Adhesive film and preparation method thereof, and shoe sole comprising adhesive film

A film and sole technology, applied in the preparation of film, film, including film soles, can solve problems such as the decrease of adhesive strength, reduce pollution, reduce production costs, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

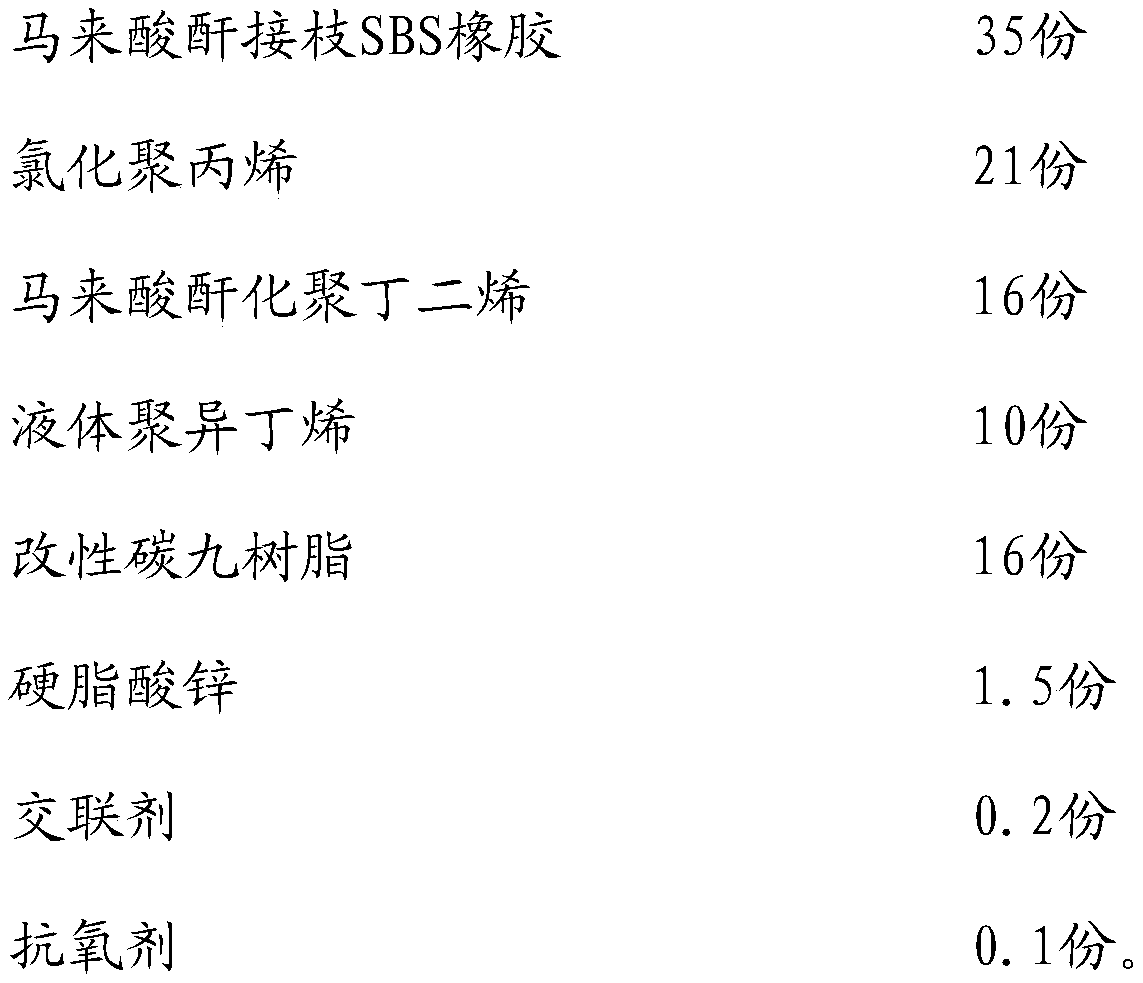

Embodiment 1

[0026] In this embodiment, a film is composed of the following components by weight: 35 parts of maleic anhydride grafted SBS rubber, 21 parts of chlorinated polypropylene CPP-B, 173116 parts of maleic anhydrided polybutadiene, liquid 10 parts of polyisobutylene, 16 parts of modified carbon nine resin, 1.5 parts of zinc stearate, 0.2 part of crosslinking agent BIBP, 0.1 part of antioxidant B1004. After the above-mentioned raw materials were internally mixed at 105°C, kneaded, and released into sheets, they were cast in a tape casting machine to obtain the adhesive film with a PET film as the base film, with a thickness of 3 mm.

[0027] Put the rubber film prepared above together with the rubber outsole to be vulcanized after kneading into the rubber vulcanization mold, stick the film on the side of the rubber outsole that needs to be pasted with the midsole, and vulcanize at 150°C for 90-240 seconds , then take out the rubber outsole, tear off the PET film, and let it cool na...

Embodiment 2

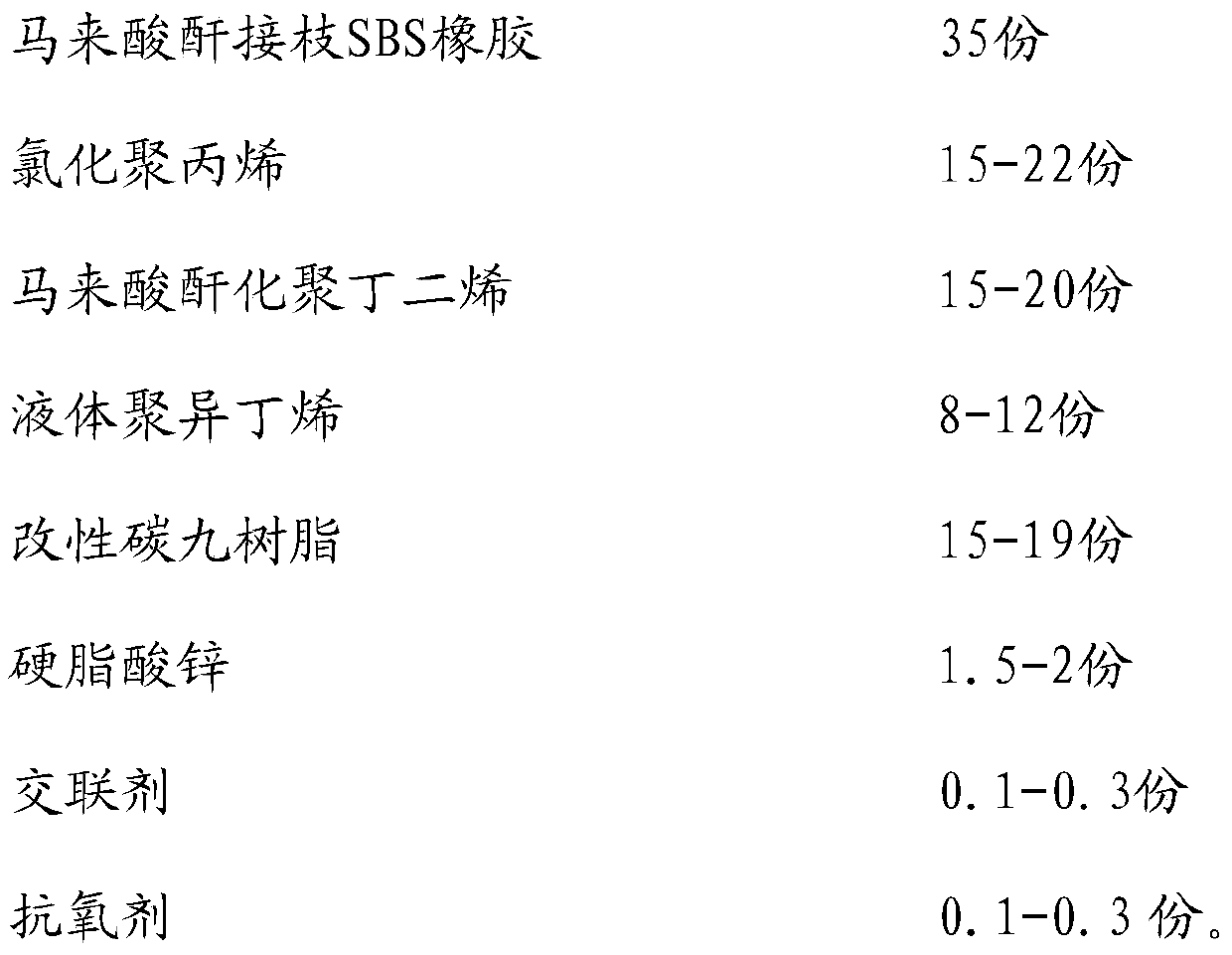

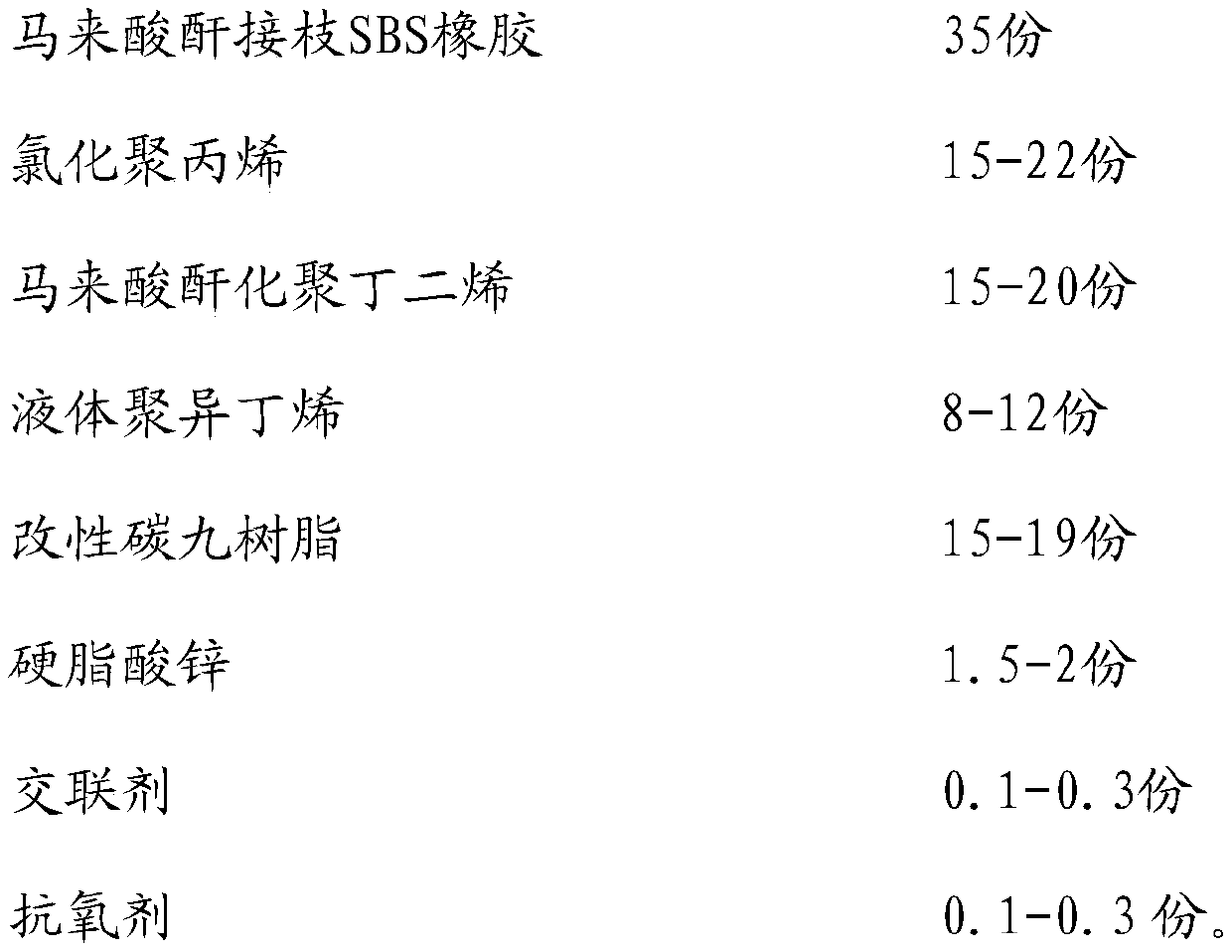

[0030] In the present embodiment, the preparation method and the use method of described adhesive film are identical with embodiment 1, difference is:

[0031] The composition of raw materials is different (see Table 1 for details).

[0032] The finished shoe sole prepared above has an initial bond strength of 5.5N / mm; after heating and aging, the bond strength is 5.4N / mm; after humidification and aging, the bond strength is 5.4N / mm.

Embodiment 3

[0034] In the present embodiment, the preparation method and the use method of described adhesive film are identical with embodiment 1, difference is:

[0035] The composition of raw materials is different (see Table 1 for details).

[0036] The finished product sole prepared above has an initial bond strength of 5.9N / mm; after heating and aging, the bond strength is 5.3N / mm; after humidification and aging, the bond strength is 5.1N / mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesion strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| adhesion strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com