a composite floor

A composite flooring technology, which is applied to floor coverings, synthetic resin layered products, and other household appliances, can solve the problems of glue opening and deformation, damage to the ecological environment, and high production costs, and achieve internal stress elimination, weight reduction, and extension. The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

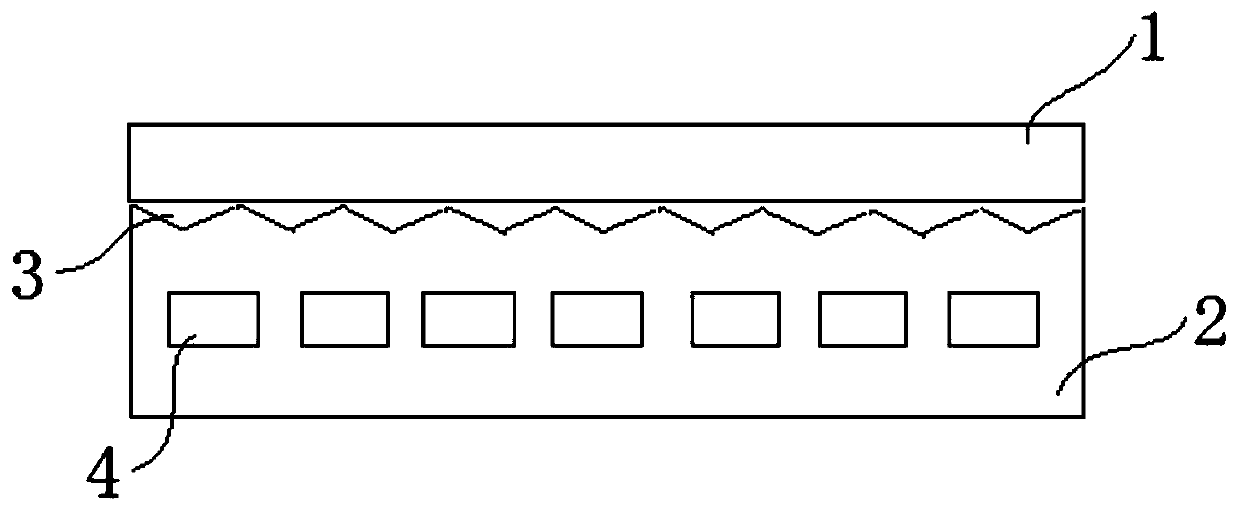

[0037] to combine figure 1 , The composite floor of this embodiment is formed by bonding the panel 1 of the upper layer and the substrate 2 of the lower layer, the panel 1 is a solid wood board, and the substrate 2 is a PVC stone-plastic board. The thickness of the substrate 2 is greater than the thickness of the panel 1, and the inside of the substrate 2 is provided with a through channel 4 along the length direction. The cross section of the through channel 4 is rectangular. One, seven through channels 4 are arranged parallel to each other along the width direction of the substrate 2 . The upper surface of the substrate 2 is provided with a substrate glue storage tank 3 along the length direction. The substrate glue storage groove 3 is a groove with a V-shaped cross section.

[0038] PVC stone-plastic board, also known as stone-wood flooring, is mostly sheet material. It is a new type of high-quality floor material. It uses natural stone powder as the main raw material to f...

Embodiment 2

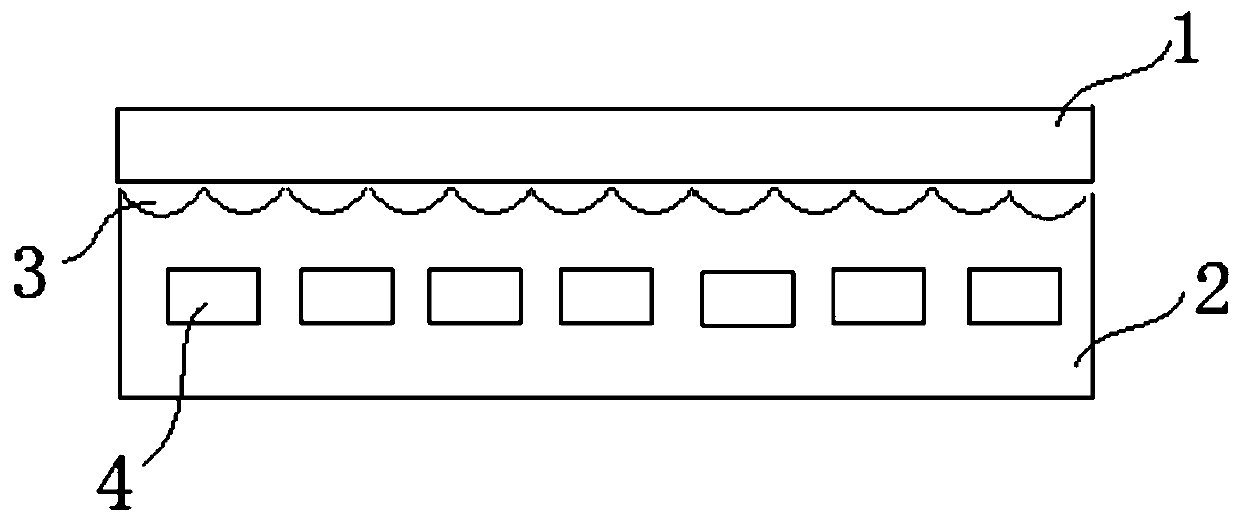

[0045] to combine figure 2 , The composite floor of this embodiment is formed by bonding the panel 1 of the upper layer and the substrate 2 of the lower layer, the panel 1 is a solid wood board, and the substrate 2 is a PVC stone-plastic board. The thickness of the substrate 2 is greater than the thickness of the panel 1, and the inside of the substrate 2 is provided with a through channel 4 along the length direction. The cross section of the through channel 4 is rectangular. One, seven through channels 4 are arranged parallel to each other along the width direction of the substrate 2 . The upper surface of the substrate 2 is provided with a substrate glue storage tank 3 along the length direction. The substrate glue storage groove 3 is a groove with an arc-shaped cross section.

Embodiment 3

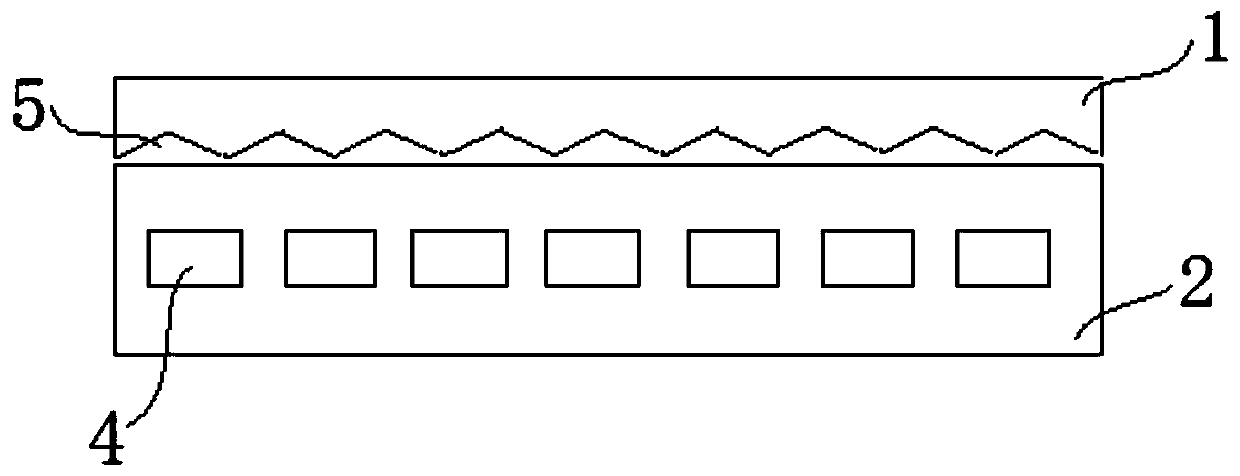

[0047] to combine image 3 , The composite floor of this embodiment is formed by bonding the panel 1 of the upper layer and the substrate 2 of the lower layer, the panel 1 is a solid wood board, and the substrate 2 is a PVC stone-plastic board. The thickness of the substrate 2 is greater than the thickness of the panel 1, and the inside of the substrate 2 is provided with a through channel 4 along the length direction. The cross section of the through channel 4 is rectangular. One, seven through channels 4 are arranged parallel to each other along the width direction of the substrate 2 . The lower surface of the panel 1 is provided with a panel glue storage tank 5 along the length direction. The panel glue storage tank 5 is a groove with a V-shaped cross section.

[0048] In the composite floor of this embodiment, panel glue storage tanks 5 are arranged on the lower surface of the panel 1 along the length direction. Melt glue, the setting of the panel glue storage tank 5 exp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com