Solid wood PVC stone-plastic double-layer composite floor

A composite, stone-plastic technology, applied in the direction of wood layered products, layered products, synthetic resin layered products, etc., can solve the production cost of double-layer composite floor and deformation, so as to avoid glue opening, reduce weight and eliminate internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

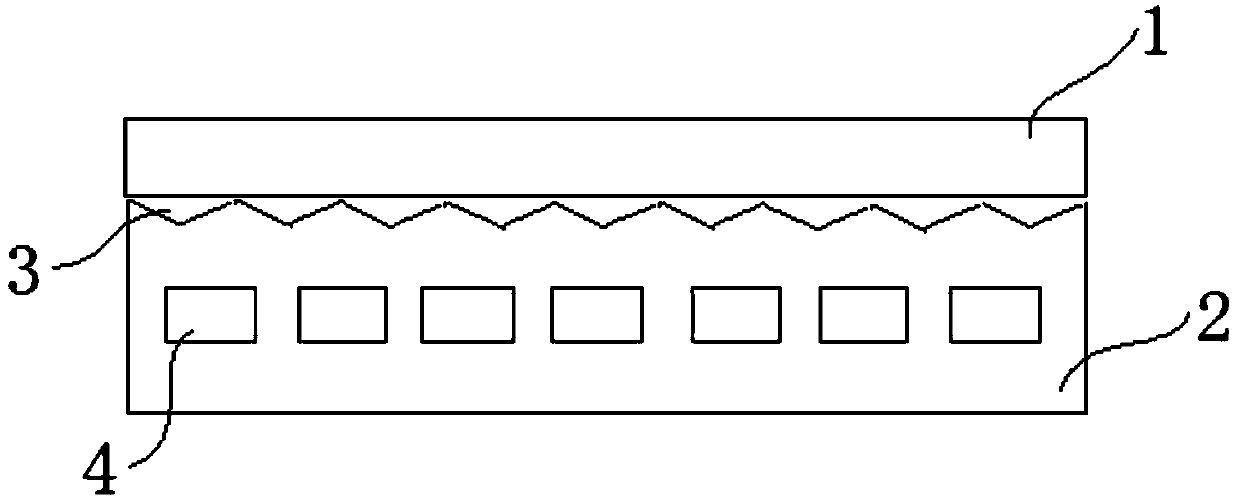

[0036] combine figure 1 , The solid wood PVC stone-plastic double-layer composite floor of this embodiment is formed by bonding the upper panel 1 and the lower substrate 2, the panel 1 is a solid wood board, and the substrate 2 is a PVC stone-plastic board. The thickness of the substrate 2 is greater than the thickness of the panel 1, and the inside of the substrate 2 is provided with a through channel 4 along the length direction. The cross section of the through channel 4 is rectangular. One, seven through channels 4 are arranged parallel to each other along the width direction of the substrate 2 . The upper surface of the substrate 2 is provided with a substrate glue storage tank 3 along the length direction. The substrate glue storage groove 3 is a groove with a V-shaped cross section.

[0037] PVC stone-plastic board, also known as stone-wood flooring, is mostly sheet material. It is a new type of high-quality floor material. It uses natural stone powder as the main raw ...

Embodiment 2

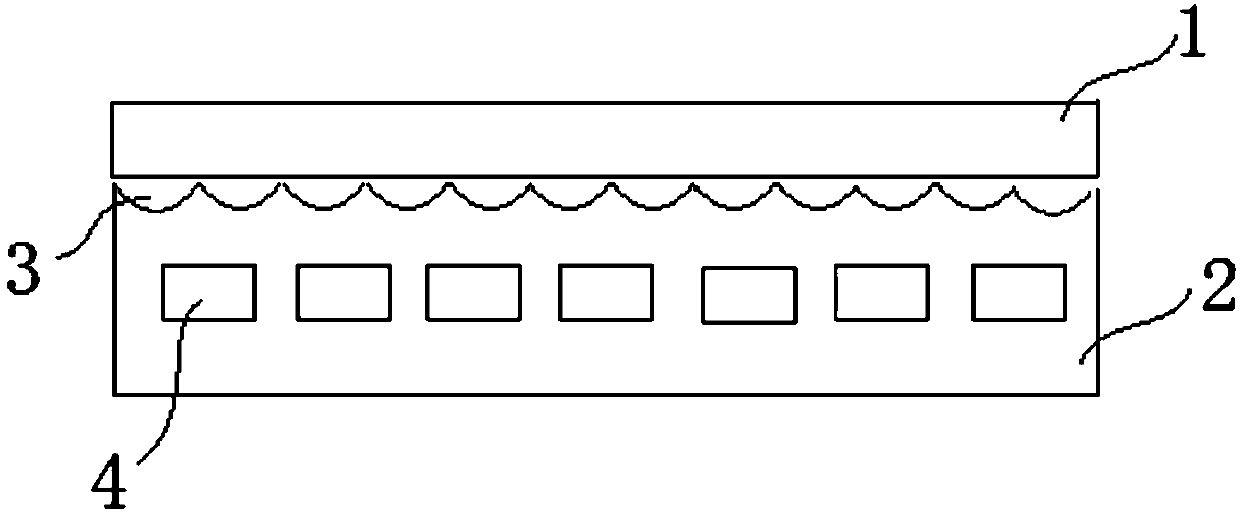

[0044] combine figure 2 , The solid wood PVC stone-plastic double-layer composite floor of this embodiment is formed by bonding the upper panel 1 and the lower substrate 2, the panel 1 is a solid wood board, and the substrate 2 is a PVC stone-plastic board. The thickness of the substrate 2 is greater than the thickness of the panel 1, and the inside of the substrate 2 is provided with a through channel 4 along the length direction. The cross section of the through channel 4 is rectangular. One, seven through channels 4 are arranged parallel to each other along the width direction of the substrate 2 . The upper surface of the substrate 2 is provided with a substrate glue storage tank 3 along the length direction. The substrate glue storage groove 3 is a groove with an arc-shaped cross section.

Embodiment 3

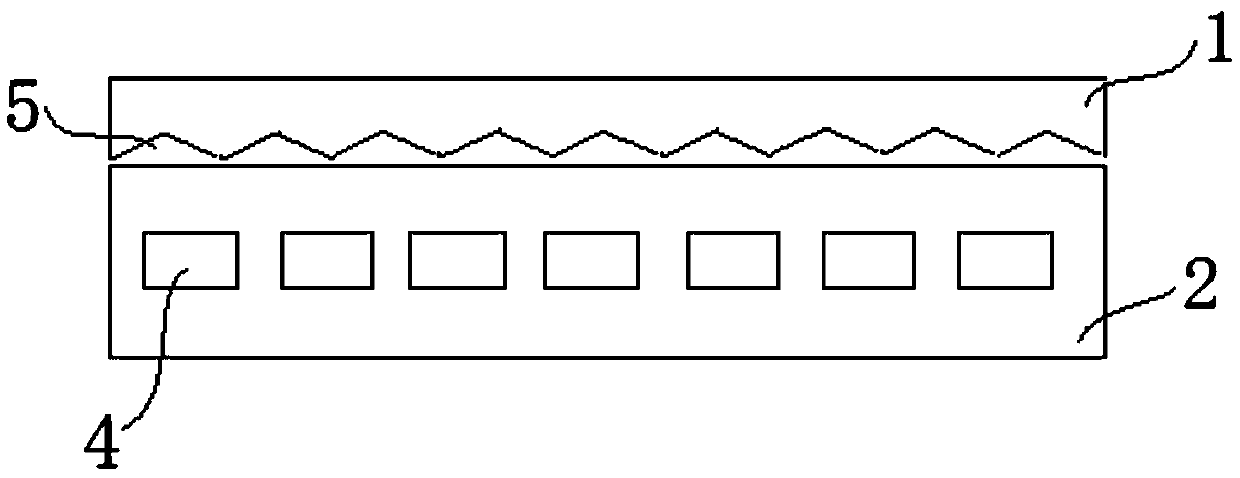

[0046] combine image 3 , The solid wood PVC stone-plastic double-layer composite floor of this embodiment is formed by bonding the upper panel 1 and the lower substrate 2, the panel 1 is a solid wood board, and the substrate 2 is a PVC stone-plastic board. The thickness of the substrate 2 is greater than the thickness of the panel 1, and the inside of the substrate 2 is provided with a through channel 4 along the length direction. The cross section of the through channel 4 is rectangular. One, seven through channels 4 are arranged parallel to each other along the width direction of the substrate 2 . The lower surface of the panel 1 is provided with a panel glue storage tank 5 along the length direction. The panel glue storage tank 5 is a groove with a V-shaped cross section.

[0047] The solid wood PVC stone-plastic double-layer composite floor of this embodiment is provided with a panel glue storage tank 5 along the length direction on the lower surface of the panel 1. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com