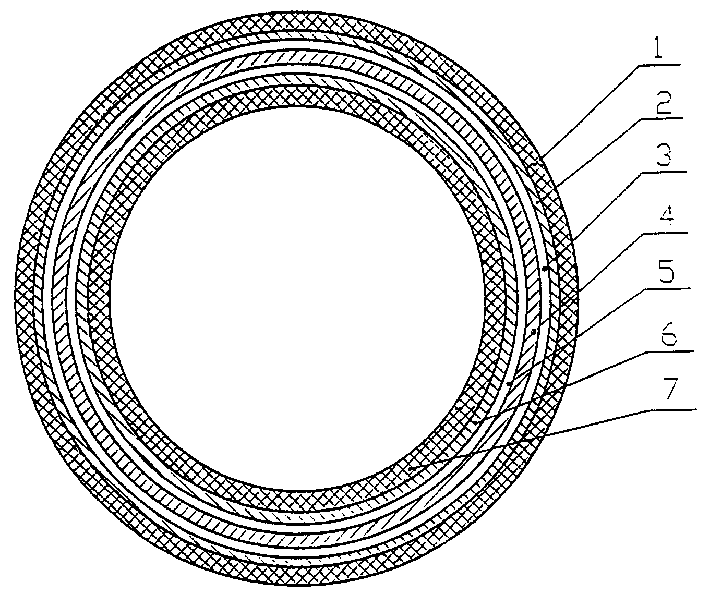

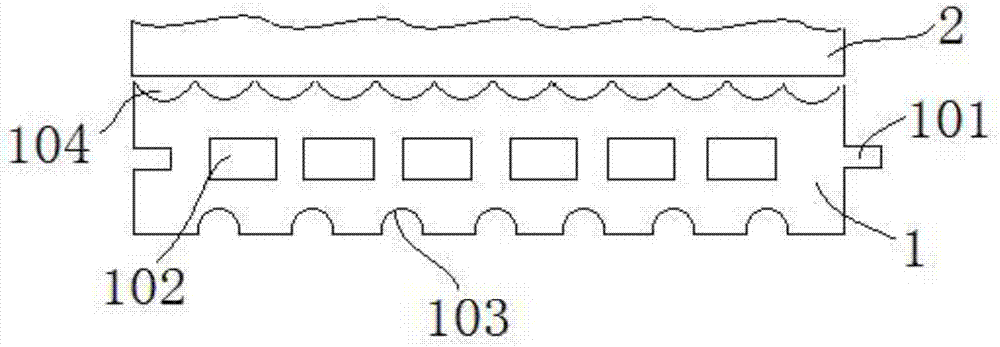

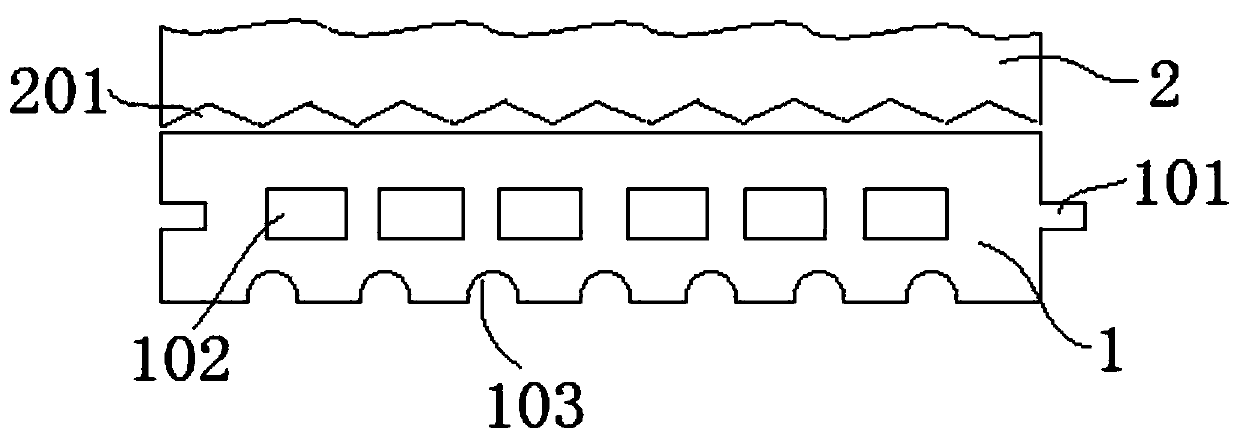

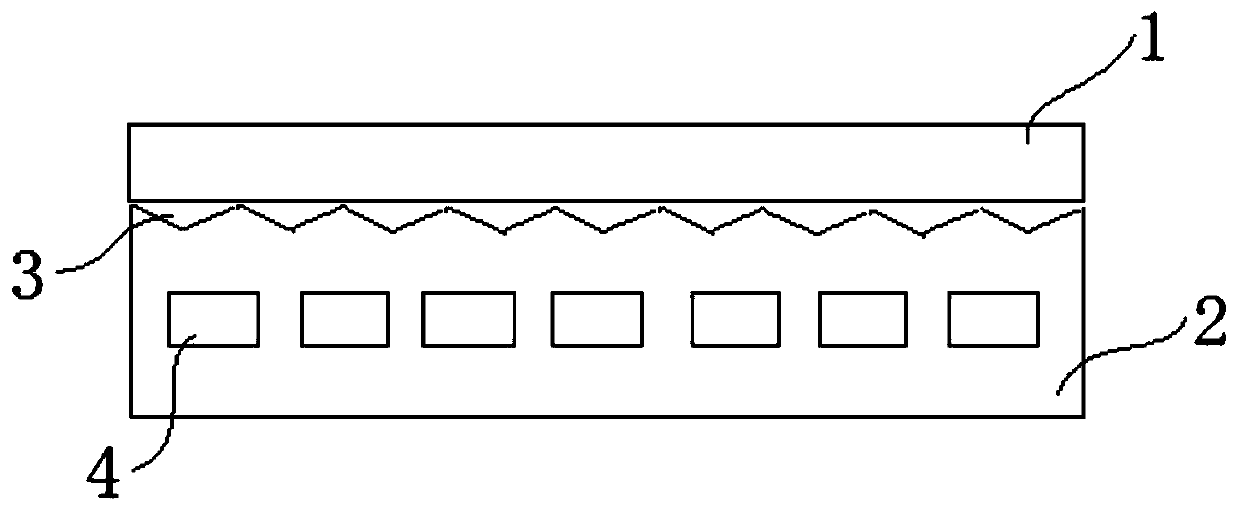

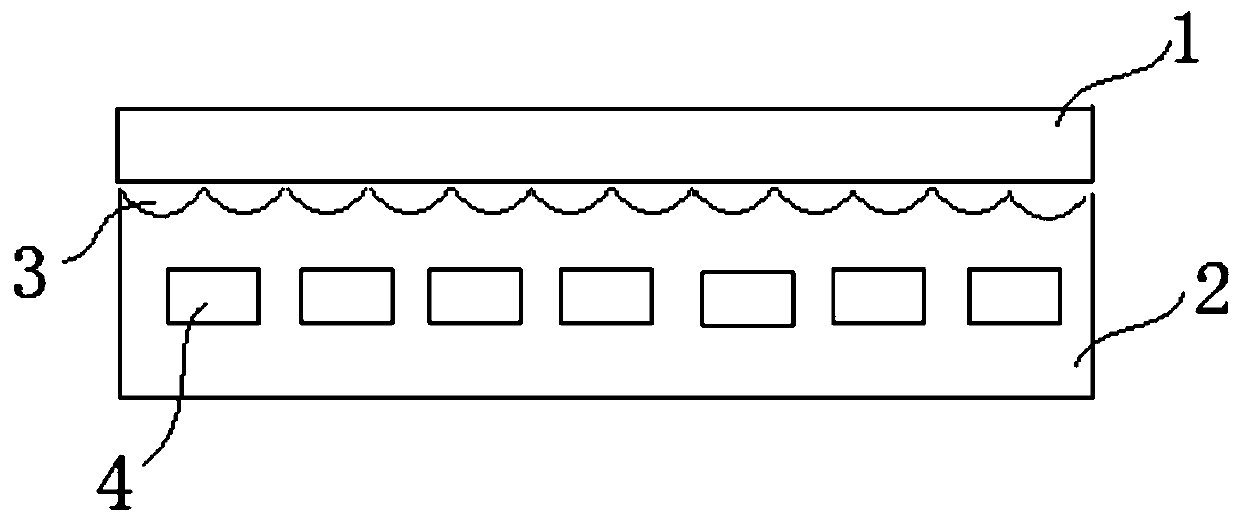

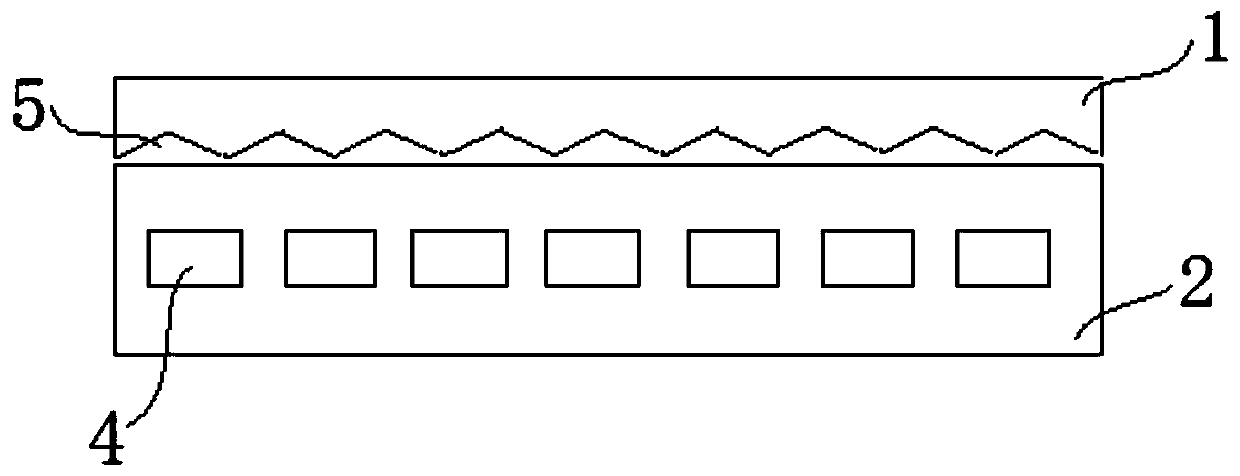

Solid wood PVC stone-plastic double-layer composite floor

ActiveCN107916764AImprove adhesionAvoid glue openingSynthetic resin layered productsConstructions elementsEcological environmentSolid wood

The invention discloses a solid wood PVC stone-plastic double-layer composite floor, and belongs to the field of floors. The floor is formed by bonding a panel at the upper layer with a substrate at the lower layer, the panel is a solid wood plate, and the substrate is a PVC stone-plastic plate; the thickness of the substrate is higher than that of the panel; the substrate is internally provided with a through passage in the length direction; the upper surface of the substrate is provided with substrate glue storage grooves in the length direction or the lower surface of the panel is providedwith panel glue storage grooves in the length direction; the substrate glue storage grooves are adjacently and continuously formed in the width direction of the substrate, and the panel glue storage grooves are adjacently and continuously formed in the width direction of the panel. The PVC stone-plastic plate is a PVC stone-plastic base material, and the PVC stone-plastic basic material is prepared according to the following steps of blending raw materials and carrying out heating, generating air pores, carrying out extrusion molding, and carrying out cooling for shaping. According to the solid wood PVC stone-plastic double-layer composite floor, the production cost of the double-layer composite floor is reduced, the ecological environment is protected, and the situations can be effectively prevented from occurring that the double-layer composite floor is unglued and deformed.

Owner:ANHUI YINUO WOOD PLASTIC SHEET TECH CO LTD

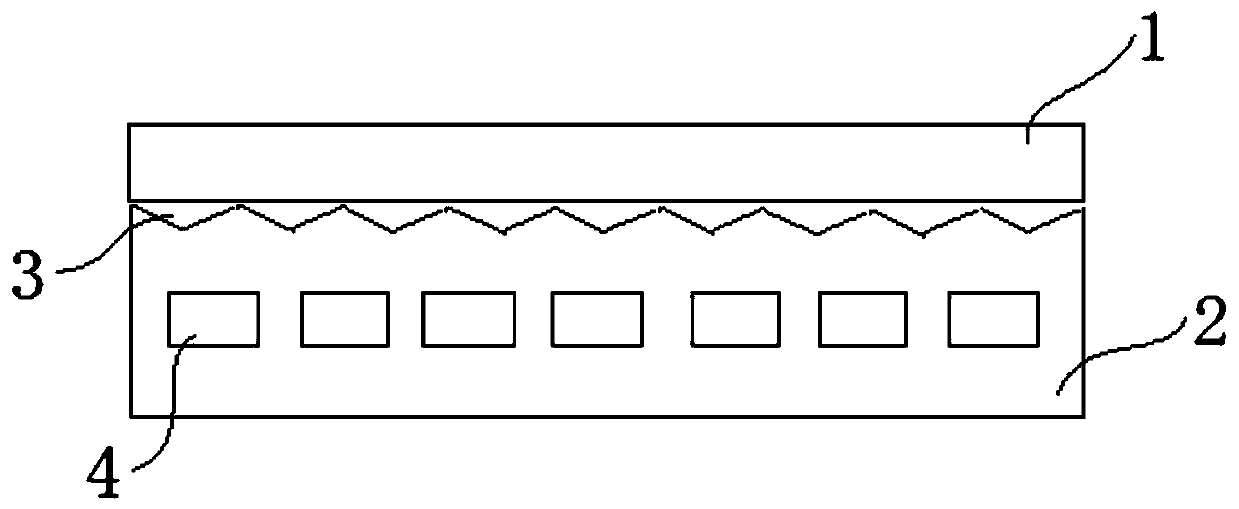

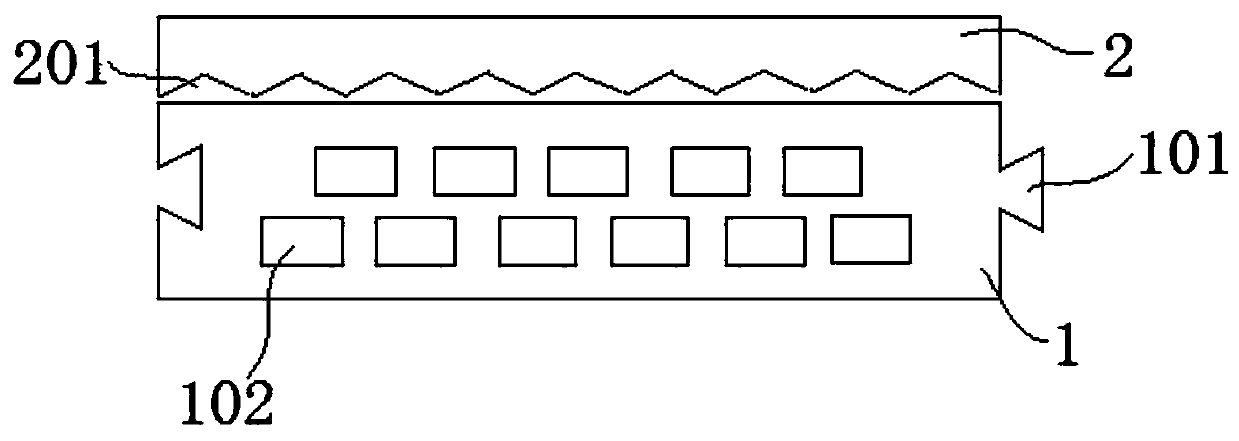

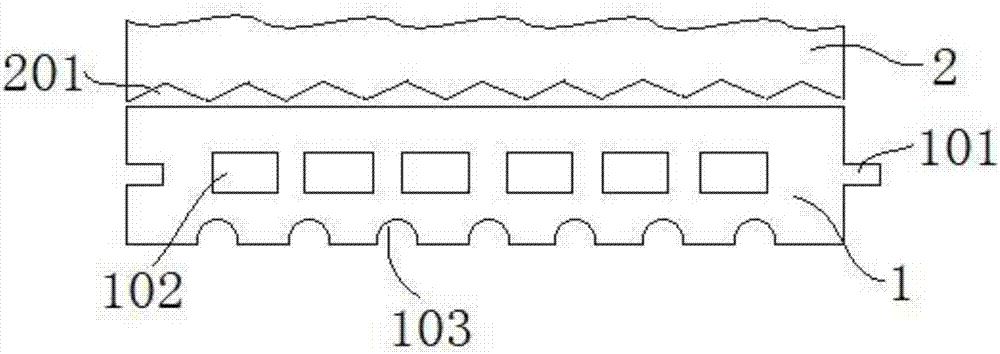

A double-layer composite floor

ActiveCN107965113BAvoid glue openingIncrease bonding areaFlooring insulationsEcological environmentEngineering

The invention discloses a double-deck combined type floor, and belongs to the field of floors. The double-deck combined type floor is formed by bonding a faceplate of the upper deck and a baseplate ofthe lower deck, wherein the baseplate is made of a PVC stone plastic plate. The upper surface of the faceplate is of an irregular raised grain wearproof surface, and the upper part of the raised grain wearproof surface is covered with a paint coating layer. A baseplate rubber storage tank is arranged on the upper surface of the baseplate in the length direction. A notch structure and a convex opening structure which are in inserted connection with each other are symmetrically formed in the two edges of the baseplate in the length direction, and a notch structure and a convex opening structurewhich are in inserted connection with each other are similarly and symmetrically formed in the two edges of the baseplate in the width direction. The PVC stone plastic plate is made of a PVC stone plastic base material, and the PVC stone plastic base material is prepared by the following steps of step a, raw material mixing and heating; step b, pore generation; step c, extruding and forming; stepd, cooling and forming. According to the double-deck combined type floor, production cost of the double-deck combined type floor is reduced, ecological environment is protected, and the occurrence oftackless and deformation phenomena of the double-deck combined type floor is effectively avoided.

Owner:ANHUI YINUO WOOD PLASTIC SHEET TECH CO LTD

Preparation method of release paper-free glue film wallpaper

InactiveCN109943243AHigh viscositySolve the problem of insufficient widthCovering/liningsOrganic non-macromolecular adhesiveWeather resistanceEngineering

The invention discloses a preparation method of release paper-free glue film wallpaper. The finished wallpaper is prepared through mixing, polymerization, extrusion, melt-blowing, airflow traction, wiring net formation and composting. The preparation method has the advantages that by mixing a tackifier with a TPU raw material, the viscosity of the TPU resin is improved; a glue film is formed through melt-blowing, airflow traction and wiring net formation and is composited with a composite layer through hot melting, so that the glue failure condition can be effectively avoided, and the strengthis enhanced; by utilizing a hot melt glue film, the weather resistance is strong, and the problem that the whole wallpaper is not wide enough is effectively solved; and the composite layer is torn down to be directly fit during the cloth adhesion, so that the wallpaper is convenient, practical and low in cost.

Owner:江苏惠沣环保科技有限公司

A solid wood pvc stone-plastic double-layer composite floor

ActiveCN107916764BAvoid glue openingIncrease bonding areaSynthetic resin layered productsConstructions elementsSolid woodEcological environment

The invention discloses a solid wood PVC stone-plastic double-layer composite floor, and belongs to the field of floors. The floor is formed by bonding a panel at the upper layer with a substrate at the lower layer, the panel is a solid wood plate, and the substrate is a PVC stone-plastic plate; the thickness of the substrate is higher than that of the panel; the substrate is internally provided with a through passage in the length direction; the upper surface of the substrate is provided with substrate glue storage grooves in the length direction or the lower surface of the panel is providedwith panel glue storage grooves in the length direction; the substrate glue storage grooves are adjacently and continuously formed in the width direction of the substrate, and the panel glue storage grooves are adjacently and continuously formed in the width direction of the panel. The PVC stone-plastic plate is a PVC stone-plastic base material, and the PVC stone-plastic basic material is prepared according to the following steps of blending raw materials and carrying out heating, generating air pores, carrying out extrusion molding, and carrying out cooling for shaping. According to the solid wood PVC stone-plastic double-layer composite floor, the production cost of the double-layer composite floor is reduced, the ecological environment is protected, and the situations can be effectively prevented from occurring that the double-layer composite floor is unglued and deformed.

Owner:ANHUI YINUO WOOD PLASTIC SHEET TECH CO LTD

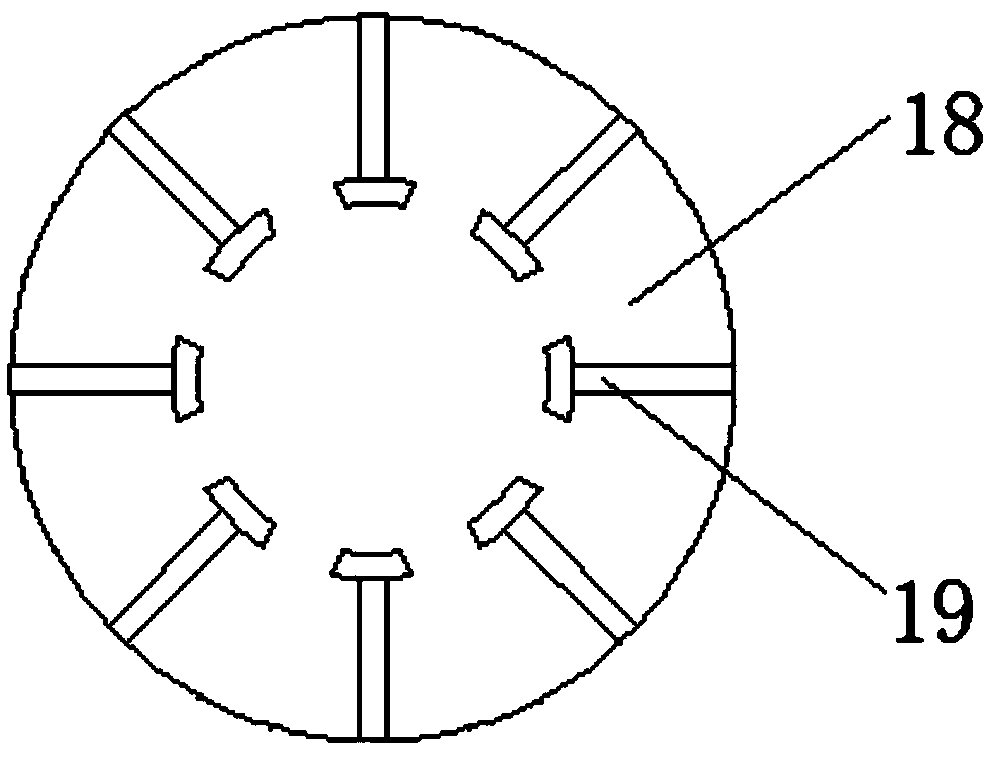

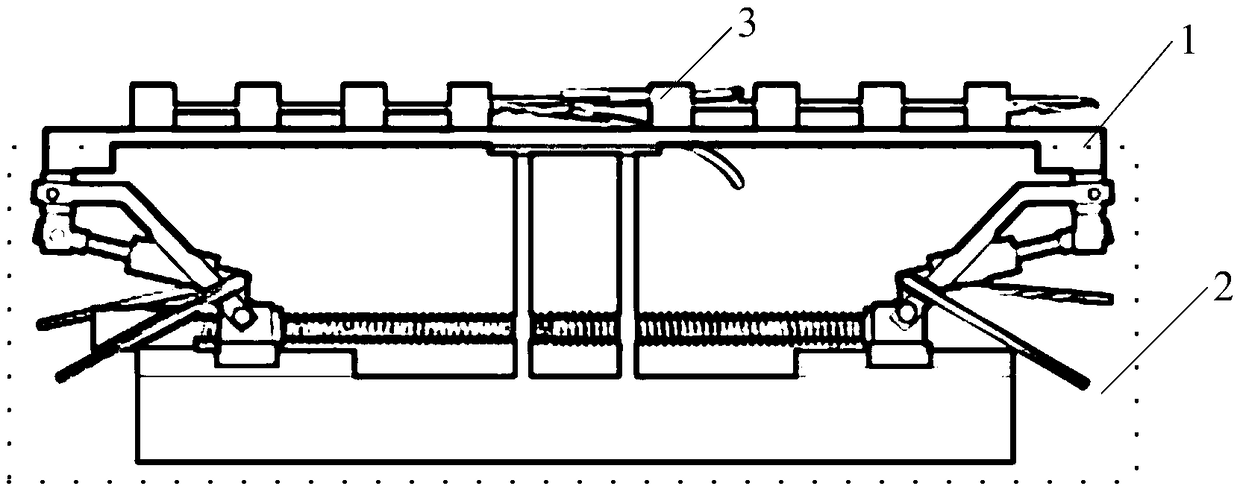

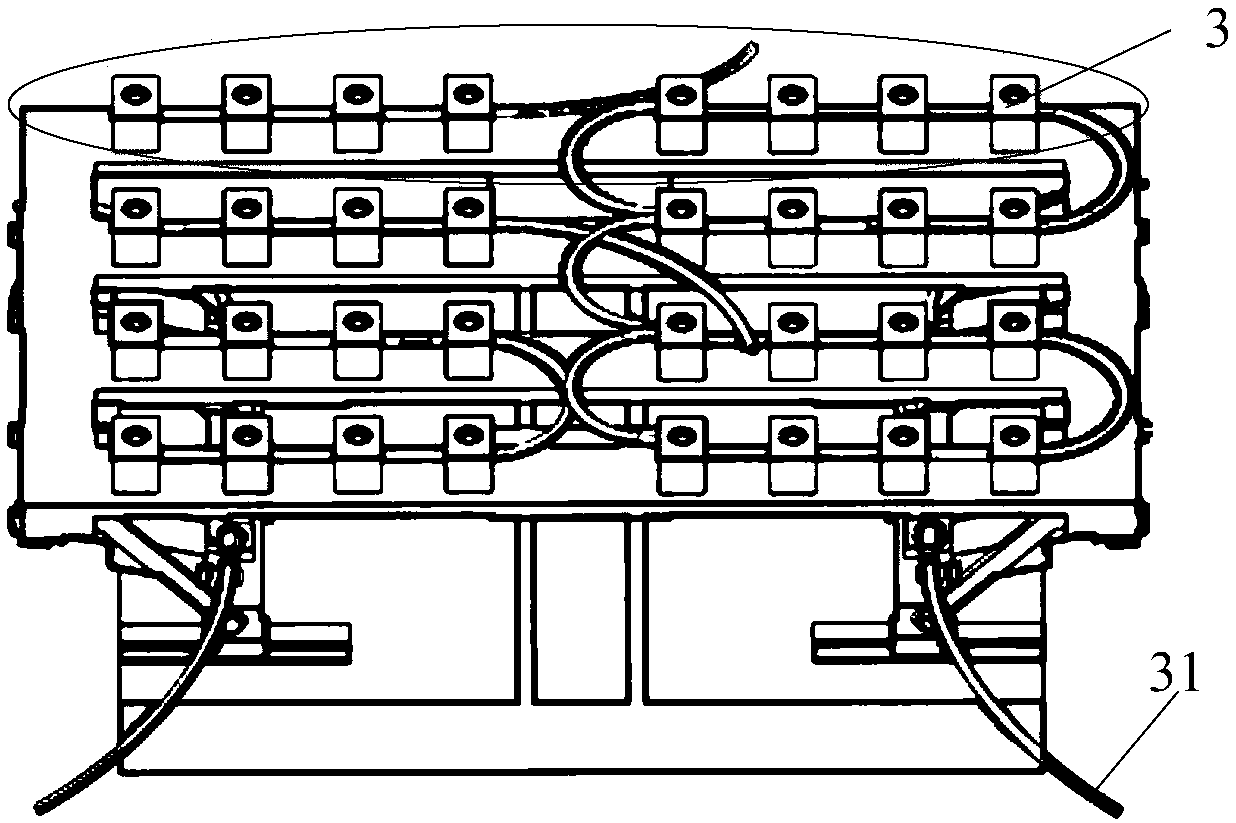

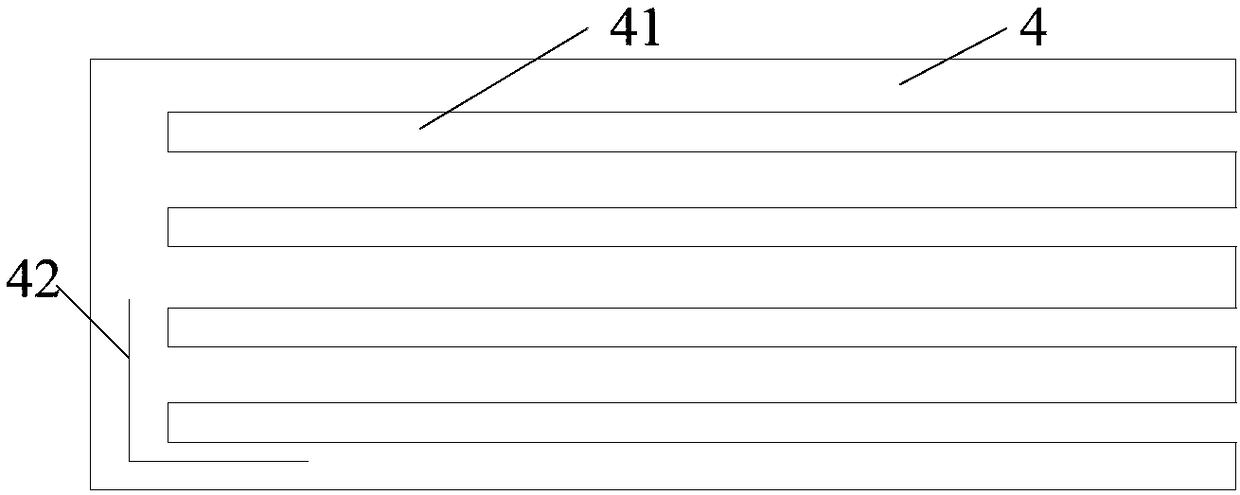

A surface assembly device

ActiveCN106737297BHigh speedAvoid glue openingMaterial gluingWork holdersMarine engineeringSurface plate

Owner:BOE TECH GRP CO LTD +1

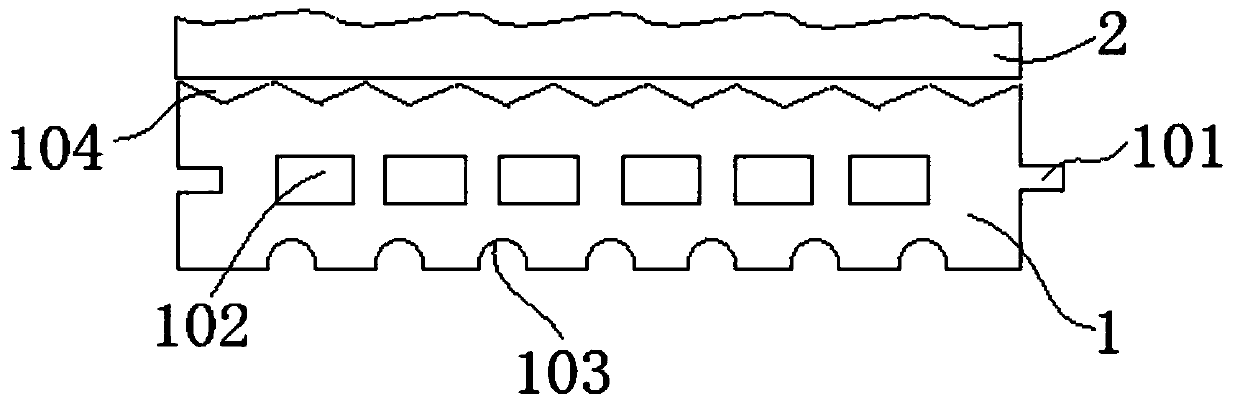

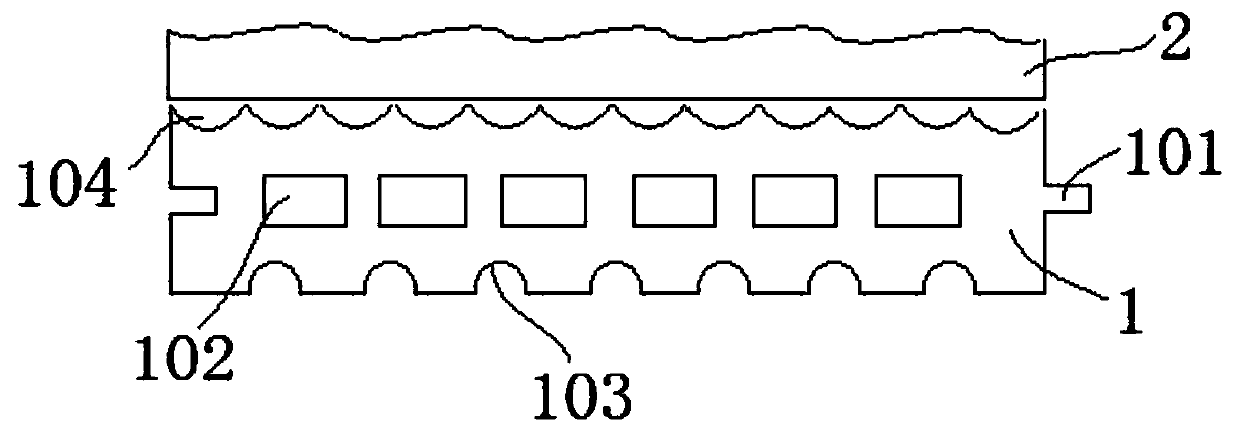

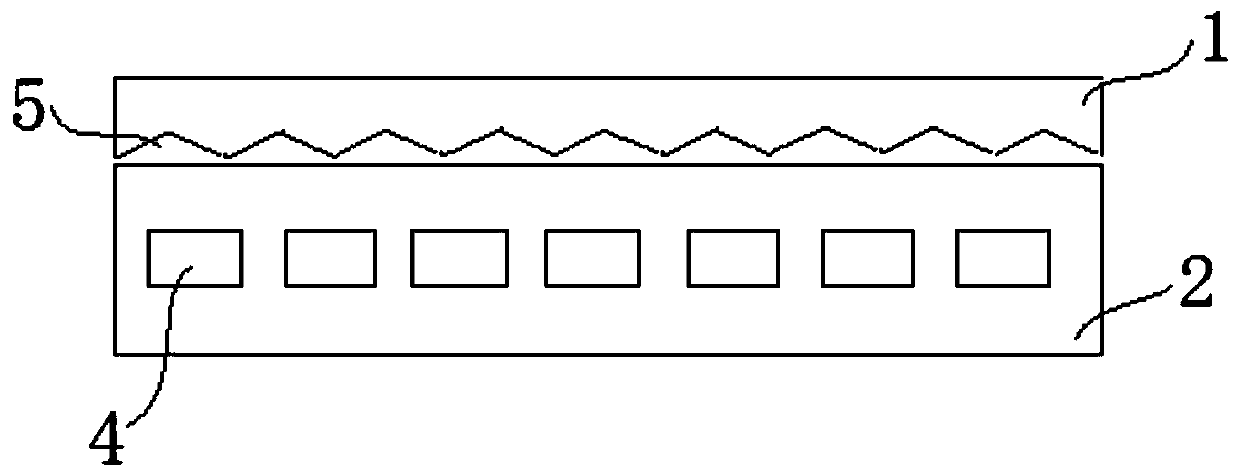

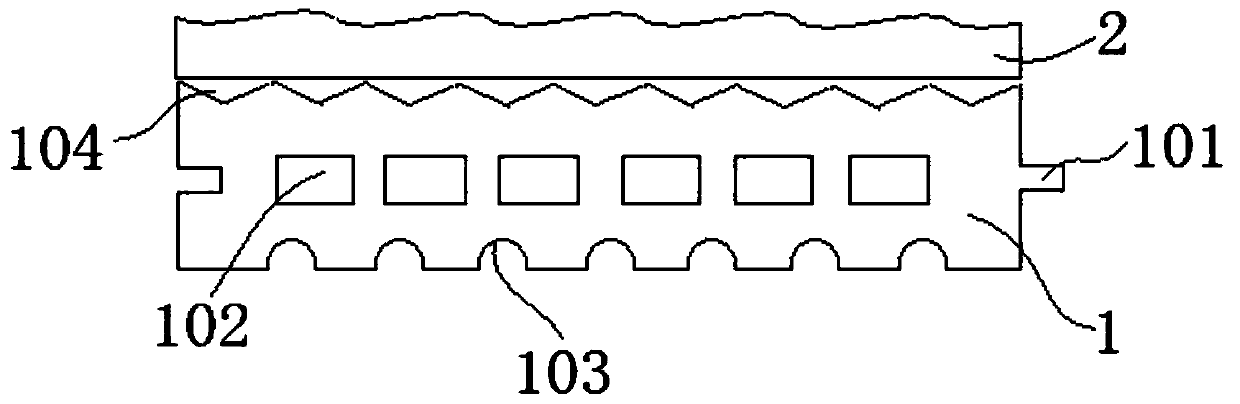

Anti-deformation double-layer composite floor

ActiveCN107938994AAvoid glue openingIncrease bonding areaFlat articlesFlooringEcological environmentEngineering

The invention discloses an anti-deformation double-layer composite floor and belongs to the field of floors. The anti-deformation double-layer composite floor is formed through bonding of a face plateon the upper layer and a base plate on the lower layer; base plate glue storage grooves are formed in the length direction of the upper surface of the base plate; a notch structure and a bulge structure for mutual inserting are symmetrically arranged at the two edges in the length direction of the base plate, and a notch structure and a bulge structure for mutual inserting are also symmetricallyarranged at the two edges in the width direction of the base plate; and an upper layer of penetrating channels and a lower layer of penetrating channels are uniformly distributed in the length direction of the interior of the base plate and arranged in a staggered mode. A PVC stone plastic plate is a PVC stone plastic base material, and the PVC stone plastic base material is prepared through the following steps of a, mixing and heating of raw materials, b, generating of air holes, c, extrusion forming and d, cooling forming. The production cost of the double-layer composite floor is reduced, the ecological environment is protected, and the glue failure and deformation phenomena of the double-layer composite floor are effectively avoided.

Owner:ANHUI YINUO WOOD PLASTIC SHEET TECH CO LTD

Urea-formaldehyde resin and urea-formaldehyde resin glue and preparation method thereof

InactiveCN100384898CImprove water retentionPrevents over-aging problemsAldehyde/ketone condensation polymer adhesivesWood veneer joiningPolymer scienceUrea-formaldehyde

This invention is a preparation method of urea formaldehyde condensate used in glued board. By adding 0.01-1% high-hydroscopicity resin of formaldehyde and aquacare's total weight, we successfully prevent glued board from overaging. It could guarantee high glue efficiency even after long-time aging. It hardly change the original process, and it's still lower-cost.

Owner:BEIJING FORESTRY UNIVERSITY

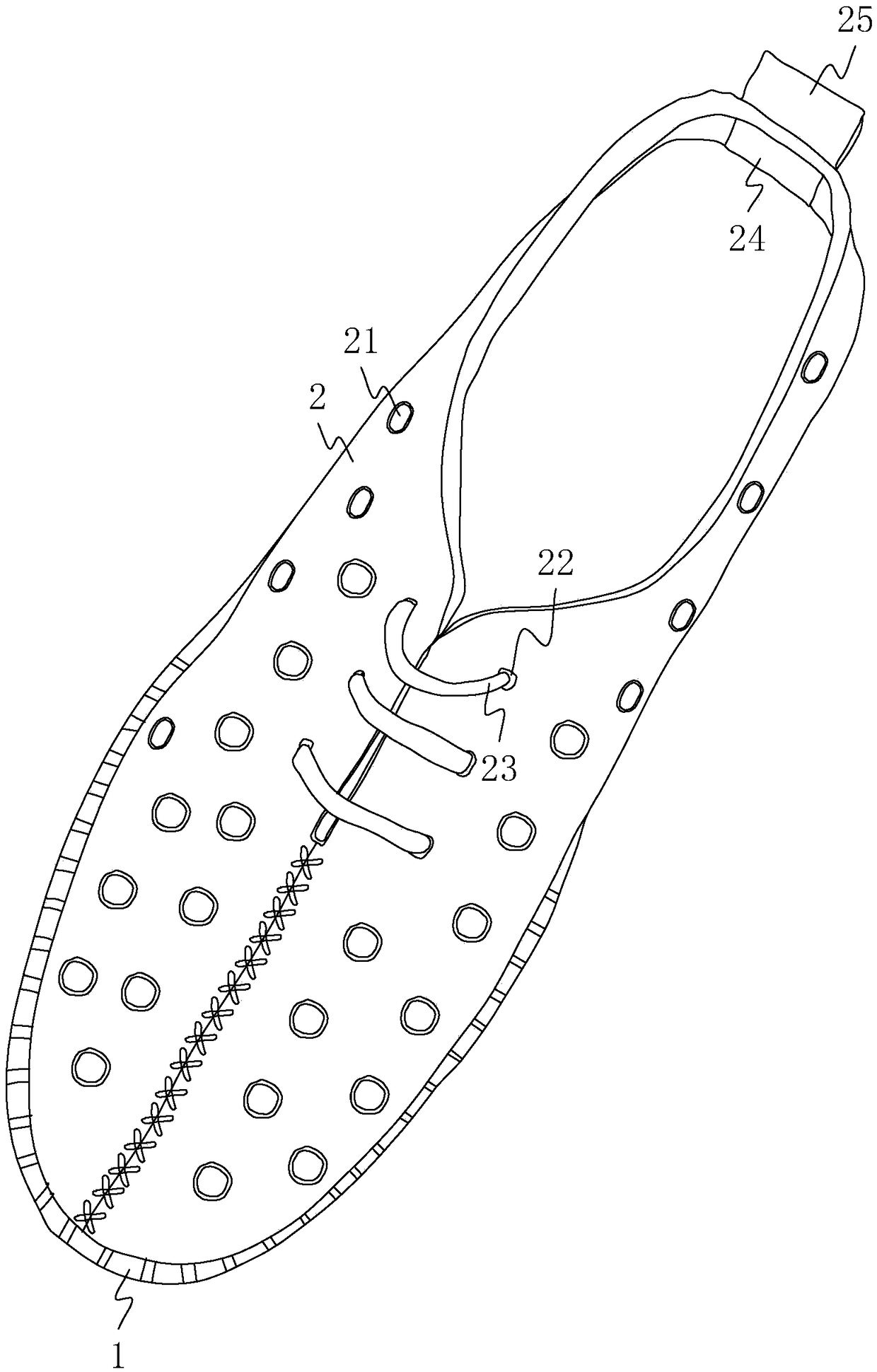

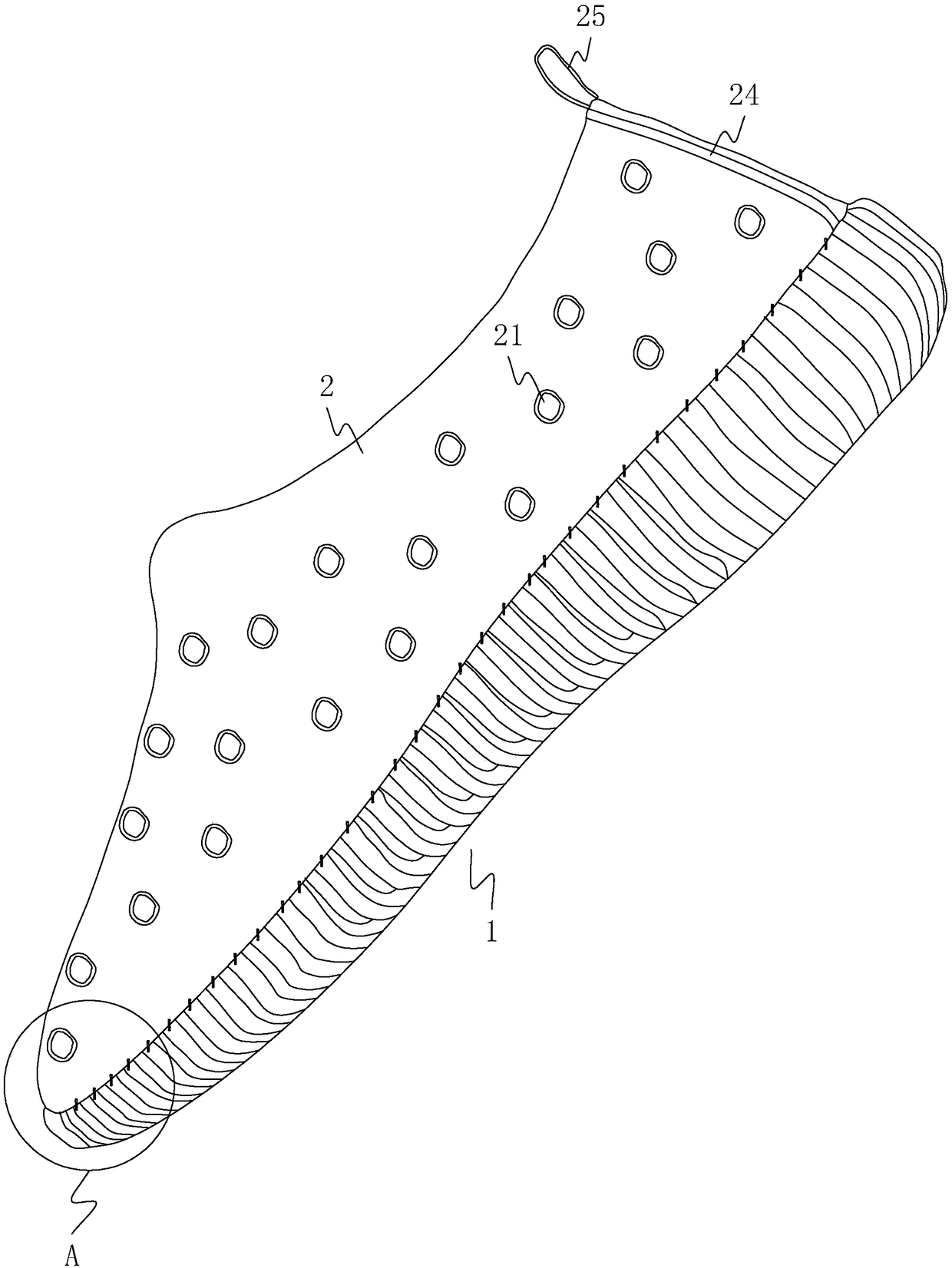

Shoes and production process thereof

PendingCN109123899AThe production and processing process is convenient and fastIncrease productivitySolesUpperEngineering

The invention discloses a shoe and a production process thereof, which relates to the shoe field. The shoe comprises a sole, a pair of uppers arranged symmetrically with each other, a pair of uppers intersected by sewing threads, a ring of first sewing holes arranged on the outer edge of the sole, a second sewing hole communicated with the sewing holes arranged on the lower end side wall of the upper, and a sewing rope pierced between the first sewing hole and the second sewing hole. The invention has the following advantages and effects: the production and processing of the shoe upper can becompleted by forming a plurality of completely identical shoe uppers at one time and adopting a sewing process, and the shoe sole and the shoe upper can be sewn and fixed at the same time through a sewing process, so that the production and processing process of the shoe is convenient and quick, and the effect of high production efficiency is achieved. By sewing instead of traditional glue bonding, the firmness between the sole and the upper is increased, the phenomenon of glue opening between the sole and the upper is avoided, the wearing service life of the shoe is prolonged, and the effectof high service life is achieved.

Owner:台州市欧港鞋业有限公司

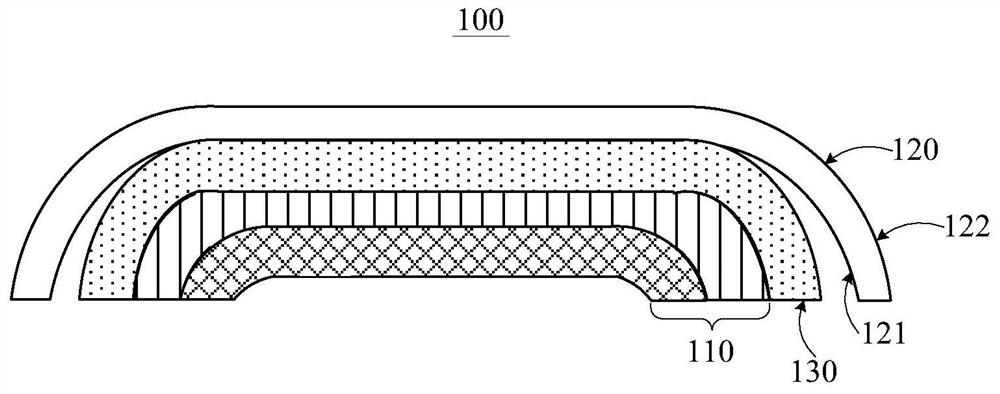

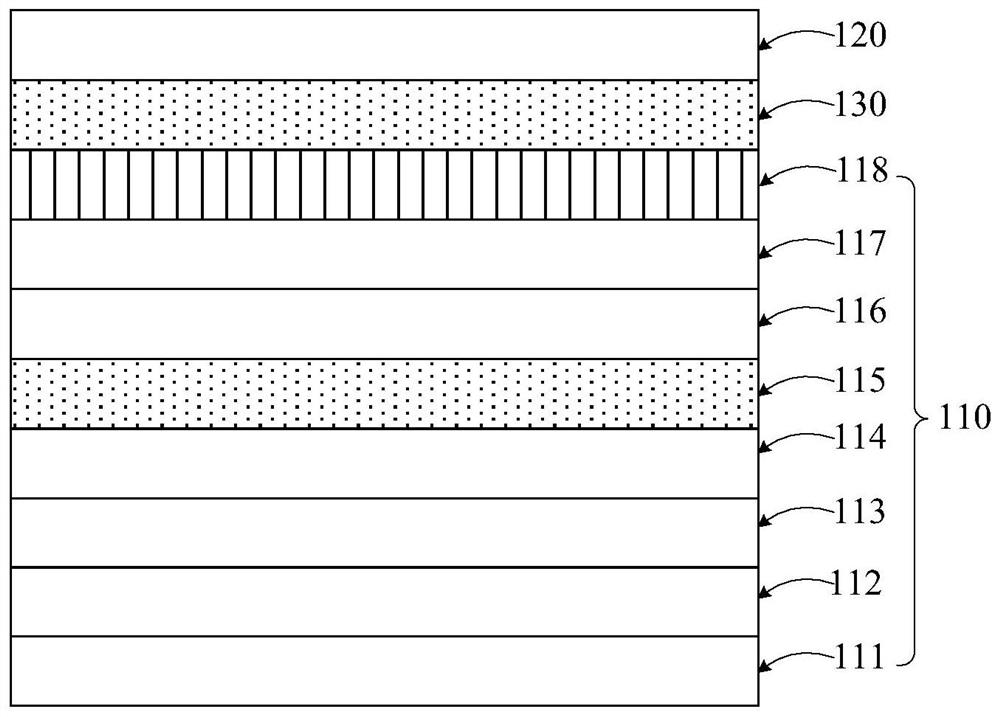

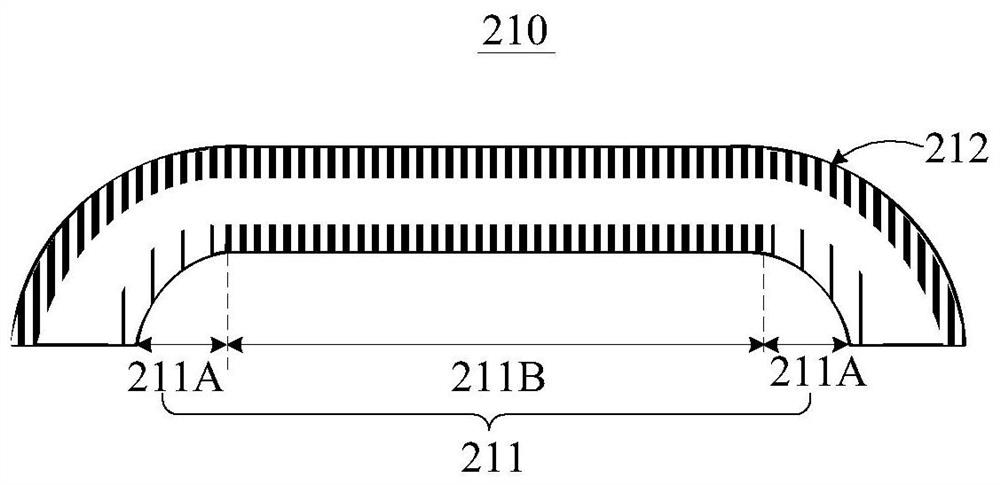

Flexible cover plate, preparation method thereof and display panel

PendingCN113990180ASmall resilienceAvoid glue openingIdentification meansStructural engineeringMechanical engineering

The embodiment of the invention provides a flexible cover plate, a preparation method thereof and a display panel, the flexible cover plate is used for covering a display substrate, the display substrate comprises a curved surface display area, the flexible cover plate comprises a first surface facing the display substrate and a second surface deviating from the display substrate, the first surface comprises a first part used for covering the curved surface display area, and the stress of the first part is smaller than that of the second surface. According to the technical scheme, the glue failure phenomenon of the flexible cover plate can be relieved or avoided.

Owner:BOE TECH GRP CO LTD

Adhesive film, preparation method of adhesive film and shoe sole including adhesive film

ActiveCN111019571BSolve problems such as hazardous substancesNo side effectsMineral oil hydrocarbon copolymer adhesivesSolesPolymer scienceModified carbon

The invention discloses an adhesive film, a preparation method of the adhesive film and a shoe sole comprising the adhesive film. The adhesive film is composed of the following raw materials in parts by weight: 35 parts of maleic anhydride grafted SBS rubber and 15-22 parts of chlorinated polypropylene , 15-20 parts of maleic anhydride polybutadiene, 8-12 parts of liquid polyisobutylene, 15-19 parts of modified carbon nine resin, 1.5-2 parts of zinc stearate, 0.1-0.3 parts of crosslinking agent, anti Oxygen agent 0.1-0.3 parts, the film is a cross-linked film containing a peroxide cross-linking agent, and vulcanized rubber and foam midsole in the process of heating and forming, chemical cross-linking occurs, strong adhesion, Good heat and water resistance, can effectively avoid the glue-opening phenomenon of combined soles caused by wet aging and heat aging, and enhance the brand effect of the product.

Owner:MAOTAI FUJIAN SOLES CO LTD

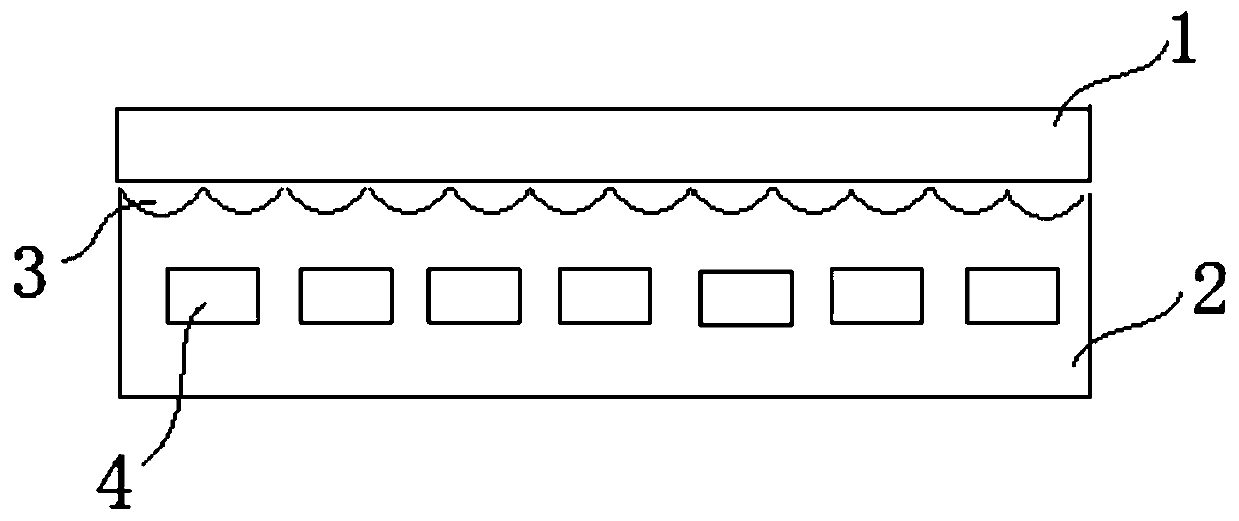

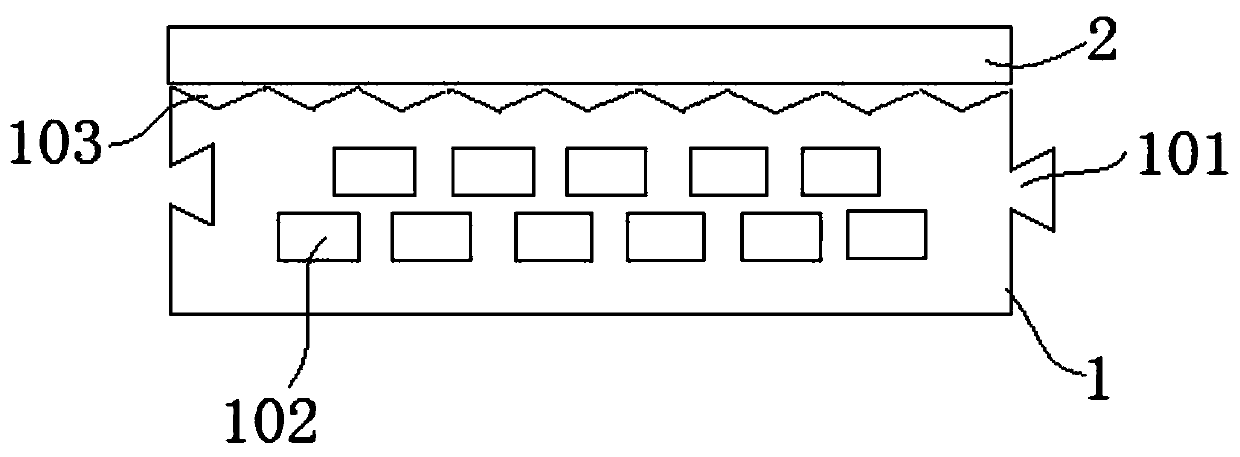

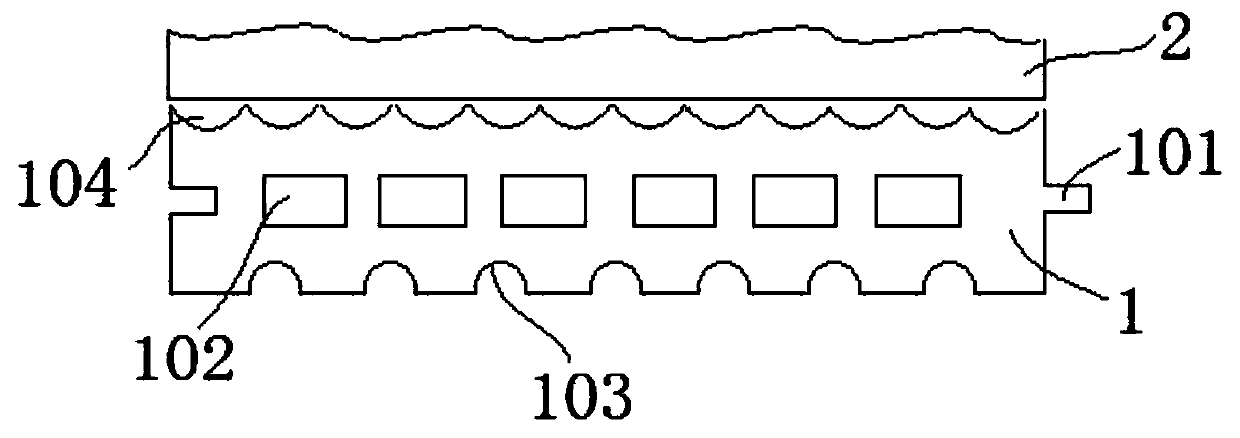

A kind of anti-deformation floor

ActiveCN107905479BAvoid glue openingIncrease bonding areaSynthetic resin layered productsFloor coveringsSolid woodEcological environment

The invention discloses an anti-deformation floor, and belongs to the field of floors. The anti-deformation floor is formed by bonding of a panel on the upper layer and a base plate on the lower layer, the panel is a solid wood panel, and the base plate is a PVC stone-plastic plate; the upper surface of the panel is covered with a paint coating layer, and the lower surface of the panel is providedwith a panel glue storage groove in the length direction; the thickness of the base plate is greater than the thickness of the panel; and an upper layer through channel and a lower layer through channel are evenly distributed in the base plate in the length direction and are arrayed in a staggered mode. The PVC stone-plastic plate is made of a PVC stone-plastic base material, and the PVC stone-plastic base material is prepared by adopting the following steps of a, raw material mixing and heating, b, pore generating, c, extrusion molding, and d, cooling molding. According to the anti-deformation floor, the production cost of a double-layer composite floor is reduced, the ecological environment is protected, and the phenomena of glue failure and deformation of the double-layer composite floor are effectively avoided.

Owner:ANHUI YINUO WOOD PLASTIC SHEET TECH CO LTD

An anti-deformation double-layer composite floor

ActiveCN107938994BAvoid glue openingIncrease bonding areaFlat articlesFlooringEcological environmentEngineering

The invention discloses an anti-deformation double-layer composite floor and belongs to the field of floors. The anti-deformation double-layer composite floor is formed through bonding of a face plateon the upper layer and a base plate on the lower layer; base plate glue storage grooves are formed in the length direction of the upper surface of the base plate; a notch structure and a bulge structure for mutual inserting are symmetrically arranged at the two edges in the length direction of the base plate, and a notch structure and a bulge structure for mutual inserting are also symmetricallyarranged at the two edges in the width direction of the base plate; and an upper layer of penetrating channels and a lower layer of penetrating channels are uniformly distributed in the length direction of the interior of the base plate and arranged in a staggered mode. A PVC stone plastic plate is a PVC stone plastic base material, and the PVC stone plastic base material is prepared through the following steps of a, mixing and heating of raw materials, b, generating of air holes, c, extrusion forming and d, cooling forming. The production cost of the double-layer composite floor is reduced, the ecological environment is protected, and the glue failure and deformation phenomena of the double-layer composite floor are effectively avoided.

Owner:ANHUI YINUO WOOD PLASTIC SHEET TECH CO LTD

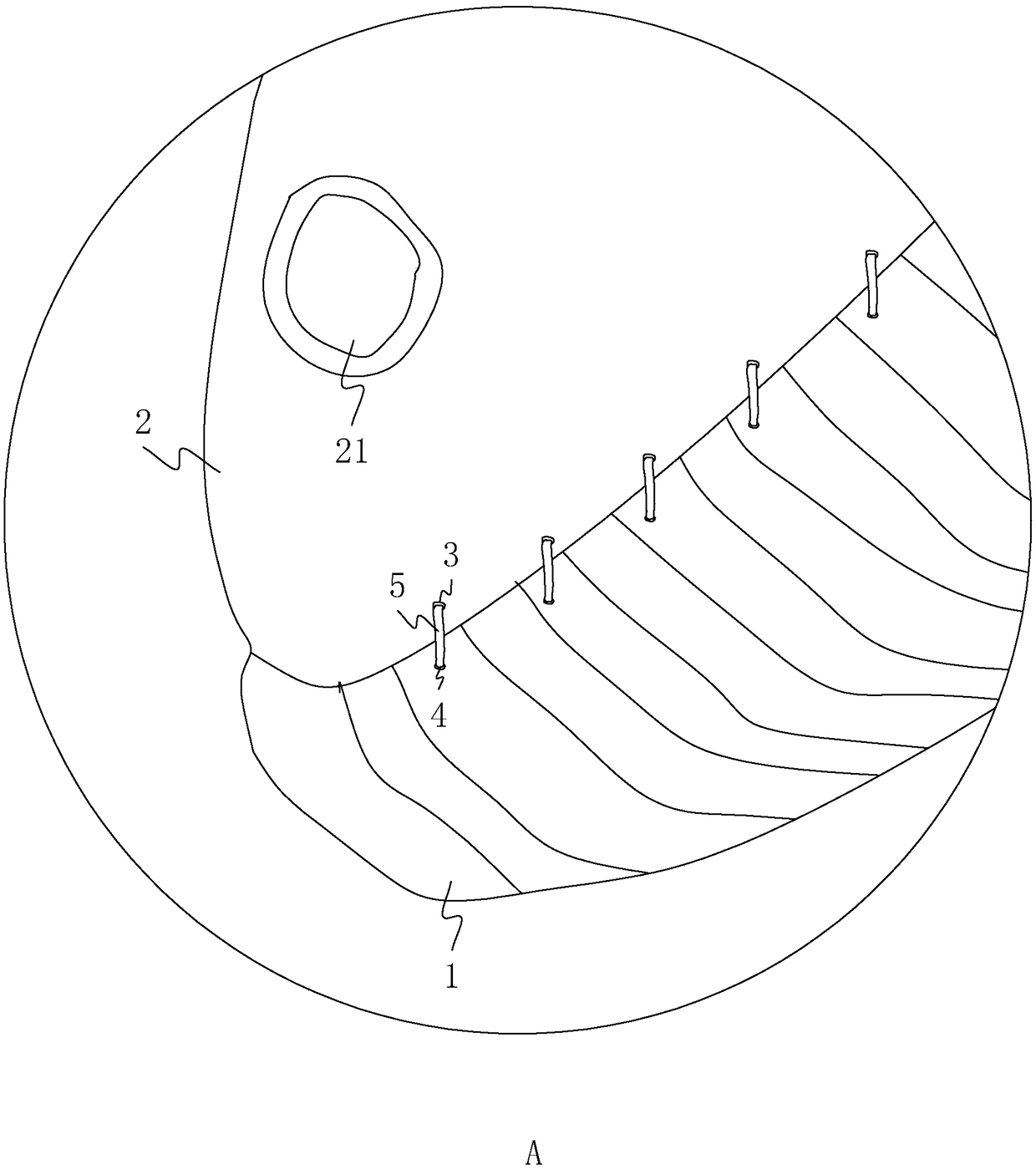

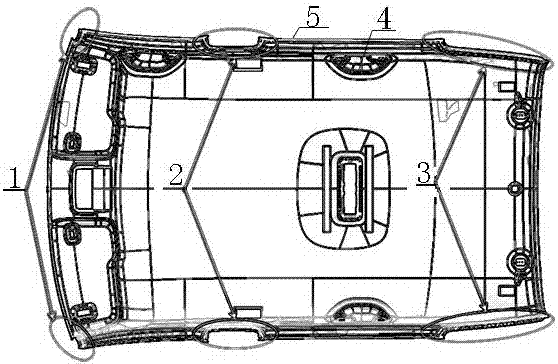

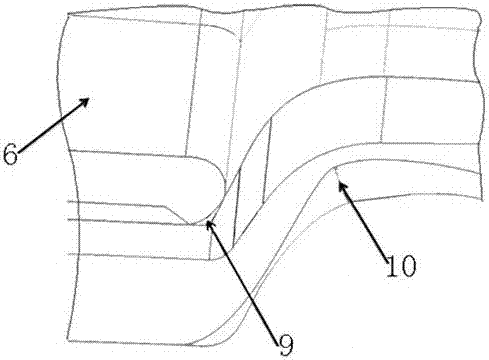

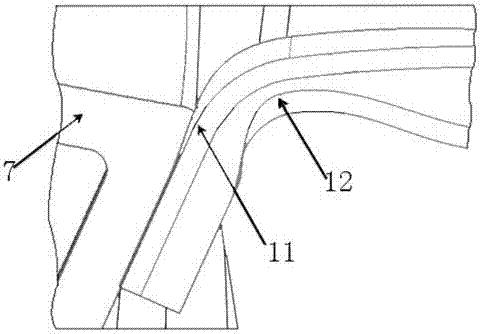

Production process for preventing pre-deformation of ceiling product

InactiveCN107226041AReduce gapIngenious designSuperstructure subunitsMetal working apparatusPre deformationManufacturing engineering

The invention relates to a production process for preventing the pre-deformation of a ceiling product. The design of the ceiling product comprises an A-column area, a B-column area, a C-column area and a handle hole area, wherein the contact surface between the ceiling product and an A-column plastic part, a B-column plastic part or a C-column plastic part is a surface A; the reverse surface of the surface A of the ceiling is a surface C; and a design for preventing pre-deformation needs to be made for the ceiling product before production. The production process for preventing the pre-deformation of a ceiling product has the advantages that materials can be better fitted to a test tool after molding, and warping deformation of the product caused by resilience can be reduced; when two layers of materials are combined, the gap between molds is reduced, so that the two layers of materials can be better combined to prevent glue failure; in order to make sure that no gap exists between the product and an opponent part during loading, the product matching area is elevated, even interference design can be performed to ensure that the product is loaded without any gap between the product and the opponent part.

Owner:NANTONG CHAODA EQUIP CO LTD

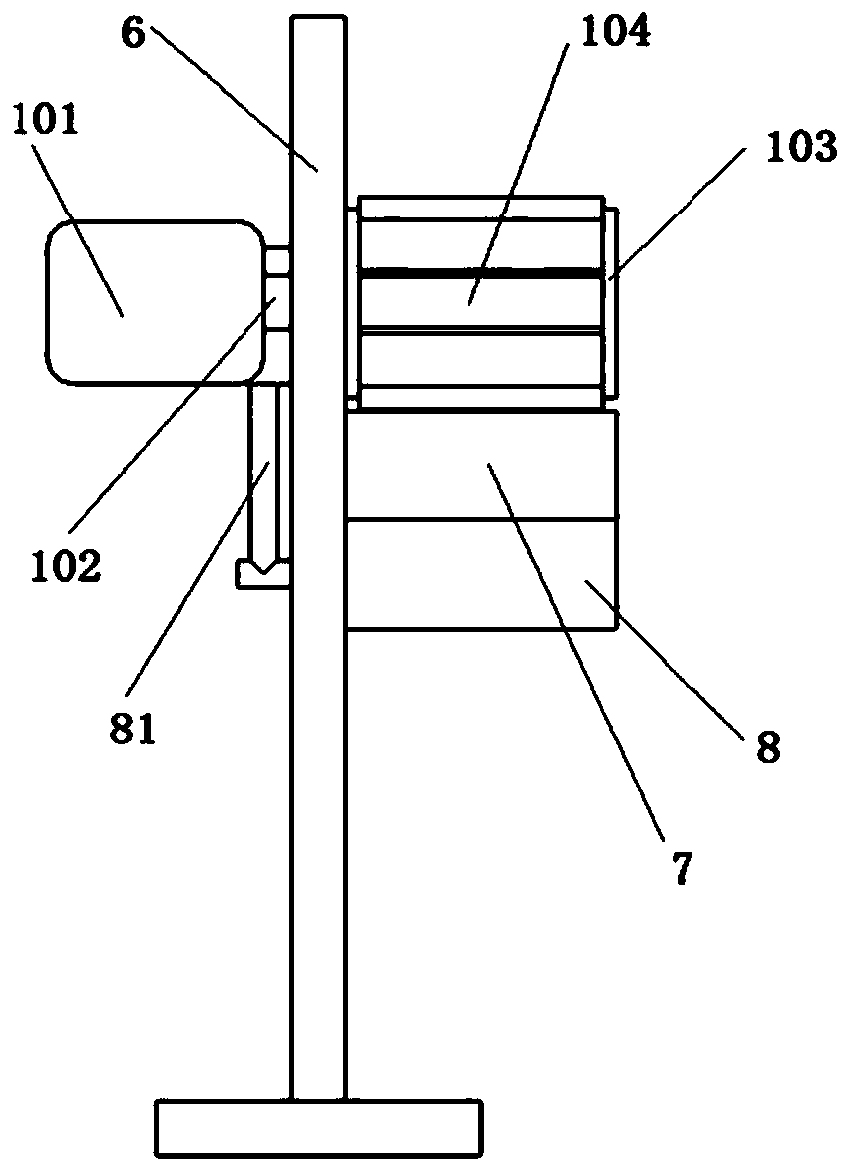

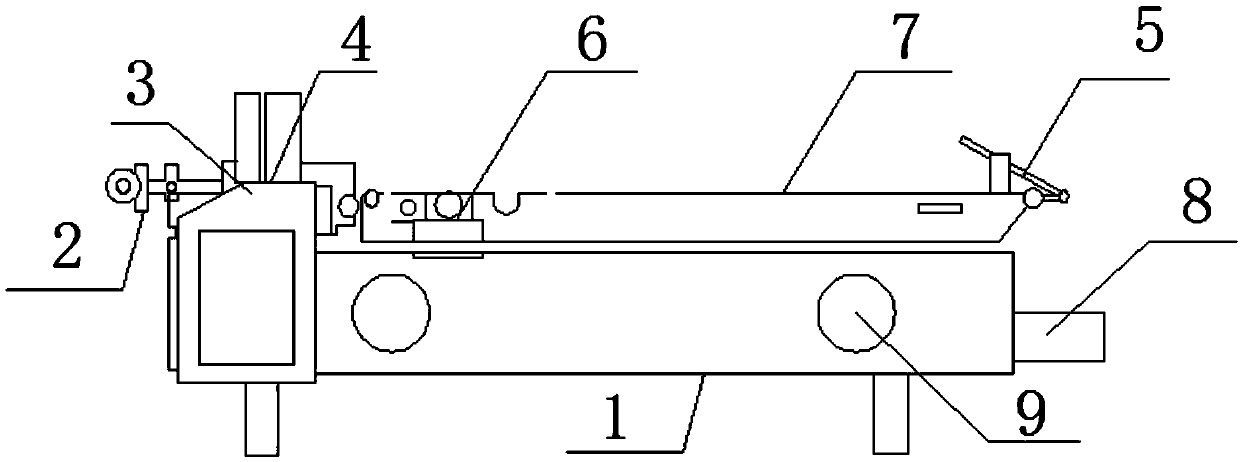

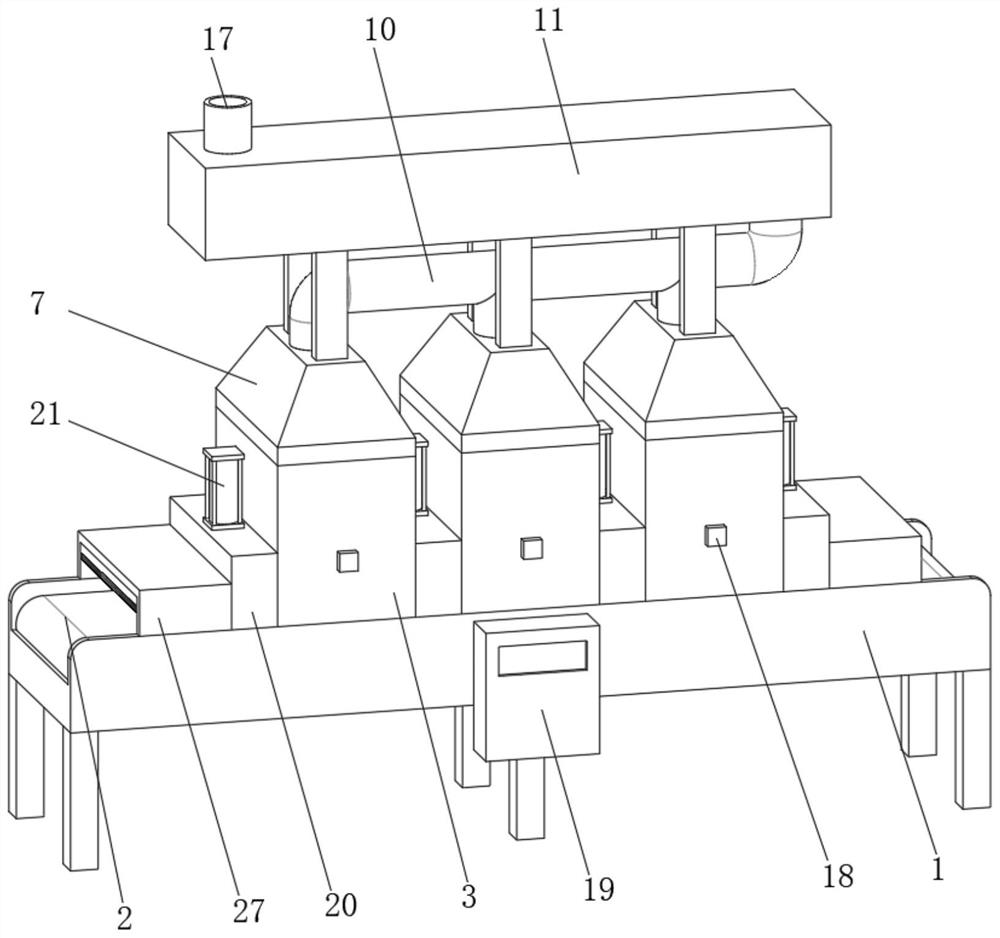

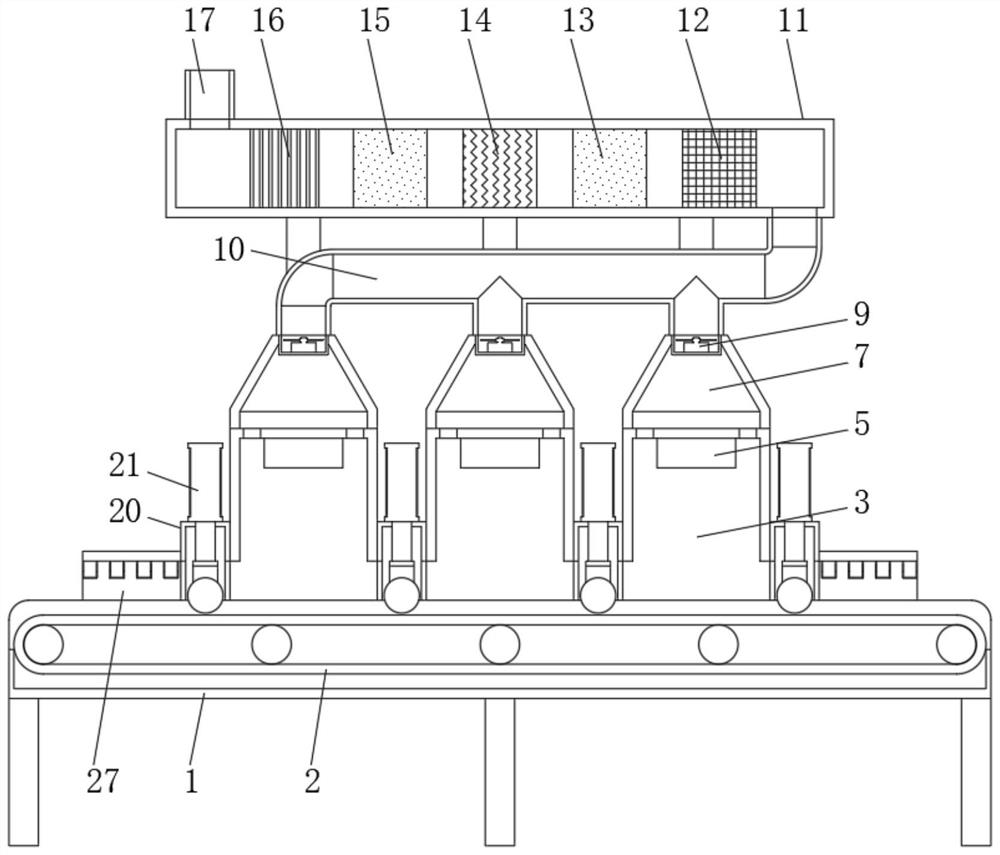

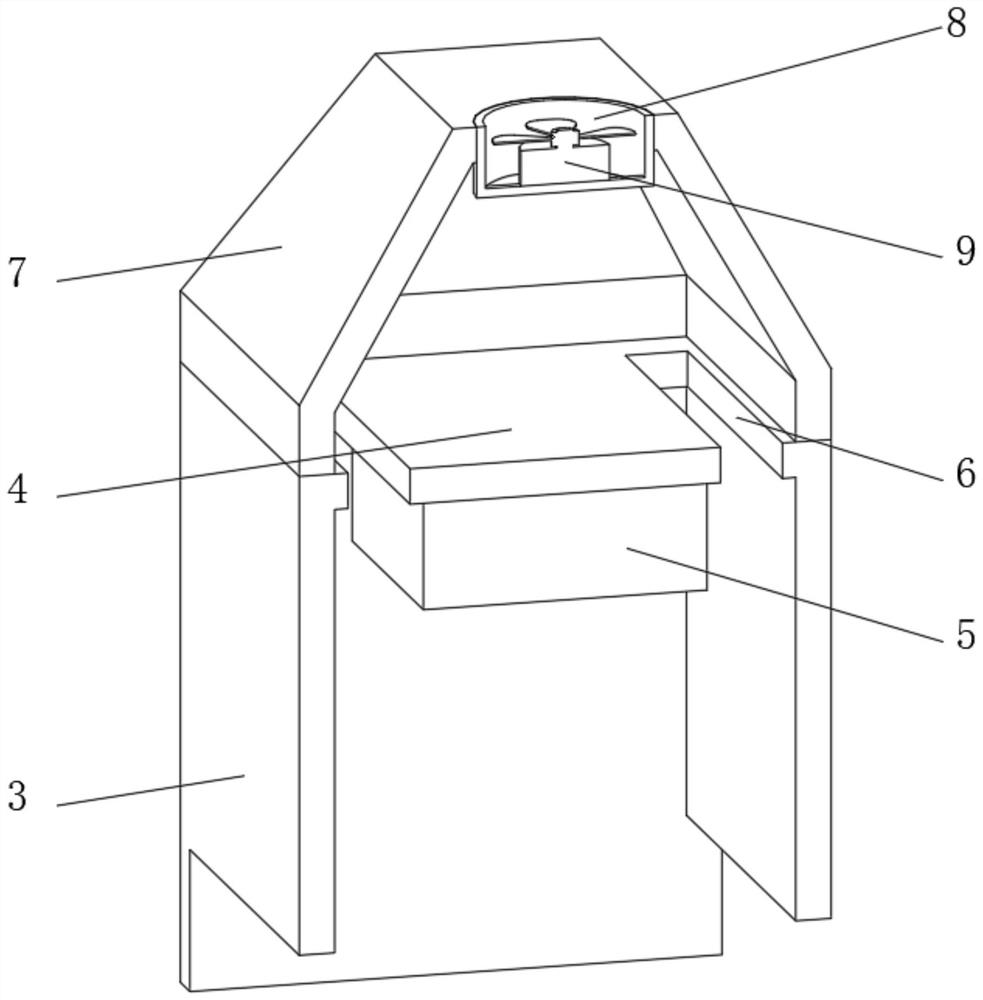

Paper box forming machine used for multiple times of extrusion

InactiveCN111331920AAvoid glue openingImprove adhesionEnvelopes/bags making machineryBox making operationsSocial benefitsMolding machine

The invention discloses a paper box forming machine used for multiple times of extrusion. The paper box forming machine comprises a rack and a conveyor mechanism. A transmission device is arranged atthe front end of the rack, and a button is arranged on the edge of the transmission device. The conveyor mechanism is connected with a cutting mechanism. An electric control box is fixedly connected to the side wall of the rack. A support is arranged at the rear end of the electric control box. A discharging opening is vertically mounted on the rack, and a transmission shaft is arranged behind thedischarging opening. The paper box forming machine is more convenient and rapid to use, is convenient to operate, has good social benefits and economic benefits and is suitable for being used and popularized, compact in structure connection and simple and convenient to use.

Owner:韩亮

Steel-plastics composite pressure pipe and its production method

Owner:XINXING DUCTILE IRON PIPES CO LTD +2

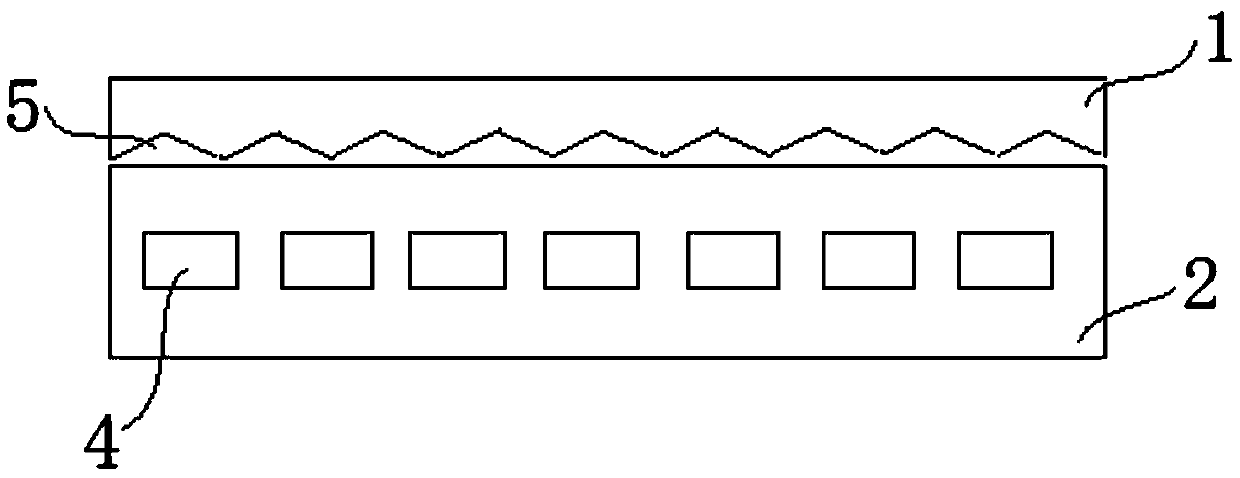

Double-deck combined type floor

ActiveCN107965113AAvoid glue openingIncrease bonding areaFlooring insulationsEcological environmentStorage tank

The invention discloses a double-deck combined type floor, and belongs to the field of floors. The double-deck combined type floor is formed by bonding a faceplate of the upper deck and a baseplate ofthe lower deck, wherein the baseplate is made of a PVC stone plastic plate. The upper surface of the faceplate is of an irregular raised grain wearproof surface, and the upper part of the raised grain wearproof surface is covered with a paint coating layer. A baseplate rubber storage tank is arranged on the upper surface of the baseplate in the length direction. A notch structure and a convex opening structure which are in inserted connection with each other are symmetrically formed in the two edges of the baseplate in the length direction, and a notch structure and a convex opening structurewhich are in inserted connection with each other are similarly and symmetrically formed in the two edges of the baseplate in the width direction. The PVC stone plastic plate is made of a PVC stone plastic base material, and the PVC stone plastic base material is prepared by the following steps of step a, raw material mixing and heating; step b, pore generation; step c, extruding and forming; stepd, cooling and forming. According to the double-deck combined type floor, production cost of the double-deck combined type floor is reduced, ecological environment is protected, and the occurrence oftackless and deformation phenomena of the double-deck combined type floor is effectively avoided.

Owner:ANHUI YINUO WOOD PLASTIC SHEET TECH CO LTD

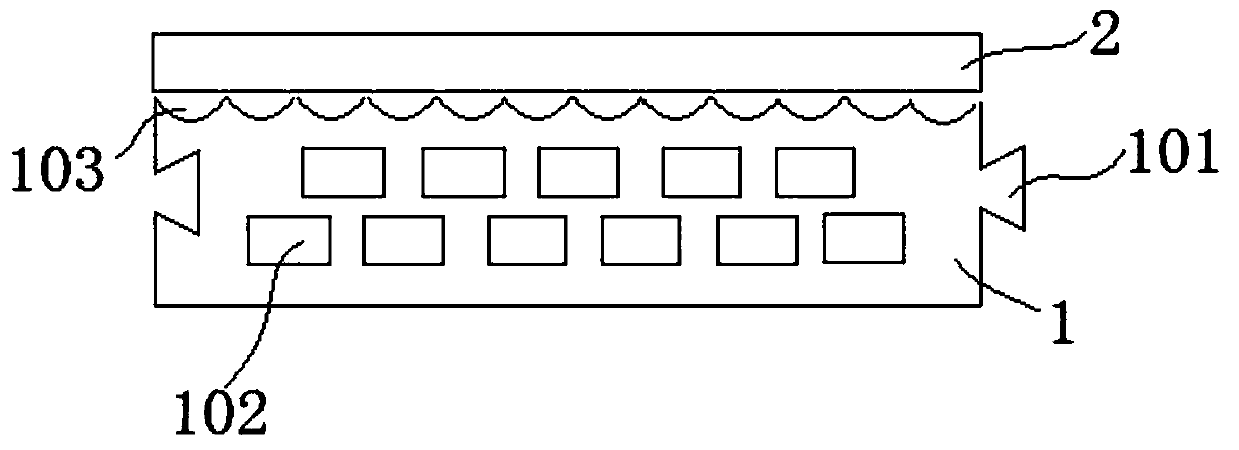

a composite floor

ActiveCN107965114BAvoid glue openingIncrease bonding areaFlooring insulationsEcological environmentEngineering

Owner:ANHUI YINUO WOOD PLASTIC SHEET TECH CO LTD

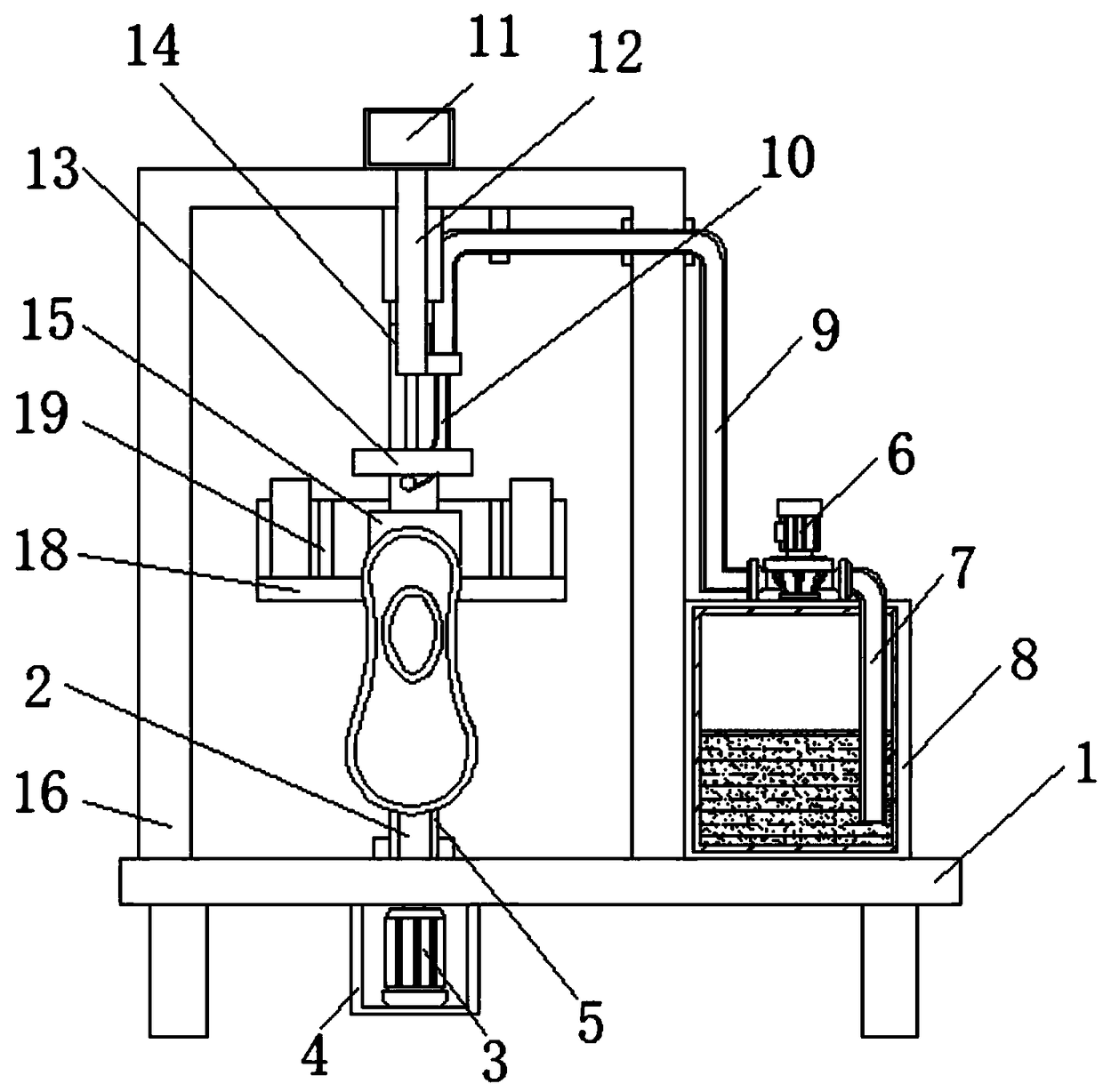

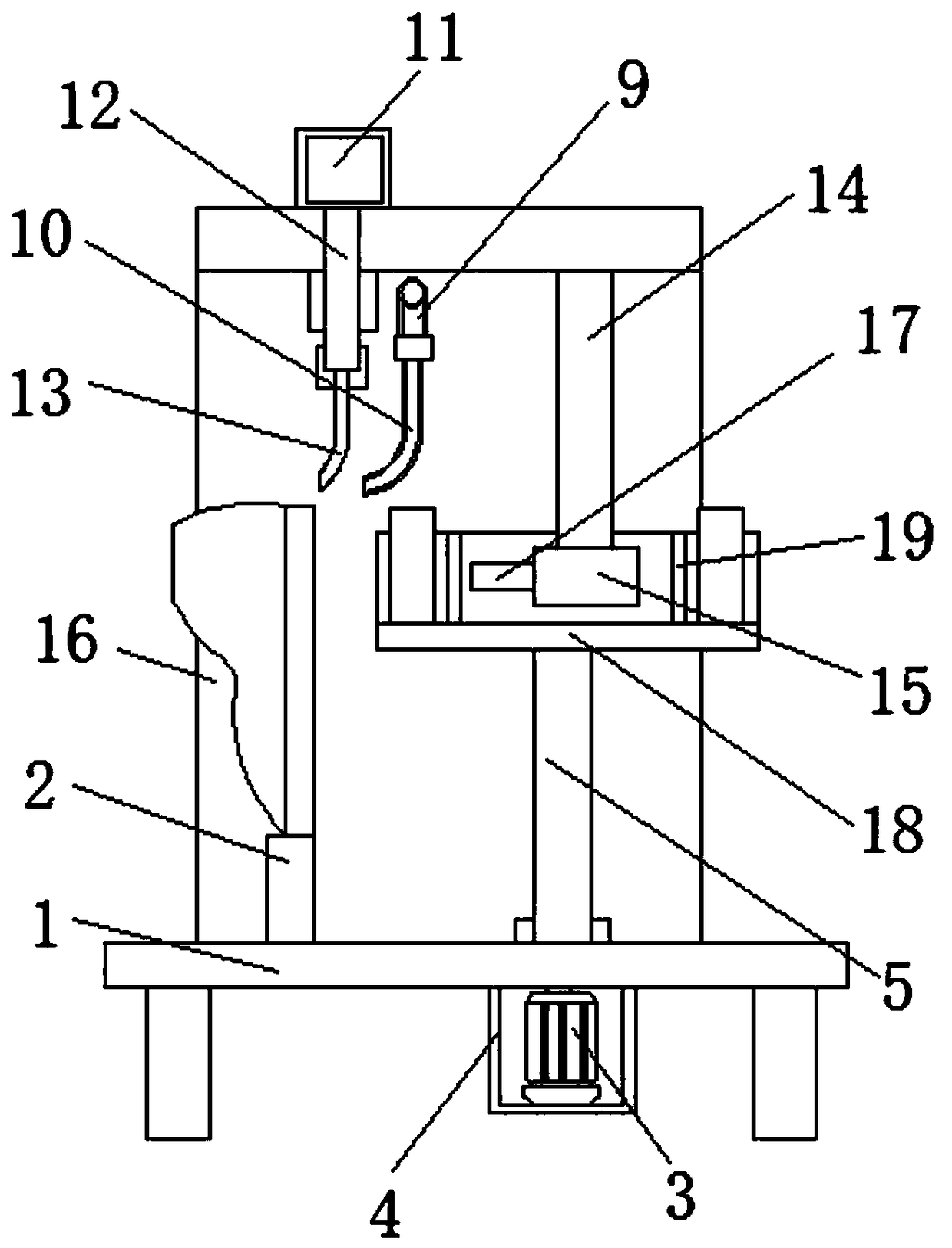

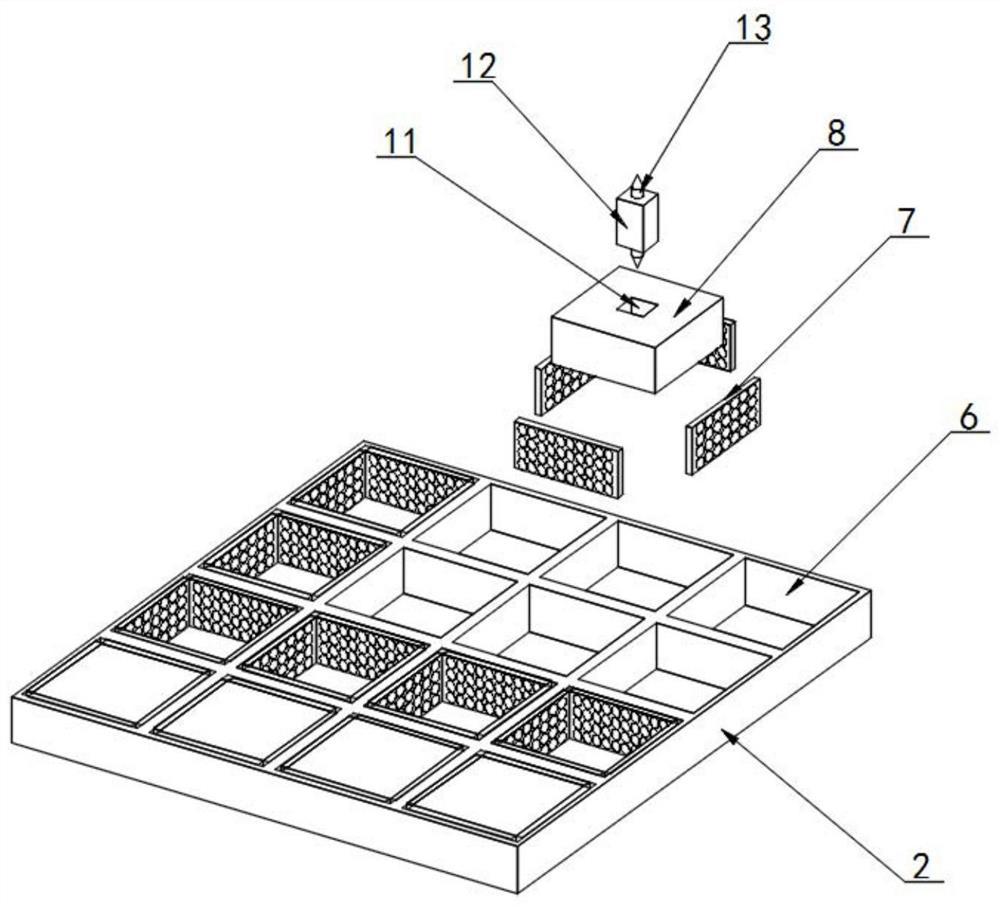

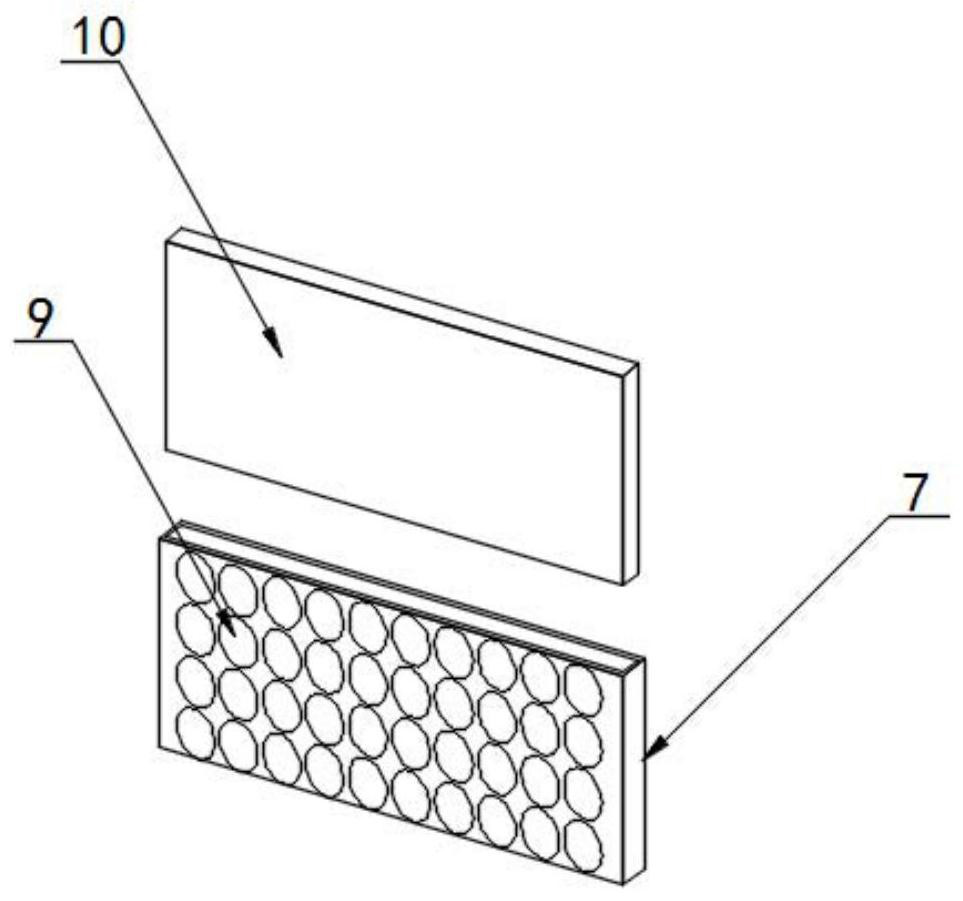

Quick glue drying equipment for honeycomb plate production

PendingCN114161774AAvoid damageAccelerate solidificationDrying solid materials with heatPaper/cardboard articlesDry glueAdhesive glue

The invention discloses quick glue drying equipment for cellular board production, and relates to the technical field of cellular board production, in particular to the quick glue drying equipment for cellular board production, which comprises a support frame, a conveying belt is mounted in the support frame, a drying box is fixedly connected to the top of the support frame, and a top plate is fixedly connected to the top of the drying box. A microwave generator is fixedly mounted at the bottom of the top plate, a moisture removal cover is fixedly mounted at the top of the drying box, and a moisture removal pipe is fixedly connected to the top of the moisture removal cover. According to the rapid glue drying equipment for cellular board production, the drying box is arranged, microwaves are generated by the microwave generator in the drying box and act on the cellular board, the microwaves can enable water molecules in glue to vibrate and rub to generate heat, the heating efficiency is high, evaporation of water is promoted, and solidification of the glue is accelerated; meanwhile, microwave heating can directly act on the interior of the cellular board, and the surface of the cellular board is prevented from being grilled at high temperature.

Owner:江苏盛翔电子科技有限公司

a composite floor

ActiveCN107938993BImprove adhesionAvoid glue openingSynthetic resin layered productsFloor coveringsEcological environmentEngineering

The invention discloses a composite floor, and belongs to the field of floors. The composite floor is formed by bonding of an upper layer panel and a lower layer base plate, the panel is a solid woodpanel, and the base plate is a PVC stone plastic plate; the thickness of the base plate is greater than that of the panel, the base plate is internally provided with a through channel in the length direction, and the lower surface of the panel is provided with panel glue-storage grooves in the length direction; and the panel glue-storage grooves are the grooves with cross sections being in V shapes, and the panel glue-storage grooves are adjacently and continuously arrayed in the width direction of the panel. The PVC stone plastic plate is made of a PVC stone plastic base material, and the PVCstone plastic base material is prepared by adopting the following steps of a, raw material mixing and heating, b, air hole generating, c, extrusion molding, and d, cooling molding. According to the composite floor, the production cost of the double-layer composite floor is reduced, the ecological environment is protected, and phenomena of glue failure and deformation of the double-layer compositefloor are effectively avoided.

Owner:ANHUI YINUO WOOD PLASTIC SHEET TECH CO LTD

Adhesive film, preparation method of adhesive film and shoe sole including adhesive film

ActiveCN111004584BImprove cohesionEnhanced interactionSolesNon-macromolecular adhesive additivesPolymer scienceCross linker

Owner:MAOTAI FUJIAN SOLES CO LTD

Coding system and method for printing labels on rubber surface

ActiveCN109703207BAccurate codingAvoid glue openingTypewritersStructural engineeringProcess engineering

The invention provides a code spraying system and method for a glued surface printing label. The system comprises a solidifying unit, a leveling unit and a detecting and code spraying unit; the solidifying unit is used for improving the bonding strength of the glued surface printing label and preventing the label from being unglued; the leveling unit is arranged on the outlet side of the solidifying unit and is used for preventing edges of the glued surface printing label from being folded; and the detecting and code spraying unit is arranged on the outlet side of the leveling unit and is usedfor performing identification and sequence code spraying on the glued surface printing label. By the aid of the code spraying system and method for the glued surface printing label, the sequence codespraying accuracy of the glued surface printing label can be improved, and the phenomena of code spraying errors can be avoided.

Owner:天津英友标贴科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com